Have you ever watched a craftsman turn a simple piece of wood into a beautiful bowl? It’s fascinating to see how lathe turning can create such stunning thin wall hollow forms. But how does this magic happen?

Lathe turning involves skill and precision. Amateurs and experts alike can create art using this technique. Imagine transforming a block of wood into an elegant vase. One simple move on the lathe can change everything!

Did you know that thin walls in hollow forms can be both challenging and rewarding? If you’ve tried woodturning before, you know that making these pieces requires a steady hand and a keen eye. Each turn brings excitement and the chance to discover something new.

So, what makes lathe turning thin wall hollow forms so special? The answer lies in the blend of art and science. Each piece tells a story, reflecting the turner’s creativity and skill. Are you ready to learn more about this captivating craft?

Lathe Turning Thin Wall Hollow Forms: Techniques And Tips

Essential Tools and Materials for Thin Wall Hollow Forms

List of recommended lathes and accessories for hollow turning.. Discussion of suitable wood species and their properties for thin wall projects..

For turning thin wall hollow forms, the right tools make all the difference. Here are some helpful suggestions:

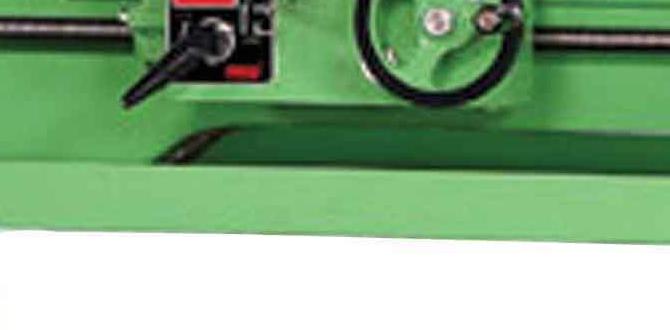

- Lathes: Look for a mini lathe or a dedicated woodturning lathe. Brands like Jet and Laguna work well.

- Accessories: Use sharp bowl gouges, hollowing tools, and a good set of calipers. A steady rest helps too.

- Wood Species: Choose lightweight woods such as maple, cherry, or birch. They create beautiful forms and are easy to work with.

These tools and materials will help make your projects successful and enjoyable!

What tools do you need for hollow turning?

You will need a strong lathe, sharp tools, and good safety gear. Safety is key! Make sure to wear goggles and a mask while working.

Techniques for Successful Thin Wall Hollow Turning

Stepbystep guide on setting up the lathe for hollow turning.. Tips for balancing the lathe and preventing vibration during the process..

Start by choosing the right speed for your lathe; this helps you avoid wobbling like a three-legged chair. Secure your piece so it won’t fly off and scare the cat! Use a good quality tool rest for support. Remember, balance is key! If your lathe shakes, it’s like trying to dance with two left feet. A sturdy base and proper weights can help. Here’s a quick table of tips:

| Tip | Description |

|---|---|

| Speed Setup | Choose a low speed for steady cuts. |

| Secure Piece | Clamp it well to prevent accidents. |

| Balance Check | Add weights or adjust legs to stabilize the lathe. |

With these steps, you’ll turn hollow forms like a pro. Keep practice fun and enjoy the process!

Safety Considerations When Turning Hollow Forms

Essential safety gear and precautions to take while operating a lathe.. Common hazards associated with thin wall turning and how to mitigate them..

Before you start turning those fancy thin-wall hollow forms, grab some safety gear! You wouldn’t want sawdust in your eye or, worse, a wood splinter attacking your face like a tiny ninja. Always wear safety glasses to protect your peepers, and don’t forget ear protection. Lathes can be noisy!

| Essential Gear | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris |

| Ear Protection | Keeps your hearing safe |

| Dust Mask | Prevents inhaling sawdust |

Common hazards include the risk of the piece shattering or grabbing tools. To avoid this, always ensure your setup is secure. Check twice, turn once! If the piece is too thin, slow down the speed. Remember, a safe workspace means a happy woodturner!

Advanced Techniques for Improved Hollow Form Design

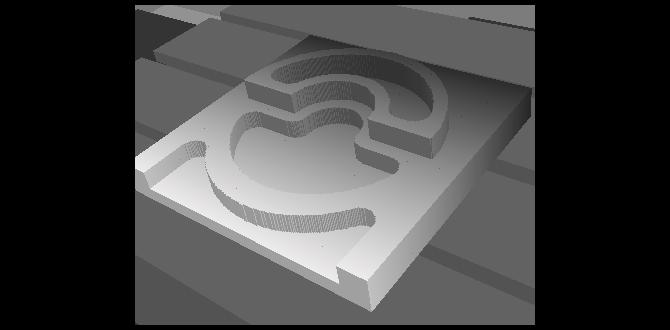

Exploration of specialized cutting tools and chisels for intricate designs.. Techniques for minimizing tearout and achieving smooth finishes..

