Have you ever wondered about the tools that create intricate shapes and parts in metal or wood? One vital tool in these processes is the milling cutter. But did you know there are two main types? You’ll find center-cutting and non-center-cutting milling cutters in many workshops. Each type has different uses and advantages.

Imagine you want to carve a piece of wood. You need a cutter that can go all the way through the material. This is where the center-cutting cutter shines. It can plunge right into the material. On the other hand, a non-center-cutting cutter may not dig in the same way. It’s mainly for moving along surfaces instead.

In this article, we will explore the differences between these two types of milling cutters. You’ll learn which one is best for your next project. Are you ready to cut through the confusion? Let’s dive in!

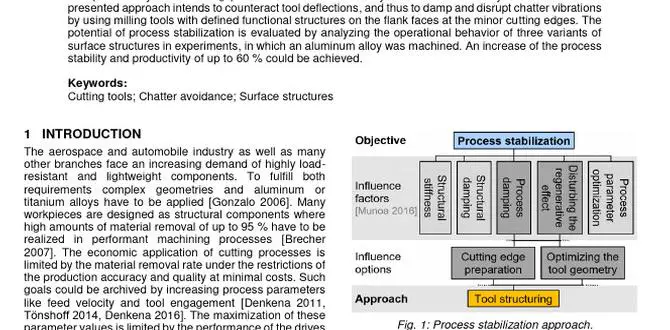

Milling Cutter Center-Cutting vs Non-Center-Cutting

Milling cutters play a vital role in shaping materials. A center-cutting cutter can cut from the middle, making it great for plunging into the workpiece. This feature allows for more versatility in machining. On the other hand, non-center-cutting cutters can only slice from the outside. They are ideal for finishing and surface work. Choosing the right type depends on your project needs. Do you need swift plunging or smooth edges? Understanding these differences helps make better choices in your milling tasks.

Understanding Milling Cutters

Definition and purpose of milling cutters. Different types of milling cutters available.

Milling cutters are tools used in machines to shape materials like metal and wood. They help create smooth surfaces and precise cuts. There are different types of milling cutters that serve various purposes. Some common types include:

- Face Cutters: Used for flat surfaces.

- End Mills: Ideal for deep cuts.

- Ball Nose Cutters: Great for curved shapes.

- T-slot Cutters: Make T-shaped grooves.

By choosing the right cutter, you can improve your work quality. This makes milling cutters important tools in manufacturing and woodworking.

What is the purpose of milling cutters?

The main purpose of milling cutters is to remove material. They allow machines to shape, cut, and create designs. Choosing the right cutter helps achieve better results.

What is a Center-Cutting Milling Cutter?

Characteristics of centercutting milling cutters. Applications and advantages in machining.

A center-cutting milling cutter can cut both vertically and horizontally. It has sharp edges on the end and sides. This design allows it to plunge into materials easily. These cutters are often used in drilling, slotting, and face milling. Their main benefits include:

- Ability to create precise holes

- Versatility in different machining tasks

- Good efficiency with reduced chip load

This makes them popular in manufacturing and metalworking. They help workers save time and effort.

What is a center-cutting milling cutter used for?

This cutter is used for tasks like drilling holes and making slots. It is great for both rough and fine cuts. Its design allows it to cut in a variety of directions, making it very useful.

What is a Non Center-Cutting Milling Cutter?

Characteristics of non centercutting milling cutters. Applications and advantages in machining.

A non-center-cutting milling cutter is a special tool that can’t plunge directly into material. It cuts only when moved sideways. This means it often leaves tricky work for other tools. They are usually cheaper and easier to make than center-cutting tools. Many machinists use them for tasks like finishing surfaces and cutting grooves. This helps save time and money in the workshop. Just remember, if you need to dig, grab a center-cutter instead!

| Characteristic | Application | Advantage |

|---|---|---|

| Only side cutting | Finishing surfaces | Cost-effective |

| Lightweight | Creating grooves | Simple design |

Key Differences Between Center-Cutting and Non Center-Cutting Milling Cutters

Comparison of cutting capabilities. Impact on machining processes and techniques.

Understanding the difference between center-cutting and non-center-cutting milling cutters is essential for machinists. Center-cutting types can slice straight down into the material, like a hot knife through butter. This makes them perfect for drilling and plunge cuts. Non-center-cutters, however, cut only on their edges. Imagine trying to slice a cake with just the side of your fork! It can be tricky and is less efficient for certain tasks.

| Type | Cutting Capability | Machining Techniques |

|---|---|---|

| Center-Cutting | Can plunge cut | Used for drilling |

| Non-Center-Cutting | No plunging | Best for edge machining |

Each type plays a different role in machining processes. Choosing wisely affects your workflow and the quality of your work. Remember, a good machinist knows their tools, and the right cutter can make all the difference!

