The lathe spindle is the rotating heart of your machine. This guide explains what it is, how it works, different types, and how to choose the right one for your projects, ensuring smooth, precise results in your workshop.

Hey there, fellow makers! Daniel Bates here from Lathe Hub. You’ve got that shiny new lathe, or maybe you’re looking to upgrade, and you’ve heard the word “spindle” a lot. It sounds important, right? That’s because it absolutely is! The spindle is the main rotating part of your lathe, and it’s where the magic happens. Getting to know your lathe’s spindle is like understanding your car’s engine – it helps you unlock its full potential and achieve those amazing, precise results you’re aiming for. Don’t worry if it seems a bit technical; we’ll break it down into simple steps, just like we always do here at Lathe Hub. Ready to get your workpiece spinning perfectly? Let’s dive in!

What Exactly is a Lathe Spindle?

At its core, a lathe spindle is the primary rotating shaft in a lathe. Its main job is to hold and rotate the workpiece or the chuck, which then holds the workpiece. Think of it as the central axle around which everything else turns. It’s connected to the lathe’s motor and drive system, translating power into controlled rotation. The precision of the spindle directly impacts the accuracy and quality of the work you can produce. A wobbly or imprecise spindle means wobbly, imprecise cuts, which is the last thing any budding machinist wants!

The spindle has a threaded or coned nose where you attach essential accessories like the chuck (to grip your material), faceplates, or drive dogs. It also contains bearings that allow it to spin smoothly and accurately at various speeds. The stability and rigidity of the spindle are paramount for handling the forces generated during machining operations, whether you’re turning wood, plastic, or metal. A robust spindle can minimize vibration and flex, leading to cleaner cuts and less tool wear.

How Does a Lathe Spindle Work?

The operation of a lathe spindle is elegantly simple yet crucial for its function. Here’s a breakdown:

- Power Transmission: The lathe’s motor generates rotational power. This power is transferred to the spindle through a belt drive, gears, or sometimes a direct drive system.

- Rotation: Once power is applied, the spindle begins to rotate. The speed of this rotation is controlled by the lathe’s speed settings, which might be adjusted via a variable speed dial, different belt positions, or gear changes.

- Workpiece Mounting: The workpiece is secured to the spindle’s nose. This can be done by:

- Threading: The spindle nose may have external threads, and the chuck or faceplate will have corresponding internal threads. Screwing the chuck onto the spindle securely attaches it.

- Taper Mount: Many spindles use a standardized taper (like an L00, L0, L1, D1, or Morse taper) on their nose. Accessories with a matching taper can be inserted and are held in place by friction and the drawbar or flange.

- Machining: As the spindle rotates the attached workpiece, you use cutting tools to shape the material. The spindle provides a stable platform for this process, ensuring consistent material removal and surface finish.

- Bearings: The spindle is supported by bearings (often in the headstock). These bearings are designed for high precision and to handle axial (pushing) and radial (sideways) loads. Good bearings ensure smooth rotation with minimal runout (wobble), which is critical for accuracy.

The relationship between the spindle speed, the diameter of the workpiece, and the cutting speed of your tool is fundamental to successful machining. Understanding these dynamics helps you select the appropriate RPM (Revolutions Per Minute) for different materials and operations.

Key Components of a Lathe Spindle System

While the spindle itself is the core, its performance is heavily reliant on a few other critical components:

- Headstock: This is the housing that contains the spindle and its bearings. It also typically houses the gearing or belt system for speed changes.

- Bearings: These are precision components that support the spindle, allowing it to rotate freely and accurately. Common types include ball bearings, roller bearings, and plain bearings, with high-quality lathes often using tapered roller bearings or angular contact bearings for maximum rigidity.

- Spindle Nose: This is the front end of the spindle where accessories are attached. It’s characterized by its threads or taper and is a crucial interface for mounting chucks and other workholding devices. Its size and type are standardized to allow for interchangeable tooling.

- Drive Mechanism: This link (belts, gears, pulleys) connects the motor to the spindle, transmitting power and allowing for speed adjustments.

- Drawbar/Flange: For non-threaded spindle noses (like those with a taper), a drawbar (a rod pulled from the back of the headstock) or a mounting flange is used to securely fasten accessories like collet chucks or specialized fixtures.

The quality and condition of these components determine how true your spindle spins, how much vibration you experience, and how accurately you can turn your parts. For example, worn bearings can lead to increased runout and poor surface finishes.

Types of Lathe Spindles

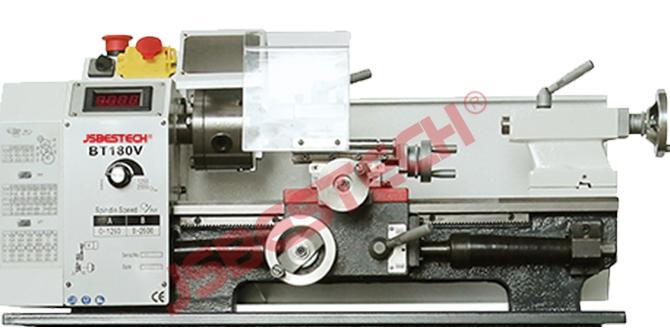

Lathe spindles can vary in design, especially when comparing wood lathes, metal lathes, and even different classes of metalworking lathes. The main distinctions often lie in their nose type, bearing configuration, and intended use.

