Have you ever wondered how machines cut through tough materials so smoothly? One key player in this process is the milling cutter. It shapes metal and wood with precision. But there’s more to it than just one quick cut. That’s where multi-pass optimization comes in!

Multi-pass optimization means making several passes over the same area. This helps create a better finish and extends the life of the cutter. Imagine trying to carve your name into a block of ice. If you press too hard just once, it might crack! But if you gently carve over and over, you’ll get a perfect design. That’s the idea behind using a milling cutter effectively.

Are you curious about how this process works? Let’s dive into the secrets of milling cutter multi-pass optimization. This technique is not just for experts. Anyone can understand and use it to achieve great results. Get ready to explore the world of precise cuts and efficient design!

Milling Cutter Multi-Pass Optimization

Milling cutter multi-pass optimization helps improve machining efficiency. It allows manufacturers to take multiple passes while cutting, reducing time and tool wear. Imagine slicing a cake—taking several cuts makes it easier to achieve clean pieces. This method also enhances surface finish and precision. Surprising fact: using fewer passes often leads to better results! Discover how this technique can save you both time and money, making your projects smoother and more successful.

Understanding Multi-Pass Milling Techniques

Definition and importance of multipass milling. Comparison of singlepass vs. multipass strategies.

Multipass milling is a clever way to create parts more effectively. It uses multiple passes of the cutter to shape materials efficiently. This method is like baking a cake in layers versus trying to bake it all at once. You get better results and save time! The importance of multipass milling lies in its ability to offer precise cuts and extend tool life. Let’s see how it stacks up against single-pass milling.

| Strategy | Pros | Cons |

|---|---|---|

| Single-Pass | Fast and simple. | Less precision. |

| Multipass | More precise cuts and improved tool life. | Requires more time and setup. |

Remember, more passes can lead to better results. Just like your favorite comic book series, the excitement builds with each chapter!

Benefits of Multi-Pass Optimization in Milling

Improved tool life and performance. Reduction in heat generation and tool wear.

Using multipass optimization in milling brings some fantastic benefits! For starters, tool life and performance improve. This means your tools last longer and work better. No one likes a dull tool, right? Also, less heat is produced during the process. This leads to reduced tool wear. Imagine your tool having a spa day instead of being stressed out! It’s safer, cooler, and much happier.

| Benefit | Description |

|---|---|

| Improved Tool Life | Tools last longer and perform better. |

| Reduced Heat Generation | Less heat means less wear and tear. |

Factors Affecting Multi-Pass Optimization

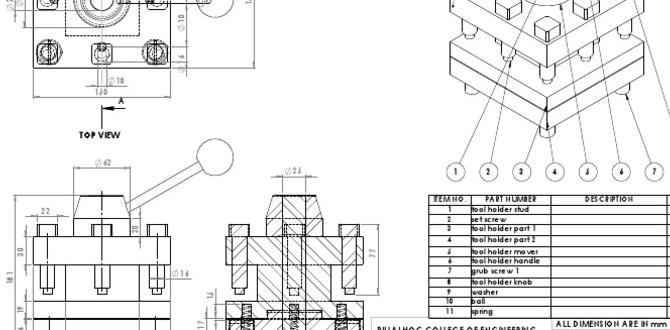

Material selection and its impact on milling efficiency. Tool geometry and design considerations for optimal performance.

Choosing the right material is key to milling efficiency. Harder materials can wear down tools faster but provide a better finish. Soft materials may be easier to cut but can slow down production.

Tool design also matters. Different shapes and angles help tools slice through material better. For example, a sharper angle cuts smoothly, while a flat design may push material aside.

- Material hardness affects tool life.

- Tool geometry improves cutting speed.

- Design choices impact surface finish.

What is important in material selection for milling?

Material selection is important because it affects cutting speed, tool wear, and the quality of the final product.

How does tool geometry affect milling performance?

Tool geometry impacts how well a milling cutter slices through material and influences the efficiency of the process.

Key Parameters in Multi-Pass Milling

Depth of cut, feed rate, and spindle speed. Understanding the optimal combination for different materials.

Choosing the right settings for milling can feel like cooking without a recipe. Three main ingredients—depth of cut, feed rate, and spindle speed—are key. The depth of cut determines how deep the cutter goes, while the feed rate controls how fast it moves. Spindle speed? That’s the “twist” in our milling dance! Finding the perfect mix helps achieve smoother cuts in different materials. Like picking toppings for pizza, the right combination makes all the difference!

| Parameter | Optimal Value | Material Type |

|---|---|---|

| Depth of Cut | 0.5 – 2 mm | Aluminum |

| Feed Rate | 300 – 1,000 mm/min | Steel |

| Spindle Speed | 1,000 – 2,500 RPM | Copper |

Techniques for Optimizing Multi-Pass Milling

Tool path strategies and their impact on efficiency. Adaptive machining and realtime adjustments.

