Have you ever tried to build something but it just wouldn’t line up right? Imagine you are creating a cool toy. You want everything to fit perfectly. This is like using a metal lathe. You need to make sure its tailstock alignment is perfect. Without it, projects might go wrong.

Here’s a fun fact for you: Even a tiny shift in alignment can ruin your project. Ever built a model plane? Imagine your wings not fitting right because you missed a small step. It’s that little adjustment that makes all the difference.

So, why does tailstock alignment matter? It’s like drawing a straight line. If your pencil wobbles, you won’t get a perfect line, right? Think of the metal lathe as a big help in the workshop. Everything must be in place for it to work its magic.

Getting the tailstock alignment just right is a bit like solving a puzzle. Each piece needs to fit perfectly. The lathe becomes a hero in helping workers craft amazing things. Does it sound interesting? Let’s explore how this tiny piece makes a big impact.

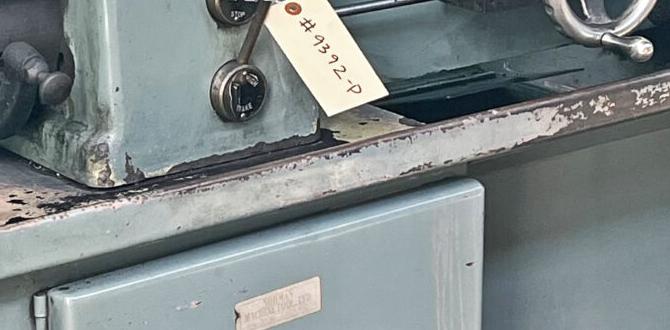

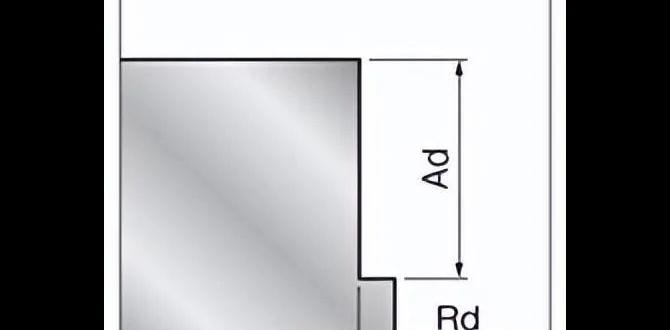

Essential Guide To Metal Lathe Tailstock Alignment Aligning The Tailstock In A Metal Lathe Is A Critical Process That Ensures Precision And Accuracy In Turning Operations. A Well-Aligned Tailstock Supports Your Workpiece And Helps Achieve Perfect Concentricity, Which Is Vital In Machining Processes That Demand Tight Tolerances. In This Guide, We Will Explore The Steps To Accurately Align Your Metal Lathe Tailstock, Discuss Common Issues That Can Arise From Misalignment, And Share Best Practices For Maintaining Alignment. Understanding Tailstock Alignment The Tailstock Is A Movable Part Of The Lathe That Holds The Non-Rotating End Of The Workpiece. Proper Tailstock Alignment Ensures That The Axis Of The Tailstock Is Parallel To The Axis Of The Lathe Bed And The Lathe Spindle. Misalignment Can Lead To Tapered Or Uneven Workpieces, Vibrations, And Unnecessary Wear On Cutting Tools And Machine Components. Steps For Aligning A Metal Lathe Tailstock 1. **Initial Setup**: Begin By Cleaning The Tailstock Base And The Lathe Bed. Any Debris Or Oil Can Affect Alignment. 2. **Check Parallelism**: Use A Dial Indicator Mounted On A Spindle To Check The Parallelism. Run The Indicator Along The Ways While The Tailstock Is Clamped In Place. Any Deviation Indicates A Need For Adjustment. 3. **Test On A Workpiece**: Turn A Test Piece Between Centers. Measure The Diameter At Both Ends. A Uniform Diameter Indicates Proper Alignment. 4. **Adjust The Tailstock**: If Misalignment Is Detected, Adjustments Can Be Made Using The Tailstock’S Adjustment Screws Or By Adding Shims As Required. 5. **Re-Test After Adjustments**: Make Sure To Repeat The Testing Process After Each Adjustment To Ensure Accuracy. 6. **Final Verification**: Once Satisfied, Perform A Final Cut On A New Workpiece To Double-Check The Alignment. Common Problems From Misalignment – **Tapered Cuts**: A Tailstock That Isn’T Aligned Will Produce Tapered Cuts, Which Are Problematic Especially For Parts That Require Precision. – **Premature Tool Wear**: Misalignment Causes Uneven Force Distribution, Leading To Faster Tool Wear. – **Vibration**: Causes Increased Chatter Marks And Reduced Surface Finish Quality. Best Practices For Maintaining Alignment – **Regular Cleaning**: Ensure That The Lathe Bed And Tailstock Are Kept Clean To Prevent Issues Caused By Dirt Or Swarf Buildup. – **Routine Checks**: Incorporate Alignment Checks Into Regular Maintenance Schedules To Prevent Major Issues. – **Use Of High-Quality Tools**: Ensure That Your Alignment Tools Are Accurate And In Good Condition. – **Documentation**: Keep A Log Of Alignment Adjustments And Results For Future Reference. By Following These Guidelines, You Can Maintain Your Lathe’S Tailstock Alignment, Ensuring Precision And Prolonging The Life Of Your Machine. Regular Attention And Maintenance Not Only Improve Your Workpiece Accuracy But Also Enhance The Overall Efficiency Of Your Machining Process.

