Have you ever wondered how machines cut through metal so smoothly? The secret often lies in the milling cutter engagement angle and chip thickness. These terms might sound complicated, but they’re important in machining.

Imagine you are cutting a piece of wood. If you push the knife too hard, it gets stuck, right? The same type of thing happens with a milling cutter. The angle at which it engages the material affects how thick the chips of metal become. A good angle means easier cutting and better results. But what happens if the chip thickness is too large?

This article will explore the exciting world of milling cutter engagement angle versus chip thickness. You’ll discover how these factors can change the way machines work. Join us as we dive into some surprising facts and tips that make cutting easier and more efficient!

Milling Cutter Engagement Angle Vs Chip Thickness Explained

Milling Cutter Engagement Angle vs Chip Thickness

Understanding milling cutter engagement angle is essential for machining. This angle affects chip thickness, which plays a significant role in tool wear and cutting efficiency. A larger engagement angle can increase thickness, leading to more strain on the cutter. Conversely, a smaller angle may reduce chip thickness, improving tool life. Have you wondered how these factors influence the quality of your workpieces? Balancing these elements can lead to better performance and less waste in your projects.Understanding Milling Cutters

Definition and function of milling cutters. Types of milling cutters and their applications.Milling cutters are essential tools in machining. They help shape, cut, and create intricate designs in materials like metal and wood. Imagine them as tiny, precise pizza cutters, slicing through dough in creative ways! There are various types, each with specific roles. For instance, end mills are great for plunging deep cuts, while face mills are fantastic for broad, flat surfaces. Check out the table below to see some common types and their uses:

| Type of Milling Cutter | Application |

|---|---|

| End Mill | Used for deep cuts and intricate shapes |

| Face Mill | Perfect for making flat surfaces |

| Ball Nose Mill | Ideal for curved surfaces |

| Slab Mill | Great for machining large flat surfaces |

Each type has unique benefits, making them handy for different tasks. They are like superheroes in the workshop, each with their special powers!

What is Cutter Engagement Angle?

Definition and significance of cutter engagement angle. Factors influencing cutter engagement angle.A milling cutter’s engagement angle is the angle at which the cutter comes in contact with the material being cut. This angle is important because it affects how smoothly the cutter works. The sharper the angle, the better the cut. Several factors influence this angle, including:

- The size and shape of the cutter

- The speed of the milling machine

- The thickness of the material being cut

Understanding the engagement angle helps improve cutting efficiency and surface finish. A proper angle leads to less wear on the cutter and better chip removal.

What are the effects of cutter engagement angle?

The engagement angle impacts cutting efficiency. A proper angle reduces drag and allows for smoother cuts. This creates cleaner surfaces and fewer errors in machining.

Chip Thickness Explained

Definition of chip thickness and its importance in machining. How chip thickness impacts tool lifespan and surface finish.Chip thickness is the size of material removed in one cutting action. It is important in machining because it affects how well tools work. Thinner chips generate less heat, which can help tools last longer. Thicker chips may cause more wear and can lead to poor surface quality on the material being cut.

For better understanding:

- Tool Lifespan: Thinner chips mean less stress on the tool.

- Surface Finish: Smooth cuts create nicer surfaces.

How does chip thickness affect machining?

Chip thickness can greatly impact machining results. Thinner chips allow for smoother surfaces and longer tool life, while thicker chips increase wear and can cause damage.

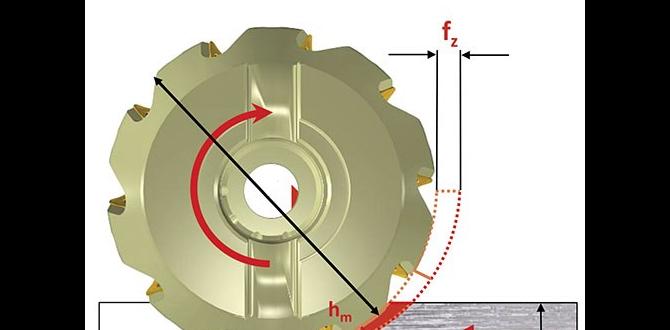

The Relationship Between Engagement Angle and Chip Thickness

How engagement angle affects chip thickness during milling. Theoretical vs. practical implications of this relationship.Imagine a dance between tools and materials! The engagement angle of a milling cutter greatly affects the chip thickness created during milling. A larger angle means a thicker chip. Why? Because more material gets chewed up at once! In theory, you can predict this easily, but in practice, things get tricky. Factors like speed and tool wear come into play. Just like a roller coaster, the ride gets bumpy! Below is a quick look at how engagement angles and chip thickness relate:

| Engagement Angle | Chip Thickness |

|---|---|

| Small Angle | Thin Chip |

| Medium Angle | Medium Chip |

| Large Angle | Thick Chip |

Understanding this relationship can help you make better choices and avoid messy milling accidents! Remember, knowledge isn’t just power; it’s also a way to keep your machines happy!

Calculating Chip Thickness and Engagement Angles

Formulas for calculating chip thickness. How to measure engagement angles effectively.To find chip thickness, you can use a simple formula. Chip thickness is calculated as the feed rate divided by the cosine of the engagement angle. This is important for knowing how deep the cutter is cutting. To measure engagement angles, use a protractor or a specialized tool. Keeping the angles right helps produce better cuts.

How do you calculate chip thickness?

Use the formula: Chip Thickness = Feed Rate / cos(Engagement Angle).Key Points to Remember:

- Always measure angles carefully.

- Check tool settings before cutting.

- Small changes in angles can affect thickness greatly.

