Quick Summary:

Unlock precision woodworking with mini wood lathe accessories! Essential upgrades like better chucks, specialized toolrests, and accurate measuring tools drastically improve accuracy, safety, and project quality. Investing in a few key accessories is the smartest way to elevate your turning skills and create flawless pieces for any project.

Hey there, fellow makers! Daniel Bates here from Lathe Hub. Are you diving into the wonderful world of mini wood lathes and finding your results aren’t quite hitting the mark? Maybe your tenons are a bit wobbly, or precise measurements feel like guesswork. It’s a common hurdle for beginners, but the good news is, it’s easily overcome! With the right mini wood lathe precision accessories, you can transform frustration into finesse. We’re going to explore some genius essentials that will boost your accuracy, enhance safety, and make turning those dream projects a whole lot easier.

Transforming Your Mini Lathe: Why Precision Accessories Matter

A mini wood lathe is a fantastic starting point for any woodworking hobbyist. It’s compact, relatively affordable, and capable of creating beautiful turned items. However, the standard accessories that come with many entry-level lathes are often basic. This can limit the precision you can achieve, making tasks like creating perfectly fitting tenons and shoulders, or turning complex curves, a real challenge. Investing in a few key precision accessories isn’t about showing off; it’s about giving yourself the tools you need to succeed. These accessories are designed to enhance control, improve accuracy, and crucially, boost safety. Think of them as upgrades that pay for themselves in better-looking projects and a more enjoyable turning experience.

Your Essential Mini Wood Lathe Precision Accessories Toolkit

Let’s get down to brass tacks. What are the absolute must-have accessories to make your mini wood lathe sing? I’ve handpicked a few that have made a significant difference in my own workshop and for countless beginners I’ve guided. These aren’t fancy gadgets; they are practical tools that solve common problems and unlock new levels of detail and accuracy.

1. The Superior Lathe Chuck: Your Workholding Game Changer

If there’s one accessory that offers the biggest bang for your buck in terms of precision and versatility, it’s a quality lathe chuck. The standard faceplate, often included with mini lathes, is fine for very basic work, but it lacks the adaptability and gripping power for more intricate turning. A chuck allows you to securely hold a variety of workpiece sizes and shapes, and its design often offers much more accurate centering.

What is a Lathe Chuck?

At its core, a chuck is a device used to grip and rotate your workpiece on the lathe spindle. Unlike a simple faceplate, a chuck uses jaws that can be expanded or contracted simultaneously to grip the wood from the inside (internal grip) or around the outside (external grip). This provides a much more secure and centered hold.

Types of Chucks for Mini Lathes:

- Scroll Chucks: These are the most common type and are excellent for beginners. They feature jaws that move in unison, driven by a scroll mechanism. They’re versatile for both internal and external gripping and come in various jaw sizes. Look for models with at least 4 jaws for maximum security.

- Cole Jaws: While not standalone chucks, these jaw attachments can be fitted to scroll chucks to provide even greater gripping surface and capacity, especially for larger or irregularly shaped pieces.

Why a Good Chuck Boosts Precision:

- Accurate Centering: Chucks are designed for precise alignment between the lathe spindle and the workpiece. This means your turning operations will be centered correctly from the start.

- Secure Grip: A well-designed chuck grips your wood firmly, reducing vibration and the risk of the workpiece coming loose. This is crucial for safety and for achieving clean cuts.

- Versatile Holding: Chucks allow you to easily mount face-to-face, between centers (using drive dogs), and by gripping internal or external tenons. This adaptability is key for turning bowls, spindles, and other projects.

When choosing a chuck, ensure it’s compatible with your lathe’s spindle thread size. Many mini lathes use common thread sizes like 1” x 8 TPI or 3/4” x 16 TPI. Always check your lathe’s specifications. Brands like Robert Sorby, Nova (Teknatool), and Record Power offer excellent options for mini lathes.

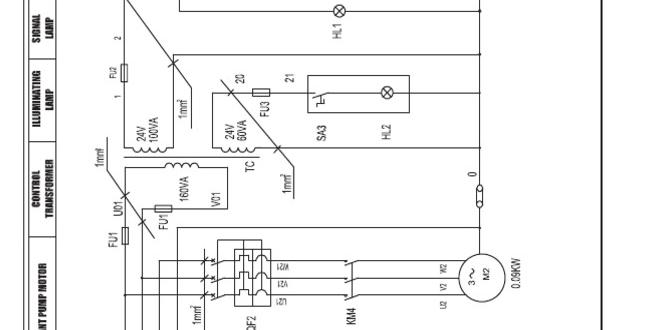

2. Specialized Tool Rests: The Foundation of Steady Cuts

The basic tool rest that comes with most mini lathes is often a simple straight bar. While sufficient for rough turning, it can make achieving smooth, controlled cuts difficult, especially for beginners. Specialized tool rests offer better support, greater maneuverability, and can be positioned more precisely relative to your workpiece.

