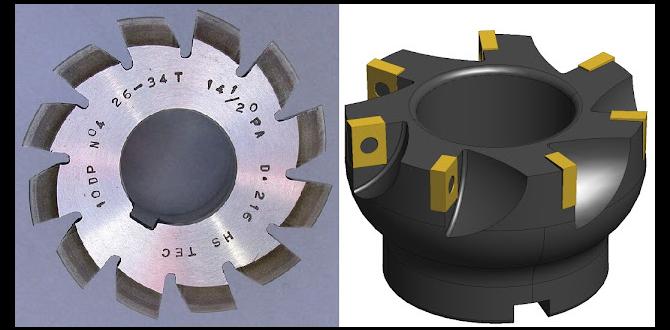

Have you ever thought about how long a milling cutter can last? It’s an interesting question. In the world of machining, the tool’s life matters a lot. How do we know the right time to change a milling cutter? That’s where tool life monitoring methods come in.

Imagine being able to track useful information about your tools. This can help you save time and money. You wouldn’t want to use a worn-out cutter; it can ruin your work and lead to trouble. Understanding the different methods for monitoring tool life is key.

There are many ways to check how long your milling cutter lasts. Each method has its own benefits and tricks. Some are simple, while others might need special equipment. Do you want to make your work easier and more efficient? Then reading more about these methods could be a game-changer for you!

Stay tuned as we explore the different milling cutter tool life monitoring methods. You might be surprised by what you learn!

Milling Cutter Tool Life Monitoring Methods: An Overview

Milling Cutter Tool Life Monitoring Methods

Milling cutter tool life monitoring methods help manufacturers keep track of how long their tools last. These methods can save money and time by preventing unnecessary tool changes. Some popular ways include using sensors to measure wear and tear. Have you ever wondered how often tools need to be replaced? By knowing when a tool wears down, businesses can avoid breakdowns and improve efficiency. It’s fascinating how technology helps make these processes smarter and more effective!Understanding Milling Cutter Tool Life

Definition of tool life in milling operations. Importance of tool life in manufacturing efficiency and cost reduction.Tool life is how long a milling cutter lasts before it needs to be replaced. Think of it like a pair of socks; they wear out after lots of use. Knowing tool life helps factories work better and saves money. Higher tool life means fewer replacements, which keeps production smooth. A study found that companies that monitor tool life can cut costs by up to 30%. So, using the right tool can save a lot of cash—and maybe even a few tantrums!

| Tool Life Importance | Benefit |

|---|---|

| Efficiency | Fewer tool changes mean faster production. |

| Cost Reduction | Less money spent on new tools. |

Factors Influencing Tool Life

Material properties of the workpiece and cutter. Cutting speed, feed rate, and depth of cut impacts.Many factors can change how long a milling cutter tool lasts. The material of both the workpiece and the cutter matters. Harder materials can wear out tools faster. Cutting speed, feed rate, and depth of cut also play big roles:

- Cutting speed: Higher speeds can cause more heat, which can shorten tool life.

- Feed rate: Faster feed can lead to rough cuts and quicker wear.

- Depth of cut: Deeper cuts can increase pressure and heat on the cutter.

Understanding these factors helps improve tool performance and lifespan.

How does material affect tool life?

The material type of both the cutter and workpiece matters greatly. Harder materials often create more wear on tools, reducing their lifespan.

Traditional Tool Life Monitoring Methods

Visual inspection and manual measurement techniques. Timebased monitoring approaches.Many people check tools by looking and measuring them. These methods help workers see when a milling cutter is wearing out. Visual inspections involve looking for signs of wear and damage. Workers use rulers or gauges to measure the tool’s size. This ensures it’s still good for cutting. Time-based monitoring means keeping track of how long a tool has been used. If a cutter runs for a set time, it may need replacing.

What are the common methods for monitoring tool life?

Common methods include visual inspections and time-based tracking of usage.Key Monitoring Techniques:

- Visual Inspection: Look for wear signs.

- Manual Measurement: Check size with tools.

- Time Tracking: Log usage time for replacements.

Advanced Tool Life Monitoring Techniques

Vibration analysis and acoustic emission monitoring. Tool wear detection using machine vision systems.Monitoring the life of tools is very important in milling. Advanced methods help us do this better. One way is through vibration analysis and acoustic emission monitoring. These techniques listen for changes in sound and vibrations to detect tool wear early. Another method is using machine vision systems. They take pictures and analyze them to see how much the tool has worn down.

- Vibration Analysis: Checks noise and vibrations. Helps find problems quickly.

- Acoustic Emission Monitoring: Listens for sounds that signal wear.

- Machine Vision Systems: Uses cameras to spot tool wear visually.

Why use advanced monitoring techniques?

