Imagine you’re building a toy robot. You have all the pieces laid out, but without the right tools, can you assemble it perfectly? A milling cutter plays a big part in shaping materials in many industries, just like the right tool helps in your project.

But how do you use a milling cutter effectively? This brings us to the idea of a milling cutter engagement strategy. It’s not just a fancy term. It’s a smart plan that helps workers use milling cutters to get the best results.

Have you ever wondered why some projects go smoothly while others get stuck? The key often lies in a good engagement strategy. This article will explore how you can enhance your use of milling cutters. Get ready to learn some fun facts and useful tips that can change the way you work!

Effective Milling Cutter Engagement Strategy For Success

Milling Cutter Engagement Strategy

Milling cutter engagement strategy helps improve cutting efficiency. By adjusting how deep and how long the cutter interacts with the material, operators can boost productivity. Did you know that proper engagement reduces tool wear and enhances precision? Imagine cutting metal or wood with ease! Learning the right angles and speeds can save both time and money. Applying this strategy may just turn a good project into a great one! Why not give it a try?Understanding Milling Cutters

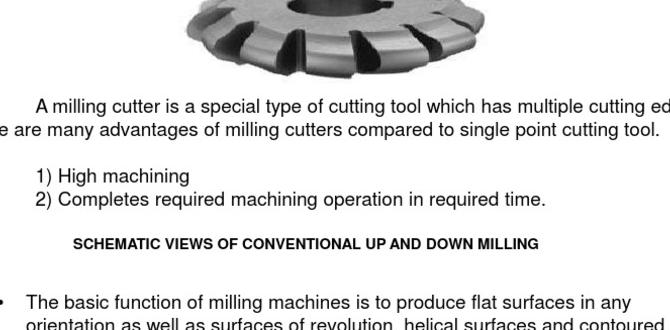

Definition and types of milling cutters. Importance of milling cutters in machining processes.Milling cutters are like magical kitchen gadgets for machines! They help shape materials into exact forms. There are different types of milling cutters, such as flat cutters for smooth surfaces and end mills for detailed work. Each cutter serves its purpose, making milling efficient and fun. These tools are crucial in machining processes. Without them, creating parts would feel like trying to bake a cake without a pan—messy and impossible!

| Type of Milling Cutter | Description |

|---|---|

| Flat Cutter | Used for flat surfaces and simple shapes. |

| End Mill | Great for detailed cuts and complex designs. |

| Ball Nose Cutter | Perfect for rounded shapes and 3D work. |

The Role of Engagement Strategy in Milling

Explanation of cutter engagement and its significance. How engagement affects tool life and machining outcomes.Understanding how cutter engagement works is essential for successful milling. This refers to how much of the cutter touches the material. Greater engagement can improve efficiency but may also lead to faster wear on the tool. Correct engagement helps increase tool life and ensures smooth machining results. Think of it as giving your tool the right hug—too tight, and it gets worn out. Too loose, and it doesn’t do its job!

| Engagement Level | Tool Life Impact | Machining Outcome |

|---|---|---|

| High | Shorter life | Rough finish |

| Optimal | Longer life | Smooth finish |

| Low | Very long life | Inconsistent results |

Factors Influencing Cutting Engagement

Material properties of workpieces. Geometry and design of milling cutters. Machine tool capabilities and settings.Different factors shape how well a milling cutter works. First, we have the material properties of the workpiece. Hard materials can be tricky and may require tougher cutters. Second, the geometry and design of the cutter matter. A well-shaped cutter can zip through materials like a hot knife through butter! Lastly, we must consider the machine tool capabilities and settings. If the machine is slow, you might as well be carving with a spoon.

| Factor | Influence |

|---|---|

| Material Properties | Affects cutter choice and speed |

| Cutter Geometry | Determines efficiency and smoothness |

| Machine Settings | Controls power and speed |

Types of Engagement Strategies

Conventional vs. climb milling techniques. Adaptive engagement strategies. Fixed vs. variable engagement parameters.Engagement strategies in milling cutters can change how effectively they work. There are two main techniques: conventional milling and climb milling. In conventional milling, the cutter moves against the workpiece, which can create a better surface finish. Climb milling, however, goes with the workpiece movement, making cuts smoother and reducing wear.

Also, adaptive engagement strategies adjust to conditions while cutting. You have fixed parameters that stay the same, or variable parameters that change based on the material or tool. Finding the right balance can enhance performance and tool life.

What is the difference between climb and conventional milling?

Conventional milling moves against the material, offering stability. Climb milling moves with the grain, which can improve efficiency.

Engagement Parameters:

- Fixed Parameters: Stay consistent for predictable results.

- Variable Parameters: Change to improve cutting based on conditions.

Determining Optimal Engagement Parameters

Calculating optimal feed rates and depth of cut. Using toolpath strategies to enhance engagement.| Parameter | Recommendation |

|---|---|

| Feed Rate | Start between 0.1 to 0.2 inches per tooth for most materials. |

| Depth of Cut | A depth of cut of 1/4 inch is usually a good starting point. |

| Toolpath Strategy | Circular and zig-zag paths often work best. |

Getting the right numbers is like baking a cake: too much flour, and you’ve got a brick! For milling, calculate optimal feed rates, starting at 0.1 to 0.2 inches. It’s also wise to keep the depth of cut around 1/4 inch. Using creative toolpath strategies like circular or zig-zag paths can enhance engagement. Think of it as a dance move—smooth steps lead to better results!