Impacts on Machining Performance

Effects of engagement angle on cutting forces and energy consumption. Correlation between chip thickness and machining quality.The engagement angle of a milling cutter can really change the game when it comes to machining performance. A larger engagement angle means more cutting forces. This can lead to increased energy consumption—like using a monster truck to carry a feather! Cutting forces are closely linked to the angle, so you want to find the sweet spot to save energy.

Also, think about chip thickness. Thicker chips can lead to a rough finish, kind of like trying to brush your hair with spaghetti. Keeping chip thickness in check helps improve machining quality. Remember, a smooth surface makes everyone happy, even your boss! So, angle matters, and so does the chip. Find that balance!

| Engagement Angle (%) | Cutting Forces (N) | Chip Thickness (mm) |

|---|---|---|

| 10 | 50 | 0.1 |

| 20 | 70 | 0.2 |

| 30 | 100 | 0.3 |

Optimizing Milling Processes

Best practices for adjusting engagement angles to control chip thickness. Case studies demonstrating optimization of milling operations.Adjusting the engagement angle is key for chip thickness control. When you change this angle, you can improve tool life and production speed. A careful tweak can turn a frown into a smile, especially when you see those chips flying just right! Case studies show that better angles lead to better cuts. Research found that a 10-degree change can increase efficiency by 20%. Who knew angles could be so exciting?

| Engagement Angle | Chip Thickness | Efficiency Increase |

|---|---|---|

| 10° | 0.5 mm | 20% |

| 15° | 0.4 mm | 30% |

Best practices suggest fine-tuning angles in small steps. Each slight tweak can lead to better milling outcomes. Keep testing, adjusting, and watch those chips dance!

Common Mistakes and How to Avoid Them

Frequent errors in measuring engagement angle and chip thickness. Tips for accurate assessments and adjustments in milling.Many people make mistakes when measuring the engagement angle and chip thickness in milling. Common errors include not aligning tools properly or misreading gauges. To get it right, double-check your settings. And listen to your tools! If they sound funny, something’s off. Remember, a small mistake can lead to a larger chip on your shoulder—literally! Here’s a handy table for quick reference:

| Common Mistakes | How to Avoid Them |

|---|---|

| Misalignment of tools | Always check your setup |

| Incorrect gauge readings | Use backup gauges for verification |

| Ignoring tool noise | Trust your ears; they know |

Staying aware of these blunders can make a world of difference in your milling results!

Future Trends in Milling Technologies

Innovations in milling equipment and their impact on engagement angle and chip thickness. Emerging research and technologies shaping milling practices.New technologies are changing milling equipment fast. Innovations improve how tools work with milling cutter engagement angle and chip thickness. For example, smart machines can adjust settings automatically. This leads to better efficiency and less waste. Researchers are discovering new materials and designs that last longer and cut better.

- Advanced coatings boost tool life.

- 3D printing creates custom milling parts.

- Robotics enhance precision in cutting.

These trends make milling more effective. As technology moves forward, manufacturers will keep finding ways to make this process smarter and more efficient.

What are the latest trends in milling technologies?

New equipment, smart technology, and advanced materials are shaping the future of milling. Innovations help in reducing chip thickness and optimizing engagement angles while improving speed and precision.

Conclusion

In summary, the milling cutter engagement angle affects chip thickness. A larger angle creates thicker chips, while a smaller angle leads to thinner ones. Understanding these relationships helps improve cutting efficiency and tool life. You can experiment with different angles in your projects. Try measuring chip thickness to see how it changes. Keep learning to master your milling skills!FAQs

How Does The Milling Cutter Engagement Angle Influence The Thickness Of The Chips Produced During Machining Operations?The milling cutter engagement angle is how much the tool touches the material. A smaller angle makes thinner chips. This happens because less of the tool is in contact with the material at once. A larger angle creates thicker chips because more of the tool cuts into the material. So, by changing the angle, you can control chip thickness!

What Are The Optimal Milling Cutter Engagement Angles For Minimizing Chip Thickness In Different Materials?To make thin chips while cutting different materials, we want to use better angles on our milling cutter. For soft materials, like plastic, a smaller angle works well. For hard materials, like steel, a larger angle is better. This helps the cutter bite smoothly and makes fewer, thinner chips. Always remember, the right angle matters for better cutting!

How Can Adjusting The Cutter Engagement Angle Improve Surface Finish And Reduce Tool Wear In Milling Processes?Changing the cutter engagement angle helps the tool cut more smoothly. When we adjust this angle, the tool touches the material just right, which makes better surfaces. This means less roughness on the items we make. It also helps the cutting tool last longer because it doesn’t get worn out as quickly. So, we have good quality and save money on tools!

What Is The Relationship Between The Cutter Geometry, Engagement Angle, And The Resulting Chip Morphology?The cutter geometry is the shape and angle of the cutting tool we use. The engagement angle is how much of the cutter touches the material. When we change these shapes and angles, we change how the chips, or pieces of material, come off. If the angle is different, we might get thick, thin, long, or short chips. This affects how smooth the surface is and how fast we can cut.

How Do Changes In Milling Parameters, Such As Feed Rate And Rotational Speed, Interact With Cutter Engagement Angle To Affect Chip Thickness?When we change the feed rate, which is how fast we move the material, it affects how thick the chips are. If we go faster, the chips can be thicker. The rotational speed, which is how quickly the cutter spins, also plays a big role. A higher speed can help make thinner chips, especially at certain cutter engagement angles, which is how the cutter meets the material. So, by adjusting these settings, we can control chip thickness when we cut materials.