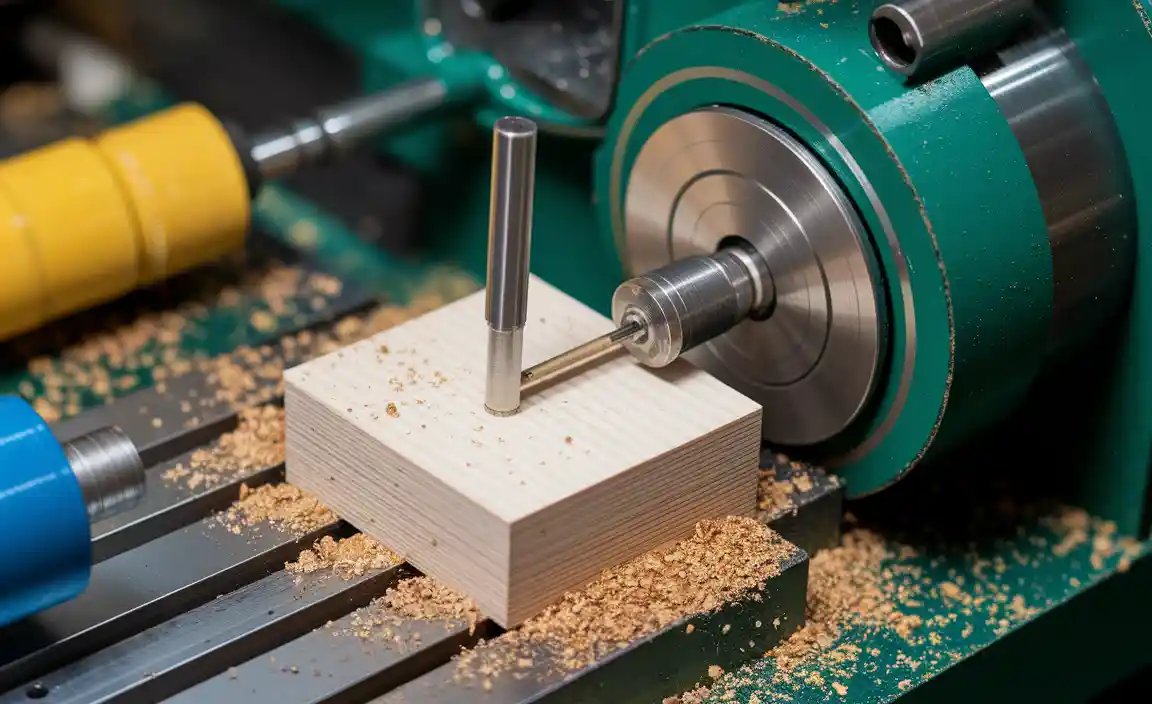

Have you ever watched a lathe spinning wood? It’s fascinating! When it comes to lathe turning, plywood is a special material. Many people think plywood is not good for turning. But that’s not true! Plywood can create beautiful shapes and designs with the right tips.

Imagine making a stunning bowl or a unique vase from plywood. It’s fun and a bit challenging. With the right techniques, you can master lathe turning plywood composite.

In this article, we will share lathe turning plywood composite turning tips. These tips will help you enjoy your projects more and improve your skills. Are you ready to learn how to work with plywood like a pro?

Lathe Turning Plywood Composite Turning Tips You Need

Understanding Plywood Composite Materials

Definition and composition of plywood composites. Advantages of using plywood in lathe turning projects.

Plywood composites are built from layers of thin wood, glued together in a sandwich style. This makes them strong, light, and perfect for all sorts of projects. Using plywood in lathe turning gives you smooth finishes and allows for creative shapes without breaking the bank. Plus, they don’t warp easily, which is great! Just imagine turning a piece and not worrying about it twisting like a pretzel. Who wouldn’t want that?

| Advantages | Description |

|---|---|

| Strength | Plywood is strong and durable for turning projects. |

| Lightweight | Easy to handle and maneuver while working. |

| Creative Designs | Allows for unique shapes and finishes. |

Essential Tools and Equipment for Lathe Turning

Recommended lathes for working with plywood composite. Key tools and accessories needed for effective turning.

To turn plywood composite successfully, you need the right tools. Start with a reliable lathe. Look for one that has a good reputation for durability. Here’s a list of essential items:

- A sturdy lathe, such as a mini-lathe or a benchtop model.

- Sharp chisels for shaping your wood.

- Sandpaper for smooth finishes.

- A faceplate for holding the wood securely.

- Safety goggles to protect your eyes.

These tools make lathe turning easy and fun!

What is the best lathe for plywood composite?

The best lathe for plywood composite is the mini lathe. Its compact design fits in small shops. It provides excellent control for detailed work.

Preparing Your Plywood Composite for Turning

Best practices for selecting and preparing plywood sheets. Importance of moisture content and acclimatization.

