Quick Summary: Soft jaws for your lathe are a game-changer for beginners and pros alike. They provide a gentle, superior grip on delicate or irregularly shaped workpieces, reducing damage and ensuring accuracy. This essential upgrade prevents marring, reduces vibration, and allows for precise machining of everything from soft metals to plastics.

Hey there, fellow makers! Daniel Bates here from Lathe Hub. Ever find yourself struggling to hold onto that tricky part on your lathe? Maybe you’re worried about scratching a delicate piece, or perhaps the standard metal chuck jaws just aren’t giving you the consistent grip you need for those finer operations. It’s a common frustration, especially when you’re starting out. But don’t worry, there’s a simple yet incredibly effective solution that can make a world of difference: using soft jaws.

In this guide, we’ll explore exactly what soft jaws are, why they’re an absolute must-have for your lathe, and how they can transform your machining experience. We’ll cover everything from selecting the right ones to fitting and using them with confidence. Get ready to experience a new level of precision and finish on your projects!

What Exactly Are Soft Jaws and Why Are They So Special?

Think of your lathe chuck as the hand holding your workpiece. The standard jaws on most metalworking chucks are made of hard metal. While they’re tough and durable, they can sometimes be a bit too aggressive, especially when you’re dealing with materials that aren’t pure steel or if your workpiece has a delicate finish.

Soft jaws, on the other hand, are usually made from softer materials like aluminum, brass, or even specialized plastics. What makes them “soft” is their ability to be machined precisely to the exact shape of your workpiece. You buy them as blank squares or rectangles, and then you machine their gripping surfaces to perfectly match whatever you need to hold. This custom fit is the secret to their magic.

This custom-fitted grip offers several fantastic benefits:

- Gentle Holding Power: They grip your part without marring or denting the surface, which is crucial for finished parts or softer materials.

- Enhanced Accuracy: A perfect fit means a more stable and concentric grip, leading to more accurate machining.

- Reduced Vibration: The softer material can absorb some of the vibrations during machining, resulting in a smoother finish.

- Versatility: You can create jaws for round, square, irregular, or even multiple parts, all within the same chuck body.

- Protects the Chuck: They act as a buffer, protecting the hard jaws of your chuck from damage.

Essentially, soft jaws give you a tailored, more precise, and gentler way to hold your work. It’s like upgrading from a firm handshake to a carefully cradled embrace for your valuable projects.

Why Are Soft Jaws an Essential Upgrade for Your Lathe?

As a beginner, you’re probably focused on getting those basic operations down. But even at this stage, the limitations of standard chuck jaws can become apparent. Investing in soft jaws early on can save you a lot of headaches and improve the quality of your work significantly. For anyone looking to move beyond the absolute basics, soft jaws are not just an accessory; they’re a fundamental tool for achieving professional results.

Protecting Your Workpieces

This is often the biggest driver for acquiring soft jaws. If you’re working with:

- Aluminum, Brass, or Copper: These softer metals can easily get gouged or deformed by hard steel jaws.

- Finished Parts: If you need to machine something that already has a polished or plated surface, soft jaws prevent those unsightly marks.

- Thin-Walled Tubing or Sleeves: Hard jaws can crush these delicate items. Soft jaws spread the gripping force more evenly.

- Woodworking Projects: While less common for woodworkers, specialized soft jaws can hold irregularly shaped wooden blanks without damage.

A damaged workpiece means wasted material and time. Soft jaws dramatically reduce this risk, ensuring your effort translates into a pristine final product.

Achieving Greater Precision

Wobble and inaccuracy often stem from a less-than-ideal grip. Hard jaws are typically serrated to bite into the material. This can work, but it’s not always the most precise method. Soft jaws, when machined correctly, conform precisely to the shape of your workpiece. This custom fit:

- Centrates Better: Ensures your workpiece is perfectly in line with the lathe’s axis.

- Reduces Runout: Minimizes any “wobble” or deviation from true rotation.

- Allows for Lighter Clamping Pressure: Because the fit is so good, you don’t need to overtighten, further protecting delicate parts.

For operations where tight tolerances are key, like making precision shafts or fitting components together, this level of accuracy is invaluable.

Versatility in Holding Applications

One set of chuck jaws can only do so much. But with soft jaws, the possibilities expand:

- Odd Shapes: Holding a square stock, a hex bar, or even an irregular casting becomes much more manageable.

- Multiple Parts: You can machine jaws to hold two or more smaller parts at once for simultaneous machining.

- Custom Fixturing: Need to hold a part that’s already been partially machined and now has a unique contour? Soft jaws can be made to accommodate.

This adaptability means your lathe can tackle a much wider range of projects without needing specialized, expensive fixtures for every single one.

