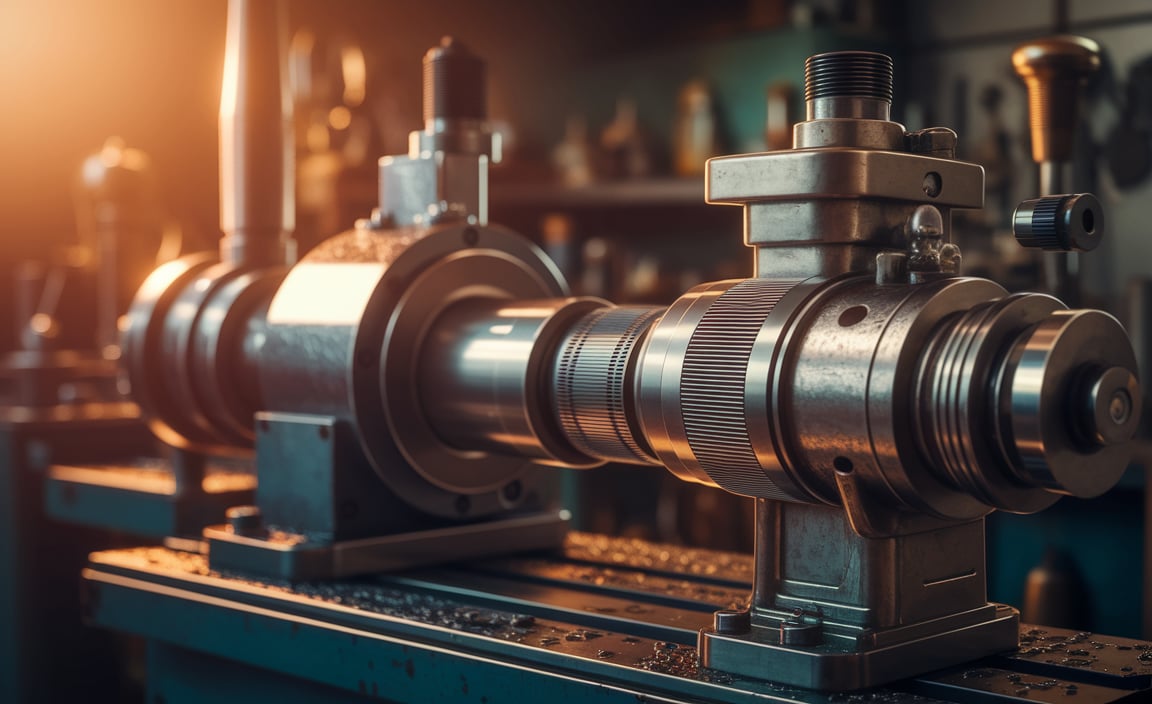

Have you ever wondered how machines create precise parts we see every day? It’s fascinating! One key player in this process is the precision metal lathe. But what if your old lathe could work like a brand-new CNC machine? That’s where the idea of a CNC retrofit comes in.

Imagine you have an old metal lathe sitting in your garage. It has served you well, but it’s not as efficient as newer models. You might think it’s time to buy a new one. However, what if you could upgrade it? A CNC retrofit allows you to update your old lathe. This makes it faster and more accurate without the cost of a brand-new machine.

Many people don’t realize how easy it can be to breathe new life into their machines. With a CNC retrofit, you can enhance your precision metal lathe. It can cut better, last longer, and save money in the long run. Isn’t that exciting? Let’s explore how this upgrade can transform your workshop!

Precision Metal Lathe Cnc Retrofit: Enhancing Accuracy Today

Discover how a precision metal lathe CNC retrofit can transform your machining experience. This upgrade enhances accuracy and efficiency, making it easier to create intricate parts. Imagine cutting down production time while boosting your output! Many users report smoother operations and reduced wear on tools. A CNC retrofit is not just a tech upgrade; it’s a game changer for hobbyists and professionals alike. It opens a world of possibilities for creative projects and engineering solutions. Why not explore the benefits today?

