Have you ever wondered how a manual metal lathe works so smoothly? One crucial part is the tailstock. Proper alignment of the tailstock can make a big difference in your projects. Imagine trying to shape metal, but your tools aren’t straight. That can lead to mistakes and wasted time.

Aligning the tailstock may sound complicated, but it doesn’t have to be! With the right steps, anyone can do it. Did you know that even a tiny misalignment can affect your work? When the tailstock is off, it can make your cuts uneven. This article will guide you through the simple process of manual metal lathe tailstock alignment.

So, are you ready to improve your skills and create better projects? Let’s dive into the world of lathe setup and get those tools in line!

Manual Metal Lathe Tailstock Alignment Techniques Explained

Manual Metal Lathe Tailstock Alignment

Aligning the tailstock on a manual metal lathe is crucial for precision work. If it’s off, it can lead to inaccurate cuts and ruined projects. You learn techniques to check and correct tailstock alignment, using tools such as a dial indicator. Have you ever wondered why your pieces aren’t fitting together? Proper alignment can solve that mystery. It’s like tuning a musical instrument—just a small adjustment can make a big difference!Understanding Tailstock Alignment

Definition and importance of tailstock alignment. Common problems caused by misalignment.Tailstock alignment is crucial for any manual metal lathe. It ensures that your workpiece stays centered and spins true. Misalignment can lead to uneven cuts, which is less than ideal when making precision parts. Imagine a wobbly cake! Common problems include tapered cuts and excessive wear on tools, which no one wants, right? Here’s a quick look at these issues:

| Problem | Effect |

|---|---|

| Uneven Cuts | Results in poor finish |

| Tapered Edges | Ruins part accuracy |

| Increased Tool Wear | Higher costs for replacements |

Getting the tailstock right means smoother sailing on your lathe journey. So, don’t let misalignment ruin your metal magic!

Tools Required for Tailstock Alignment

Essential measuring tools (dial indicators, levels, etc.). Recommended alignment jigs and fixtures.To align the tailstock of your lathe correctly, gathering the right tools is crucial. Essential measuring tools include:

- Dial indicators: They help measure small distances accurately.

- Levels: They check if the machine is flat and even.

Additionally, having the right alignment jigs and fixtures can make the job easier. These tools hold the tailstock in place during adjustments, ensuring perfect alignment every time.

What tools do I need for tailstock alignment?

You need tools like dial indicators, levels, and alignment jigs.Why are these tools important?

They help ensure precision and accuracy, making your work more efficient and precise.Step-by-Step Guide to Tailstock Alignment

Initial setup of the lathe and tailstock. Procedure for checking alignment with indicators. Adjustments needed for achieving perfect alignment.Getting your lathe ready is like prepping for a big race. Start by making sure your lathe and tailstock are set up properly. Use a straightedge to align it. Next, check the alignment with indicators. Place one on the tailstock and one on the spindle. Spin the lathe slowly and watch the readings. If they don’t match, adjustments are needed. Loosen the tailstock screws and nudge it until everything lines up. Think of it as comedy night – alignment is key for the best performance!

| Step | Action |

|---|---|

| 1 | Setup the lathe and tailstock |

| 2 | Check alignment with indicators |

| 3 | Make adjustments as needed |

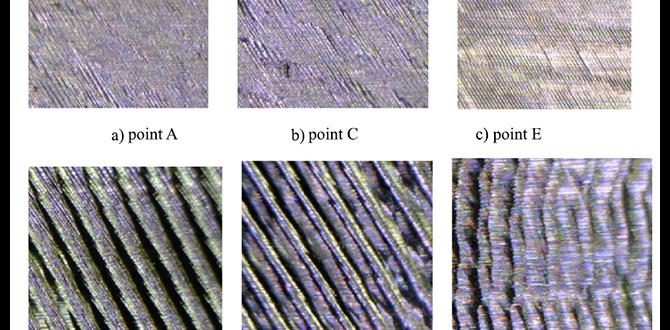

Common Tailstock Alignment Techniques

Discussing different techniques (offset, taper, etc.). Pros and cons of each alignment method.Tailstock alignment can be tricky but fear not! There are several ways to tackle it. One method is **offset alignment**, which uses a shim to adjust the tailstock’s height. This can be easy, but it may not always fix every issue. Another choice is **taper alignment**. This one’s great for precision, as it aligns using a tapered rod, but it takes time and patience. Here’s a quick look at the pros and cons:

| Method | Pros | Cons |

|---|---|---|

| Offset Alignment | Simple setup | May miss slight misalignments |

| Taper Alignment | High precision | Time-consuming |

Choosing the right method can feel like picking pizza toppings: everyone has their favorite! Remember, it’s all about finding what works best for your lathe.

