Imagine watching an artist carve a masterpiece from wood. The slightest twist or tilt seems simple, but it takes skill and precision. Similarly, adjusting a metal lathe compound rest is like fine-tuning a musical instrument. Have you ever seen a lathe in action? It’s a machine that spins metal so you can shape it. You might wonder, how does it turn a plain metal rod into something amazing?

Picture this: a metal lathe is like a potter’s wheel, but for metal. Adjusting the compound rest is critical. It helps guide your tool to cut and shape metal with precision. Without the right adjustment, your metal piece might not turn out as expected. Adjusting it can feel like solving a fun puzzle. It’s both challenging and rewarding!

Here’s a fun fact: did you know the compound rest can move in many directions? This clever tool helps create unique shapes. Just think of all the amazing things we can make with it! But before we dive into the details, let’s learn why these adjustments matter so much.

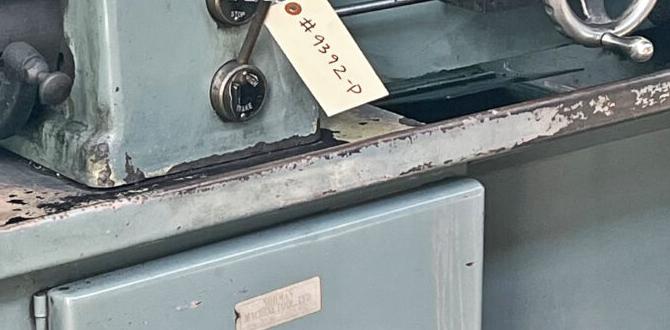

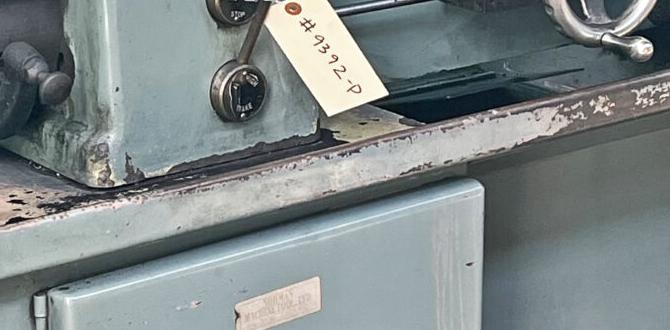

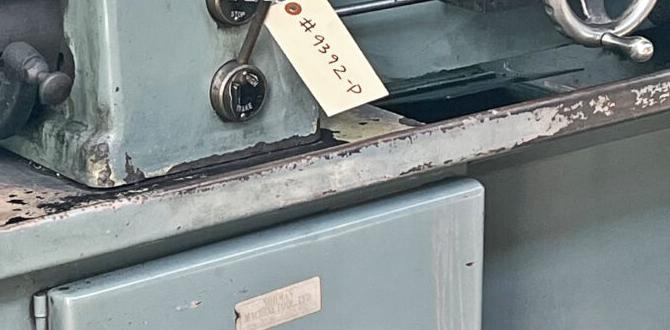

Mastering Metal Lathe Compound Rest Adjustment Techniques Understanding How To Properly Adjust The Compound Rest On A Metal Lathe Is A Crucial Skill For Achieving Precision In Machining Tasks. The Compound Rest, A Vital Component Of The Lathe, Allows For Angled Cuts And Fine-Tuning During The Turning Process. Whether You Are A Novice Or An Experienced Machinist, It’S Important To Familiarize Yourself With The Techniques And Adjustments Needed For Optimal Performance. What Is A Compound Rest? The Compound Rest Is A Part Of The Lathe That Supports The Cutting Tool. It Can Slide And Rotate, Enabling The Machinist To Cut Angles, Tapers, And Perform Intricate Operations That Are Not Possible When Using The Carriage Or Cross-Slide Alone. This Adds Versatility To The Lathe, Making It Possible To Execute Complex Cuts With Precision. Why Compound Rest Adjustment Matters Proper Adjustment Of The Compound Rest Is Essential For Achieving Accurate Cuts, Minimizing Tool Wear, And Ensuring Smooth Operation. Incorrectly Set Compound Rests Can Lead To Inaccuracies In Material Removal, Increased Tool Chatter, And Potential Damage To The Workpiece Or Lathe. Step-By-Step Guide To Adjusting The Compound Rest 1. **Secure The Lathe:** Ensure That Your Lathe Is Powered Off And Stable. Engage All Safety Protocols To Prevent Accidents During Adjustment. 2. **Align The Rest:** Begin By Loosening The Compound Rest Screws. Position The Rest At The Desired Angle, Using An Angle Gauge If Necessary. Most Operations Use Common Angles Like 29 Degrees For Threading. 3. **Tighten Screws:** Once The Correct Angle Is Set, Tighten The Screws Evenly To Avoid Shifting. Ensure That The Rest’S Base Is Secure And Does Not Move During Machining. 