Have you ever wondered why some machines produce smoother surfaces than others? The secret often lies in the tools they use. One of those essential tools is the milling cutter. These cutters shape and finish materials to create everything from car parts to kitchen utensils.

But not all milling cutters are the same. Different types can lead to different surface finishes. So, how do you know which cutter will give you the best results? That’s where our milling cutter surface finish comparison comes in.

Imagine building a model car. You want it to look perfect. Choosing the right milling cutter can help you achieve that flawless finish. Surprisingly, even small changes in tool design can make a big difference in the final look.

Join us as we explore the world of milling cutters. We will compare various options to find out which one truly delivers the best surface finish. Get ready to sharpen your knowledge!

Milling Cutter Surface Finish Comparison: An In-Depth Analysis

Milling Cutter Surface Finish Comparison

Curious about milling cutters and their smoothness? Different milling cutters create unique surface finishes. Some leave a shiny look, while others provide a rougher texture. Factors like cutter material and cutting speed greatly influence the final result. Did you know that the right choice can also boost tool life? Choosing wisely can save time and improve product quality. Understanding these differences helps in making better decisions for your projects. Wouldn’t you want the best finish possible?Understanding Surface Finish in Milling

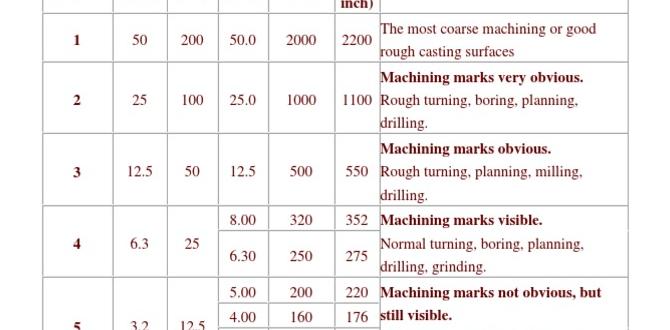

Definition of surface finish. Importance of surface finish in machining processes.Surface finish is all about how smooth or rough a material’s surface feels after machining. Think of it like the difference between a potato and a polished apple! A good surface finish is crucial because it affects how the part works and looks. A smooth finish can reduce wear and tear, making machines last longer. It’s like giving your tools a nice spa day. In machining, achieving the right surface finish can improve performance and even save money!

| Surface Finish Type | Importance |

|---|---|

| Rough Finish | Good for holding lubricants, but may wear down faster. |

| Smooth Finish | Reduces friction and improves appearance. |

| Mirror Finish | Highly polished, great for aesthetics and certain applications. |

Factors Affecting Surface Finish

Influence of cutter material and design. Role of cutting speed, feed rate, and depth of cut.Several factors affect how smooth a surface can be when using a milling cutter. The material and shape of the cutter play a big role in the final finish. The cutting speed, or how fast the cutter moves, also matters. A faster speed often leads to a better surface finish. The feed rate, or how quickly the material is fed into the cutter, can change the outcome too. Lastly, the depth of cut, or how deep the cutter goes, affects the finish quality as well.

How does cutter material and design influence surface finish?

The material and design of the cutter are crucial for achieving a fine surface finish. Harder, high-quality materials provide better results compared to softer ones. The shape of the cutter can improve cutting efficiency and surface smoothness too.

Factors to Consider:

- Material type (e.g., carbide, high-speed steel)

- Cutter shape (e.g., flat, ball-nose)

What role do cutting speed, feed rate, and depth of cut play?

These three factors greatly determine the surface finish quality. Higher cutting speeds often yield smoother surfaces. Adjusting the feed rate can either improve or worsen the finish. The depth of cut should be balanced to avoid rough surfaces.

Key Points:

- Higher cutting speed = better finish

- Proper feed rate is essential

- Adjust depth of cut for quality results

Comparative Analysis of Milling Cutters

Carbide vs. HighSpeed Steel (HSS) cutters. Solid vs. Inserted milling cutters.Different milling cutters work better for specific tasks. Let’s look at two types: carbide and High-Speed Steel (HSS) cutters. Carbide cutters last longer and handle tougher jobs than HSS cutters, but they can be more expensive.

Also, there are solid and inserted milling cutters. Solid cutters are one piece and strong, while inserted cutters use replaceable blades. Inserted cutters can be cheaper and easier to fix. Choosing the right type makes a big difference in how well a job is done!

How to choose between milling cutters?

Choosing the right milling cutter can depend on the job scale and cost. Carbide is better for tough jobs, while HSS is good for softer materials. Inserted cutters are useful for quick repairs.

- Carbide – Longer life but costs more.

- HSS – Cheaper and good for soft materials.