Cost-Effectiveness in the Long Run

While there’s an initial cost for buying blank soft jaws, they are often more economical than constantly fighting with inaccurate grips or repairing damaged parts. A set of blank jaws is relatively inexpensive compared to the cost of materials and the potential time lost due to machining errors. Plus, the blank jaws themselves are typically reusable if you need to machine them for a different part later, though often you’ll keep specific soft jaws for recurring projects.

Types of Soft Jaws

When you start looking for soft jaws, you’ll notice a few key variations. The main differences are in the material and the way they mount to your chuck.

Material Options

The most common materials are:

- Aluminum: Lightweight, easy to machine, and offers good grip without being overly aggressive. A great all-around choice for many materials.

- Aluminum Alloy (e.g., 6061-T6): Stronger and more durable than pure aluminum, offering a good balance of machinability and toughness.

- Brass: Softer than aluminum, excellent for holding very delicate or easily damaged surfaces. It’s also non-sparking, which can be a consideration in some environments.

- Steel (Hardened or Mild): While the concept is “soft” jaws, sometimes softer steel alloys are used for applications requiring more rigidity or higher clamping forces than aluminum can handle. These still get custom machined.

- Delrin or Acetyl (Plastics): These engineering plastics are excellent for holding non-ferrous metals, plastics, and wood. They are very gentle and non-marring.

For most beginners working with metal, aluminum or an aluminum alloy is usually the go-to choice.

Mounting Styles

Soft jaws are designed to fit specific types of chucks. The most common are:

- Direct Mount (Dovetail): These jaws have a dovetail profile that recesses directly into matching dovetails on the chuck jaws. They provide a very secure and precise fit.

- Top Jaws: These are the most common. They typically screw onto the base jaw of your chuck. The base jaw has T-slots or other features for the top jaws to attach to. They are easier to swap out.

- Full Jaws: Some systems use full-length jaws that extend the entire height of the chuck jaw assembly.

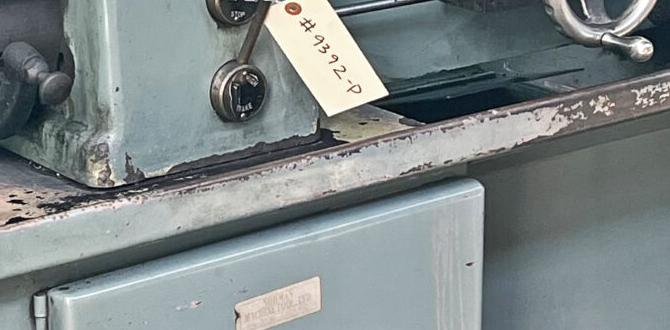

You need to ensure the soft jaws you purchase are compatible with your specific chuck model (e.g., manufacturer, size, and type of chuck). A guide to lathe chucks can help you identify yours if you’re unsure.

What You’ll Need to Machine Your Soft Jaws

The beauty of soft jaws is that they are designed to be machined on your own lathe! This means you can create custom jaws for a specific part right when you need them. You don’t need a milling machine, though that can make the job easier. Here’s what you’ll want:

Essential Tools

- Your Lathe: The star of the setup.

- Chuck Wrench: To operate your chuck.

- Measuring Tools:

- Vernier Calipers or Digital Calipers: For accurate measurements.

- Dial Indicator: To ensure concentricity and check for runout.

- Height Gauge or Trammel Bar (optional but helpful): For setting up cutter height.

- Cutting Tools:

- A Good Quality Lathe Tool Bit: Typically a carbide or high-speed steel (HSS) bit suitable for the jaw material (e.g., aluminum). A square-nose or round-nose tool is often used for gripping surfaces.

- Parting Tool or Grooving Tool (optional): For creating specific grooves or stops.

- Drill Bits and Tap Set (if needed): For creating threaded holes to secure your workpiece to the soft jaws.

- Small Hammer and Brass Punch: For tapping the jaws into final position if using direct-mount types.

- Vice (optional): If you need to drill and tap holes in the jaws while they are off the machine.

- Safety Gear: Safety glasses are non-negotiable! Gloves are recommended when handling metal.

Step-by-Step Guide: Machining Your First Set of Soft Jaws

Let’s get down to business! This process might seem daunting at first, but by taking it step-by-step, you’ll find it quite manageable. We’ll focus on the most common scenario: creating custom gripping surfaces for a round bar on a standard 3-jaw chuck.

Step 1: Prepare Your Chuck and Jaws

- Clean the Chuck: Ensure your chuck, especially the jaw T-slots or dovetails, is clean and free of debris.

- Mount the Blank Jaws: Install your blank soft jaws onto your chuck. Make sure they are seated correctly according to their design (e.g., dovetail fully seated, top jaws properly aligned).

- Tighten the Jaws: Chuck the jaws onto a piece of scrap material that is roughly the size and shape you intend to grip later. This helps simulate the clamping force and position the jaws correctly for machining their gripping surfaces. Don’t overtighten – just snug.