Why Tool Rests Matter for Precision:

- Ergonomics and Control: A well-designed tool rest positions your gouge or chisel at the optimal angle and height, allowing for more controlled movements and fewer catches.

- Smoothness: Better support under your tool leads to smoother cuts and reduces the chance of chatter marks on your turned piece.

- Versatility for Different Shapes: Beyond just a straight bar, specialized rests can accommodate curved shapes or allow for more nuanced angling.

Key Tool Rest Accessories:

- Curved Tool Rests: These are essential for turning bowls and hollow forms. They allow you to get closer to the workpiece and maintain the correct tool angle for hollowing and shaping the exterior.

- Offset Tool Rests: These unique rests allow you to position your tool rest further away from the spindle axis, which can be incredibly useful for turning very large diameter bowls or platters on a mini lathe. They provide clearance and better support.

- Micro-Adjustable Tool Rests: For ultimate precision, some rests offer fine adjustments in height and angle, allowing you to dial in the perfect position for critical cuts like tenons or shoulders.

Always ensure your tool rest is positioned correctly – the top of the rest should be slightly below the centerline of your workpiece when turning between centers, and slightly above the cutting edge of your tool when working at the top of the cut. For bowl turning, the rest is typically positioned closer to the bowl’s exterior. Never turn with the tool rest too high, as this increases the risk of a catch. The Woodturners Guild of New Zealand offers excellent safety guidelines, which include proper tool rest setup.

3. Drive Centers and Live/Spur Centers: Getting Started Securely

To turn spindles or to use the “between centers” method, you’ll need to hold your wood between the headstock and tailstock. The basic spur drive center can work, but more advanced options offer better grip and less damage to the wood.

Drive Centers:

- Spur Drive Center: This is the most common type, with a cone and one or two spurs that bite into the wood. It’s effective but can leave significant marks.

- Cole Jaws (as Drive Tenons): As mentioned with chucks, Cole Jaws can also be used to create a tenon on your workpiece that a chuck can grip for spindle turning.

- Self-Ejecting Drive Centers: Some drive centers have a mechanism that helps to release the workpiece more easily than standard ones.

Live vs. Spur Centers (Tailstock End):

- Live Center: This center rotates with your workpiece held in the tailstock. This dramatically reduces friction, prevents the wood from being scored, and makes it easier to reposition or remove the workpiece. It’s a huge upgrade for precision and convenience.

- Spur Center (Tailstock): Similar to the drive center, this bites into the wood. It’s less ideal for long-term holding or frequent adjustments due to friction and potential damage.

Using a live center on the tailstock end is highly recommended for any turning that involves holding between centers. It ensures smooth rotation without binding, which is paramount for precise cuts on spindles, tool handles, and table legs.

4. Calipers and Measuring Tools: Precision in Every Dimension

Precision isn’t just about how securely you hold your wood; it’s also about achieving the exact dimensions you need. Basic measuring with a tape measure can be tricky when the piece is spinning. Specialized measuring tools designed for lathes make a world of difference.

- Calipers:

- Outside Calipers: Used to measure the outside diameter of your workpiece. Essential for checking tenon sizes for lids, glue-up joints, or achieving uniform diameters on spindles.

- Inside Calipers: Used to measure internal diameters, such as the inside of bowls or the size of dowels you need to fit.

- Bow Dividers: These look like large compasses with pointed ends and are fantastic for transferring measurements, marking out diameters, or laying out precise spacing. Many turners use them to set the inside diameter of bowls before hollowing.

- Digital Calipers: While not lathe-specific, high-quality digital calipers are invaluable. You can stop the lathe, measure precisely, and mark your workpiece or adjust your tool rest and tools. They offer dead-on accuracy for everything from tenon depth to overall piece dimensions.

- Depth Gauge: For turning items like bowls, knowing how thin the walls are is critical. A simple depth gauge or a laser-liner can help you monitor wall thickness accurately.

The key here is consistency. If you need a tenon to be precisely 1 inch in diameter for a lid, calipers are your best friend. They allow you to measure and scrape/turn until you hit that exact dimension, ensuring a perfect fit every time. Resources from woodworking guilds often emphasize accurate measurements for joinery and fitting.

5. Lathe-Specific Sanding and Finishing Tools

Achieving a smooth, flawless finish is often the final hallmark of precision turning. Standard sandpaper can be awkward to use effectively on a spinning workpiece, leading to uneven sanding patterns or potential burns. Specialized tools make this process much easier and more effective.