Metal Lathe Tailstock Alignment

Ever tried aligning a metal lathe’s tailstock? It’s like fixing a toy car’s wheels! Perfect tailstock alignment ensures smooth cuts and accurate shapes. Misalignment may cause wobbling and uneven edges. Imagine trying to draw a straight line with a wobbly hand—frustrating, right? Adjusting the tailstock helps keep things steady. Double-check your setup often. Did you know regular maintenance extends your lathe’s life? Keep it aligned, and enjoy precise crafting every time!Understanding the Importance of Tailstock Alignment

Explanation of tailstock’s role in metal lathe operations. Consequences of misalignment in precision machining.The tailstock is a vital part of a metal lathe. It holds the tool steady for precise machining. If it is not aligned correctly, parts can come out wrong. When you are making something, even a small mistake can be a big problem. Picture turning a wobbly wheel on a bike. It would not ride straight. The same happens here. Always check the tailstock! An aligned tailstock means smooth and perfect results.

Why is tailstock alignment crucial?

Misalignment leads to errors. When parts don’t fit, there could be wasted time and materials. Also, a misaligned tailstock can harm the machine. This alignment makes sure everything works right.

How can one check tailstock alignment?

Using a dial indicator is a smart way. Place it on the workpiece and spin it around. If the needle moves, the tailstock needs adjusting. This simple test helps keep the machine accurate.

Common Causes of Tailstock Misalignment

Wear and tear of components over time. Improper setup and handling during machine operation.Tailstock misalignment can happen for a couple of reasons.

First, parts of the machine wear down over time. This wear and tear can change the way the tailstock fits.

Second, improper setup and handling during operation can create problems. If the tailstock isn’t placed right, it won’t align properly.

- Check for worn parts regularly.

- Make sure to set up the machine carefully.

- Handle the machinery gently.

What causes tailstock misalignment?

Common causes include wear from use and poor setup during operation. Always check your tools to avoid issues.

Tools Required for Accurate Tailstock Alignment

List of essential tools and instruments needed. Safety equipment for alignment procedures.To get your tailstock aligned perfectly, a few tools will be your trusty sidekicks. First, you’ll need a digital caliper for precise measurements. Next, grab a level to ensure everything sits straight. A center finder helps locate the center point perfectly. Don’t forget about safety glasses to protect your peepers! Here’s a handy list:

| Tool | Purpose |

|---|---|

| Digital Caliper | For accurate measurements |

| Level | To check for straightness |

| Center Finder | To find center points |

| Safety Glasses | To protect your eyes! |

With these tools, your alignment will be more accurate than a cat landing on its feet!

