Have you ever wondered how metal pieces get their perfect shapes? One secret lies in the tiny teeth of milling cutters. These clever tools help carve out materials with great precision. But did you know the spacing between their teeth can change everything? It can impact how smoothly they cut and even how fast they work.

Imagine trying to cut a cake with a knife that has big gaps between the little teeth. It would be messy, right? In the same way, milling cutter tooth spacing plays a vital role in machining. Optimizing this spacing can either boost productivity or lead to mistakes.

Let’s dive into the world of milling cutter tooth spacing optimization. This journey will reveal how small changes can make a huge difference in manufacturing. You’ll learn interesting facts and tips that can change the way you think about cutting tools. So, are you ready to find out more?

Milling Cutter Tooth Spacing Optimization Techniques Explained

Milling Cutter Tooth Spacing Optimization

Milling cutter tooth spacing optimization helps improve machining efficiency. By adjusting tooth spacing, we can reduce vibrations and enhance surface finish. Imagine cutting a cake with a dull knife; it makes slices uneven. The same goes for milling. Proper spacing makes cleanup easier and saves time. Engineers often test different spacings to find the best fit for materials. This not only boosts performance but also lowers costs. In manufacturing, small changes can lead to big results.Understanding Milling Cutters

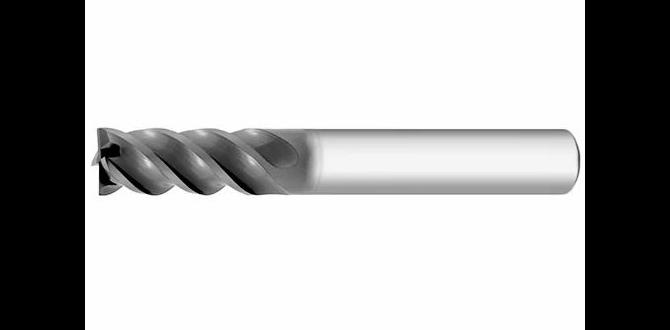

Definition and types of milling cutters. Importance of tooth design in milling operations.Milling cutters are special tools used in machines to shape materials like metal or wood. They come in various types, including:

- Face mills

- End mills

- Ball nose cutters

- Slab mills

The design of the cutter’s teeth plays a huge role in how well it works. Good tooth design helps in smooth cutting and better efficiency. This means faster work and less waste. Therefore, knowing about milling cutter tooth spacing optimization can improve your projects.

What are the Types of Milling Cutters?

There are different types of milling cutters, and each one serves a specific purpose. For instance, face mills are great for flat surfaces, while end mills can reach deeper areas.

Significance of Tooth Spacing in Milling

Impact of tooth spacing on cutting performance. Relation between tooth spacing and material removal rate.Tooth spacing in milling is like the spacing in a good friendship. It needs to be just right! If teeth are spaced too far apart, they might not cut well. Think of it as trying to slice cake with a very far away knife. On the other hand, if they’re too close, they could choke on the material. The right spacing helps maintain a great cutting performance and boosts the material removal rate efficiently. So, remember: a well-spaced tooth is a happy tooth!

| Tooth Spacing | Cutting Performance | Material Removal Rate |

|---|---|---|

| Wide spacing | Poor | Low |

| Optimal spacing | Excellent | High |

| Narrow spacing | Risky | Moderate |

Factors Influencing Tooth Spacing Optimization

Material properties and workpiece characteristics. Cutting speed and feed rate considerations.Several factors play a role in optimizing tooth spacing on milling cutters. First, material properties can affect how well the cutter performs. Harder materials may require closer spacing to cut accurately, while softer materials may need wider spacing. Next, cutting speed and feed rate are crucial. A faster speed can lead to more heat, which might change how the material responds. It’s like trying to slice bread with a slow knife—it just doesn’t work as well!

| Factor | Effect on Tooth Spacing |

|---|---|

| Material Properties | Hard materials need closer teeth |

| Cutting Speed | High speed may require careful spacing |

| Feed Rate | Fast feed might affect depth |

In the end, think of tooth spacing as the secret recipe for success in milling! Adjust it according to your material and speed, and you’ll cut like a pro.

Methods for Optimizing Tooth Spacing

Analytical approaches to determine ideal spacing. Computational modeling and simulation techniques.Finding the perfect tooth spacing for milling cutters is like solving a puzzle. One smart way is to use analytical approaches. These methods help figure out the ideal spacing based on math and physics. Next, we can dive into computational modeling. This tech marvel allows us to simulate different scenarios on a computer. Think of it like a video game for engineers to see what works best without wasting real materials!

| Method | Description |

|---|---|

| Analytical Approaches | Uses math to find the best tooth spacing. |

| Computational Modeling | Simulates different designs to save resources. |

These methods help create tools that cut better and last longer. After all, no one wants a dull blade on their pizza cutter, right?

Tool Wear and Tooth Spacing Correlation

How tooth spacing affects tool longevity. Strategies for minimizing wear through optimization.Imagine a party where every guest has enough space to dance. That’s what tooth spacing does for milling cutters. If the teeth are too close together, they rub and wear out faster. But with the right distance, they perform like a well-coordinated dance team, increasing the tool’s life. To keep our cutters happy, consider optimizing the spacing. Regularly check tooth wear and adjust accordingly to reduce wear. Remember, every little tweak counts!

| Tooth Spacing | Tool Longevity |

|---|---|

| Too Close | Increased Wear |

| Optimal Distance | Extended Life |

| Far Apart | Less Cutting Efficiency |

Strategies like monitoring wear and adjusting spacing can help keep tools sharp and happy. Optimizing tooth spacing is like giving your milling cutter a spa day—it’s all about treating it right!