- Sanding Jigs/pads: These are often rubber or foam pads that you can hold against the spinning wood. You wrap sandpaper around them, providing an even surface and good control. Some are designed to hold sandpaper strips, others have hook-and-loop surfaces for PSA (pressure-sensitive adhesive) discs.

- Detail Sanding Tools: For smaller or intricate areas, smaller sanding blocks or even specialized rotary sanding attachments for drills can be used, though be cautious with drill attachments on a lathe!

- Finishing Applicators: Tools designed to apply finishes evenly, such as specialized wands or applicators that can be held against the wood.

The goal with sanding is to remove tool marks and achieve a consistent surface across the entire turned piece. Using proper sanding techniques and tools, like those mentioned, ensures that your workpiece is smooth and ready for finishing, highlighting the hours of careful turning you’ve put in.

Table: Accessory Comparison for Precision Turning

Here’s a quick look at how these essential accessories stack up in terms of their impact on precision and versatility:

| Accessory | Primary Precision Benefit | Versatility Factor | Beginner Recommendation Level |

|---|---|---|---|

| Quality Lathe Chuck | Accurate centering, secure grip | High (various holding methods) | Essential (Highest Priority) |

| Curved/Offset Tool Rests | Controlled cuts on complex shapes | Medium (for bowls/platters) | High (especially for bowls) |

| Live Center (Tailstock) | Smooth, friction-free rotation | High (for spindle work) | Essential |

| Bow Dividers/Calipers | Precise dimensioning and marking | High (general woodworking) | Essential |

| Specialized Sanding Tools | Even surface finishing, no burn marks | Medium (finishing process) | Highly Recommended |

Advanced Precision: Beyond the Basics

Once you’ve got the core precision accessories, you might want to explore even more specialized tools that can refine your work further. These are often for those who are getting very serious about specific types of turning or want to achieve an almost machine-like finish.

- Templated Cutters (for Bowls): Some turners use templates and specialized cutters to achieve very consistent interior profiles in bowls.

- Bowl Gouge and Spindle Gouge Grinding Jigs: While not directly on the lathe, ensuring your turning tools are ground to the correct, consistent bevel angles is CRITICAL for precision. Grinding jigs ensure that your tools perform predictably every time. Check out resources from tool manufacturers like Robert Sorby for guidance on tool geometry.

- Lathe Face Shield and Dust Collection: Safety and health are paramount. While not directly for precision in turning, a good face shield prevents injury that could end your turning career. Dust collection helps you see your work clearly and breathes easier. A clean workshop is a precise workshop.

Safety First: Always!

I can’t stress this enough – safety is the most important accessory you can bring to your lathe. Precision and beautiful results mean nothing if you haven’t protected yourself. Before investing in any new accessory, ensure you understand how it works and how it impacts your safety procedures.

Always:

- Wear a safety face shield or goggles.

- Use a dust mask or respirator.

- Ensure your tool rest is positioned correctly and securely.

- Lock the tailstock when needed.

- Keep your tools sharp. Dull tools are dangerous and produce poor results.

- Never wear gloves when operating a lathe – they can get caught and pull you in.

- Mount workpieces securely.

- Stand to the side of the turning path, not directly in front of it.

Understanding and practicing safe lathe operation is the bedrock upon which all precision turning is built. Organizations like the Occupational Safety and Health Administration (OSHA) provide guidelines for machine safety that are applicable in workshop settings.

FAQ: Your Mini Lathe Precision Accessory Questions Answered

What is the single most important accessory for improving precision on a mini wood lathe?

For most beginners, a quality lathe chuck is the most impactful accessory for precision. It provides a much more secure and accurately centered grip on your workpiece compared to a basic faceplate, dramatically improving stability and reducing wobble for cleaner cuts.

Do I really need specialized tool rests, or is the one that came with my lathe good enough?

While the standard tool rest can be used, specialized rests like curved ones for bowls offer significantly better support and control. This allows for smoother cuts, reduces the risk of catching the tool, and makes it easier to achieve the desired shapes and finishes, thus improving your precision.

How do calipers help with precision turning?

Calipers (both outside and inside) allow you to measure your workpiece’s dimensions accurately while the lathe is stopped. This is crucial for ensuring repeatable sizes, creating perfectly fitting tenons, maintaining consistent diameters on spindles, or achieving exact wall thicknesses on bowls.

Is it better to buy a chuck with 3 jaws or 4 jaws?

For mini wood lathes, a 4-jaw scroll chuck is generally recommended. The four jaws move independently or in sets, providing more versatility in gripping various workpiece shapes, including round, square, and irregular forms. They offer a more secure and often more precise grip than basic 3-jaw scroll chucks.

When should I consider upgrading my drive center?

If you do a lot of spindle turning (items longer than they are wide), consider upgrading from a basic spur