- Indicate the Jaws: Use a dial indicator to ensure that the outside of each blank jaw is running as true as possible. You want them to be perfectly aligned with the chuck’s axis. Adjust as needed by a very slight tap with a soft mallet.

Step 2: Set Up Your Cutting Tool

- Tool Height: Set your cutting tool bit precisely to the centerline of the workpiece. This is crucial for a clean cut and to prevent glazing or chatter. Use a height gauge or a spare piece of stock and a dial indicator.

- Secure the Tool: Ensure your tool post is securely holding the cutting bit.

Step 3: Machine the Gripping Surfaces (Internal Grip Example)

This assumes you want the soft jaws to grip around a round workpiece.

- First Cut: Take a light facing cut across the gripping surface of each jaw. This creates a clean, flat start.

- Grooving or Contouring: Now, you’ll machine the actual gripping shape. For a round bar, you’ll typically create a U-shaped or V-shaped groove.

- Roughing Pass: Use a steady feed rate to begin removing material. Don’t try to take too much off at once.

- Depth of Cut: Gradually increase the depth of cut or make multiple passes. Measure accurately! You want the groove to be slightly smaller than your desired workpiece diameter. This smaller size allows the jaws to ‘bite’ into the workpiece.

- Using a Dial Indicator: After each pass, you can use a dial indicator to check the depth and diameter of the groove.

- Finishing Pass: Once you’re close to the desired size, take a lighter finishing pass to get a smooth surface for optimal grip.

- Repeat for All Jaws: Ensure all four (or three) jaws are machined to the exact same dimensions. This is critical for a consistent grip.

Step 4: Create Clamping Provisions (Optional but Recommended)

If you plan to machine a part that will be held securely by the soft jaws (e.g., drilling and tapping a hole in the jaw for a set screw, or creating a pocket for a shoulder), this is the time. For a simple external grip, this might not be necessary, but for internal gripping or securing a specific shape, you might need to:

- Machine Pockets: Create recesses in the jaws to accommodate shoulders or specific profiling of your workpiece.

- Drill and Tap for Set Screws: If you want a truly secure hold, you can drill and tap holes into the gripping surface of the soft jaws. These holes will ideally be positioned so that a set screw can press against your workpiece. Ensure the tap drill size results in a hole that doesn’t compromise the jaw’s integrity.

If drilling and tapping, it’s often easier to remove the jaws from the chuck and secure them in a vice to perform these operations accurately.

Step 5: Test Fit

- Install the Soft Jaws: Remount the now-machined soft jaws onto the chuck.

- Chuck Your Workpiece: Carefully bring the chuck jaws onto your actual workpiece.

- Check for Grip: Gently try to rotate the workpiece by hand. It should be held firmly but without excessive force that could deform it.

- Indicate Again: Use your dial indicator to check the concentricity of your workpiece in the jaws. You should see very little runout.

If the fit isn’t perfect, you can often make slight adjustments by re-machining the gripping surfaces or by using shims if your chuck allows. Remember, practice makes perfect!

Machining Example: Gripping a Square Bar

Let’s say you need to hold a square bar. The process is similar, but you’ll machine square or rectangular pockets in your soft jaws. Sometimes, this is best done with a milling attachment on your lathe, but you can also do it with standard turning tools carefully and progressively.

Key Differences:

- Instead of a round groove, you’ll be creating square or rectangular openings.

- You’ll likely need tools that can create square corners, or you’ll have to live with slight radii at the corners of your pocket.

- For a perfect square grip on all four sides, you sometimes need specialized jaw types or faceplates, but for many applications holding on two or three sides is sufficient.

With square stock, you might machine a pocket that is just slightly larger than the corner-to-corner dimension of your square bar. The grip comes from the faces of the jaws pressing onto the angled sides of the square.

For more advanced work, a rotary indexer or a dedicated dividing head can allow you to create precision pockets for very accurate square or polygonal holding.

When to Use Soft Jaws vs. Hard Jaws

It’s not about replacing your hard jaws entirely, but knowing when to use each.

Use Soft Jaws When:

- Holding sensitive or easily damaged materials (soft metals, finished parts, plastics, wood).

- Achieving maximum concentricity and minimal runout on critical dimensions.

- Holding irregularly shaped workpieces that standard jaws can’t grip securely.

- Performing light-duty or finishing cuts where a very controlled grip is needed.

- You need to hold multiple identical parts in a specific orientation.

Use Hard Jaws When:

- Roughing cuts on robust materials where solid grip is paramount and surface finish isn’t yet a concern.

- Gripping standard round or hexagonal stock for general-purpose machining.

- You need extreme clamping force that softer jaw materials might not withstand.

- Cost is a major factor for simple,