Have you ever wondered how a milling cutter stays in place while working hard? It’s all about clamping torque. This magic number helps keep the cutter steady. If it’s too low, the cutter can slip and cause problems. If it’s too high, it can damage tools.

Imagine you’re trying to fix a toy with a screw. If you don’t tighten it enough, the toy falls apart. But if you tighten it too much, you might break it. The same thing happens with milling cutters.

A milling cutter clamping torque chart can guide you. It shows the right numbers to use for different tools. With this chart, you can make sure everything works perfectly. Let’s dive into the importance of using a milling cutter clamping torque chart for better results in your work.

Milling Cutter Clamping Torque Chart For Optimal Performance

Milling Cutter Clamping Torque Chart

Understanding a milling cutter clamping torque chart is key for successful machining. It helps determine the right torque needed to secure cutting tools. Proper clamping ensures smooth operation and reduces the risk of tool damage. Did you know that incorrect torque can lead to costly mistakes? By mastering this chart, you not only enhance safety but also improve the quality of your work. Use the chart wisely, and watch your projects succeed!Understanding Milling Cutters

Definition and purpose of milling cutters in machining. Types of milling cutters and their applications.Milling cutters are tools that shape materials. They help machines make precise cuts in metal, wood, and plastic. These cutters come in many forms. Each type serves a special purpose.

- End Mills: Used for detailed work and creating various shapes.

- Face Mills: Great for making flat surfaces.

- Ball Nose Cutters: Ideal for curved surfaces.

Choosing the right cutter matters. It affects the quality of your work. Knowing the types helps in selecting the best tool for each job. Understanding this can lead to better machining results.

What are the uses of milling cutters?

Milling cutters are used for shaping materials, removing excess material, and creating detailed features on workpieces.

Importance of Clamping Torque

Explanation of clamping torque in relation to milling performance. Consequences of improper clamping torque on tool life and machining accuracy.Clamping torque is very important in milling. It keeps the cutting tool steady during work. If the torque is too low, the tool might slip. This results in poor cuts and can ruin the piece being worked on. Too high torque can damage the tool and shorten its life. A good balance helps achieve smooth and accurate cuts every time.

What happens if clamping torque is incorrect?

Improper clamping torque can lead to serious issues.

- Increased wear on tools

- Poor machining accuracy

- Lower quality of the finished product

Factors Affecting Clamping Torque

Material properties of the milling cutter and workpiece. Tool geometry and design considerations.Several things can change clamping torque. First, the materials of the milling cutter and the workpiece matter a lot. For example, hard materials need more torque to keep things tight. Next, the design of the tool plays a big role too. Sharp edges help grip better, and shapes can either hold or let go. It’s like trying to hold a slippery fish—you’ll need a strong grip!

| Factor | Impact on Torque |

|---|---|

| Material Properties | Harder materials require higher torque |

| Tool Geometry | Affects grip and stability during milling |

So remember, the right material and tool shape can make your milling journey smoother. Otherwise, you might end up wrestling with your equipment!

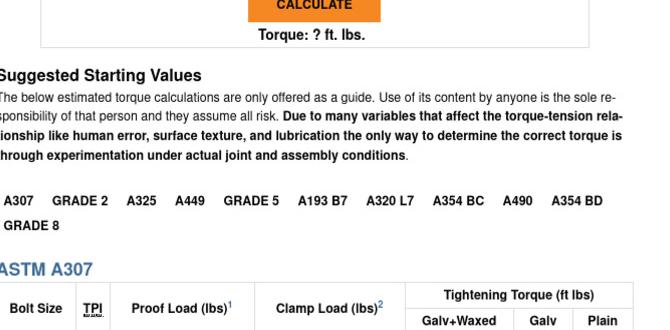

Reading the Clamping Torque Chart

Explanation of how to interpret a milling cutter clamping torque chart. Importance of manufacturer specifications in selecting torque values.Understanding a milling cutter clamping torque chart isn’t rocket science—it’s more like baking a cake! First, look at the numbers that tell you how tight to clamp. Each value shows the right amount of force needed for different tools. Always check manufacturer specifications; they are like a recipe that guarantees your success. Not following them? Well, you might end up with a kitchen disaster, or in this case, a broken cutter!

| Tool Type | Clamping Torque (Nm) |

|---|---|

| Standard Cutter | 20-40 |

| Heavy-Duty Cutter | 50-70 |

| Fine Finish Cutter | 30-50 |

So remember, use the right torque. Your cutter will thank you by lasting longer and performing better! And maybe even throw a little party with all those shavings!

Steps to Calculate Required Clamping Torque

Detailed process for calculating clamping torque for different milling operations. Examples of calculations for common milling applications.To find the right clamping torque for milling, follow these steps:

- Determine the required torque using specifications for your milling cutter.

- Use a formula that includes factors like cutter diameter and material type.

- Consult a torque chart that matches the cutter and operation.

For example, when using a diameter of 20mm, the torque might be 55 Nm for aluminum. Always check your chart for the most accurate values.

How can I calculate clamping torque for milling?

You can calculate clamping torque by using specific formulas and charts tailored to your cutter type and operation.Example Calculations:

- For a 10mm cutter, use 25 Nm as per the chart.

- A 25mm cutter may require 80 Nm.

