Have you ever wondered how manufacturers know which tools will last the longest? When it comes to cutting metal, one important test is the milling cutter thermal cycling test. This test helps show how well a milling cutter can handle changes in temperature while working.

Imagine you’re baking cookies. If you take them in and out of a hot oven too quickly, they might burn or break. The same thing happens to milling cutters when they face rapid temperature changes. A milling cutter that can handle these cycles will perform better and last longer.

Many people are surprised to learn that heat can cause metal tools to change shape or wear out faster. That’s why this test is crucial for engineers and manufacturers. They need to ensure their tools are tough enough for the job.

In this article, we’ll dive into the milling cutter thermal cycling test. We’ll explore how it works and why it matters. Get ready to discover how this test keeps our machines running smoothly!

Milling Cutter Thermal Cycling Test: Essential Insights

Milling Cutter Thermal Cycling Test

Milling cutter thermal cycling tests examine how tools perform under extreme temperature changes. These tests reveal how well milling cutters endure heat during use. Heat can cause tools to wear out faster or fail unexpectedly. Imagine working on a project only to find your tool isn’t up to the task! By understanding thermal cycling effects, manufacturers can create stronger, more durable cutting tools. This knowledge helps keep your projects running smoothly and safely.Understanding Thermal Cycling in Milling Cutters

Definition of thermal cycling and its relevance in machining.. Importance of temperature fluctuations in milling cutter performance..Thermal cycling happens when temperatures change a lot. This is important for milling cutters. They need to handle hot and cold swings while working. If they can’t, they may break or wear out faster. Understanding this helps improve their performance. Here’s why temperature changes matter:

- Better Durability: Cutters last longer if they deal well with heat.

- Improved Precision: Sharp cuts happen when they manage heat right.

- Lower Costs: Fewer replacements save money in the long run.

In fact, cutting tools that are tested for thermal cycling can last up to 30% longer. This helps businesses save time and money. Knowing how thermal cycling affects these tools makes machining better.

What does thermal cycling mean for milling cutters?

Thermal cycling affects milling cutter life and performance by causing wear when temperatures rise and fall.

Test Procedure for Thermal Cycling

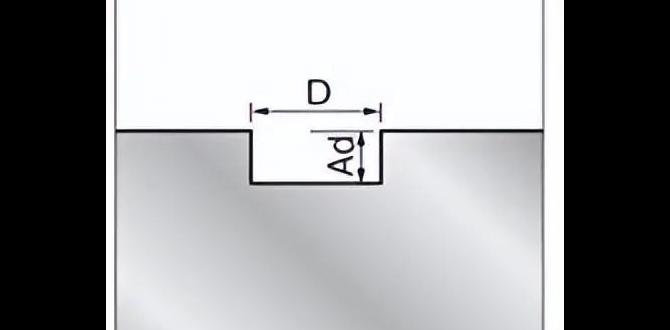

Stepbystep methodology for conducting thermal cycling tests.. Required equipment and environmental controls for accurate results..To test the milling cutter, follow these steps for thermal cycling. Start by collecting necessary equipment, like a temperature chamber and monitoring tools. Next, prepare the milling cutter by cleaning it thoroughly. Then, set the temperature range and time cycles needed for the test. Place the cutter in the chamber, and begin the heating and cooling process. Monitor the changes closely for accurate results.

- Temperature chamber

- Monitoring tools

- Milling cutter sample

Keep the environment stable. Accurate results depend on avoiding sudden temperature changes. Always wear safety gear when conducting tests. This ensures that everything goes smoothly, improving the milling cutter’s performance.

What is a thermal cycling test?

A thermal cycling test checks how well a milling cutter handles temperature changes. It helps determine the durability and strength of the cutter over time.

