Have you ever wished you could stop your metal lathe quickly? A foot brake can help you do just that. It’s not just about safety; it also makes your work easier. Imagine working on a project and suddenly having a way to halt everything with a tap of your foot.

Setting up a metal lathe foot brake might seem tricky at first. But with the right setup guide, it can be simple. Many people get surprised by how helpful this tool can be in their workshops.

Have you heard that a well-installed foot brake can improve your accuracy? It lets you focus on your work without worrying about slowing down the lathe by hand. This setup guide will walk you through everything you need to know.

Get ready to boost your lathe experience. Learning how to properly setup a metal lathe foot brake can be a game changer. Are you ready to dive in?

Complete Setup Guide For Metal Lathe Foot Brake Installation

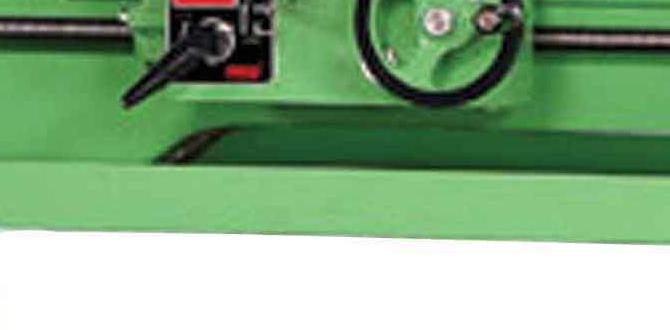

Setup Guide for Metal Lathe Foot Brake

Setting up a metal lathe foot brake can greatly enhance your safety and efficiency. This guide walks you through the steps to install and use the brake effectively. Did you know that proper foot brake installation can prevent accidents and improve precision? You’ll learn about tools needed, adjusting the brake for your specific lathe model, and safety tips. Understanding these elements makes your metalworking experience smoother and safer. Make your projects easier with the right setup!Understanding the Importance of a Foot Brake in Metal Lathes

Role of a foot brake in enhancing safety during operation. Comparison with other types of braking systems.A foot brake plays an essential role in metal lathes. It enhances safety by allowing quick stops during operation. This feature helps prevent accidents. In comparison to other braking systems, like hand brakes, foot brakes offer better control. Operators can focus more on their work with their hands free.

- Quick Response: Foot brakes respond instantly to pressure.

- Hands-Free Operation: This keeps both hands on the material.

- Less Fatigue: Using foot brakes reduces strain on the hands.

Overall, a foot brake is vital for safe and effective lathe work.

Why is a foot brake important in metal lathes?

A foot brake is important because it increases safety and efficiency during operations. It allows for quick stopping, helping to avoid accidents and keeping your hands free for better control.

Necessary Tools and Materials for Setup

List of tools required for installation. Recommended materials for optimal performance.Starting your journey with a metal lathe foot brake? You’ll need a few key tools to get the job done smoothly. First, gather a socket wrench and a screwdriver for assembly. You’ll also want wire cutters and pliers for any electrical connections. A sturdy measuring tape is essential to make sure everything fits just right. Lastly, don’t forget safety glasses—because nobody wants metal shavings in their eyes!

| Tools Required | Recommended Materials |

|---|---|

| Socket Wrench | High-Quality Brake Pads |

| Screwdriver | Durable Cables |

| Wire Cutters | Rubber Grommets |

| Pliers | Lubricant |

| Measuring Tape | Safety Gear |

These tools and materials will ensure optimal performance and keep your setup hassle-free. Remember, a well-prepared workspace is a happy workspace! Who knew safety could be so stylish with those glasses?

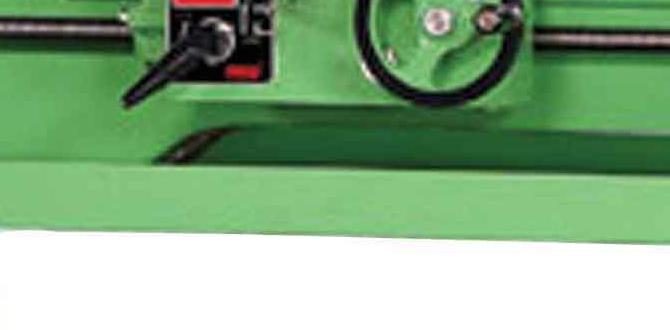

Step-by-Step Installation Process

Detailed guide on installing the foot brake on a metal lathe. Common pitfalls to avoid during installation.Installing a foot brake on your metal lathe may sound tricky, but it’s as easy as pie—if that pie didn’t require any baking! Start by gathering your tools: a wrench, screwdriver, and maybe a snack for energy. Remember, a hungry worker is an unhappy worker!

Here’s a quick step-by-step guide:

| Step | Action |

|---|---|

| 1 | Turn off the lathe and unplug it. |

| 2 | Locate the mounting area for the foot brake. |

| 3 | Attach the foot brake using screws. |

| 4 | Check connections and secure them tightly. |

| 5 | Test the brake with gentle pressure. |

Watch out for common mishaps, like forgetting to unplug the lathe or using the wrong screws—yikes! Double-check everything, and if you follow these tips, you’ll avoid turning your workspace into a scene from a slapstick comedy. Good luck, and may your lathe be as smooth as your jokes!

Adjusting and Calibrating the Foot Brake

Importance of proper adjustment for effective braking. Instructions for testing and calibrating brake responsiveness.Adjusting the foot brake on your metal lathe is important for safety. A well-calibrated brake helps stop the machine quickly and prevents accidents. Test your brake by turning on the lathe and pressing the foot pedal to see how it responds. Make sure it stops the lathe smoothly.

- Check the pedal sensitivity.

- Ensure there is no delay in stopping.