Step-by-Step Tailstock Alignment Procedure

Initial inspection and preparation steps. Detailed process for aligning the tailstock with the headstock.Before diving into alignment, start with an initial inspection. Check if your lathe is clean and free of debris. A sneaky chip could ruin your day! Next, gather your tools: a dial indicator and a wrench. Now, let’s align the tailstock. Position the tailstock close to the headstock. Tighten it gently but don’t overdo it. Use the dial indicator to measure any misalignment. Move the tailstock left or right as needed. Keep adjusting until it aligns perfectly. Voila! Your lathe is ready for action. Now, go ahead and make some metal magic!

| Steps | Actions |

|---|---|

| Inspection | Clean your lathe and check for debris. |

| Tools | Get a dial indicator and wrench. |

| Positioning | Place tailstock near headstock. |

| Adjustment | Measure and align using dial indicator. |

| Completion | Tighten gently and check for readiness. |

Techniques for Measuring and Verifying Alignment

Methods for measuring tailstock alignment accurately. Using dial indicators to check for alignment errors.Measuring tailstock alignment is key to smooth machining. One popular method is using dial indicators. These handy tools can spot tiny misalignments that might make your work wobbly. Simply attach the dial indicator to the tailstock and check against the bed. If the needle wiggles more than a worm on a hot sidewalk, it’s time to adjust!

| Technique | Details |

|---|---|

| Dial Indicator Method | Use a dial indicator for precise readings. |

| Visual Inspection | A quick check with your eyes can also help. |

With these methods, you can keep your lathe running straight as an arrow. Remember, a well-aligned tailstock saves time and keeps your projects on track!

Troubleshooting Alignment Issues

Identifying signs of alignment problems. Solutions and adjustments to correct alignment errors.Sometimes, you might notice problems with your metal lathe. Alignment issues can cause uneven cuts. Here are some signs to look for:

- Parts don’t fit well.

- Strange noises when using the lathe.

- Vibration during operation.

If you see these signs, don’t worry! You can fix it. Check the tailstock. Make sure it’s straight. Adjust the screws if needed. Regular checks help keep everything in line!

What are common problems with tailstock alignment?

Common problems include misalignment leading to poor cuts and difficulty in fitting tools. Regular inspection helps catch these issues early.

How to adjust tailstock alignment?

- Loosen the tailstock screws.

- Gently move the tailstock until it aligns.

- Tighten the screws.

Maintenance Tips to Ensure Lasting Alignment

Routine checks and maintenance practices. Tips for prolonging the lifespan of the lathe machine.To keep your lathe working well, do routine checks. Check the tailstock often to ensure it stays aligned. Clean the machine regularly to remove dust and debris. Always lubricate moving parts for smooth operation. This simple care can make your lathe last longer.

- Inspect the tailstock alignment monthly.

- Use the right lubricant.

- Keep tools clean and dry.

- Tighten fasteners regularly.

How can I maintain my lathe for better performance?

Maintaining your lathe helps it run better and last longer. Always keep it clean and check for wear. Regular care can save you money and time in the long run.

Conclusion

Aligning a metal lathe’s tailstock is crucial for precision. Ensure accuracy by regularly checking and adjusting it. Use simple tools like a dial indicator. Proper alignment reduces errors and improves your projects. To learn more, explore guides online or ask experienced machinists for tips. Keep practicing, and you’ll master tailstock alignment in no time!FAQs

What Are The Key Steps To Ensure Proper Alignment Of The Tailstock On A Metal Lathe?To align the tailstock on a metal lathe, first, check that the lathe is level. Next, loosen the tailstock locking bolts so you can move it. Use a straight rod or a center drill to find the center of the spindle. Adjust the tailstock until it lines up with the spindle. Finally, tighten the bolts and double-check the alignment.

How Can Misalignment Of The Tailstock Affect The Accuracy Of Machining Operations On A Lathe?If the tailstock is not lined up correctly, it can cause problems. It may push the workpiece off-center. This means cuts might be uneven or wrong. As a result, the final product won’t fit or look right. We want everything to be straight and smooth on a lathe, so proper alignment is important!

What Tools Or Techniques Are Commonly Used To Check And Adjust The Tailstock Alignment?To check and adjust the tailstock alignment, you can use a few simple tools. A dial indicator is one tool that shows if the tailstock is straight. You can also use a test bar, which is a long, straight rod. First, you put the bar in the tailstock, then measure how straight it is. If it’s not right, you can adjust the tailstock until it is!

How Often Should The Tailstock Alignment Be Checked And Calibrated For Optimal Performance?You should check the tailstock alignment regularly. A good rule is to check it every few weeks. It’s important to do this after moving your machine or changing settings. This helps ensure your work is accurate and safe. If you notice any problems, fix them right away.

What Are The Common Signs That Indicate The Tailstock May Be Misaligned During Operation?If the tailstock is misaligned, you might see the tool cutting unevenly. Your piece may wobble or vibrate while you work. You could also notice strange marks or scratches on the material. If you hear a weird noise, that’s another sign to check it.