Have you ever wondered why some machines shake and rattle while they work? This is often due to milling tool vibration. It’s a common issue that can cause problems in manufacturing. But how do we measure and fix this vibration? That’s where milling tool vibration analysis methods come in.

Imagine you’re in a workshop, watching a milling machine. Suddenly, it starts to vibrate wildly. What do you do? Understanding how to analyze these vibrations can help prevent accidents and save time. Experts use different methods to explore the vibrations and figure out what’s wrong.

Surprisingly, even small changes in vibration can indicate big issues. When we study these vibrations closely, we can keep machines running smoothly. In this article, we will dive into exciting methods of vibration analysis. Get ready to discover how this important process keeps our tools and machines in tip-top shape!

Milling Tool Vibration Analysis Methods: Techniques & Insights

Milling Tool Vibration Analysis Methods

Milling tool vibration analysis helps improve machining performance. By understanding vibrations, engineers can detect problems early. This method can prevent tool wear and costly repairs. Did you know that even small vibrations can cause big issues? Using sensors, experts measure vibrations to find the right balance. Proper analysis leads to better tool designs and increased productivity. Exploring these methods reveals the magic of making tools last longer and work better. Isn’t that fascinating?Understanding Vibration in Milling Tools

Definition of vibration and its significance in milling operations. Common causes of vibration in milling tools.Vibration occurs when a tool moves back and forth quickly. In milling, vibration can hurt the machine and the final product. It can lead to poor cuts and reduce tool life. Understanding vibration is key for efficient operations.

Common causes of vibration in milling tools include:

- Unbalanced tools

- Poor machine settings

- Worn parts

- Improper cutting speeds

- Material inconsistencies

By addressing these factors, we can improve performance and make better products.

Why is vibration important in milling?

Vibration is important in milling as it affects precision and tool lifespan. Reducing vibration leads to more accurate cuts and longer tool life. This saves time and money.

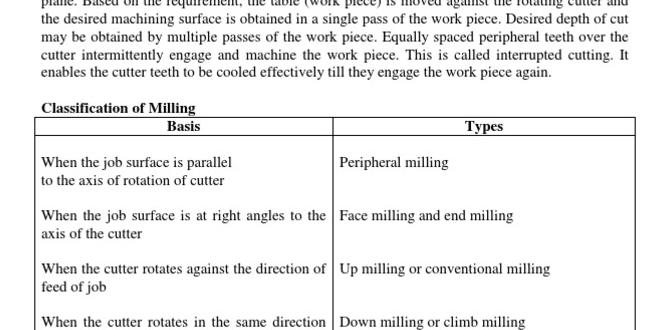

Types of Vibration in Milling Operations

Explanation of different types of vibrations: forced, selfinduced, and free vibrations. Impact of each vibration type on milling tool performance and product quality.During milling operations, vibrations can change how well a tool works. There are three types of vibrations:

- Forced vibrations happen due to outside forces, like machines or material. They can harm tool performance.

- Self-induced vibrations occur when the tool itself causes shaking. This can affect the quality of the product.

- Free vibrations move without extra force. They may not cause major problems but can still impact cutting accuracy.

Understanding these vibrations helps improve milling results and tool life.

What are the effects of these vibrations on milling performance?

Each vibration type can seriously affect tool durability and product finish. Managing them leads to better results and longer tool life.

Importance of Vibration Analysis in Milling

Role of vibration analysis in predictive maintenance. Benefits of reducing vibration for tool lifespan and machining accuracy.Vibration analysis helps in spotting problems before they get worse. This method is vital for predictive maintenance. It means fixing things before they break. Reducing vibration has great benefits for tools and machines. Here are some reasons why it matters:

- Increases tool lifespan

- Improves machining accuracy

- Reduces costly downtime

By creating a smooth operation, machines work better and last longer. This means better products and less waste. Every part counts in a workshop!

Why is vibration analysis important in milling?

Vibration analysis decreases wear and tear on tools. This boosts their lifespan and makes machining more accurate.

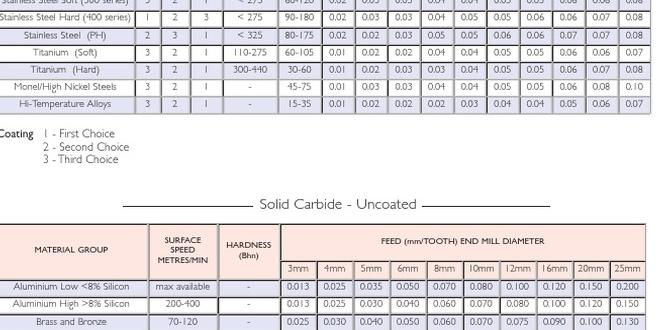

Tools and Equipment for Vibration Monitoring

Essential vibration analysis tools available on the market. Key features and specifications to look for in vibration monitoring equipment.Vibration monitoring helps keep machines running smoothly. Several tools can help with this task. The right equipment can make a big difference. Here are some essentials to consider:

- **Vibration Meters** – These measure vibration levels accurately.