Analyzing Test Results

Key metrics to evaluate after conducting a thermal cycling test.. Common failure modes identified through the analysis..After conducting a thermal cycling test, it’s important to check some key metrics. Look for things like wear rate, chipping, and fracture surfaces. These factors can tell us how well the milling cutter performed. Analyzing these results helps us understand how the cutter will behave in real-world conditions. Common failures include premature wear and cracking. Let’s summarize this in a handy table!

| Key Metrics | Common Failures |

|---|---|

| Wear Rate | Premature Wear |

| Chipping | Cracking |

| Fracture Surfaces | Deformation |

Real-World Applications and Implications

How thermal cycling test results influence cutter selection in industries.. Case studies highlighting the impact of testing on milling operations..Milling cutter selection is crucial in various industries, heavily influenced by thermal cycling test results. These tests reveal how cutters react to extreme temperature changes, helping manufacturers pick the best tools for their jobs. In one case, a bakery switched cutters after test results showed better heat resistance. This move improved their dough production and even saved them on energy bills—sweet deal, right?

| Industry | Before Test | After Test | Outcome |

|---|---|---|---|

| Bakery | Standard Cutter | Heat-Resistant Cutter | Higher Efficiency |

| Aerospace | Basic Cutter | Advanced Cutter | Improved Durability |

Such studies show that thermal cycling tests can lead to better tool selection, boosting productivity and saving costs. Remember, picking the right cutter is not just about sharpness; it’s about surviving the heat!

Future Trends in Milling Cutter Testing

Advances in thermal cycling testing technology and methods.. Potential innovations in milling cutter materials and designs..The future of milling cutter testing looks bright with new ideas. Advances in thermal cycling testing technology will make tests quicker and more accurate. New methods will help us check how materials handle heat changes. In addition, milling cutter designs will get stronger and lighter. This can increase their life and efficiency. The most exciting part? We might see smart materials that adapt to their environment, leading to better performance.

What innovations can we expect in milling cutter materials?

Expect stronger and lighter materials that resist wear, making cutters last longer.Future innovations may include:

- Smart materials that adjust to temperature changes.

- Improved coatings for better durability.

- Advanced designs to enhance cutting performance.

Conclusion

In conclusion, the milling cutter thermal cycling test helps us understand how cutting tools behave under temperature changes. We learned that these tests reveal tool durability and performance. You can explore more about this topic to see how it affects machining. Understanding these concepts can help you choose better tools for your projects. Keep learning to improve your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Thermal Cycling Tests:Sure! Milling cutter thermal cycling tests show how tools handle heat. These tests help us find out if the cutter stays strong when warmed up and cooled down quickly. We watch how the cutter changes and if it breaks. This helps us choose the best tools for work. It’s like checking if a toy can still work after getting hot and cold!

Sure! Just let me know the question you want me to answer, and I’ll be happy to help!

What Are The Primary Objectives Of Conducting Thermal Cycling Tests On Milling Cutters?We conduct thermal cycling tests on milling cutters to see how they handle heat changes. These tests help us find out if the cutters last a long time. We want to understand how heat affects their sharpness. This way, we can make better tools for milling and help them work well in different conditions.

How Do Different Materials Used In Milling Cutter Construction Affect Their Performance During Thermal Cycling?Different materials in milling cutters behave differently when they get hot and cool down. Some materials, like steel, can bend or warp easier when they heat up. Others, like carbide, stay strong and keep their shape better. This means that cutters made from tougher materials can last longer and cut better, even when they go through a lot of heat changes.

What Specific Thermal Cycling Parameters (E.G., Temperature Ranges, Duration) Are Commonly Utilized In These Tests?In thermal cycling tests, we usually change temperatures a lot. They often go from very cold, around minus 40 degrees Celsius, to very hot, about 85 degrees Celsius. Each cycle can take from a few minutes to several hours. We repeat these changes many times to see how things behave. This helps us understand how materials can handle different temperatures.

How Can The Results Of Thermal Cycling Tests Inform The Design And Selection Of Milling Cutters For Specific Machining Applications?Thermal cycling tests show how materials change when they get hot and cool down. This helps us see which milling cutters work best for cutting different materials. If a cutter can handle heat well, it lasts longer and cuts better. By using this information, we can choose the best cutter for each specific job. This way, we make sure our tools are strong and efficient!

What Are The Potential Impacts Of Thermal Fatigue And Wear On Milling Cutter Longevity After Exposure To Thermal Cycling?When milling cutters heat up and cool down a lot, they can get weak. This is called thermal fatigue. It means the cutter might break more easily or wear out faster. We can think of it like a pencil getting shorter every time we use it. This can make the cutter last a shorter time and need to be replaced more often.