Case Studies on Tooth Spacing Optimization

Realworld examples of successful optimization. Lessons learned from various milling applications.In the world of milling, adjusting tooth spacing can make a big difference. Take *Company A*, for example. They changed their cutter spacing and boosted their efficiency by 25%! That’s like finding a secret pizza slice – everyone wants in! Another example is *Company B*, which learned that proper spacing reduced tool wear significantly. Less wear means more time to shine (and more dough saved). Here’s a summary of important lessons:

| Company | Optimization Result |

|---|---|

| Company A | 25% efficiency boost |

| Company B | Less tool wear |

These case studies show that thoughtful adjustments can lead to great outcomes. So next time you think about milling, remember – spacing can be your best friend!

Future Trends in Milling Cutter Design

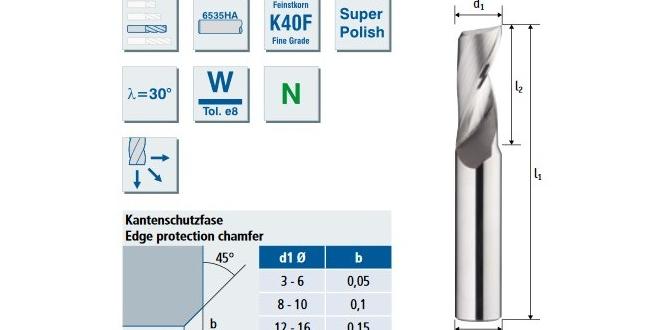

Emerging technologies and innovations in cutter design. The role of advanced materials in tooth spacing optimization.The future of milling cutter design is bright with new technologies. 3D printing is making it easier to create unique shapes. Designers can test different tooth spacings quickly. This helps to find the best fit for various materials. Advanced materials like carbide and ceramics are now used to boost durability. Combining these materials with smart designs means we can improve cutter performance and tooth spacing optimization. As we innovate, cutters will work better and last longer.

How do new technologies affect milling cutters?

New technologies improve milling cutters by making them stronger and more efficient. 3D printing allows for quick changes in design. This means better tooth spacing for better cutting!

Key Innovations:

- 3D printing for customized designs.

- Use of advanced materials for strength.

- Smart designs to improve tooth spacing.

Best Practices for Implementing Tooth Spacing Optimization

Stepbystep guide for manufacturers. Common pitfalls and how to avoid them.Tooth spacing optimization can feel like a puzzle, but it’s easier than it looks! First, measure the current specifications using precision tools. Next, adjust spacing based on the material you’re cutting. Too close? You might create a ruckus! Too far? You’ll get less done.

Here’s a handy table to guide you:

| Step | Action | Tip |

|---|---|---|

| 1 | Measure existing spacing | Shorter isn’t always better! |

| 2 | Adjust spacing | Think Goldilocks: just right! |

| 3 | Test cuts | Be like a scientist and experiment! |

Avoid common pitfalls by checking your measurements twice—like your mom would when baking cookies. And remember, patience pays off!

Conclusion

In summary, optimizing milling cutter tooth spacing improves cutting efficiency and tool lifespan. You can achieve better results by adjusting spacing based on material and project needs. Remember, a well-optimized cutter not only saves time but also cuts costs. Explore more about milling techniques to sharpen your skills and enhance your projects. Start experimenting with spacing today!FAQs

What Factors Influence The Optimal Tooth Spacing On A Milling Cutter For Achieving Maximum Efficiency And Precision In Machining Operations?Tooth spacing on a milling cutter affects how well it cuts. If the teeth are too far apart, the cutter may miss some spots. If they are too close, it can get stuck or wear out quickly. We want a good balance to get smooth cuts and keep the cutter strong. Other things like the material we’re cutting and the speed also matter.

How Can Varying The Tooth Spacing Design Impact The Overall Performance And Lifespan Of A Milling Cutter In Different Materials?Varying the tooth spacing on a milling cutter can change how it cuts different materials. If the teeth are too close together, they may get blocked or wear out quickly. More space can help the cutter handle tough materials better. This means the cutter can last longer and work faster, giving us better results. So, the right spacing helps the cutter perform well and last longer.

What Numerical Simulation Methods Can Be Employed To Analyze And Optimize The Tooth Spacing Of Milling Cutters For Specific Cutting Conditions?To analyze and improve tooth spacing in milling cutters, you can use computer simulations. These simulations help us show how the cutter works under different conditions. One method is finite element analysis (FEA), which checks how materials bend and break. Another option is computational fluid dynamics (CFD), which looks at how coolants flow during cutting. Using these tools, we can find the best tooth spacing for better cutting.

How Does The Choice Of Tooth Spacing Affect The Chip Removal Efficiency And Surface Finish Quality In Milling Processes?When we choose how far apart the teeth on a milling tool are, it changes how well it works. If the teeth are close together, they can take away more chips from the material. This helps make the surface smoother. If the teeth are farther apart, they might not cut as well, leading to rough spots. So, tooth spacing is important for both cleaning up the material and making it look nice!

What Are The Trade-Offs Between Wider Versus Narrower Tooth Spacing In Terms Of Cutting Forces, Vibration, And Heat Generation During Milling Operations?Wider tooth spacing in milling makes cutting easier. This can lower cutting forces, meaning less pressure is needed. However, it may create more vibration and heat. On the other hand, narrower tooth spacing can increase cutting forces, but it reduces vibration and heat. So, you have to balance these things based on what you need!