Identifying and Troubleshooting Misalignment Issues

Signs of misalignment during operations. Solutions for common misalignment problems.Misalignment issues in a manual metal lathe can cause problems. You might see uneven cuts or feel vibrations during operation. These signs mean it’s time to check the tailstock. To fix common problems, follow these steps:

- Check the alignment: Use a dial indicator for precision.

- Tighten loose parts: Make sure all screws are secured.

- Adjust the tailstock: Move it until it lines up correctly.

By keeping an eye out for these signs, you can ensure smooth operations.

How do I know if my lathe is misaligned?

If you notice uneven cuts, strange vibrations, or excessive wear on tools, your lathe might be misaligned. Addressing these issues quickly can save time and materials.

Maintaining Proper Tailstock Alignment

Regular inspection intervals and maintenance tips. Preventative measures to keep tailstock aligned.To keep the tailstock aligned, check it regularly. Inspect it every few uses. This will catch small issues before they become big problems. Here are some tips:

- Clean the area often to avoid dust buildup.

- Tighten screws regularly for better stability.

- Check for wear and tear on parts. Replace if needed.

- Use a dial indicator to measure alignment correctly.

Staying proactive helps maintain your machine’s accuracy. This will lead to better work quality and longer tool life.

Why is tailstock alignment important?

Proper alignment leads to better accuracy. Without it, you risk damaging your workpieces or tools.

Real-World Applications of Proper Tailstock Alignment

Industries that benefit from precise tailstock alignment. Case studies showcasing improved accuracy and efficiency.Many industries rely on proper tailstock alignment. This includes manufacturing, aerospace, and automotive sectors. They need precise measurements for better products. Case studies show that businesses with accurate alignment see improved results. For example:

- Manufacturing: More parts made without defects.

- Aerospace: Creates safe and reliable components.

- Automotive: Boosts engine performance and longevity.

These examples show that investing in tailstock alignment can save time and money while enhancing quality.

Why is proper tailstock alignment important?

Proper tailstock alignment ensures that parts are made accurately. This reduces waste and increases efficiency in production.

Advanced Techniques and Tips for Experienced Operators

Tips for finetuning alignment during intricate operations. Discussing advanced tools and technologies for alignment.Advanced operators can sharpen their manual metal lathe tailstock alignment skills with a few smart tricks. Use a dial indicator for precise measurements. This tool helps to ensure the tailstock is perfectly aligned. Adjustable tailstocks and laser alignment devices also add to the accuracy during complex tasks. These tools give a clear picture of the setup, helping you make fine adjustments easily.

How can I improve alignment in intricate operations?

Use precise measuring tools like dial indicators and laser guides. These tools help you check the alignment in a detailed way, making it easier to adjust for better results.

Conclusion

In conclusion, aligning the tailstock on a manual metal lathe is essential for accurate machining. Proper alignment helps eliminate errors and ensures smooth operations. You can regularly check the tailstock’s position for better results. For more detailed instructions, explore guides and videos online. With practice, you’ll become skilled at tailstock alignment, improving your lathe work significantly.FAQs

What Are The Key Steps To Check And Adjust The Alignment Of A Manual Metal Lathe Tailstock?First, we need to check if the tailstock is straight. You can do this by putting a long, straight bar between the tailstock and the headstock. Then, look at the gap between the bar and the tailstock. If there’s a space, we need to adjust it. You can move the tailstock side to side until it lines up nicely with the bar. Make sure to tighten everything back up once it looks good!

How Can Improper Tailstock Alignment Affect The Quality Of Turned Parts In A Lathe?If the tailstock on a lathe isn’t lined up correctly, it can cause problems. The part you’re shaping might be uneven. This makes your finished piece look bad or not fit together well. You want everything to be straight and smooth, so proper alignment is really important. Always check it before you start working!

What Tools Are Commonly Used For Tailstock Alignment On Manual Lathes?To align the tailstock on a manual lathe, we use a few simple tools. One tool is a dial indicator, which measures tiny movements. We also use a straightedge to check if everything is even. Sometimes, a test piece helps us see if the tailstock is in the right place. These tools help us make sure our work is precise.

How Often Should The Tailstock Alignment Be Checked And Why Is It Important For Precision Machining?You should check the tailstock alignment every time you set up your machine. It’s important because it helps make sure your parts are shaped correctly. If the alignment is off, your pieces might not fit together well. This can cause mistakes in your work. Regular checks help keep everything precise and working smoothly.

What Are The Common Signs That Indicate A Tailstock Misalignment In A Manual Metal Lathe?If the tailstock is misaligned, you might notice a few signs. Your workpiece may wobble or feel uneven when cutting. You might also see that it’s not making smooth, straight lines. The tool might dig in too hard or not cut at all. These signs mean the tailstock needs to be checked and fixed.