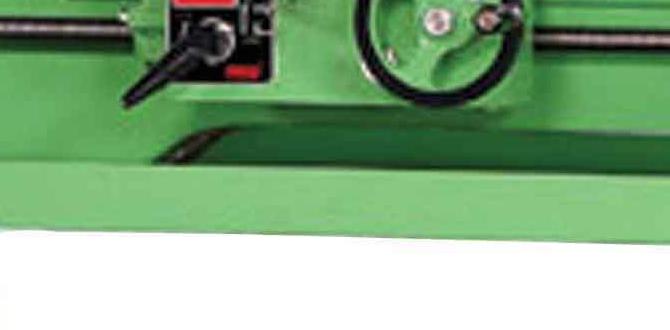

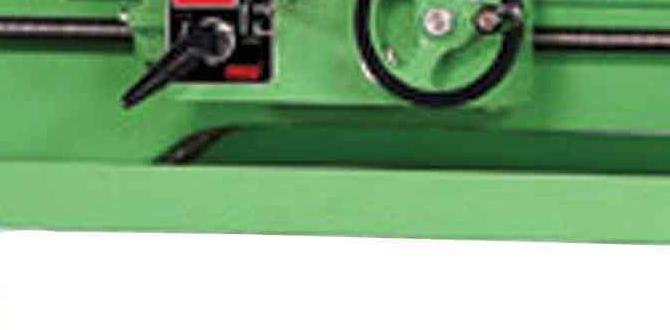

Understanding Precision Metal Lathes

Definition and purpose of precision metal lathes. Key features that set precision lathes apart from standard lathes.

Precision metal lathes are machines that create precise shapes from metal. They spin the metal while cutting tools shape it. These lathes are important for making small, detailed parts for machines and tools. They stand out because of their accuracy and speed. Here are some key features:

- High precision: They can create very exact measurements.

- Advanced controls: They use digital technology for better adjustments.

- Durable materials: Made from strong metals that last longer.

These features help make precision lathes essential for many industries.

What makes precision metal lathes important?

They are vital for producing high-quality parts that need exact specifications while saving time and effort.

Benefits of CNC Retrofit for Metal Lathes

Improved accuracy and repeatability in machining. Enhanced productivity and reduced labor costs. CNC retrofitting for metal lathes is a game changer! It boosts accuracy and makes every cut precise, like a chef slicing a perfect tomato. This means parts fit together like puzzle pieces, reducing mistakes. With enhanced efficiency, you can churn out more products in less time, just like a hamster on a wheel—but way less sweaty! Plus, you’ll save big on labor costs since fewer workers are needed. Now, let’s look at how this all adds up:

| Benefit | Impact |

|---|---|

| Improved Accuracy | Less mistakes in machining |

| Enhanced Productivity | More items produced per hour |

| Reduced Labor Costs | Fewer workers required |

Key Components of a CNC Retrofit Kit

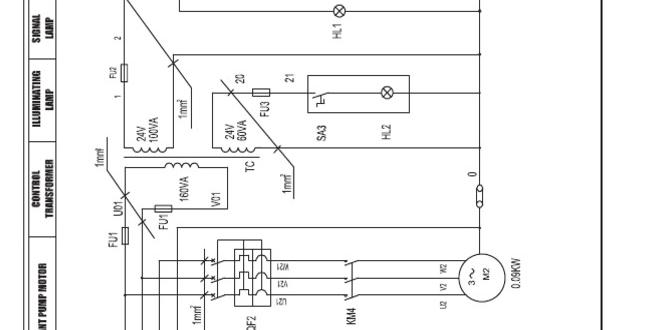

Essential hardware: motors, control units, and sensors. Software requirements and compatibility.

Setting up a CNC retrofit kit requires key parts to make everything work well. First, you’ll need motors for smooth movement. Control units manage how the lathe operates, while sensors help track the machine’s position. For software, ensure it matches your hardware. It guides the lathe’s actions and must be easy to use.

- Motors: Provide power for movement.

- Control Units: Direct operations.

- Sensors: Monitor position.

Finding software that fits is crucial. It should connect easily with the hardware to ensure everything runs smoothly.

What software do I need for a CNC retrofit?

Proper software is essential for effective CNC operation. It must work well with your motors and control units. Look for user-friendly options for the best results.

The CNC Retrofit Process Explained

Stepbystep guide to retrofitting a precision metal lathe. Common pitfalls and how to avoid them.

Retrofitting a precision metal lathe can seem tricky, but it helps improve its performance. Here’s a simple guide to make it easier:

- Start by taking apart the lathe carefully.