1. Spindle Nose Types

This is one of the most important distinctions, as it dictates what accessories you can mount. For metalworking, standardized nose types are common:

- Threaded Nose: Simple and common, especially on older or smaller lathes. Common thread sizes might be 1-8 TPI (Threads Per Inch) or 2-8 TPI. You simply screw your chuck on.

- Cam-Lock (D1) Spindle Nose: A very popular and robust standard, especially on South Bend and many other American-style lathes. It features a tapered face with locking pins or cams that engage in corresponding slots on the back of the chuck or faceplate. This provides a secure, repeatable, and rigid mounting that is also quick to change. Sizes range from D1-3 through D1-11 and larger.

- Long Taper (L) Spindle Nose: Found on many European and some American-style lathes. Examples include L00, L0, L1, L2, etc. These utilize a male taper on the spindle and a female mating surface on the chuck with a drawbar or bolt circle for secure attachment. They offer excellent rigidity and accuracy.

- Morse Taper (MT) Spindle Nose: While primarily used for live centers, drill chucks, and other tooling that fits directly into the tailstock, some very small hobby lathes might use a Morse taper on the spindle nose itself. It’s less common for heavy-duty chuck mounting due to its relatively shallow taper for such applications.

For wood lathes, the spindle nose is typically simpler, often just a threaded stud (like 1-8 TPI) to attach chucks and faceplates. Some may also have Morse tapers in the spindle for mounting bowls directly or for use with screw chucks.

2. Spindle Bearing Configurations

The type of bearings used significantly impacts rigidity, accuracy, and speed capabilities:

- Plain Bearings: Older lathes, particularly some woodworking lathes, might use plain bronze or Babbitt bearings. These require lubrication and are less precise than anti-friction bearings, usually limiting higher speeds.

- Ball Bearings: Common on many smaller lathes and some wood lathes. They offer good speed capabilities but can have more deflection under load compared to roller bearings.

- Roller Bearings: Used in many metal lathes for their high load capacity and rigidity.

- Tapered Roller Bearings: Often found in higher-quality metal lathes. Two tapered roller bearings are typically used, one on the front and one on the back of the spindle. They can be preloaded to achieve extreme rigidity and minimal runout, making them ideal for precise metalworking.

- Angular Contact Bearings: Similar to tapered roller bearings, these are excellent for handling both radial and axial loads and provide high precision and rigidity.

3. Spindle Types by Machine Type

- Wood Lathe Spindles: Generally simpler, often threaded or a basic taper. The forces are primarily radial. Speed is crucial for different wood turning techniques.

- Metal Lathe Spindles: Designed for much higher precision and load-bearing capacity. They feature standardized nose types (like D1 or L00) and high-precision bearing arrangements to handle the significant forces in metal cutting. Spindle runout is measured in tenths of a thousandth of an inch or less.

- milling machine spindles: While not a lathe, milling machine spindles are similar in concept but designed for very different forces (sideways cutting forces are dominant). They use specialized tool holders like R8, CAT, or BT tapers.

Understanding these differences helps explain why a specific chuck might not fit your lathe or why one type of lathe is better suited for delicate woodworking versus heavy-duty metal machining.

Choosing the Right Spindle (or Lathe) for Your Needs

When considering a lathe, the spindle is a critical factor. While you often can’t change the spindle on an existing lathe, knowing what to look for when buying a new one or understanding your current setup is vital.

For Woodworking and Lighter Hobby Use:

- Spindle Nose: A standard 1-8 TPI thread is perfectly adequate for mounting chucks and faceplates on most wood lathes. The ability to easily attach and remove accessories is key.

- Bearings: Good quality ball bearings are usually sufficient. Look for lathes that specify sealed, lubricated-for-life bearings.

- Morse Taper: Having a Morse Taper (MT2 or MT3 is common) in both the headstock and tailstock is very useful for mounting specialized woodworking accessories like drive centers, spur drives, and for using the tailstock to support bowls.

- Speed Range: Wood lathes benefit from a wide speed range, often with variable speed control, allowing fine-tuning for different wood types and turning operations (e.g., slow for roughing, faster for finishing).

For Metalworking and Precision Projects:

- Spindle Nose: This is where you’ll want to pay close attention. For interchangeability and access to a wide range of quality chucks and accessories, look for standardized taper nose types like D1-4, D1-6, or L00, L0. These offer superior rigidity and accuracy.

- Bearings: Check for high-precision bearings, ideally tapered roller bearings or angular contact bearings. These are crucial for minimizing runout and vibration under heavy cutting loads.