- Solid cutters – Strong and durable.

- Inserted cutters – Easier to replace parts.

Case Studies: Real-World Applications

Examples of surface finish results achieved with different cutters. Comparison of performance in various materials.Imagine you’re using different tools to cut a cake. Each tool gives a different slice. In milling, it’s the same! Different cutters can make various surface finishes. For instance, a high-speed steel (HSS) cutter shines on softer materials like aluminum. On the other hand, a carbide cutter is perfect for harder materials like steel. This means you get smoother results with the right tool!

| Material | Tool | Surface Finish |

|---|---|---|

| Aluminum | HSS Cutter | Excellent |

| Steel | Carbide Cutter | Very Good |

| Plastic | High-Speed Cutter | Good |

So, choosing the right milling cutter is like selecting the perfect knife for your cake. It can make a huge difference! Who would want a rough slice when you could have a smooth one?

Best Practices for Selecting Milling Cutters

Guidelines on choosing the right cutter for desired surface finish. Tips for optimizing machining parameters for better results.Choosing the right milling cutter can feel like picking a favorite ice cream flavor—so many choices! First, consider the desired surface finish. A smooth finish? A fine tooth cutter is your best buddy. Next, keep an eye on machining parameters. Faster speeds can slice through materials quickly but remember, too fast might lead to a bumpy ride.

| Milling Cutter Type | Surface Finish Quality |

|---|---|

| Fine Tooth Cutter | Smooth and Shiny |

| Coarse Tooth Cutter | Rugged and Textured |

| End Mill | Versatile Finish |

Lastly, don’t forget your cutting parameters. Adjust them like a chef balancing flavors. The right mix creates the tastiest results!

Future Trends in Milling Cutter Technology

Innovations in cutter materials and coatings. Predictions for the evolution of milling technology and its impact on surface finish.New materials and coatings for milling cutters are changing the game. These innovations help make cutters stronger and last longer. For example, coatings like titanium nitride reduce wear and improve surface finish. As technology evolves, we can expect even better tools that make precise cuts without damage.

Experts predict that future milling technology will focus on:

- Higher efficiency

- Better durability

- Improved surface finishes

This means smoother products and less time needed for repairs.

What are the benefits of the new milling cutter materials?

The new materials have greater hardness, which means they can cut better and last longer. They can also create smoother surfaces on finished products. This innovation helps industries produce high-quality items.

Conclusion

In summary, comparing milling cutter surface finishes helps you choose the best tools for your projects. Different cutters create various surface textures, affecting quality and performance. Pay attention to materials and speeds for the best results. You can experiment with various cutters and read more about milling techniques to improve your skills. Happy milling!FAQs

What Are The Key Factors That Influence The Surface Finish Achieved By Different Types Of Milling Cutters?The surface finish of a milled item depends on a few important things. First, the type of milling cutter matters. Some cutters are sharp and smooth, which helps make a clean finish. Second, the speed you use when cutting can affect how rough or smooth the surface is. Lastly, using the right feed rate, or how fast you move the material, also plays a big role in how nice the surface looks.

How Does The Material Of The Milling Cutter Affect The Quality Of The Surface Finish On Machined Parts?The material of the milling cutter is very important. If you use a hard material, it cuts better and smoother. This helps make the surface of the part shiny and nice. If the cutter is dull or soft, it can leave bumps and scratches. So, using the right cutter helps us get a better finish on our parts.

In What Ways Do Milling Cutter Geometry And Design Contribute To Variations In Surface Finish During Machining Operations?Milling cutter geometry and design are like the shape and sharpness of scissors. A sharp cutter makes smooth cuts, which means a nicer surface. If the cutter is dull or not shaped well, it can leave rough edges. The number of cutting edges also matters. More edges help create a better finish because they share the work.

How Can Cutting Parameters Such As Feed Rate And Spindle Speed Optimize Surface Finish When Using Different Milling Cutters?You can improve the surface finish of your workpiece by adjusting the feed rate and spindle speed. The feed rate is how fast the cutter moves through the material. A slower feed rate can make a smoother surface. Spindle speed is how fast the cutter spins. A higher spindle speed also helps create a nicer finish. By finding the right balance between these two, you can get better results with different milling cutters.

What Are The Best Practices And Techniques For Selecting The Appropriate Milling Cutter To Achieve The Desired Surface Finish In Specific Materials?To choose the right milling cutter, you should first know what material you are working with, like metal or wood. Next, consider the type of finish you want—smooth or rough. Use a cutter that matches those needs. For soft materials, you can use a cutter with lots of teeth for a fine finish. Lastly, remember to adjust the speed and feed rate to get the best result!