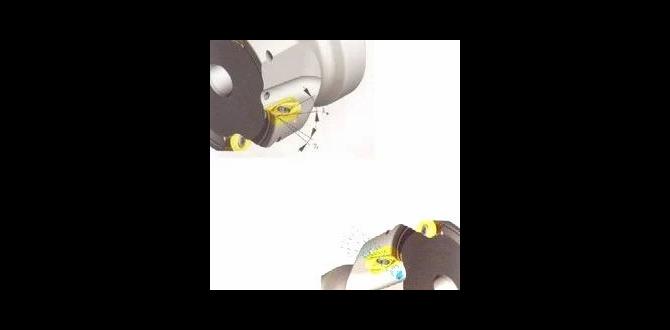

Imagine a busy workshop filled with loud machines, spinning and cutting metal. In such places, milling cutters work hard. But did you know that the right coolant flow can make a big difference? Proper milling cutter coolant flow optimization can boost productivity and keep machines running smoothly.

Have you ever used a fan to cool off on a hot day? Similarly, in machining, coolant helps prevent overheating. When too much heat builds up, tools can wear out quickly. Did you realize that a well-optimized coolant flow can extend their life? This means fewer replacements and less downtime!

But how can you achieve the best coolant flow? It starts with understanding your machines and their needs. Small changes can lead to big improvements. So, let’s explore how to make the best choices for milling cutter coolant flow optimization and keep those machines humming!

Milling Cutter Coolant Flow Optimization Techniques Unveiled

Milling Cutter Coolant Flow Optimization

Optimizing coolant flow for milling cutters is crucial for enhancing performance. Proper coolant helps keep the cutter cool and reduces wear. Did you know that improved coolant flow can increase cutting speeds and reduce energy use? By adjusting flow rates, manufacturers can achieve better surface finishes on materials. This optimization leads to longer tool life and lower overall costs. Finding the right balance can turn your milling process into a smooth and efficient operation.Understanding Coolant Functions in Milling

Discuss the role of coolant in milling operations.. Explain the types of coolants used in milling processes..Coolant plays a big role in milling operations. It helps keep the tool and material cool, avoiding overheating. This is important because hot tools can wear out quickly. Besides cooling, it also clears away chips and debris, like a superhero taking out the trash!

There are mainly two types of coolants used in milling:

| Type of Coolant | Description |

|---|---|

| Water-based Coolants | These are mixed with water and are great at cooling. They are common and cost-effective. |

| Oil-based Coolants | This type is thick and reduces friction very well. It’s like grease for your favorite squeaky toy. |

Using the right coolant can boost performance. Remember, it’s not just about being cool; it’s about staying cool!

Importance of Coolant Flow Optimization

Highlight the benefits of optimized coolant flow on tool lifespan.. Discuss how coolant flow affects surface finish and machining accuracy..Coolant flow optimization is like giving your tools a refreshing drink! It helps them last longer and stay sharp. More flow means cooler tools, which can double their lifespan. Plus, proper coolant flow makes surfaces smooth like a baby’s bottom and improves machining accuracy. Less chatter, better results—that’s the goal! Here’s a quick look at how it all connects:

| Benefit | Effect |

|---|---|

| Lifespan of Tools | Increased by up to 50% |

| Surface Finish | Smoother and shinier! |

| Machining Accuracy | Higher precision! |

Factors Affecting Coolant Flow in Milling

Identify key factors influencing coolant flow rates.. Explore the impact of nozzle design and placement on coolant efficiency..Many elements play a role in how coolant flows during milling. First, pump speed is crucial; higher speeds can increase flow rates like a kid on a sugar rush! Next, the nozzle design is important because it should aim right at the cutting tool. If it’s too far away, it’s like missing the target at a carnival game. Additionally, coolant viscosity affects flow—thicker fluids are like swimming through molasses. Check out this table for a snapshot of these factors:

| Factor | Impact |

|---|---|

| Pump Speed | Increases flow rates |

| Nozzle Design | Affects coolant targeting |

| Coolant Viscosity | Influences flow smoothness |

By paying attention to these elements, you can help achieve the best coolant flow for smoother milling.

Techniques for Optimizing Coolant Flow

Review various techniques for enhancing coolant flow, such as adjustments in pressure and volume.. Discuss the use of advanced coolant delivery systems and technologies..To improve coolant flow, consider these techniques:

- Adjust pressure and volume for better performance.

- Use advanced coolant delivery systems to target specific areas.

- Incorporate technologies like misting or high-pressure systems.

- Regularly check and clean nozzles for optimal flow.

- Test different coolant types for effectiveness.

These methods can lead to improved machining quality. Studies show that proper coolant flow reduces wear on milling cutters and increases tool life. Consider experimenting with these techniques to see what works best for your setup!

What are the ways to enhance coolant flow?