Best Practices for Clamping Torque Application

Recommended tools and techniques for applying clamping torque. Common mistakes to avoid during the clamping process.Choosing the right tools is key for applying clamping torque effectively. Use a digital torque wrench for accuracy. This helps in reaching the right tension without overdoing it. Common mistakes include not checking the surface for dirt or rust before clamping. Also, skip the habit of applying too much force. Follow these guidelines for better results:

- Check surfaces before clamping.

- Use a digital torque wrench.

- Avoid over-tightening.

- Lubricate threads if required.

What tools should I use for clamping torque?

Use tools like a digital torque wrench for precise measurements. These help prevent mistakes and ensure safety.

Torque Settings for Different Milling Operations

Suggested torque settings for various types of milling operations (face milling, end milling, etc.). Comparison of torque settings across different milling cutter materials.Choosing the right torque is key for different milling tasks. Each operation needs specific settings. For example, face milling uses different torque than end milling. Here are some quick suggestions:

- Face Milling: 50-70 Nm

- End Milling: 30-50 Nm

- Slot Milling: 40-60 Nm

Different cutter materials also need different torque settings. Harder materials, like carbide, may require more torque than softer ones, like HSS. This helps keep the tools secure and working well, improving performance.

How do milling cutter materials affect torque settings?

Different materials need different torque levels. Harder materials like carbide can need higher torque. Softer materials like HSS work better with less torque. This can help you perform better in your milling jobs.

Monitoring and Maintenance of Clamping Torque

Techniques for regularly checking and maintaining clamping torque. Tools and technologies for torque monitoring in machining environments.Keeping an eye on clamping torque is like checking your favorite dessert recipe. Too much or too little can ruin it! Regularly checking torque helps avoid mishaps in machining. Use a torque wrench or a digital torque meter for accuracy. These handy tools ensure everything stays tight and secure. You can also set reminders for checks, so you never “forget”—like that time you forgot your friend’s birthday!

| Tools | Purpose |

|---|---|

| Torque Wrench | To measure applied torque accurately |

| Digital Torque Meter | For precise digital readouts |

Maintaining proper clamping torque is vital for safe operations. Remember, consistent checks can prevent tool failures and accidents. So, don’t be a torque slacker; make it a habit! Your machines will thank you with smooth performances—and you might even get a smile from the tool shed!

Case Studies: Clamping Torque in Action

Realworld examples of clamping torque impact on machining effectiveness. Analysis of improvements made through proper torque management.Many companies have seen results from using the right clamping torque. For example, one factory improved its machining speed by 25% after adjusting their torque settings. Proper torque keeps tools in place. This leads to better cuts and less waste. Here are some key improvements:

- Reduced tool wear

- Fewer machine errors

- Better product quality

By managing clamping torque, companies find that even small changes can make a big difference.

What is the impact of clamping torque on machining?

Proper clamping torque improves tool performance and reduces errors. This leads to faster production and better quality. Using the right torque is essential for success.

Frequently Asked Questions about Milling Cutter Clamping Torque

Common queries regarding clamping torque and their answers. Expert insights on troubleshooting clamping torque issues in machining.Many people wonder about the right clamping torque for milling cutters. A few common questions pop up. For instance, how do you know the right amount? Check your tool’s manual, as it usually has a handy chart! Need to fix a problem? Often, it’s too tight or too loose. A good trick? Always use a torque wrench to double-check your settings. It’s like having a friend who knows the perfect hug pressure. If it feels off, don’t be shy—readjust!

| Common Questions | Quick Answers |

|---|---|

| What happens if the torque is too low? | Tools may slip! |

| Can too much torque break the tool? | Yep, it can! |

| How often should I check clamping torque? | Before every use! |

Conclusion

In summary, a milling cutter clamping torque chart helps you find the right tightness for your tools. Using the correct torque prevents damage and ensures safety. Remember to always refer to the chart when working. For more tips on using milling cutters, check out other resources or guides. They can help you improve your skills and confidence in machining!FAQs

What Is The Recommended Clamping Torque For Different Sizes Of Milling Cutters?The recommended clamping torque depends on the size of the milling cutter. For small cutters, you should use about 10 to 20 Newton-meters (Nm). For medium-sized cutters, use 20 to 30 Nm. For large cutters, aim for 30 to 50 Nm. Always check the tool’s manual for exact numbers!

How Does The Material Of The Milling Cutter Affect The Required Clamping Torque?The material of the milling cutter can change how tight we need to clamp it. If the cutter is hard, it might require more torque to hold it in place. But if it’s softer, we can use less torque. So, the type of material helps decide how strong we need to tighten the cutter. This way, we make sure it stays secure while we work.

What Are The Potential Consequences Of Using Incorrect Clamping Torque On Milling Cutters?Using the wrong clamping torque on milling cutters can cause big problems. If the torque is too low, the cutter might slip or come loose. This can ruin your work and damage the cutter. If it’s too high, it can break the cutter or hurt the machine. It’s important to tighten things just right!

How Can Operators Accurately Measure And Apply The Clamping Torque For Milling Cutters?To measure and apply clamping torque for milling cutters, you can use a special tool called a torque wrench. First, check the instructions for the right amount of torque needed. Then, you slowly tighten the wrench until it clicks. This click means you have the correct clamp tightness. Always recheck your work to make sure everything is secure and safe.

Are There Industry Standards Or Guidelines For Establishing Clamping Torque Values For Various Milling Applications?Yes, there are guidelines for clamping torque in milling. These guidelines help us know how tight to make tools so they work well. We can find these rules from machine makers and industry groups. They help us keep everything safe and running smoothly. Always check these guides when you’re working on a project.