- Adjust as needed for a firm but easy press.

Regular checks keep the brake working well, providing peace of mind as you work on your projects.

How can I check the brake responsiveness?

To check brake responsiveness, step on the pedal while the machine is running. If it stops immediately, your brakes are good. If there’s a delay, adjust the tension on the mechanism.

Maintenance Tips for Longevity

Regular maintenance practices to keep the foot brake in optimal condition. Signs indicating the need for maintenance or repairs.To keep your foot brake in tip-top shape, regular maintenance is key. Check for squeaks or resistance when you step on it. These signs mean it might need some TLC. Inspect bolts and screws too; they like to wander off! Bright red flags include strange noises or sudden stops. Change brake pads when they wear thin, and clean the area to prevent dirt buildup. Little care now can save you from big repairs later!

| Maintenance Task | Frequency | Signs of Issues |

|---|---|---|

| Check brake resistance | Every month | Squeaks or sticking |

| Inspect bolts | Every three months | Loose or missing bolts |

| Change brake pads | Every six months | Worn down pads |

| Clean brake area | Monthly | Dirt accumulation |

Safety Practices While Using the Foot Brake

Essential safety precautions to implement. Emergency procedures in case of brake failure.Using a metal lathe is fun, but safety is key! Always wear safety goggles to protect your eyes from flying debris. Don’t forget gloves, but ensure they are snug to avoid getting caught in moving parts. Always check the foot brake before use; a faulty brake can turn your lathe into a runaway train!

| Essential Precautions | What to Do If Brake Fails |

|---|---|

| Wear safety goggles | Immediately stop machine power |

| Check your tool settings | Alert others and call for help |

| Position feet correctly | Use emergency shutoff switch |

Always have an emergency plan. Even the best machines can act a little crazy sometimes. If your brake fails, turn off the power without delay. Be a hero and ensure everyone is safe!

Troubleshooting Common Issues

Common problems encountered with foot brakes and their solutions. When to seek professional assistance.Foot brakes on metal lathes can be tricky sometimes. Here are a few common problems and their fixes:

- Brake sticks: This can happen due to dirt or dust. Clean it well.

- No response: Check the connections and power. Sometimes wires get loose.

- Uneven stopping: Adjust the tension on the brake pedal. It might need fine-tuning.

If these tips don’t help, it’s time to call a pro. They know how to handle tricky repairs!

What should I do if my foot brake is not working?

You can try cleaning or checking the connections. If it’s still not working, consider calling a technician. They have the right tools to fix it safely.

Comparing Different Foot Brake Options

Review of various foot brake types available in the market. Pros and cons of each type to help with purchasing decisions.In the world of foot brakes for metal lathes, choices abound! Each type brings something unique to the table—or should we say, the lathe? Let’s break it down:

| Type | Pros | Cons |

|---|---|---|

| Mechanical | Simple to use, low maintenance. | Can be less responsive. |

| Pneumatic | Strong stopping power, smooth action. | Requires air supply, more complicated setup. |

| Hydraulic | Precise control, very effective. | Can be pricey, needs careful installation. |

Each option has its ups and downs. Choosing the right foot brake can feel like deciding between pizza and tacos—both are great, but you can only have one! Think about your needs, then go for the brake that fits best. Remember, happy lathing means less brake drama!

Conclusion

In conclusion, a setup guide for a metal lathe foot brake helps you work safely and efficiently. We learned that having a properly installed foot brake prevents accidents and improves control. Make sure to read your lathe’s manual for specific instructions. Practice using the foot brake to become familiar with it. Don’t hesitate to explore more resources for tips and best practices!FAQs

Here Are Five Related Questions On The Topic Of Setting Up A Metal Lathe Foot Brake:To set up a metal lathe foot brake, first find a good spot for it. You want it to be easy to reach while you work. Then, attach the brake to the lathe following the instructions. After that, test the brake by pressing it with your foot to make sure it works. Always have someone help you if you’re not sure!

Sure, I can help with that! Just let me know what question you need answered.

What Tools And Materials Are Needed For Installing A Foot Brake On A Metal Lathe?To install a foot brake on a metal lathe, you need a few tools and materials. First, grab a wrench to tighten screws. You will also need screws and brackets to hold the brake in place. A drill is helpful if you need to make holes. Lastly, have some safety gear like gloves and goggles to protect yourself while working.

How Do I Determine The Ideal Location For The Foot Brake In Relation To The Lathe?To find the best spot for the foot brake on a lathe, stand comfortably in front of it. Make sure you can reach the brake easily with your foot. You want it to be close but not in the way of your tools. Test it by stepping on the brake while using the lathe to see if it feels right. Adjust it if needed so you can stop the lathe quickly and safely.

What Are The Safety Precautions To Consider When Setting Up A Foot Brake On A Metal Lathe?When you set up a foot brake on a metal lathe, first make sure the machine is turned off. Check that the brake is working properly before using it. Keep your hands and clothing away from moving parts. Wear safety glasses to protect your eyes. Always be ready to stop the machine quickly if something goes wrong.

How Do I Properly Wire The Foot Brake To Ensure It Functions Correctly With The Lathe’S Motor?To wire the foot brake, turn off the power first. Connect the brake wires to the motor’s control box. Make sure the wires fit tightly and correctly. Check that everything is secure. Finally, turn the power back on and test the brake. It should stop the lathe when you press it.

What Steps Should I Follow To Test The Foot Brake After Installation To Ensure It’S Functioning Safely And Effectively?First, you should press the foot brake pedal gently to see if it feels firm. Next, check if the brake lights turn on when you press the pedal. Then, try stopping the vehicle from a slow speed in a safe area to see if it works well. Finally, listen for any strange noises while braking. If everything seems okay, your foot brake is ready to use!