Common Mistakes in Milling Cutter Engagement

Identifying frequent issues and their impact on performance. Best practices to avoid engagementrelated problems.Many folks make mistakes with milling cutters, and these errors can hurt performance. Common problems include incorrect speeds and feeds or choosing the wrong tool for the job. When this happens, cutting efficiency drops, and you might end up with a mess instead of a masterpiece. To dodge these pitfalls, always double-check your machine settings and choose the right cutter for your project.

| Common Mistakes | Impact on Performance | Best Practices |

|---|---|---|

| Wrong speed/feeds | Decreased efficiency | Verify machine settings |

| Inappropriate tool selection | Poor finish quality | Select the right cutter |

By avoiding these blunders, you’ll be well on your way to smoother milling adventures. Remember, no one wants to be the person responsible for a cutter drama, right?

Case Studies: Successful Implementation of Engagement Strategies

Examples of companies optimizing their milling processes. Impact of effective engagement strategies on production efficiency.Many companies have improved their milling processes using unique engagement strategies. For example, a leading automotive manufacturer optimized their cutter selection. They discovered that the right milling cutter engagement strategy could cut production time by 20%. Another case involved a metalworking company that increased its output by 15% simply by adjusting the engagement of their tools. These changes show how effective strategies can lead to better efficiency on the shop floor.

What impact do engagement strategies have on production efficiency?

Effective engagement strategies can boost production efficiency significantly. Companies using these strategies often see higher output and better quality products.

Benefits of Engagement Strategies:

- Increased productivity

- Reduced waste

- Improved product quality

Future Trends in Milling Cutter Engagement

Emerging technologies and their potential influence. Predictions for advancements in engagement strategies.The future of milling cutter engagement is bright and full of surprises. New technologies are popping up everywhere! These innovations can make cutting more efficient and precise than ever. Imagine a robot that knows exactly how to cut without wasting time or materials. Predictions say engagement strategies will focus on *real-time data* and *smart tools* to adapt instantly. This means better cuts and less hassle for everyone. Remember, in a world driven by tech, we might see tools so smart they could probably give us advice on our lunch choices too!

| Technology | Potential Influence |

|---|---|

| AI and Machine Learning | Improved cutting efficiency and precision |

| Robotics | Faster, automated processes |

| Data Analytics | Better planning and resource management |

Conclusion

In conclusion, a milling cutter engagement strategy helps you improve machining efficiency. You should choose the right cutter, adjust speeds, and monitor wear. By doing this, you save time and resources. To learn more, consider reading about specific cutter types. Experiment with different strategies to find what works best for you!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Engagement Strategy:Sure! Here are five questions about milling cutter engagement strategies: 1. What does engagement mean in milling? 2. Why is it important to choose the right cutter? 3. How can you improve cutting speed? 4. What happens if the cutter is too dull? 5. How do you plan your cuts better? Let me know if you want answers to these questions!

Sure! I’m ready to help. Just ask your question, and I’ll give you a simple, clear answer.

What Factors Should Be Considered When Determining The Optimal Engagement Strategy For A Specific Milling Operation?When deciding how to use a milling machine, think about the type of material you will work with. You should consider how thick or tough it is. Also, look at the machine’s speed and power to make sure it fits your needs. Don’t forget to check how precise you need your work to be. Finally, think about safety and whether you have the right tools and protection for the job.

How Does Cutter Geometry Influence The Effectiveness Of Milling Cutter Engagement Strategies?Cutter geometry means the shape and design of the milling cutter. It affects how well the cutter can slice through material. A good shape helps the cutter cut smoothly and easily. If the cutter is sharp and pointed, it works better in tight spaces. This makes cutting faster and reduces damage to other parts.

In What Ways Can Adjusting Feed Rate And Depth Of Cut Enhance The Efficiency Of Milling Operations Based On Engagement Strategies?You can make milling operations better by changing the feed rate and depth of cut. The feed rate is how fast the machine moves while cutting. If you speed it up just right, you can save time. The depth of cut is how deep the machine goes into the material. If you find the best depth, it cuts smoother and uses less energy. This helps the machine work faster and last longer!

What Role Does Coolant Use Play In Milling Cutter Engagement Strategies, Particularly In Terms Of Tool Wear And Surface Finish?Using coolant helps keep milling cutters cool while they work. It can reduce tool wear, making tools last longer. When tools last longer, they can make smoother surfaces. This means the things we cut look nicer and work better. Coolant is important for both saving tools and improving how things look!

How Can Modern Machining Technologies, Such As Adaptive Control Systems, Improve Milling Cutter Engagement Strategies In Real-Time Operations?Modern machining technologies help us make better tools for cutting metal. Adaptive control systems can change how deep or fast we cut while we’re working. This means we can use our tools better and make smoother pieces. By adjusting in real-time, we avoid breaking tools and wasting materials. So, we get better results and save time!