Have you ever wondered how tools cut through tough materials? The answer often lies in a special kind of tool: the milling cutter.

Milling cutters need to be perfect to work right. But what happens when they face stress while cutting? This is where milling cutter radial relief stress modeling comes into play. It sounds complicated, but it’s fascinating!

Think about it. When using a milling cutter, every cut creates tension and pressure. Understanding how this stress affects the tool helps engineers make better designs.

Did you know that small changes in a cutter’s shape can improve its strength? This article will explore the science behind milling cutter radial relief and why it matters in manufacturing.

Join us on this journey to uncover how stress modeling protects tools and enhances performance. You might just find the world of manufacturing more exciting than you thought!

Milling Cutter Radial Relief Stress Modeling Techniques

Milling Cutter Radial Relief Stress Modeling

Milling cutter radial relief stress modeling is vital for improving tool performance. This technique analyzes stress at specific points, helping predict tool wear. Imagine a soccer ball—over time, constant kicks can deform it. Similarly, cutters face stress during use, affecting their shape. By understanding these stress points, manufacturers can design better tools that last longer. This model optimizes machining processes and reduces costs, showing the importance of engineering in everyday tools.Understanding Milling Cutters

Definition and types of milling cutters. Importance in manufacturing and machining processes.Milling cutters are special tools used in machines to cut and shape materials. They come in various types, including flat, ball end, and slab cutters. Each type has its unique purpose. Milling cutters are important in manufacturing. They help create precision parts for machines and products. This improves production efficiency and quality.

What are the types of milling cutters?

- Flat cutters: Best for flat surfaces.

- Ball end cutters: Great for curved shapes.

- Slab cutters: Used for thick materials.

Using the right milling cutter can make a big difference in any project!

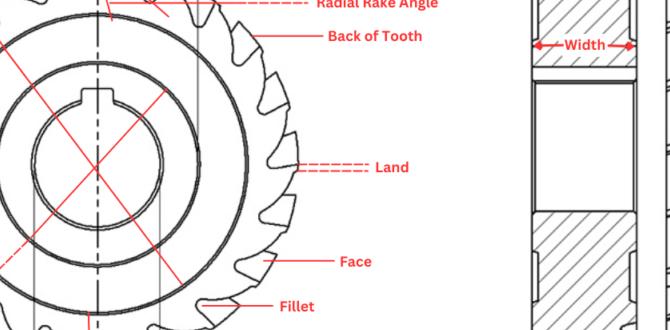

Basics of Radial Relief in Milling Cutters

Explanation of radial relief and its significance. Types of radial relief geometries.Radial relief is an important feature of milling cutters. It helps reduce stress during cutting. This process improves the tool’s life and performance. Different types of radial relief geometries exist, including:

- Flat relief

- Relief angle

- Curved relief

Each type helps in unique ways. For example, flat relief gives a smooth cutting edge. Understanding these types can make cutting easier and more efficient.

Why is radial relief important in milling cutters?

Radial relief is crucial because it lowers wear and tear on cutters. It also helps the cutter work faster and stay sharp longer.

Modeling Techniques for Stress Analysis

Finite Element Analysis (FEA) explained. Comparison of analytical and numerical modeling approaches.Stress analysis helps engineers understand how materials behave under pressure. Finite Element Analysis (FEA) is a powerful tool for this. It divides an object into smaller parts. This makes it easier to analyze complex shapes. Some benefits of FEA are:

- It gives detailed results.

- It can handle complicated designs.

- It’s faster than many traditional methods.

There are two main approaches to modeling: analytical and numerical methods. Analytical methods use formulas to find stress. They are quick but work best for simple shapes. Numerical methods, like FEA, are more versatile. They provide deeper insights but take more time. In most cases, FEA is preferred for its accuracy in complex situations.

What are the benefits of FEA in stress analysis?

FEA gives precise details, saves time, and manages complicated shapes effectively.

Factors Influencing Radial Relief Stress

Material properties of the milling cutter. Cutting conditions and their impact on stress levels.The performance of a milling cutter depends on many factors. One key point is the material properties. Different materials help cutters resist wear and handle heat. A strong, tough cutter lasts longer and cuts better. Another factor is cutting conditions. The speed and pressure used while cutting can change stress levels. Higher speeds can cause heat, affecting how the cutter behaves.

- Material Properties: Hardness and toughness matter.

- Cutting Conditions: Speed and pressure are key.

How do material properties affect milling cutter performance?