4. **Test The Movement:** Gently Move The Compound Rest Back And Forth To Feel For Any Resistance Or Play. Adjust The Gib Screws If Necessary To Fine-Tune The Movement. The Action Should Be Smooth With No Excess Play. 5. **Check Tool Alignment:** Make Sure That The Cutting Tool Is Aligned Correctly In Relation To The Workpiece. Tool Height Should Be Adjusted To Centerline Height. Common Mistakes To Avoid – **Over-Tightening The Gib Screws:** This Can Restrict Movement And Increase Wear, Reducing The Life And Smooth Operation Of The Compound Rest. – **Ignoring Tool Height:** Incorrect Tool Height Can Cause Rubbing Rather Than Cutting, Affecting Both Tool And Workpiece. – **Neglecting Regular Maintenance:** Periodically Check And Lubricate Moving Parts To Ensure Longevity And Optimal Performance. In Conclusion, Mastering The Adjustments Of The Compound Rest On A Metal Lathe Is Paramount For Effective Machining. By Following The Guidelines Above, You Can Confidently Handle Various Projects, Ensuring Precision And Safeguarding Your Equipment. Remember, Practice Makes Perfect, And With Time, These Adjustments Will Become Second Nature.

Unlocking the Secrets of Metal Lathe Compound Rest Adjustment

The metal lathe compound rest makes precise cuts possible. Adjust it right, and your project shines. Imagine slicing through metal like slicing through butter! It’s all about getting that perfect angle, achieved with simple tweaks. Can you believe adjusting a lathe can be that smooth? It’s fascinating how the compound rest, small yet powerful, gives you ultimate control. Ready for your next big creation? The magic starts here!Importance of Proper Adjustment

Impact of adjustment on accuracy and precision in machining.. Common issues arising from misalignment or improper adjustment..Getting the adjustment right is like baking a perfect cake. Too much sugar or not enough flour can ruin everything! A proper adjustment ensures that your machining is accurate and precise. If the compound rest is misaligned, your pieces may end up looking like a Picasso – all wobbly and weird. Common problems like uneven cuts can happen if things are off. So, get that adjustment right, or you might be spending more time fixing mistakes than making masterpieces!

| Adjustment Quality | Impact on Machining |

|---|---|

| Proper Adjustment | High accuracy and precision |

| Misalignment | Uneven cuts and errors |

Tools Needed for Adjustment

List of essential tools required for compound rest adjustment.. Safety gear and precautions to consider during the process..To adjust the compound rest on your metal lathe, you’ll need a few key tools. These tools ensure that your setup is precise and safe. Here’s a quick toolbox checklist:

| Tool | Purpose |

|---|---|

| Wrench | Tightening and loosening bolts |

| Caliper | Measuring depth and width |

| Level | Checking the surface balance |

| Clean Cloth | Wiping off debris |

Don’t forget your safety gear! Wear gloves and goggles to stop flying metal shavings from becoming a surprise gift to your eyes and fingers. Safety first, fun second, right?

