Have you ever wondered how woodworkers achieve smooth, polished surfaces? The secret often lies in a handy tool called the lathe turning sanding mandrel with Velcro. This clever device simplifies sanding and makes it a lot more enjoyable.

Imagine creating a beautiful wooden bowl. You’ve done the carving, and now it’s time to make it shine. But how can you make that rough wood feel smooth? The answer is right here: using a lathe turning sanding mandrel can help you achieve that perfect finish.

What’s great about a mandrel with Velcro is its simple design. You can easily swap out sandpaper disks, saving time and effort. Plus, it sticks securely, so you can focus on your project without interruptions.

Did you know that modern woodworkers love these mandrels? They save them from the hassle of traditional sanding methods. Instead of struggling with different tools, they can quickly change grits and keep crafting. Isn’t that a fun way to improve your craft?

Let’s dive into how a lathe turning sanding mandrel with Velcro can revolutionize your woodworking projects and make sanding a breeze!

Lathe Turning Sanding Mandrel With Velcro: An Essential Tool

What is a Lathe Turning Sanding Mandrel?

Definition and purpose of a sanding mandrel in lathe operations. Key features of Velcro sanding mandrels.

A sanding mandrel is a tool that helps woodworkers and craftsmen smooth surfaces. It fits onto a lathe, allowing you to rotate and sand materials easily. The purpose is to create a nice finish on objects like wood or metal. Key features of Velcro sanding mandrels include:

- Easy-to-attach sanding disks.

- Strong grip with Velcro.

- Variety of disk grits available.

- Flexibility for different shapes.

This tool makes sanding faster and more efficient, giving you great results!

What are the benefits of using a lathe turning sanding mandrel?

It saves time and gets smoother finishes! The Velcro feature allows quick changes between sanding disks. Plus, it helps you reach tricky spots easily.

Benefits of Using Velcro Sanding Mandrels

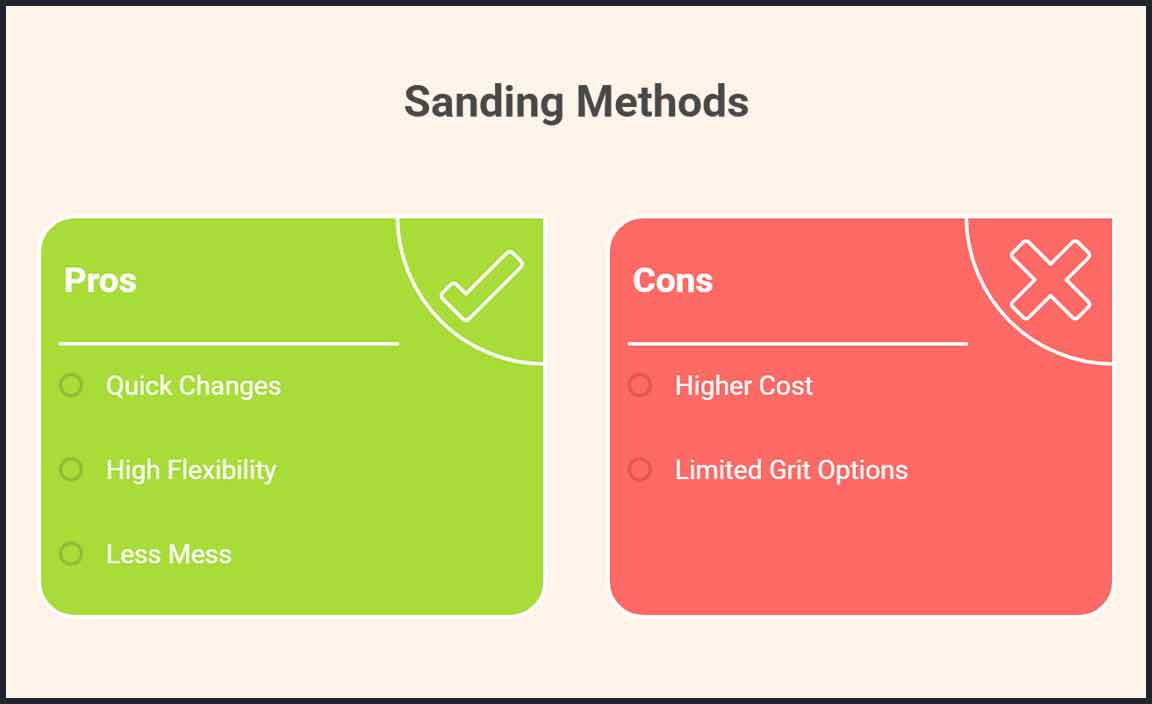

Advantages of Velcro over traditional methods. Enhanced flexibility and efficiency in sanding.