Enhancing coolant flow involves adjusting pressure, using advanced delivery systems, and ensuring regular maintenance.

Measuring Coolant Flow Effectiveness

Explain methods for evaluating coolant flow performance.. Introduce KPIs for assessing the impact of optimized coolant flow on milling operations..To see how well coolant flows, you need to measure its effectiveness. One way is to check the temperature of the tools before and after milling. Another method is to calculate the flow rate of the coolant. This helps you understand if the flow is steady. Think about using key performance indicators (KPIs) like chip removal rate or tool life. These KPIs show how optimized coolant flow boosts milling operations.

What are the ways to assess coolant flow?

To assess coolant flow, you can measure temperature differences and flow rates. Tracking KPIs like chip removal and tool life also helps you see improvements in milling.Some important KPIs include:

- Chip removal rate

- Tool wear rate

- Surface finish quality

Case Studies: Successful Coolant Flow Optimization

Present realworld examples of companies that improved performance through coolant flow optimization.. Analyze the results and lessons learned from these scenarios..Several companies have successfully improved their operations by optimizing coolant flow. For instance, a large automotive parts manufacturer revamped their coolant system and cut downtime by 40%. Another company in the aerospace sector noticed a 30% increase in tool life after fine-tuning their coolant flow. These examples show how a little tweak can lead to big gains. Remember, even small changes can make a splash! 🍉

| Company | Industry | Result |

|---|---|---|

| AutoParts Inc. | Automotive | 40% reduction in downtime |

| AeroTech Ltd. | Aerospace | 30% increase in tool life |

Future Trends in Coolant Flow Optimization

Discuss emerging technologies and practices in coolant flow management.. Explore the potential impact of automation and smart systems on coolant optimization..New technologies are shaking up coolant flow management, making it smarter and more efficient. Automation is a game changer, allowing machines to automatically adjust coolant flow. This means less waste and better cooling for cutting tools. Imagine your mill adapting its coolant like a ninja! Smart systems can track performance and suggest changes, optimizing flow as it goes. The future of milling looks cooler, literally!

| Trend | Description |

|---|---|

| Automation | Automatic adjustments for better efficiency. |

| Smart Systems | Tracking tools and suggesting flow changes. |

| Recycling Coolant | Using advanced filtering to reuse fluids. |

Conclusion

Milling cutter coolant flow optimization is crucial for better machining. You can improve tool life and productivity by using the right coolant flow. Check your machines regularly for optimal performance. Remember, proper cooling reduces heat and improves accuracy. Explore more about coolant types and best practices to enhance your projects. Start applying these tips today for better results!FAQs

What Are The Most Effective Coolant Flow Rates For Different Types Of Milling Cutters To Optimize Cooling And Lubrication During Machining Operations?To keep milling cutters cool and well-lubricated, we need to use the right amount of coolant. For smaller cutters, like end mills, a flow rate of about 5 to 10 liters per minute works well. For larger cutters, like face mills, we might need 10 to 20 liters per minute. It’s important to adjust the flow rate based on the cutter size and the material we’re working with. This helps keep everything running smoothly and prevents damage.

How Does The Nozzle Positioning Of Coolant Delivery Systems Influence The Effectiveness Of Coolant Flow In Milling Processes?The nozzle positioning of coolant delivery systems helps direct the coolant exactly where it’s needed during milling. When the nozzles are positioned close to the tool and workpiece, they can spray coolant more effectively. This keeps the tool cool and prevents it from getting too hot, which can cause damage. Good positioning means better cooling, longer tool life, and smoother cuts, making our work easier and more efficient.

What Materials And Designs For Milling Cutters Have Been Shown To Benefit The Most From Optimized Coolant Flow In Terms Of Tool Life And Surface Finish?We have learned that many milling cutters can do better with good coolant flow. For example, cutters made from high-speed steel and carbide benefit a lot. They last longer and make smoother surfaces when cooled right. Also, special designs with better shapes help the coolant reach more areas. This way, we keep them cool and working well.

How Can Advanced Monitoring Technologies (Like Sensors And Iot) Be Integrated Into Milling Machines To Enhance Real-Time Coolant Flow Optimization?We can use sensors and the Internet of Things (IoT) to help milling machines work better. First, we put sensors on the machine to check how much coolant is flowing. Then, these sensors send the information online so we can see it in real time. If the coolant isn’t flowing enough, we can fix it right away. This helps keep the machine cool and working well!

What Are Some Common Challenges Faced In Maintaining Optimal Coolant Flow During High-Speed Milling, And What Strategies Can Be Employed To Overcome Them?In high-speed milling, keep coolants flowing well can be hard. Sometimes, the coolant can get blocked or not reach the tool. This can cause the tool to get too hot and wear out faster. To fix this, we can use better coolant nozzles and make sure no dirt blocks the flow. Checking and cleaning the system regularly helps too!