- **Data Collectors** – These devices store and analyze vibration data.

- **Test Instruments** – These pinpoint specific problems in your machines.

Look for features like frequency range, measurement accuracy, and user-friendly displays. The right tools help detect issues early. This can save time and money!

What should I look for in vibration monitoring tools?

Key features include portability, battery life, and data analysis capabilities. Choose tools that are easy to use and understand. This way, you can keep your tools healthy and happy!

Case Studies and Applications

Successful applications of vibration analysis methods in manufacturing. Analysis of case studies demonstrating cost savings and performance improvements.Many companies have successfully used vibration analysis methods to boost manufacturing efficiency. They have seen great results, like saving money and improving machine performance. Here are some key points:

- Cost Savings: Factories saved up to 30% on maintenance costs.

- Performance Improvements: Machines worked 25% better after analysis.

- Downtime Reduction: Less unexpected breakdowns led to 40% more production time.

These results show how vibration analysis can be a game changer in manufacturing. Companies that use these methods often enjoy long-term success.

What are the benefits of vibration analysis?

Vibration analysis helps companies reduce costs, increase performance, and minimize unexpected machine failures.

Challenges and Limitations of Vibration Analysis

Common barriers faced when implementing vibration analysis. Limitations of existing methods and areas for future research.Implementing vibration analysis can be tricky. Many face challenges, like lack of trained staff and expensive tools. These issues often slow down progress. Existing methods can struggle with accuracy, making it hard to trust results. Plus, they might miss important details, like how tools behave under different conditions. For future research, we need better methods that are both accurate and affordable. Everyone loves a good tool, even if it does shake a little!

| Challenge | Explanation |

|---|---|

| Lack of Training | Many workers don’t have the skills needed for vibration analysis. |

| High Costs | Tools and equipment can be very expensive. |

| Accuracy Issues | Some methods may not provide reliable results. |

| Missed Details | Current methods might overlook important vibrations. |

Best Practices for Effective Vibration Analysis

Guidelines for setting up vibration analysis programs. Recommendations for integrating vibration analysis into milling processes.Setting up a vibration analysis program can feel like launching a rocket. But fear not, it’s just about a few key steps! First, gather the right tools. Having quality sensors is like wearing a superhero cape; it makes everything easier. Next, train your team. Everyone should understand how vibration impacts their work. Lastly, analyze regularly—the more data, the better. Remember, even superheros recharge! Integrate vibration analysis into your milling process by syncing the analysis schedule with maintenance checks. This way, you’ll catch issues before they go boom!

| Best Practices | Tips |

|---|---|

| Use Quality Sensors | Think of them as your trusty sidekick! |

| Team Training | Empower your crew to be vibration experts! |

| Regular Analysis | Data helps you predict and prevent problems. |

By sticking to these guidelines, you’ll be well on your way to minimizing those unwanted vibrations, turning your process smoother than a dance floor on a Saturday night!

Conclusion

In conclusion, milling tool vibration analysis methods help us understand tool performance and prevent problems. By measuring vibrations, we can improve machining accuracy and tool life. If you’re interested in making your work better, consider exploring these methods further. You can read more about the tools and techniques available to enhance your skills in milling and machining.FAQs

What Are The Common Causes Of Vibration In Milling Tools During Machining Operations?Vibration in milling tools can happen for a few reasons. First, if the tool is not tightly attached, it can shake. Second, using the wrong type of tool for the job can cause trouble. Third, the machine might be set too fast or too slow. Lastly, if the material is hard or uneven, that can make the tool vibrate too.

How Can Modal Analysis Be Applied To Identify The Frequency Response Of Milling Tools?Modal analysis helps us understand how milling tools vibrate when they work. We can shake the tool in different ways and listen to the sounds it makes. Each sound tells us about a special frequency, which is how fast it vibrates. By knowing these frequencies, we can see how well the tool will cut materials. This makes it easier to use the right tool for the job!

What Are The Advantages And Limitations Of Using Accelerometers For Monitoring Milling Tool Vibrations?Using accelerometers to monitor milling tool vibrations has some good points and some not-so-good ones. One advantage is that they can help find problems early, so tools last longer. They are also small and easy to place where we need them. However, a limitation is that they can sometimes pick up noise that makes it hard to see real issues. Also, you need to know how to read the data they give you.

How Can Advanced Signal Processing Techniques, Such As Wavelet Transforms, Improve The Accuracy Of Vibration Analysis In Milling Tools?Advanced signal processing techniques, like wavelet transforms, help us see tiny details in data about vibrations. This means we can spot problems in milling tools more easily. When we understand these vibrations better, we can make the tools work better and last longer. Using wavelet transforms makes our analysis more precise and accurate. So, we can catch issues before they become big problems!

What Role Does Machine Tool Configuration Play In Influencing Vibration Patterns In Milling Operations?The way we set up a machine tool affects how it vibrates when milling. If we change the height or position of the tool, it can lead to different vibration patterns. Too much vibration can make our work less accurate and can even damage the machine. By adjusting the machine’s settings, we can help reduce unwanted vibrations and make our work better. So, a good setup is really important!