Using Velcro sanding mandrels can change your sanding game! They offer some cool benefits over old-fashioned methods. First, they allow for quick changes. Switch out sandpaper in seconds, almost as fast as you can say “abracadabra!” This saves time and makes the job easier. Plus, they give you better flexibility. You can sand different shapes without drama. So, wave goodbye to those sticky messes and say hello to efficient sanding!

| Advantage | Velcro Sanding Mandrel | Traditional Methods |

|---|---|---|

| Change Speed | Very Fast | Slow |

| Flexibility | High | Low |

| Cleanliness | Less Mess | More Mess |

Choosing the Right Velcro Sanding Mandrel for Your Project

Factors to consider: material, grit size, and compatibility. Tips for selecting the best option based on project requirements.

Finding the best velcro sanding mandrel can make your project shine. Think about three important factors:

- Material: Choose sturdy options that suit your task.

- Grit Size: Select finer grits for smooth finishes and coarser grits for shaping.

- Compatibility: Ensure it fits your lathe design and sanding paper.

Check which sanders your project needs. This makes picking the right mandrel easier and better for your work.

What features should I look for in a velcro sanding mandrel?

Look for durability, size options, and ease of use. A strong mandrel helps sand smoothly. Right sizes fit better and work faster.

How to Properly Install and Use a Velcro Sanding Mandrel

Stepbystep guide to installation. Best practices for effective usage.

To set up a Velcro sanding mandrel, start with these simple steps. First, grab your mandrel and insert it into the lathe’s chuck. Tighten it snugly, like you would hug your favorite pillow. Next, peel off the backing from your sanding disc and press it firmly onto the mandrel. Make sure it’s center-stage; nobody likes a lopsided performance!

While using it, keep your speed moderate. Too fast, and you might turn your wood into a dreaded sawdust storm. Apply light pressure; let the sandpaper do the work. It’s not a wrestling match! Follow these tips for a smooth finish and a happy workspace.

| Step | Action |

|---|---|

| 1 | Insert mandrel into the lathe chuck. |

| 2 | Tighten securely. |

| 3 | Peel and stick sanding disc. |

| 4 | Adjust lathe speed to medium. |

| 5 | Apply light pressure while sanding. |

Maintenance and Care for Longevity

Cleaning and storing your Velcro sanding mandrels. Signs of wear and when to replace them.

Keeping your Velcro sanding mandrels clean is key to making them last. Wipe them down after use to remove dust and debris. Store them in a dry place, away from moisture, to keep them in top shape. Watch for signs of wear, like fraying edges or dull surfaces. If they don’t grip well, it’s time for a replacement. Think of it like replacing your old shoes—no one wants to slip on a banana peel!

| Signs of Wear | Action |

|---|---|

| Fraying edges | Replace immediately! |

| Dull surface | Time for a new one! |

| Poor adhesion | Get a fresh mandrel! |

Common Mistakes to Avoid

Typical errors when using sanding mandrels. How to troubleshoot common issues.

Using sanding mandrels can be tricky. One common mistake is not securing the sandpaper properly. This can make it flap around like a bird trying to take off! Always check that the Velcro holds tight. Another issue arises when you apply too much pressure. This can wear out the paper faster than a kid can finish their homework. If your results look uneven, try slowing down and adjusting your grip.

| Common Mistakes | How to Fix |

|---|---|

| Loose Sandpaper | Check Velcro and press down firmly. |

| Too Much Pressure | Lighten your touch for smoother finish. |

| Uneven Surface | Slow down and adjust your grip. |

Advanced Techniques for Professionals

Innovative methods for optimizing sanding processes. Case studies from experienced users.

Optimizing sanding processes requires smart techniques. Professionals use tools to improve their work. One common method is to use a lathe turning sanding mandrel with velcro. This makes changing sandpaper easier and faster.

Here are some innovative methods:

- Use different grits for various materials.

- Keep the workspace tidy to avoid distractions.