Getting fancy with hollow forms? Grab some specialized cutting tools and chisels! These help us create intricate designs that look stunning. Sharp tools cut better and keep lines clean. Plus, they reduce tearout – that annoying “oops” moment when wood chips go flying! To make surfaces smooth, try sanding with different grit levels. Start rough and finish fine. Remember: patience wins this game. Let your design shine, like your best friend’s weird haircut!

| Technique | Description |

|---|---|

| Specialized Tools | Use chisels designed for fine details. |

| Minimize Tearout | Make smoother cuts with proper angles. |

| Sanding Techniques | Start with coarse grit, end with fine. |

Maintenance of Tools and Lathe for Longevity

Best practices for maintaining your lathe and tools used for hollow turning.. Importance of regular maintenance to improve performance and safety..

Taking care of your lathe and tools is very important. Regular maintenance helps them work better and become safer to use. Follow these simple tips for keeping your lathe in good shape:

- Clean after each use to prevent dust buildup.

- Check moving parts for oil and lubricant.

- Sharpen tools regularly for smooth cuts.

- Inspect for loose screws and parts.

With good care, your tools can last a long time. This means more fun and less hassle while making those cool thin wall hollow forms!

Why is regular maintenance important?

Regular maintenance improves performance and safety. It keeps tools sharp and machines running smoothly. This makes projects easy and enjoyable.

Common Challenges in Turning Thin Wall Hollow Forms

Discussion of typical problems faced by beginners and advanced turners.. Solutions and strategies to overcome these challenges effectively..

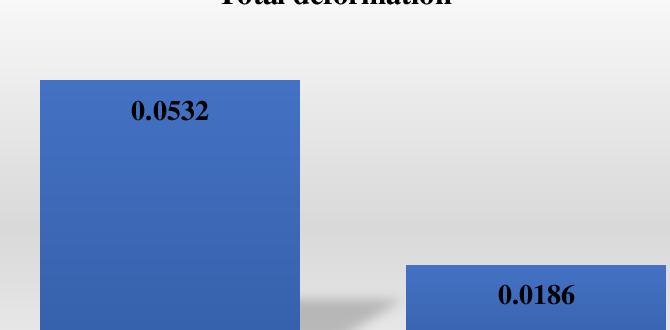

Turning thin wall hollow forms can be tricky. Beginners often face issues like breakage and wobbling during the lathe process. Advanced turners may struggle with achieving smooth finishes. Here are some common challenges and solutions:

- Maintain steady speed to avoid wobbling.

- Use sharp tools to get a clean cut.

- Support the piece properly to prevent breakage.

By practicing these tips, both new and experienced turners can create stunning hollow forms with ease.

What are common problems in lathe turning?

Common problems include instability, breakage, and rough finishes. Beginners often need to learn proper techniques, while advanced turners may require skill to refine their work.

Showcasing Your Thin Wall Hollow Forms

Ideas for presenting and displaying your finished works.. Opportunities for selling or exhibiting hollow form art..

After crafting your thin wall hollow forms, the fun begins! Consider displaying them at local art shows or galleries. Create a beautiful setup with eye-catching backgrounds. How about some natural light? It makes your creations shine! You can sell your art online too. Use photos that show off their shape and detail. And remember, if someone says they can see their reflection in your piece, it might be time to rethink your mirror placement!

| Display Ideas | Sales Opportunities |

|---|---|

| Art shows and exhibitions | Online marketplaces |

| Local galleries | Social media platforms |

| Craft fairs | Art auctions |

Conclusion

In summary, lathe turning thin wall hollow forms requires skill and practice. You can create beautiful pieces by mastering control and choosing the right materials. Start with simple designs and gradually challenge yourself. Explore online tutorials or join a workshop to improve your technique. Remember, every expert was once a beginner—so keep practicing and enjoy the journey!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Turning Thin Wall Hollow Forms:

Sure! Here are my answers about lathe turning thin wall hollow forms. 1. **What is a lathe?** A lathe is a tool that spins wood or metal to shape it. You can make fun items like bowls and vases. 2. **What is a hollow form?** A hollow form is a shape that is empty inside. We can create it by turning the outer part on a lathe. 3. **Why is it hard to turn thin walls?** Turning thin walls is tricky because they can break easily. We need to be careful and go slowly. 4. **How do we make sure the walls are even?** We check the thickness as we turn. You can use a caliper, which is like a ruler for measuring. 5. **What should you wear while using a lathe?** You should wear safety glasses and ear protection. This helps keep your eyes and ears safe from dust and noise.

Sure! Please go ahead and ask your question, and I’ll provide an answer that fits your needs.