Step-by-Step Adjustment Process

Detailed explanation of the adjustment process for the compound rest.. Visual aids or diagrams to assist in understanding each step..Adjusting the compound rest on a metal lathe can feel like solving a puzzle without the picture on the box. First, check the bolts on the compound rest—make sure they’re snug but not too tight. You don’t want it to be a stubborn mule! Next, unlock the compound by turning the handwheel. Adjust the angle using the degree scale, and remember, it’s like finding the perfect nap angle—comfortable but not droopy!

Visual aids can help clarify this process. Below is a simple table outlining each step:

| Step | Action |

|---|---|

| 1 | Check bolts |

| 2 | Unlock the compound |

| 3 | Adjust angle |

| 4 | Lock it in place |

Once you’ve adjusted it, double-check that everything moves smoothly. If it doesn’t, fear not—no one likes a cranky machine! And, just like a well-cooked pancake, keep tweaking until it’s just right!

Troubleshooting Common Adjustment Problems

Identifying signs of incorrect adjustment (e.g., chatter, incorrect angles).. Solutions for common issues encountered during adjustment..Sometimes, adjusting the metal lathe can be tricky. Signs of incorrect adjustments include loud noises, known as chatter, and pieces that don’t fit right. These issues make it hard to work properly. To fix them, check your settings and angles. Make sure everything is aligned. It’s also good to look for wear and tear on parts. If you notice problems, try the following:

- Inspect for misalignment.

- Tighten loose screws.

- Adjust angles carefully.

What are common signs of adjustment issues?

Common signs include vibrations, poor cuts, and uneven surfaces. This can tell you something is off with your adjustments!

Maintenance Tips for Long-lasting Performance

Regular maintenance practices for the compound rest and its components.. Best practices to prevent wear and preserve accuracy over time..To keep your metal lathe’s compound rest working well, regular maintenance is key. Cleaning dust and chips helps parts move smoothly. Lubricate moving parts to reduce friction. This can prevent wear and keep your machine accurate.

- Check for tightness regularly.

- Adjust the compound rest carefully.

- Inspect for rust and clean as needed.

- Replace worn parts quickly.

These simple steps help ensure your lathe lasts longer and works better!

How often should I maintain my metal lathe?

It’s best to check your lathe every few weeks. Regular checks mean issues get caught early.

Advanced Techniques for Professionals

Techniques for finetuning the compound rest for complex projects.. Adjustments for specific machining applications and techniques..Fine-tuning your compound rest can enhance your projects. Here are some advanced techniques:

- Precision adjustment: Ensure your compound rest is level for accurate cuts.

- Angle setting: Adjust angles carefully for intricate shapes.

- Locking mechanism: Use the locking system to secure your settings while machining.

Different projects need different approaches. Don’t rush; take your time to make each adjustment. This focus leads to better results.

How can I adjust for complex shapes?

To adjust for complex shapes, start with your compound rest leveled. Always check your angles with a protractor. Small tweaks can make a big difference!

Important Tips for Specific Projects:

- Use light pressure when machining delicate materials.

- Keep tools sharp for smooth finishes.

Conclusion

Adjusting a metal lathe’s compound rest is important for precision. It helps you cut accurately and confidently. By tightening screws and setting angles carefully, you ensure smooth operation. Practice what you’ve learned to get better. To explore more, check out books or videos on lathe techniques. Keep safe, stay curious, and enjoy working with your lathe!FAQs

Sure! Here Are Five Related Questions About Metal Lathe Compound Rest Adjustment:Sure! The compound rest helps you cut shapes on a metal lathe. You can move it to make different cuts. First, check if it is tight. Then, loosen the screws a little to adjust it. Finally, when it looks right, tighten the screws back up. Always be careful while doing this!

Sure! I can help with that. Please provide the question you want me to answer.