- Adjust the speed of the lathe for the best results.

Experienced users have shared these tips. They found that creating a consistent sanding routine helps produce high-quality finishes. They also stress the importance of regular tool maintenance.

What are best practices for using a sanding mandrel?

Best practices include choosing the right sandpaper grit, maintaining a steady speed, and keeping the workspace clean for better results.

Frequently Asked Questions (FAQs)

Addressing common concerns and inquiries. Clarification on misunderstandings regarding Velcro sanding mandrels.

Have you ever wondered about those fuzzy sanding tools? Many people ask if Velcro sanding mandrels are really worth it. The answer is a big yes! They save time and give you a smooth finish. Another common question focuses on durability. Rest assured, these mandrels can last through many projects. However, some folks think the Velcro wears out quickly—nope! It’s designed to stick around. Now, let’s tackle more of your burning questions in the table below.

| Question | Answer |

|---|---|

| Do Velcro sanding mandrels work with all sandpaper? | Yes, they fit a variety of sandpaper types! |

| Can I use them with a regular lathe? | Absolutely, just attach them and you’re good to go! |

| Are they easy to clean? | Yes! A quick shake will do the trick. |

Conclusion

In summary, a lathe turning sanding mandrel with Velcro is a great tool for woodworkers. It helps you sand surfaces smoothly and efficiently. You can easily change sanding discs, making it versatile. We encourage you to try using this tool in your projects. For more tips on woodworking, check out additional resources or guides!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Turning Sanding Mandrels With Velcro:

Sure! When you use a lathe to make things round, you might need sanding mandrels. A mandrel is a tool that holds sandpaper to smooth surfaces. Velcro helps the sandpaper stick to the mandrel. This way, you can easily change the sandpaper when it wears out. It makes your project look nice and shiny!

Of course! Please provide me with the question you’d like me to answer.

What Are The Advantages Of Using A Velcro Sanding Mandrel For Lathe Turning Compared To Traditional Sanding Methods?

Using a Velcro sanding mandrel makes sanding easier on a lathe. You can quickly change sandpaper when it gets dull. The Velcro sticks well, so the sandpaper stays in place while you work. This method lets you sand smooth surfaces better and faster than with old methods. It’s fun and lets you finish your project neatly!

How Do You Properly Install And Secure Sandpaper On A Velcro Sanding Mandrel For Optimal Performance?

To install sandpaper on a Velcro sanding mandrel, first, take the sandpaper and find the rough side. This rough side has tiny hooks that stick to the Velcro. Next, press the sandpaper firmly onto the Velcro on the mandrel. Make sure it’s smooth and flat without any bumps. Lastly, check that it’s tightly attached before you start sanding to get the best results!

What Materials Are Commonly Recommended For Velcro Sanding Mandrels In Terms Of Durability And Compatibility With Different Lathe Projects?

For Velcro sanding mandrels, many people recommend using rubber or hard plastic. These materials are strong and last a long time. They work well on different lathe projects, helping you sand wood and other materials easily. You can trust them to stay on your lathe while you work.

Can You Provide Tips For Achieving An Even Finish When Using A Velcro Sanding Mandrel On Curved Or Intricate Shapes?

To get an even finish with a Velcro sanding mandrel, hold it gently against the curve. Move it in small circles to cover all areas. Change the sanding paper often to keep it sharp. Don’t press too hard; let the tool do the work. Finally, check your progress often to fix any rough spots.

What Safety Precautions Should Be Taken When Using A Lathe With Velcro Sanding Mandrels, Especially Regarding Dust Management And Proper Tool Handling?

When using a lathe with Velcro sanding mandrels, wear a mask to protect your lungs from dust. Make sure to wear safety glasses to shield your eyes. Keep the workspace clean by using a vacuum or broom to remove dust. Always handle tools carefully, and keep your fingers away from the spinning parts. Look out for loose clothing or hair that could get caught in the lathe.

Resource:

-

Woodworking Basics Sanding Tips: https://www.woodmagazine.com/materials-guide/finishes/sanding-tips

-

DIY Lathe Projects Guide: https://www.familyhandyman.com/list/diy-lathe-projects/

-

Safety Guidelines for Using Power Tools: https://www.osha.gov/power-tools-safety

-

Velcro Technology Explained: https://www.velcro.com/about-us/our-story/