Have you ever thought about how a metal lathe works? It’s a fascinating tool that helps create many everyday items. But setting up a lathe workshop can be tricky. You need the right tools and safety features to work effectively.

One key feature is the foot brake on a metal lathe. This handy tool can stop the lathe quickly. Imagine if you are in the middle of a project and need to stop fast! A foot brake makes it easy and safe.

Setting up your lathe workshop with this feature can make your work smoother. Picture this: you’re turning a piece of metal, and then suddenly you need to focus. With a simple press of your foot, you can stop the lathe instantly. Isn’t that cool?

In this article, we will explore the best ways to set up a lathe workshop. We’ll share tips on choosing the right lathe, the importance of a foot brake, and how to stay safe while working. Get ready to bring your metalworking skills to the next level!

Essential Metal Lathe Foot Brake For Your Lathe Workshop Setup

Lathe Workshop Setup: Metal Lathe Foot Brake

Setting up your lathe workshop is exciting and vital for safety. A metal lathe foot brake is a critical feature. It allows quick stops when needed. Imagine working on a project and needing sudden control! You can prevent accidents this way. Creating a comfortable workspace goes beyond tools. Proper layout enhances productivity. Keep materials organized and close at hand. With the right setup, efficiency soars, and creativity flows. Consider how a small change can make a big difference in your projects!Choosing the Right Space for Your Workshop

Importance of location and workspace layout. Factors to consider: lighting, ventilation, and accessibility.Setting up your workshop is like finding the perfect spot to plant a tree. You need a good location and smart layout! Consider lighting—natural light is like sunshine for your creativity. Ventilation is key, too; nobody likes working in a stuffy room! Access matters—make sure your tools are easy to reach. Imagine tripping over tools like a movie slapstick moment; not funny! Don’t forget your safety gear, and enjoy your space!

| Factor | Importance |

|---|---|

| Lighting | Brightens your workspace, helps with detail |

| Ventilation | Healthy air for safe breathing |

| Accessibility | Easy tool reach for smooth work |

Essential Tools and Equipment for Your Workshop

Musthave tools for a metal lathe setup. Additional equipment to enhance functionality and safety.Setting up a workshop for a metal lathe means having the right tools. Key tools make work easier and safer. Here are some must-have items:

- Metal lathe: Your main tool for shaping metal.

- Foot brake: Great for safety. It lets you stop quickly.

- Cutting tools: Different shapes for various tasks.

- Chucks: Hold workpieces securely.

Adding extra equipment can improve your setup. Keep a fire extinguisher nearby. Use safety goggles for eye protection. A sturdy workbench also helps. These additions make your workshop not only effective but also safe.

What are essential tools for a metal lathe setup?

Essential tools include a metal lathe, cutting tools, and a foot brake. Each tool plays an important role in your work process.

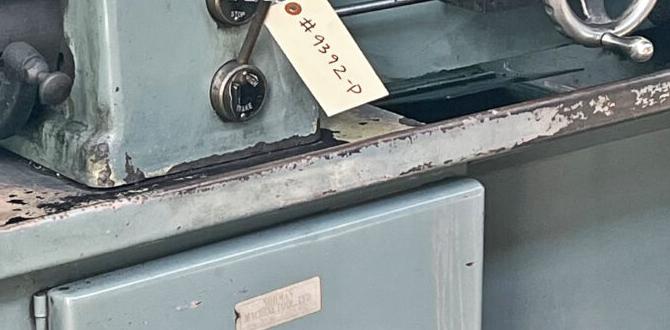

Step-by-Step Guide to Setting Up Your Metal Lathe

Preparing the workspace and ensuring stability. Installing and aligning the metal lathe for optimal performance.Creating a great workspace is key for your metal lathe. Start by cleaning the area and making sure it’s strong enough to hold the machine. Nobody wants their lathe doing the cha-cha! Next, level the lathe using shims or adjustable feet. This will help it work smoothly. Remember, an unsteady lathe can lead to wobbly projects, and nobody wants a wonky donut! Check that the tailstock and headstock are in line. Use a simple laser level for accuracy.

| Step | Action |

|---|---|

| 1 | Prepare the workspace |

| 2 | Clean the area |

| 3 | Ensure stability |

| 4 | Align the lathe |

Lastly, don’t forget about the foot brake! A good foot brake helps you stop quickly and safely, just like a superhero pressing the brakes on a runaway car. Ensure it’s installed properly for a smoother experience.

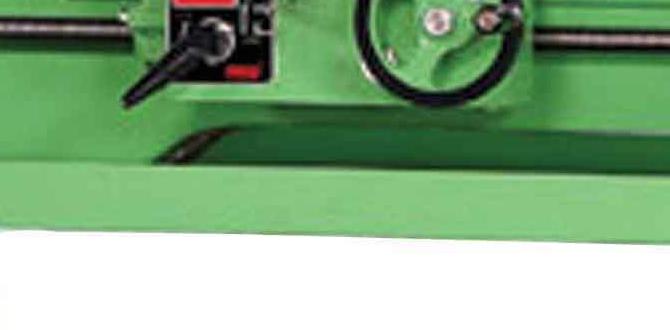

Integrating a Foot Brake for Safety and Efficiency

Benefits of a foot brake in lathe operation. How to install and test the foot brake effectively.A foot brake in your lathe setup offers key benefits. It helps you stop the lathe quickly. This feature can prevent accidents and improve work efficiency. Installing a foot brake is simple. Start by selecting the right foot pedal kit. Fix it securely to the floor. Then, connect the brake to the lathe. Testing the brake is important too. Make sure it responds quickly and smoothly. Regular checks will ensure safe operations.