What Is The Purpose Of The Compound Rest On A Metal Lathe, And How Does It Affect The Machining Process?The compound rest on a metal lathe helps you angle and move the cutting tool. This makes it easier to shape the metal parts exactly how you want. By adjusting the tool’s position, you can make precise cuts and create different shapes. This means you can make better, more accurate parts for your projects.

How Do You Adjust The Compound Rest To Achieve Accurate Angle Cuts On A Workpiece?To adjust the compound rest, first, find the angle you want to cut. You can use a protractor to measure it. Next, loosen the handles on the rest and turn it to the right angle. Then, tighten the handles so it stays in place. Finally, double-check the angle before you start cutting.

What Tools Are Necessary For Properly Adjusting The Compound Rest On A Metal Lathe?To adjust the compound rest on a metal lathe, you need a few tools. First, have a wrench to tighten or loosen screws. A ruler or caliper helps you measure angles. A level ensures everything is even. Finally, a screwdriver is useful for adjusting small parts. These tools make it easier to set everything up just right.

What Are Some Common Mistakes To Avoid When Adjusting The Compound Rest To Ensure Precision?When you adjust the compound rest, avoid these mistakes. Don’t skip checking the angles carefully; they help the tool cut right. Always tighten the screws properly after adjusting, or things can move out of place. Make sure to measure twice, so you don’t make mistakes while cutting. Lastly, keep your workspace clean, so you can see everything clearly!

How Can Wear And Tear On The Compound Rest Impact Its Adjustment, And What Maintenance Practices Can Be Implemented To Prolong Its Lifespan?Wear and tear on the compound rest can make it hard to adjust. When parts get worn, they may not fit well. This can lead to mistakes in cutting or shaping materials. To keep it working well, we can clean it often, check for loose parts, and apply some oil to moving parts. Taking care of it helps it last longer!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About Metal Lathe Compound Rest Adjustment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! The compound rest helps you cut shapes on a metal lathe. You can move it to make different cuts. First, check if it is tight. Then, loosen the screws a little to adjust it. Finally, when it looks right, tighten the screws back up. Always be careful while doing this!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I can help with that. Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of The Compound Rest On A Metal Lathe, And How Does It Affect The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest on a metal lathe helps you angle and move the cutting tool. This makes it easier to shape the metal parts exactly how you want. By adjusting the tool’s position, you can make precise cuts and create different shapes. This means you can make better, more accurate parts for your projects.”}},{“@type”: “Question”,”name”: “How Do You Adjust The Compound Rest To Achieve Accurate Angle Cuts On A Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the compound rest, first, find the angle you want to cut. You can use a protractor to measure it. Next, loosen the handles on the rest and turn it to the right angle. Then, tighten the handles so it stays in place. Finally, double-check the angle before you start cutting.”}},{“@type”: “Question”,”name”: “What Tools Are Necessary For Properly Adjusting The Compound Rest On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the compound rest on a metal lathe, you need a few tools. First, have a wrench to tighten or loosen screws. A ruler or caliper helps you measure angles. A level ensures everything is even. Finally, a screwdriver is useful for adjusting small parts. These tools make it easier to set everything up just right.”}},{“@type”: “Question”,”name”: “What Are Some Common Mistakes To Avoid When Adjusting The Compound Rest To Ensure Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you adjust the compound rest, avoid these mistakes. Don’t skip checking the angles carefully; they help the tool cut right. Always tighten the screws properly after adjusting, or things can move out of place. Make sure to measure twice, so you don’t make mistakes while cutting. Lastly, keep your workspace clean, so you can see everything clearly!”}},{“@type”: “Question”,”name”: “How Can Wear And Tear On The Compound Rest Impact Its Adjustment, And What Maintenance Practices Can Be Implemented To Prolong Its Lifespan?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Wear and tear on the compound rest can make it hard to adjust. When parts get worn, they may not fit well. This can lead to mistakes in cutting or shaping materials. To keep it working well, we can clean it often, check for loose parts, and apply some oil to moving parts. Taking care of it helps it last longer!”}}]}