Advanced techniques help save money and time by identifying wear early. They make sure machines work better. Better machines mean better products.

Data-Driven Tool Life Estimation

Implementing machine learning algorithms for predictive maintenance. Role of IoT in realtime monitoring and data collection.Machine learning is like a magic crystal ball for predicting when tools need a break! By using clever algorithms, we can spot patterns and predict when a milling cutter might wear out. Meanwhile, IoT gadgets are our watchful eyes, collecting data in real-time. They send updates faster than you can say “tool life!” So, with these tools combined, we can keep our machines happy and working longer. Who knew monitoring could be this fun?

| Method | Description |

|---|---|

| Machine Learning | Predicts when tools wear out using data. |

| IoT Monitoring | Gathers real-time data for better insights. |

Case Studies in Tool Life Monitoring

Examples of successful implementation in industrial settings. Comparison of traditional vs. advanced methods in real scenarios.In many factories, tool life monitoring can be a game changer! Companies have seen great results by using both traditional and advanced methods. For example, a team at a large automotive plant tracked tool wear using old school methods like time and manual checks. This approach worked but had its quirks, like forgetting to check every time. With a modern system, one company used sensors and digital tools. They easily spotted wear and saved time and money. Their tools lasted longer, making everyone happier!

| Method | Advantages | Disadvantages |

|---|---|---|

| Traditional | Simple and low-cost | Prone to errors |

| Advanced | Accurate with real-time data | Higher initial investment |

Both styles have their perks! Traditional methods are easy but can be less reliable. Advanced methods are accurate and save resources, but they need more investment. Choosing the right fit helps keep factories running smooth and boosts smiles all around!

Future Trends in Tool Life Monitoring

Emerging technologies and innovations shaping the future. The impact of Industry 4.0 on milling cutter tool life management.New tools and smart technology are changing how we track milling cutter tool life. Industry 4.0 is bringing amazing ideas into the world of manufacturing. Innovations like IoT, AI, and data analytics help monitor tools better. They make it easy to predict when tools need replacements. This leads to fewer breaks and better productivity.

- IoT sensors collect real-time data on tool usage.

- AI algorithms analyze this data for better predictions.

- Cloud computing allows for easy access to information anywhere.

Conclusion

In summary, milling cutter tool life monitoring methods help you track tool wear and performance. Knowing how to monitor tools can save time and money. You can use techniques like vibration analysis or cutting force measurement. We encourage you to explore these methods further to improve your machining processes. Understanding tool life means better results for your projects!FAQs

Sure! Here Are Five Questions Related To Milling Cutter Tool Life Monitoring Methods:Sure! Here are five questions about how we can keep track of milling cutter tool life. First, we can ask how do we know when a tool is worn out? Next, what signs show that the tool is getting dull? We might wonder if we can use machines to help watch the tool. Another question could be, can we measure how much the tool cuts before it wears down? Lastly, we can think about what sensors we need to check the tool’s condition.

Sure! Just provide me with the question, and I’ll give you a clear and simple answer.

What Are The Primary Indicators Used To Assess The Tool Life Of Milling Cutters In Real-Time Applications?To know how long milling cutters last, we check a few important things. First, we look at how much the cutter wears down. We also measure the surface quality of the metal being cut. Another sign is how much energy the machine uses. If the cutter makes strange noises or vibrations, that can mean it needs to be replaced soon.

How Can Sensor Technology Be Integrated Into Milling Machines For Effective Tool Life Monitoring?We can add sensors to milling machines to watch how the tools are working. These sensors can feel heat and vibrations. When tools start to wear out, the sensors send us alerts. This helps us change the tools before they break, making everything run better. It keeps our machines safe and saves us time!

What Are The Advantages And Disadvantages Of Using Machine Learning Algorithms For Predicting Milling Cutter Tool Wear?Using machine learning to predict milling cutter tool wear has good and bad points. The good part is that it can help us see wear patterns quickly. This means we can change tools before they break. However, the bad part is that we need a lot of data to train the computer. If we don’t have enough data, the predictions might not be accurate.

How Does Coolant Usage Impact The Monitoring And Extension Of Milling Cutter Tool Life?Using coolant helps keep the milling cutter cool while it works. This makes the tool last longer and work better. When we use coolant, we can see when the tool is getting dull. This helps us know when to change it before it breaks. Overall, coolant helps us take care of our tools and extends their life.

What Are The Common Methods For Collecting Data On Milling Cutter Performance During Operation, And How Can This Data Be Utilized For Improved Tool Life Management?We can collect data on milling cutter performance using sensors, cameras, and special software. These tools help us see how well the cutter is working. We can also measure things like the temperature and sound during cutting. By analyzing this data, we can find ways to make our tools last longer. This helps us save money and work better!