Selecting the Right Milling Cutter for Your Project

Factors to consider when choosing between centercutting and non centercutting. Recommended scenarios for each type.

Choosing the right milling cutter can feel like picking a snack from a vending machine. You need to know what you want! First, think about center-cutting vs. non-center-cutting. Center-cutting mills can plunge straight down, making them great for doing tasks like drilling holes. Non-center-cutting mills only cut on the sides, so they work best for shaping materials.

Consider what you’re making. For complex shapes, go with a center-cutting mill. If you’re just trimming edges, a non-center-cutting one is perfect. Remember, the right tool can save you time and maybe even your sanity! Here’s a quick table to help:

| Type | Best Use |

|---|---|

| Center-Cutting | Drilling and plunging |

| Non-Center-Cutting | Trimming and contouring |

Pick wisely, and watch your project come to life, just like magic—minus the rabbits!

Common Mistakes to Avoid When Using Milling Cutters

Misapplications of centercutting and non centercutting cutters. Tips for effective use and maintenance.

Using milling cutters can feel like magic, but watch out for those tricky mistakes! First, don’t confuse center-cutting cutters with non-center-cutting ones. Why? Because a non-center-cutting cutter can’t plunge into materials like its fancy friend. Always check the cutter type before starting your project to avoid a disaster!

For better results, keep your tools clean and sharp. Dull tools can turn your masterpiece into a messy spaghetti! Lastly, remember to use the right speed. If it’s too fast, you might as well be playing tag with your tools. Maintaining your cutters helps them last longer and saves you money!

| Milling Cutter Type | Plunge Capability | Use Case |

|---|---|---|

| Center-Cutting | Yes | Great for drilling and general milling |

| Non-Center-Cutting | No | Best for profiling and finishing |

Now you’re set to avoid common mishaps and enjoy a smoother milling experience. Happy cutting!

FAQs About Milling Cutters

Common questions and misconceptions. Expert insights on milling cutter selection and use.

Milling cutters come in many types, and choosing the right one can be tricky. Some questions pop up often, like, “What is a center-cutting milling cutter?” or “Do I need non-center-cutting tools?” These tools are used for different jobs. Center-cutting cutters can cut down and sideways, while non-center-cutting cutters can only cut sideways. This can matter depending on the job you’re doing.

What are common misconceptions about milling cutters?

Many people believe all milling cutters are the same. However, different cutters serve specific purposes. Understanding your material and project needs is key.

What should I consider when selecting a milling cutter?

- Material Type: What you are cutting matters.

- Cutting Depth: Some tools cut deeper than others.

- Speed: Make sure your machine runs at right speed.

Knowing these points can help you pick the best tool for your project. Don’t hesitate to ask experts for guidance!

Conclusion

In summary, center-cutting milling cutters can cut through materials from the top and bottom, making them versatile. Non-center-cutting cutters only work from the top, which limits their use. Knowing the difference helps you choose the right tool for your project. Explore more about milling cutters to enhance your skills and make smarter choices in your work!

FAQs

What Are The Main Differences In Design Between Center-Cutting And Non-Center-Cutting Milling Cutters?

Center-cutting milling cutters can cut both down and sideways. They have sharp edges at the center. Non-center-cutting cutters can only cut sideways. This means you need to start a hole first with them. So, center-cutting tools are more versatile than non-center-cutting tools.

In What Machining Applications Would You Prefer To Use A Center-Cutting Milling Cutter Over A Non-Center-Cutting One?

You would use a center-cutting milling cutter when you need to start cutting in the middle of a piece. This is helpful for making holes or starting a groove. A non-center-cutting cutter can only cut if it starts from the edge. So, if you need flexibility and precision, choose a center-cutting milling cutter!

How Does The Ability To Plunge Cut Differ Between Center-Cutting And Non-Center-Cutting Milling Cutters?

Center-cutting milling cutters can plunge cut, which means they can go straight down into the material. This lets you make holes in the middle of a piece. Non-center-cutting milling cutters cannot do this. They can only cut from the side, so you must start from the edge to make cuts.

What Types Of Materials Are Best Suited For Machining With Center-Cutting Versus Non-Center-Cutting Milling Cutters?

Center-cutting milling cutters work best with softer materials like plastic and aluminum. They can cut straight down into the material. Non-center-cutting milling cutters are better for harder materials like steel. They need to move across the surface instead of going straight down. So, choose the right cutter for the job!

What Are The Potential Drawbacks Of Using A Non-Center-Cutting Milling Cutter In Certain Scenarios?

Using a non-center-cutting milling cutter can be tricky in some situations. It can’t start a cut in the middle of a piece. This means you must start from the edge, which takes more time. If you need to make detailed shapes, it might not work as well. You could also have to use extra tools, which can slow you down.