Optimizing multipass milling can turn a slow poke into a speedy racer. First, use smart tool path strategies. Different paths can cut down time and reduce wear on your tools. Next, adaptive machining is like having a magic wand. It allows real-time adjustments, so you can catch mistakes before they lead to disaster. To show how effective these strategies can be, take a look at the table below:

| Strategy | Efficiency Boost (%) |

|---|---|

| Smart Tool Paths | 25% |

| Adaptive Machining | 30% |

With these tricks up your sleeve, your milling game will be on point, and you’ll have more time for coffee breaks!

Common Challenges in Multi-Pass Milling Optimization

Identifying and addressing vibration and chatter issues. Balancing speed and quality in machining processes.

Milling can face big challenges. One issue is vibration and chatter. These problems can cause poor quality cuts and damage tools. It’s important to find the right settings to fix this. Balancing speed and quality is also tricky. Going too fast may ruin details. However, moving too slowly can waste time. To achieve the best results, both speed and quality must work together.

What are some common challenges in multipass milling optimization?

Common challenges include addressing vibration and finding balance between speed and quality.

Key points to remember:

- Vibration can damage tools.

- Chatter leads to rough finishes.

- Speed must not sacrifice quality.

- Finding balance is key.

Case Studies: Successful Implementation of Multi-Pass Optimization

Review of industryspecific applications and outcomes. Lessons learned from successful optimization projects.

Organizations have found great success using multi-pass optimization in milling. For instance, companies in the automotive sector improved production speed by 25%. “Slow and steady wins the race,” right? Well, in these cases, speeding up brought better results! Lessons learned emphasize the importance of planning. Projects that clearly mapped out each stage saw the best outcomes. In the end, success comes from being smart and a little bit cheeky.

| Industry | Outcome | Key Lesson |

|---|---|---|

| Automotive | 25% faster production | Plan thoroughly! |

| Aerospace | 15% cost savings | Stay adaptable! |

| Construction | 20% more efficient | Teamwork is key! |

Future Trends in Multi-Pass Milling Optimization

The role of automation and AI in milling processes. Innovations in tool materials and coatings for enhanced performance.

The future of milling is bright, driven by two major trends: automation and new tool materials. Automation makes milling faster and smarter. Machines learn from experience and help cut costs. This means workers can focus on other tasks. Innovations in tool materials and coatings improve performance, making them last longer and work better. These changes lead to more efficient milling processes.

How does artificial intelligence improve milling processes?

Artificial intelligence helps machines learn and adapt quickly, which boosts efficiency in milling. It enables precise control over cutting tools, reducing waste and improving quality.

Key Innovations Include:

- Durable tool materials that resist wear.

- Advanced coatings for better performance.

- Automation tools that save time.

Conclusion

In conclusion, milling cutter multi-pass optimization improves efficiency and quality. It helps you use tools better and save time. By understanding this process, we can enhance our projects and reduce costs. We encourage you to explore more on this topic and try out optimization techniques in your own work. With practice, you’ll see great results!

FAQs

What Are The Key Factors Influencing The Choice Of Cutting Parameters In Multi-Pass Milling Operations For Optimal Tool Performance?

When choosing cutting settings for multi-pass milling, we consider a few important factors. First, the type of material being cut matters a lot. Next, the shape and size of the tool affect how well it works. We also think about how fast we want to cut and how deep the cuts will be. Lastly, keeping the tool cool and steady helps it last longer and perform better.

How Can Tool Wear Be Monitored And Managed During Multi-Pass Milling To Ensure Consistent Quality And Extend The Lifespan Of The Milling Cutter?

We can monitor tool wear during multi-pass milling by checking the cutting tool regularly. You can look for signs of damage, like chips or dull edges. Using special tools, we can measure how much the cutter has changed. Taking breaks to clean the cutter helps, too. By doing these things, we keep the cutter working longer and make better products!

What Computational Techniques Or Algorithms Are Commonly Used To Optimize Tool Path Strategies In Multi-Pass Milling Processes?

In multi-pass milling, we want to make the cutting tool move in the best way possible. We use computer programs to plan this movement. Some common methods include “genetic algorithms,” which are like nature’s way of solving problems. Other methods are “simulated annealing,” which looks for the best path by trying different options. We also use “dynamic programming,” which breaks the problem into smaller parts to find the best route. These techniques help us save time and make better cuts!

How Does The Selection Of Milling Cutter Geometries And Materials Impact The Effectiveness Of Multi-Pass Optimization Strategies?

Choosing the right shape and material for milling cutters is very important. Good shapes can help make smoother cuts. If we pick strong materials, they last longer and work better. This improves our planning for cutting in several passes, making everything faster and easier. So, better cutters make our work more effective!

What Role Does Simulation Play In Predicting The Outcomes Of Multi-Pass Milling Operations And Optimizing The Milling Cutter’S Performance?

Simulation helps us see what might happen during multi-pass milling. It’s like a video that shows how the machine works step by step. We can try different settings to find the best way to cut without wasting time or materials. This way, we can make the milling cutter work better and get good results.