What are the benefits of a foot brake in lathe operations?

The foot brake improves both safety and speed. It allows for immediate stopping, reducing the risk of injury. Workers can focus on their tasks without worrying about accidental movements.

How to install and test a foot brake:

- Select the right foot pedal kit.

- Fix the pedal securely to the floor.

- Connect it to the lathe.

- Test the brake for quick response.

Safety Precautions for Lathe Workshop Setup

Essential safety gear and practices to adopt. Common hazards to be aware of in a metal lathe workshop.Your lathe workshop can be a fun place, but safety rules need to be front and center! Start with wearing safety goggles and ear protection to shield your eyes and ears from flying chips and loud noise. A dust mask can be a lifesaver too, especially if you enjoy breathing clean air! Remember, loose clothes and long hair are like best friends with lathes—they love to get caught! Keep the workspace tidy to avoid tripping over tools. Wow, you’ll be a safety superstar!

| Common Hazards | Safety Precautions |

|---|---|

| Flying debris | Wear safety goggles |

| Loud noises | Use ear protection |

| Flammable materials | Keep workspace clear |

| Moving parts | Avoid loose clothing |

Stay alert and always check your tools. Did you know that most accidents happen due to distractions? Yikes! So, focus and keep your fingers away from the blade! Following these steps can turn you into a lathe wizard, and make your workshop a safer and more enjoyable place to create!

Maintenance Tips for Longevity of Your Metal Lathe

Routine checks and preventative maintenance strategies. Troubleshooting common issues that may arise during operation.Taking care of your metal lathe is key to its long life. Regular checks keep it running smoothly. Check the oil levels and look for any rust or dirt. Clean the machine often. This will help stop problems before they start. If something goes wrong, try these tips:

- Listen for strange noises. They may mean something is loose or damaged.

- Feel for vibrations. This can show that parts are not balanced.

- Look for unusual wear. Check the tools and workpieces for signs of damage.

Don’t forget to take notes after each check. It helps to spot issues quickly! Keep your lathe in good shape, and it will work better for you.

What are some common maintenance tasks for a metal lathe?

Common tasks include:

- Wiping down surfaces.

- Checking lubrication levels.

- Tightening loose bolts.

Doing these tasks helps ensure your lathe runs perfectly!

Conclusion

In summary, setting up a lathe workshop with a metal lathe foot brake is essential for safety and control. Always ensure the foot brake is functional and easily accessible. Remember, proper setup improves your work quality and protects you while you create. For more tips on workshop safety, consider reading guides or watching videos to enhance your skills.FAQs

Certainly! Here Are Five Related Questions On The Topic Of Setting Up A Metal Lathe Workshop With A Focus On The Foot Brake:Sure! Setting up a metal lathe workshop is exciting. First, make sure your workshop is safe and tidy. The foot brake helps you stop the lathe quickly when you press it with your foot. This keeps you safe while you work. Always check that the brake works well before starting any project.

Sure! Please provide me with the question you’d like me to answer.

What Are The Essential Components Needed To Install A Foot Brake System On A Metal Lathe?To install a foot brake system on a metal lathe, you need a few important parts. First, you need the foot pedal which lets you control the brake. Next, you need a brake assembly that stops the lathe when you press the pedal. You also need cables to connect the pedal and brake. Finally, some screws and tools will help you put everything together.

How Does A Foot Brake Enhance Safety And Efficiency During Metal Lathe Operations?A foot brake helps you stop the metal lathe quickly when you need to. This makes it safer because you can avoid accidents. It also lets you keep your hands free to work better. With the foot brake, you can be more efficient and focus on your task without distractions.

What Steps Should Be Taken To Ensure Proper Alignment And Functionality Of The Foot Brake In A Lathe Workshop?To make sure the foot brake on a lathe works well, you should first check the brake pedal. Make sure it moves easily and isn’t stuck. Next, look at the brake cables to see if they are tight and not worn out. Then, test the brake by pressing it to see if it stops the machine quickly. Finally, always remember to keep the area around the brake clean and clear.

Are There Specific Maintenance Practices That Should Be Followed To Keep The Foot Brake System In Optimal Condition?Yes, you can take care of the foot brake system. First, check the brake fluid often. Make sure it’s full and clean. Next, look at the brake pads for wear. If they are thin, replace them. Finally, get a mechanic to look at your brakes once a year. This helps keep everything working well and safe!

How Can A Foot Brake Be Integrated Into Existing Lathe Setups, And What Considerations Should Be Taken Into Account For Custom Installations?You can add a foot brake to a lathe by connecting it to the machine’s controls. First, choose a good spot for the brake. Make sure it’s easy to reach while you’re working. You should check if your lathe needs special parts or tools. Always follow safety rules to keep everyone safe.