- Next, install the CNC components.

- Connect the electronics and wires.

- Test each part to ensure it works well.

- Finally, calibrate the machine for precise settings.

Watch out for common mistakes. Don’t rush, as wrong connections can lead to errors. Always double-check instructions to avoid setbacks. Plan ahead to make the process smooth.

What are common pitfalls in the CNC retrofit process?

Common pitfalls include incorrect wiring, skipping steps, or rushing the calibration. Always take your time and follow each step carefully.

Choosing the Right Retrofit Kit

Factors to consider: machine specifications, user experience, and budget. Comparison of popular retrofit kits on the market.

Selecting a retrofit kit is not as tricky as finding your lost key in a couch! First, think about your machine’s specifications. Every lathe has unique features, and matching them is crucial. Next, consider your experience level; some kits might feel like rocket science! Finally, let’s talk budget—who wants to break the bank? Here’s a quick comparison of popular kits:

| Kit Name | Features | User Level | Price |

|---|---|---|---|

| Kit A | High speed, easy install | Beginner | $300 |

| Kit B | Advanced control options | Intermediate | $600 |

| Kit C | Top-notch durability | Expert | $900 |

Pick wisely, or you might end up with a fancy paperweight instead of a precision powerhouse!

Maintenance Tips for Retrofitted CNC Lathes

Regular checks and calibration techniques. Troubleshooting common issues encountered. Keeping your retrofitted CNC lathe in top shape is key to smooth operations. Regular checks can save you from headaches later. Check belts, lubricants, and all screws. Don’t forget to calibrate! A well-calibrated lathe is like a well-tuned piano — music to your ears!

Common troubles? They happen! If your lathe starts to misbehave, look for loose connections or worn out parts. Sometimes a little cleaning or tightening can solve big problems. Remember, even machines need a tune-up!

| Issue | Quick Fix |

|---|---|

| Unusual noises | Check for loose parts |

| Inaccurate cuts | Recalibrate the settings |

| Overheating | Ensure there’s proper lubrication |

Real-life Case Studies

Success stories from businesses that improved efficiency through retrofitting. Lessons learned and insights from retrofitting projects.

Many businesses have seen great success by retrofitting machines. For example, a small factory improved its output by 30% after upgrading its equipment. Retrofitting helps companies save time and money. Key lessons include:

- Invest in quality parts.

- Train staff for new processes.

- Regular maintenance boosts efficiency.

These changes can lead to better productivity and happier employees! Many factories are now excited to share their stories of success.

What are the benefits of retrofitting?

Retrofitting brings many benefits. It can reduce waste and improve production speeds. Companies often report a boost in profits and employee satisfaction. By updating their machines, businesses stay competitive in their industries.

The Future of CNC Technology in Metalworking

Emerging trends in CNC retrofitting and automation. Predictions for developments in precision metal lathes and CNC systems. “`html

Technology in metalworking is changing faster than you can say “precision metal lathe CNC retrofit”! Automation is becoming the new best friend of CNC machines. Industries are now excited about retrofitting older machines. This makes them smarter and faster without breaking the bank. Experts predict that future lathes will not only be precise but also super smart, maybe even capable of telling jokes! Imagine your lathe saying, “I’m not just cutting metal; I’m reshaping the future!”

| Emerging Trends | Future Predictions |

|---|---|

| Increased Automation | Smarter, more intuitive machines |

| Integration with AI | Enhanced predictive maintenance |

| Retrofit Upgrades | More efficient production processes |

With so many exciting changes on the way, the world of CNC is set to become a vibrant dance floor where efficiency and fun meet!

“`

Conclusion

In conclusion, a precision metal lathe CNC retrofit upgrades your machine for better accuracy and efficiency. You gain modern technology without buying a new lathe. This change helps you create high-quality parts faster. If you’re curious about retrofitting, research your options and consider talking to an expert. This upgrade can boost your skills and projects!

FAQs

What Are The Key Components Needed For Retrofitting A Precision Metal Lathe With Cnc Capabilities?

To upgrade a metal lathe to CNC, you need a few important parts. First, get a computer to control the lathe. Next, you’ll need motors that move the tools and the lathe itself. Don’t forget sensors to help position everything correctly. Finally, you’ll need special software to tell the computer how to do the work.