Choosing the right plywood is vital for a fun turning project. Look for sheets without cracks or knots. Check if they are smooth; a bumpy ride is for roller coasters, not for your lathe! Before turning, check the moisture content. Too much moisture can make your wood twist like a pretzel. Allow your plywood to acclimatize in your workspace for a few days. This helps it get used to the humidity and temperature, preventing surprises while turning.

| Best Practices | Description |

|---|---|

| Select Quality Plywood | Avoid knots and cracks. |

| Check Moisture | Keep it at a balanced level. |

| Acclimatize | Let it relax before turning. |

Techniques for Effective Lathe Turning

Stepbystep turning techniques specific to plywood composites. Tips for achieving smooth finishes and avoiding tearouts.

Turning plywood composites on a lathe can be fun and rewarding! First, make sure to set your lathe speed right; a slower speed often works better. Hold your tool at the correct angle to cut smoothly. Use sharp tools to prevent tearouts, which are like tiny wood hiccups! Sand the surface gently afterward to achieve a lovely finish. Remember, patience is key. It’s like trying to bake a cake—rush it, and it might just flop!

| Technique | Tip |

|---|---|

| Speed Setting | Start slow! |

| Tool Angle | Keep it sharp and at the right angle! |

| Sanding | Be gentle; think of it as a soothing spa day for wood! |

Common Challenges and Solutions in Plywood Turning

Identifying and mitigating common issues (splitting, chipping). Troubleshooting tips for a flawless turning experience.

Plywood turning can have challenges, like splitting and chipping. These problems can happen when the wood is too dry or the lathe speed is too high. Thankfully, you can fix these issues! Look for good quality plywood and adjust your tools. Here are some helpful tips:

- Use sharp tools for clean cuts.

- Turn at a lower speed to avoid chipping.

- Moisten the wood slightly to prevent splitting.

- Check for knots before starting.

With these tips, you can enjoy a smoother turning experience!

What is the best way to prevent chipping in plywood?

Using sharp tools and turning at a lower speed helps to prevent chipping. Additionally, choose high-quality plywood, and apply a finish to protect the edges. This practice creates a better result in your projects.

Finishing Techniques for Plywood Composite Projects

Recommended finishing products and methods. Importance of sanding and sealing for durability.

Finishing your plywood composite project is very important. It makes your project look smooth and protects it. Start by using products like wood stain and clear sealers. These helps the wood shine and resist damage. Sanding is a key step before finishing. It removes rough spots and helps the sealant stick better. For best results, use:

- Fine-grit sandpaper for smoothing.

- Primer before painting or staining.

- A good quality sealer to protect the surface.

Remember, sealing adds to durability. It keeps your project safe from water and wear. This way, your hard work lasts longer!

What are the best finishing products for plywood composite?

Wood stain and clear sealer are top choices. They enhance wood’s beauty and protect it from damage.

Safety Precautions While Lathe Turning

Essential safety gear and practices. Common safety hazards and how to avoid them.

Before starting any lathe turning project, put on your safety gear! This includes a face shield, ear protection, and gloves. Remember, safety first—nobody wants a bad hair day from flying wood shavings! Watch out for common hazards like loose clothing and long hair; they can get caught in the machine. Always keep your work area tidy to avoid trips and slips.

| Safety Gear | Purpose |

|---|---|

| Face Shield | Protects face from flying debris |

| Ear Protection | Reduces loud machine noise |

| Gloves | Protects hands from splinters |

Stay alert and focused. If you feel tired, take a break. Remember, it’s better to pause than to “turn” into a human pretzel!

Inspiring Project Ideas Using Plywood Composites

Creative projects showcasing latheturned plywood. Tips for designing and executing your own unique models.

Creating with plywood composites can be fun and rewarding! You can make various projects that show off your lathe turning skills. Think about crafting items like bowls, toys, or decorative pieces. Here are some tips to inspire your designs:

- Start simple; choose easy shapes.

- Experiment with colors and patterns.

- Use a sturdy lathe for exact cuts.

- Safety first; always wear goggles.

With these ideas and tips, you can create unique models that impress everyone!

What are some fun project ideas for lathe-turned plywood?

You can make items like wooden bowls, chess pieces, or even art sculptures for your home. These projects can showcase your skills and creativity!

Conclusion

In summary, lathe turning plywood is fun and rewarding. Use sharp tools and go slow for better results. Always secure your project well to avoid accidents. Don’t forget to sand the edges for a smooth finish. You can explore more tips online to improve your skills. Let’s keep experimenting and creating amazing projects together!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Turning Plywood Composite:

Sure! Here are five related questions on the topic of lathe turning plywood composite: 1. What is lathe turning? 2. How do you use a lathe? 3. Can you turn plywood? 4. What tools do we need? 5. Why is plywood good for turning? These questions help us understand how to shape wood using a special machine called a lathe.

