Imagine building a giant sandcastle at the beach. You need the right tools, right? The same idea applies to milling. Milling is like crafting with metal. But instead of sand shovels, we use milling tool holders. So, what makes these holders so vital?

Think about fitting pieces of a puzzle together. Without the right holder, the machine can’t cut metal precisely. Did you know that even a tiny wobbly tool can ruin a metal masterpiece? It’s like trying to draw straight lines with a shaky hand.

Milling tool holders keep everything steady. They hold the tools tightly for perfect cuts. This guide will take you through choosing the best holders. Are you ready to learn about the secret guardians of perfect metalwork? Let’s dive in!

Comprehensive Guide To Milling Tool Holders

Milling Tool Holders Guide

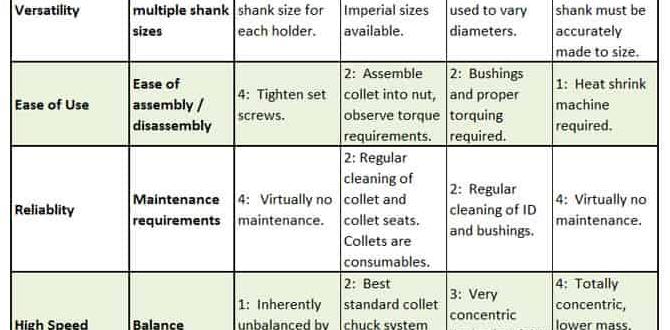

Have you ever wondered how machine shops stay precise? Milling tool holders make it happen! They keep drill bits and cutting tools secure and stable. Imagine playing a game of Jenga. The right tool holder keeps the stack from toppling. For beginners, understanding basic types like collet chucks and end mill holders helps. Did you know? Using the right holder reduces wear and tear on tools, keeping them sharp longer!How to Choose the Right Milling Tool Holder

Factors to consider when selecting a tool holder. Compatibility with different milling machines.Picking the perfect milling tool holder is like choosing the right shoes; it can make or break your workday! First, check if your tool holder is a good match for your milling machine; it’s a bit like ensuring your socks match your shoes. Next, consider factors like size, gripping power, and material. Oh, and don’t forget compatibility! No one likes it if the tool holder is dancing around while you’re working. Make sure everything fits snugly. Here’s a quick guide:

| Factor | Importance |

|---|---|

| Size | Ensures a tight fit |

| Gripping Power | Keeps tools steady |

| Material | Affects durability |

And remember, a well-chosen tool holder is like a trusty sidekick: always there to help! So, take your time picking the right one, and you’ll be a machining hero in no time. Compatibility with your equipment is key, so always double-check before buying.

Material Considerations for Tool Holders

Popular materials used in milling tool holders. Pros and cons of different material choices.Choosing the right material for milling tool holders is crucial for efficiency and durability. Some popular materials include steel, carbide, and titanium, each offering unique benefits. Steel is strong and cost-effective, but it may rust. Carbide is excellent for high-speed tasks but can be pricey. Titanium is lightweight and resistant to wear but might be less available. Understanding these pros and cons ensures picking the best fit for the job.

| Material | Pros | Cons |

|---|---|---|

| Steel | Strong, Cost-effective | Prone to rust |

| Carbide | High-speed efficiency | Expensive |

| Titanium | Lightweight, Wear-resistant | Less available, Costly |

In the words of an industry expert, “Selecting the right material can make or break a milling operation.” So, choose wisely, for the tool holder is like the miller’s trusty sidekick – crucially significant and sometimes, even more attractive!

Maintenance and Care of Tool Holders

Best practices for prolonging the lifespan of tool holders. Common maintenance tasks and their frequency.Keeping your tool holders in good shape is like giving them a spa day! Regular maintenance can help them live longer. First, always clean your tool holders after use. A quick wipe will keep dirt away, and nobody likes a grungy tool holder! Check for wear and tear every month. Tighten any loose screws before they decide to take a vacation on their own. Remember, a happy tool holder is a productive tool holder!

| Maintenance Task | Frequency |

|---|---|

| Clean tool holders | After every use |

| Inspect for wear | Monthly |

| Tighten screws | Before use |

Innovations and Trends in Milling Tool Holders

Recent advancements in tool holder technology. Emerging trends and their impacts on milling operations.New designs in milling tool holders are changing the game. These advancements make machining more precise and efficient. Smart technology helps tool holders adjust automatically. This means machines can work faster with fewer mistakes. Emerging trends include lightweight materials and eco-friendly options. These improvements not only save time but also cut costs. Here are some key points:

- Advanced materials boost durability.