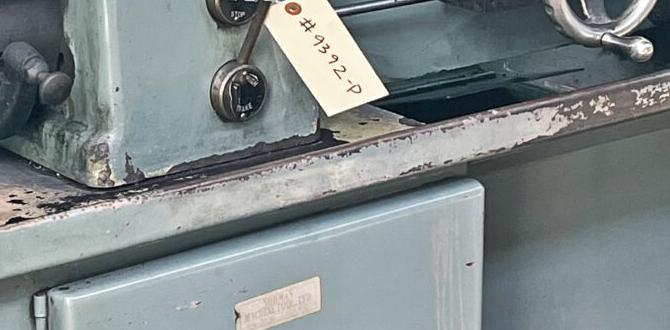

How Can I Assess Whether My Existing Metal Lathe Is A Suitable Candidate For A Cnc Retrofit?

To see if your metal lathe can be changed to a CNC (Computer Numerical Control) machine, start by checking its size and weight. A solid and heavy lathe is better for a retrofit. Next, look at its current features. If you already have good motors and parts, it’s a plus. Finally, check if you can find a CNC kit that fits your lathe model easily.

What Are The Advantages And Disadvantages Of Retrofitting An Older Lathe Versus Purchasing A New Cnc Lathe?

Retrofitting an older lathe means you upgrade it with new parts. It’s usually cheaper than buying a new CNC lathe. You get to keep a machine you already know how to use. However, it might not work as well as a brand-new one. A new CNC lathe is often faster and has better features, but it costs more money. So, you have to decide what’s best for you!

What Software Options Are Recommended For Controlling A Retrofitted Cnc Metal Lathe?

For a retrofitted CNC metal lathe, we can use software like Mach3 or LinuxCNC. Mach3 is easy to use and great for beginners. LinuxCNC is free and works well with many machines. Both help control how the lathe moves to cut metal accurately. You should choose the one that you find easiest to use.

What Common Challenges Should I Expect During The Cnc Retrofit Process Of A Precision Metal Lathe?

During the CNC (Computer Numerical Control) retrofit of your metal lathe, you might face a few challenges. First, fitting new parts can be tricky; they need to match perfectly. Second, making sure the software works smoothly with your old machine can be hard. Lastly, learning to use the new controls may take time. Be patient, and ask for help if you need it!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Components Needed For Retrofitting A Precision Metal Lathe With Cnc Capabilities? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To upgrade a metal lathe to CNC, you need a few important parts. First, get a computer to control the lathe. Next, you’ll need motors that move the tools and the lathe itself. Don’t forget sensors to help position everything correctly. Finally, you’ll need special software to tell the computer how to do the work.”}},{“@type”: “Question”,”name”: “How Can I Assess Whether My Existing Metal Lathe Is A Suitable Candidate For A Cnc Retrofit? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To see if your metal lathe can be changed to a CNC (Computer Numerical Control) machine, start by checking its size and weight. A solid and heavy lathe is better for a retrofit. Next, look at its current features. If you already have good motors and parts, it’s a plus. Finally, check if you can find a CNC kit that fits your lathe model easily.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Retrofitting An Older Lathe Versus Purchasing A New Cnc Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Retrofitting an older lathe means you upgrade it with new parts. It’s usually cheaper than buying a new CNC lathe. You get to keep a machine you already know how to use. However, it might not work as well as a brand-new one. A new CNC lathe is often faster and has better features, but it costs more money. So, you have to decide what’s best for you!”}},{“@type”: “Question”,”name”: “What Software Options Are Recommended For Controlling A Retrofitted Cnc Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a retrofitted CNC metal lathe, we can use software like Mach3 or LinuxCNC. Mach3 is easy to use and great for beginners. LinuxCNC is free and works well with many machines. Both help control how the lathe moves to cut metal accurately. You should choose the one that you find easiest to use.”}},{“@type”: “Question”,”name”: “What Common Challenges Should I Expect During The Cnc Retrofit Process Of A Precision Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “During the CNC (Computer Numerical Control) retrofit of your metal lathe, you might face a few challenges. First, fitting new parts can be tricky; they need to match perfectly. Second, making sure the software works smoothly with your old machine can be hard. Lastly, learning to use the new controls may take time. Be patient, and ask for help if you need it!”}}]}