Sure! Just let me know the question you want me to answer.

What Are The Best Types Of Tools To Use For Turning Plywood Composites On A Lathe To Achieve A Smooth Finish?

To get a smooth finish on plywood composites while using a lathe, you should use sharp tools. A bowl gouge and a skew chisel work well. Make sure to keep your tools clean and sharp. You can also use sanding pads to polish the surface after shaping. This way, your project will look nice and smooth!

How Can You Prevent Tear-Out And Chipping When Turning Plywood Composites On A Lathe?

To prevent tear-out and chipping when turning plywood on a lathe, you can use sharp tools. Sharp tools cut cleanly and make fewer rough edges. You should also turn the wood slowly at first, so it doesn’t break apart. Lastly, try to support the wood well so it stays steady while you work.

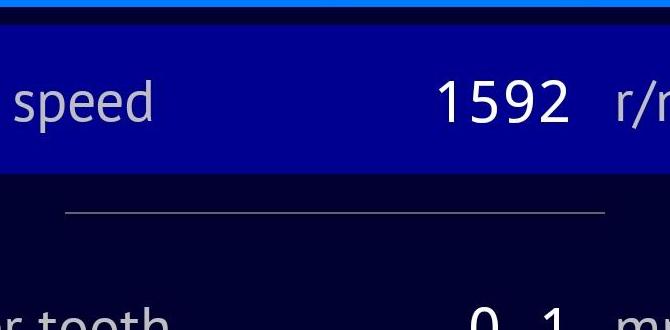

What Speed Settings Are Recommended For Lathe Turning Plywood Composites To Ensure Safety And Efficiency?

When turning plywood on a lathe, start with a speed of about 800 to 1,200 RPM (revolutions per minute). This range helps you work safely and smoothly. If the plywood feels rough or burns, you can lower the speed. Always wear safety gear, like goggles, to protect your eyes.

Are There Specific Adhesives Or Construction Techniques That Should Be Considered When Selecting Plywood Composites For Lathe Turning?

Yes! When you choose plywood for lathe turning, think about the glue used in it. Some glues can be strong, while others might not hold well when spun fast. Look for plywood made with waterproof glue. This helps it stay strong and not break apart while you are working. Always check how thick the plywood is too, as thicker pieces are better for turning.

How Does The Grain Orientation Of Plywood Layers Affect The Turning Process And Final Appearance Of The Finished Piece?

The grain orientation of plywood layers matters a lot when we turn it. If the wood grain goes one way, it will cut smoothly. If the grain goes the opposite way, it can splinter and break. This affects how nice the finished piece looks. We want it to be smooth and pretty!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Turning Plywood Composite:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions on the topic of lathe turning plywood composite: 1. What is lathe turning? 2. How do you use a lathe? 3. Can you turn plywood? 4. What tools do we need? 5. Why is plywood good for turning? These questions help us understand how to shape wood using a special machine called a lathe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Best Types Of Tools To Use For Turning Plywood Composites On A Lathe To Achieve A Smooth Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a smooth finish on plywood composites while using a lathe, you should use sharp tools. A bowl gouge and a skew chisel work well. Make sure to keep your tools clean and sharp. You can also use sanding pads to polish the surface after shaping. This way, your project will look nice and smooth!”}},{“@type”: “Question”,”name”: “How Can You Prevent Tear-Out And Chipping When Turning Plywood Composites On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To prevent tear-out and chipping when turning plywood on a lathe, you can use sharp tools. Sharp tools cut cleanly and make fewer rough edges. You should also turn the wood slowly at first, so it doesn’t break apart. Lastly, try to support the wood well so it stays steady while you work.”}},{“@type”: “Question”,”name”: “What Speed Settings Are Recommended For Lathe Turning Plywood Composites To Ensure Safety And Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When turning plywood on a lathe, start with a speed of about 800 to 1,200 RPM (revolutions per minute). This range helps you work safely and smoothly. If the plywood feels rough or burns, you can lower the speed. Always wear safety gear, like goggles, to protect your eyes.”}},{“@type”: “Question”,”name”: “Are There Specific Adhesives Or Construction Techniques That Should Be Considered When Selecting Plywood Composites For Lathe Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes! When you choose plywood for lathe turning, think about the glue used in it. Some glues can be strong, while others might not hold well when spun fast. Look for plywood made with waterproof glue. This helps it stay strong and not break apart while you are working. Always check how thick the plywood is too, as thicker pieces are better for turning.”}},{“@type”: “Question”,”name”: “How Does The Grain Orientation Of Plywood Layers Affect The Turning Process And Final Appearance Of The Finished Piece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The grain orientation of plywood layers matters a lot when we turn it. If the wood grain goes one way, it will cut smoothly. If the grain goes the opposite way, it can splinter and break. This affects how nice the finished piece looks. We want it to be smooth and pretty!”}}]}