What Are The Essential Tools And Materials Required For Turning Thin Wall Hollow Forms On A Lathe?

To turn thin wall hollow forms on a lathe, you need a few key tools and materials. First, you need a lathe, which spins the wood. You also need sharp chisels to shape the wood. Sandpaper helps smooth the surface. Finally, thin wood pieces or blocks are good materials to work with.

How Does The Design Of The Hollow Form Affect The Turning Process And Final Outcome?

The shape of the hollow form really matters when we turn it. If the form is wide, it’s easier to reach inside. If it’s narrow, we need special tools to get to those tight spaces. A good design helps us make smoother shapes and cool designs. This means the final piece can look better and be more fun to use!

What Techniques Can Be Employed To Minimize Warping Or Cracking In Thin Wall Hollow Forms During The Turning Process?

To avoid warping or cracking, you can start by using stable wood that is always dry. Make sure to turn the hollow form slowly and carefully. You should also keep the tools sharp so they cut smoothly. After turning, let the wood rest and dry slowly in a safe place. This helps keep it strong and prevents damage.

How Do You Properly Secure And Support Thin Wall Hollow Forms On The Lathe To Ensure Safety And Precision While Turning?

To safely turn thin wall hollow forms on a lathe, we should use a special chuck to hold the piece. A chuck grips the wood tightly without crushing it. You can also support the piece with a tailstock for extra stability. Make sure everything is tight and check it while the lathe is off. Always wear safety goggles and keep your hands clear while it spins.

What Finishing Techniques Are Recommended For Enhancing The Appearance And Durability Of Thin Wall Hollow Forms After Turning?

To make your thin wall hollow forms look nice and last longer, you can sand them smooth first. Use fine sandpaper to get rid of rough spots. Then, you can apply a clear finish, like varnish or oil, to protect the wood and make it shine. Don’t forget to let each layer dry before adding more. This will give your project a beautiful look and help it stay safe from damage.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Turning Thin Wall Hollow Forms:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are my answers about lathe turning thin wall hollow forms. 1. **What is a lathe?** A lathe is a tool that spins wood or metal to shape it. You can make fun items like bowls and vases. 2. **What is a hollow form?** A hollow form is a shape that is empty inside. We can create it by turning the outer part on a lathe. 3. **Why is it hard to turn thin walls?** Turning thin walls is tricky because they can break easily. We need to be careful and go slowly. 4. **How do we make sure the walls are even?** We check the thickness as we turn. You can use a caliper, which is like a ruler for measuring. 5. **What should you wear while using a lathe?** You should wear safety glasses and ear protection. This helps keep your eyes and ears safe from dust and noise.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question, and I’ll provide an answer that fits your needs.”}},{“@type”: “Question”,”name”: “What Are The Essential Tools And Materials Required For Turning Thin Wall Hollow Forms On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To turn thin wall hollow forms on a lathe, you need a few key tools and materials. First, you need a lathe, which spins the wood. You also need sharp chisels to shape the wood. Sandpaper helps smooth the surface. Finally, thin wood pieces or blocks are good materials to work with.”}},{“@type”: “Question”,”name”: “How Does The Design Of The Hollow Form Affect The Turning Process And Final Outcome?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The shape of the hollow form really matters when we turn it. If the form is wide, it’s easier to reach inside. If it’s narrow, we need special tools to get to those tight spaces. A good design helps us make smoother shapes and cool designs. This means the final piece can look better and be more fun to use!”}},{“@type”: “Question”,”name”: “What Techniques Can Be Employed To Minimize Warping Or Cracking In Thin Wall Hollow Forms During The Turning Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To avoid warping or cracking, you can start by using stable wood that is always dry. Make sure to turn the hollow form slowly and carefully. You should also keep the tools sharp so they cut smoothly. After turning, let the wood rest and dry slowly in a safe place. This helps keep it strong and prevents damage.”}},{“@type”: “Question”,”name”: “How Do You Properly Secure And Support Thin Wall Hollow Forms On The Lathe To Ensure Safety And Precision While Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To safely turn thin wall hollow forms on a lathe, we should use a special chuck to hold the piece. A chuck grips the wood tightly without crushing it. You can also support the piece with a tailstock for extra stability. Make sure everything is tight and check it while the lathe is off. Always wear safety goggles and keep your hands clear while it spins.”}},{“@type”: “Question”,”name”: “What Finishing Techniques Are Recommended For Enhancing The Appearance And Durability Of Thin Wall Hollow Forms After Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your thin wall hollow forms look nice and last longer, you can sand them smooth first. Use fine sandpaper to get rid of rough spots. Then, you can apply a clear finish, like varnish or oil, to protect the wood and make it shine. Don’t forget to let each layer dry before adding more. This will give your project a beautiful look and help it stay safe from damage.”}}]}