- Automatic adjustments enhance precision.

- Eco-friendly options support sustainability.

What are some recent advancements in milling tool holders?

Recent advancements include smart technology that allows automatic adjustments and new materials that increase durability.

How do emerging trends impact milling operations?

These trends lead to faster machining and lower costs, making business operations more profitable.

Common Problems with Tool Holders and Solutions

Troubleshooting common issues faced with tool holders. Expert tips for resolving tool holder problems efficiently.Tool holders can be tricky! Sometimes they get stuck or wobble like they’re dancing at a party. To fix these problems, keep your tool holders clean and tight. If a tool is loose, it can mess up your work. Try replacing worn parts because they won’t hold tools well. Here’s a quick table for tips:

| Problem | Solution |

|---|---|

| Stuck tool holder | Use light tapping to free it up. |

| Wobbly tools | Check for dirt and tighten screws. |

| Wear and tear | Replace worn parts quickly! |

By staying on top of these issues, you’ll keep your milling tool holders happy and working well. Remember, a little care can save you a lot of hassle! And who wouldn’t want more time for snacks?

Safety Considerations with Tool Holders

Essential safety tips for using milling tool holders. Regulatory standards and compliance requirements.Using milling tool holders can be safe if you follow some simple steps. Always wear protective gear like goggles and gloves. Check your equipment regularly for any damage. Make sure everything fits correctly to prevent accidents. Follow your company’s rules to stay safe. It is also crucial to know the safety standards and regulations. This helps keep you and others safe.

- Wear proper personal protective equipment (PPE).

- Inspect tools and holders for damage.

- Ensure correct installation and compatibility.

- Follow safety regulations and guidelines.

What are the key safety tips for milling tool holders?

Always wear safety gear and keep your tools in good shape. Check your tools often and make sure they fit well. Following all safety rules helps ensure everyone’s safety.

Conclusion

Milling tool holders keep your tools steady and precise. Understanding their types helps you choose the right one. Using the right holder improves your work quality and tool lifespan. Try exploring different holders to find what works best for you. For more tips, read more guides or ask questions in technology forums. Happy milling!FAQs

Here Are Five Related Questions On The Topic Of Milling Tool Holders:Milling tool holders are parts that keep cutting tools in place while they work. They help hold the tool tight so it doesn’t move. You can change them easily when you need a different tool. This way, you can do different jobs with the same machine. They are important for making sure everything works smoothly.

Sure! Please provide me with the question you’d like me to answer.

What Are The Different Types Of Milling Tool Holders And How Do They Vary In Design And Application?Milling tool holders are special devices that hold cutting tools in machines. There are a few types, like collet chucks, end mill holders, and face mill holders. Collet chucks grip tools tightly and are good for small jobs. End mill holders hold bigger tools and are great for heavy work. Face mill holders can hold multiple blades, making them useful for wide surfaces. Each type is made for different tasks, depending on what you need to cut or shape.

How Do You Properly Install And Secure A Milling Tool Holder To Ensure Optimal Performance During Machining?First, make sure the milling tool holder is clean and free of dirt. Then, put the tool holder into the machine’s spindle. Tighten it securely using the right wrench. Always check if it’s tight by giving it a little tug. Finally, test the machine to see if everything works smoothly before you start working.

What Factors Should Be Considered When Selecting A Milling Tool Holder For Specific Materials Or Cutting Operations?When choosing a milling tool holder, you should think about the material you’re cutting. Different materials need different tools. You also need to consider the type of work you’re doing. Some tools work better for fine details, while others are good for heavy cuts. Finally, make sure the holder fits well with your machine.

How Do Milling Tool Holders Impact The Accuracy And Surface Finish Of The Machined Components?Milling tool holders keep cutting tools steady while they work. When they’re strong and tight, they help cut shapes more accurately. This means the parts we make look smoother and nicer. If the tool holder is loose, the cuts can be wobbly, and the surface can look rough. So, good tool holders help us make better parts!

What Are The Common Maintenance Practices For Milling Tool Holders To Prolong Their Lifespan And Maintain Precision?To keep milling tool holders working well, you should clean them after each use. This helps remove dirt and chips. You can also check for any damage, like scratches or dents. Regularly tighten any loose parts to ensure everything stays in place. Finally, store them in a dry place to prevent rust.