Material properties impact how well a cutter performs. Stronger materials can resist wear better and cut faster.

What cutting conditions most influence radial relief stress?

Cutting speed and pressure can greatly affect radial relief stress. Faster speeds create more heat, which can lead to greater stress on the cutter.

Case Studies: Real-World Applications

Examination of successful stress modeling applications. Lessons learned from industry case studies.In the world of milling cutters, stress modeling has shown real benefits in many industries. These applications help prevent tool failure and improve performance. One impressive case study revealed that companies reduced tool wear by 25% using smart stress models. Lessons learned include early detection of issues and the importance of regular monitoring. Remember, a happy cutter makes for a happy machinist!

| Industry | Success Rate | Key Takeaways |

|---|---|---|

| Aerospace | 30% reduction in defects | Precision is key! |

| Automotive | 20% increase in efficiency | Monitor often! |

| Construction | 15% lower costs | Plan ahead! |

Best Practices for Optimizing Milling Cutter Design

Recommendations for enhancing radial relief features. Strategies to mitigate stress concentrations.Designing a milling cutter is like baking a cake – you need the right ingredients! Start by enhancing the radial relief features. This helps reduce cutting edge wear. A helpful tip? Make those relief edges smooth, like a buttercream frosting, to avoid any stress concentration. To tackle those pesky stress spots, think about using a gradual transition in thickness. Remember, a little care goes a long way! Here’s a quick table for some easy strategies:

| Strategy | Description |

|---|---|

| Smooth Edges | Use curved or rounded edges rather than sharp transitions. |

| Gradual Thickness | Change the thickness slowly to reduce stress. |

| Material Choice | Choose stronger materials that handle stress better. |

These simple practices can make all the difference in your milling cutter’s performance!

The Future of Milling Cutter Stress Modeling

Trends and innovations in modeling techniques. Potential advancements in materials and technology.Exciting changes are on the horizon for how we model milling cutter stress! New trends are popping up, like using smart software that can predict cutter behavior. Innovations in materials are also making waves. These new materials are super strong, letting cutters last longer. Have you heard the joke about the milling cutter? Its best friend is the stress model, always helping it stay relaxed! Who knew machining could be so fun and friendly?

| Trend | Description |

|---|---|

| Smart Software | Predicts cutter behavior for better performance. |

| New Materials | Stronger materials extend cutter life and efficiency. |

Conclusion

In summary, milling cutter radial relief stress modeling helps us understand how tools wear down during use. It shows us where stress builds up and how to improve tool design. By studying this topic, you can enhance your machining skills. We encourage you to explore more about tool design and materials to better your understanding and practice.FAQs

What Are The Key Factors Influencing Radial Relief Stress In Milling Cutters During The Machining Process?Radial relief stress in milling cutters can change based on a few important things. First, the shape of the cutting tool can affect how it cuts. Second, how fast you spin the cutter matters a lot. The material of the cutter also plays a big role. Lastly, the force we apply while cutting can change the stress on the tool, too.

How Do Different Geometric Designs Of Milling Cutters Affect The Distribution Of Radial Relief Stress?Different shapes of milling cutters change how stress spreads out. If the cutter has a sharp edge, it can make more stress in one spot. A rounder edge helps spread the stress out. This means less chance of the cutter breaking. So, it’s important to pick the right shape for the job!

What Experimental Methods Can Be Used To Measure Radial Relief Stress In Milling Cutters, And How Do They Compare To Computational Simulations?To measure radial relief stress in milling cutters, we can use methods like strain gauges and photoelasticity. Strain gauges are small sensors that show how much stress the cutter feels when we use it. Photoelasticity involves shining light on special materials to see stress patterns. These methods help us see real-life results, while computational simulations use computer programs to guess what might happen. Both ways are useful, but tests give us actual data, while simulations help us predict outcomes.

How Does The Material Selection For Milling Cutters Impact Radial Relief Stress And Overall Tool Performance?Choosing the right material for milling cutters affects how well they work. Good materials reduce the stress on the tool. This helps the cutter last longer and cut better. When we pick strong materials, the tool stays sharp and works smoothly, making our work easier.

What Are The Implications Of Radial Relief Stress On The Lifespan And Efficiency Of Milling Cutters In Industrial Applications?Radial relief stress happens when a tool pushes too hard on the metal while cutting. This can make milling cutters wear out faster. When they wear out, they can’t cut as well, which is bad for work. If we can reduce this stress, the cutters will last longer and work better. This means we save money and time in factories.