- Spindle Diameter and Bore: A larger spindle diameter and a generous spindle bore (the hole running through the spindle) allow you to pass larger stock material through the headstock. For example, a 1.5-inch (38mm) bore is significantly more capable than a 1-inch (25mm) bore.

- Spindle Runout: Manufacturers of quality metal lathes will specify the maximum allowable runout of the spindle (e.g., 0.0001 inches or 0.002mm). This is a key indicator of precision.

- Gear vs. Belt Drive: Lathes with geared headstocks often provide more torque at low speeds, while belt-driven headstocks can sometimes offer a smoother, quieter operation and higher maximum speeds.

Resource Link: For a deeper dive into lathe specifications and what they mean for machining, the National Institute of Standards and Technology (NIST) offers valuable insights into measurement and standards in manufacturing.

When selecting a lathe, think about the types of projects you envision. If you’re just starting with small metal parts, a smaller lathe with a simpler spindle nose might be fine. If you plan on turning larger metal stock or require very high precision, investing in a lathe with a more robust, standardized spindle interface and superior bearings is essential.

Maintaining Your Lathe Spindle for Longevity and Accuracy

Just like any precision machine component, your lathe spindle needs care to perform at its best. Regular maintenance is key to ensuring accuracy, smooth operation, and a long lifespan for your machine.

| Task | Frequency | Notes |

|---|---|---|

| Clean Spindle Nose Threads/Taper | After each use or before mounting work | Remove chips, dust, and old lubricant. Use a clean rag and a soft brush. For metal lathes, a light application of rust-inhibiting oil is good. |

| Check Spindle Runout | Periodically, or if accuracy issues arise | Mount a test indicator to the cross-slide. Indicate the spindle nose. Consult your lathe manual for acceptable limits. Most metal lathes aim for <0.0005″. |

| Lubricate Bearings | As per manufacturer’s schedule (e.g., monthly, quarterly) | Use only the recommended lubricant specified in your lathe’s manual. Over-greasing or using the wrong type can damage bearings. |

| Inspect Drive Belts/Gears | Monthly | Check for wear, cracks, or excessive looseness. Ensure proper tension. For gear drives, check oil levels and listen for unusual noises. |

| Clean Headstock Exterior | Weekly | General cleaning to prevent debris buildup. |

| Check for Vibration/Noise | During operation | Unusual noises or excessive vibration can indicate bearing issues, imbalance, or loose components. Investigate immediately. |

For metal lathes, maintaining the precise fit between the spindle and its bearings is critical. Avoid dropping the spindle or subjecting it to shock loads. If you suspect bearing issues or significant runout on a metal lathe, it’s often best to consult a qualified technician or refer to your specific lathe’s service manual before attempting repairs yourself.

For wood lathes, while precision is important, durability is often the primary concern. Regular cleaning and ensuring the threads for chucks are clean and undamaged will go a long way. If your wood lathe develops play in the headstock, it might be time to consider bearing replacement. Many manufacturers provide detailed guides on how to do this.

Common Spindle-Related Issues and Troubleshooting

Even with the best maintenance, you might encounter some issues related to your lathe’s spindle or its accessories. Here’s how to tackle them:

- Excessive Runout (Wobble):

- Cause: Worn or damaged spindle bearings, bent spindle, improperly mounted chuck, dirt/debris on spindle nose or chuck mounting surface.

- Solution: Clean spindle nose and chuck mounting. Check chuck for damage/wear. If runout persists, suspect bearing issues or a bent spindle (especially on older/worn machines). For metal lathes, this is a critical issue requiring professional attention or careful DIY repair if you’re experienced.

- Chuck Won’t Thread On/Off Smoothly:

- Cause: Damaged threads on spindle nose or chuck, debris in threads, misalignment.

- Solution: Thoroughly clean both threaded surfaces. Inspect for damaged threads. Try gently engaging the spindle rotation while attempting to thread the chuck on/off to help align threads. Never force it.

- Lathe Vibrates Excessively During Operation:

- Cause: Unbalanced workpiece, loose headstock components, worn spindle bearings, motor issues.

- Solution: Ensure the workpiece is properly balanced and securely mounted. Check that the chuck is tight. Listen for the vibration source – if it seems to come from the headstock, bearing wear is a common culprit.

- Difficulty Mounting Collets (Metal Lathes):

- Cause: Dirt in the spindle bore or collet, worn collet, worn spindle taper.

- Solution: Clean the spindle bore and the collet thoroughly. Ensure you are using the correct collet for your spindle type (e.g., 5C, 16C, ER). If the collet still won’t seat properly, it might be worn or the spindle taper needs inspection.

- Heat Buildup at Headstock:

- Cause: Over-tight or worn bearings, insufficient lubrication, excessive speed.

- Solution: Stop the lathe immediately if you notice excessive heat. Check bearing lubrication. If properly lubricated and the heat persists, bearings may be damaged or incorrectly preloaded. For wood lathes, check belt tension; sometimes tight