Have you ever watched a machine cut metal? It’s pretty amazing! In the world of milling, two terms often come up: step-over and step-down. Understanding these concepts can make a big difference in how well a project turns out. But what do they mean?

Imagine you’re baking a cake. You want the layers to be just right. If you pour too much batter in one spot, the cake might overflow. The same idea applies to milling. Step-over is like how far the machine moves sideways after each cut. Step-down is how deep the cut goes. Both actions can change the final result significantly.

Did you know that using the right technique can save time and materials? Choosing between step-over and step-down can be like deciding whether to use a big spoon or a small one. Each choice has its own effects. So, let’s dive deeper into these milling terms and see how they can improve your projects!

Step-Over Vs Step-Down In Milling: Key Differences Explained

Understanding Step-Over vs Step-Down in Milling

When milling, understanding the difference between step-over and step-down is crucial. Step-over refers to the distance between each pass of the cutter. A larger step-over means less overlap, while a smaller one gives a smoother finish. Step-down, on the other hand, describes how deep the tool cuts into the material. Choosing the right method can affect both speed and finish quality. Did you know that adjusting these settings can save time and materials? Discovering which technique works best can lead to better results!What is Step-over in Milling?

Definition and explanation of stepover. Importance of stepover in milling operations.Stepover in milling is the distance a tool moves sideways during each pass. Imagine a tiny dance, where the cutter performs a side shuffle across the material. This movement is crucial because it affects the surface finish and tool life. A wider stepover can speed up the process but might leave a rough finish, while a smaller one leads to smooth edges—like butter! Choosing the right stepover can be the difference between a happy tool and a grumpy one.

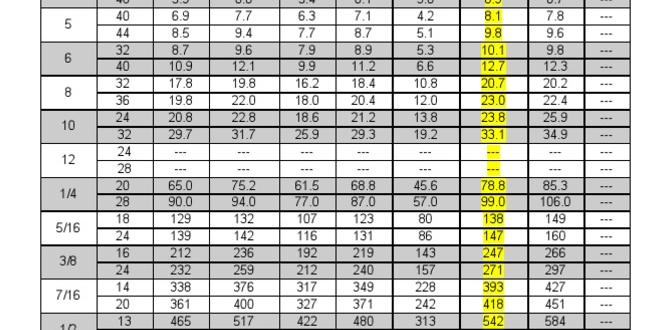

| Stepover | Effect on Milling |

|---|---|

| Wider Stepover | Faster but rough finish. |

| Narrow Stepover | Smoother finish, but slower. |

What is Step-down in Milling?

Definition and explanation of stepdown. Relevance of stepdown in milling processes.Stepdown in milling is the process of lowering the cutting tool gradually, bit by bit. Instead of going deep in one go, it carefully “steps down” to achieve the desired depth. This method is important because it helps in making smooth finishes and prevents tool breakage. Think of it as a gentle slide instead of a big leap. In milling, using stepdown makes for better control and efficiency.

| Benefits of Stepdown | Key Points |

|---|---|

| Prevents Tool Damage | Less stress on the tool. |

| Smoother Surfaces | Results in clear finishes. |

| Improved Accuracy | Better control of depth. |

Overall, stepdown is a clever trick that makes milling easier and more effective. Remember, in the milling world, it’s all about those baby steps!

Key Differences Between Step-over and Step-down

Comparative analysis of stepover and stepdown techniques. Effects on tool wear and machining accuracy.Stepover and stepdown techniques have key differences in milling. Stepover refers to how far a tool moves sideways after each pass, while stepdown is how deep the tool goes into the material. A wider stepover can speed things up, but it may cause more tool wear and lower accuracy. In contrast, a smaller stepover can help achieve tight tolerances and better finishes. Remember, it’s all about balance—too much of either can cause headaches. Think of it like a dance: too big a step, and you might trip!

| Technique | Effect on Tool Wear | Effect on Machining Accuracy |

|---|---|---|

| Stepover | Higher wear with large distances | Less accurate with large distances |

| Stepdown | Wear depends on depth | Better accuracy with smaller steps |

Applications of Step-over in Milling

Industries and scenarios where stepover is preferred. Advantages of using stepover in various projects.Many industries benefit from using stepover in milling. This technique is great for making parts like molds and complex shapes. It helps create smooth surfaces and reduces the need for extra finishing work. Here are some key advantages:

- Improved surface quality: Stepover makes parts look better.

- Efficiency: It saves time and effort by reducing steps.

- Flexibility: Works well for different materials and shapes.

Using stepover can be a game changer for projects in manufacturing and design. It’s all about making work easier and better!

Why use stepover in milling?

Stepover helps create smoother surfaces and saves time on projects.

Applications of Step-down in Milling

Common uses of stepdown in milling operations. Benefits of implementing stepdown in specific contexts.Step-down milling is popular for various tasks. It works wonders when creating parts with different depths. This method is often used in aerospace and automotive industries, where precision is key. One big perk is its ability to enhance surface finish. Workers love that it reduces tool wear, leading to fewer tool changes. Plus, who wouldn’t want smoother cuts and faster results? Here’s a quick look at the benefits:

| Application | Benefits |

|---|---|

| Aerospace Components | High precision with a smooth finish |

| Automotive Parts | Reduces tool wear, saving time |

| Custom Designs | Allows for flexibility in depth |

So, if you want to make parts that shine, step-down milling is the way to go. Your tools will thank you, and the parts will look fabulous!

Choosing Between Step-over and Step-down

Factors to consider when selecting a milling strategy. Impact of material type and desired finish on decisionmaking.When picking a milling strategy, think about a few key points. The material type matters. Some materials are soft; others are hard. Softer materials may benefit from larger stepover, while harder ones need careful stepdowns. Also, consider the desired finish. Smooth finishes need smaller steps. For example:

- Soft materials: Use a larger stepover.

- Hard materials: Go for smaller stepdowns.

- Smooth finish: Smaller steps are the best choice.

By weighing these factors, you can make a smarter decision for your milling project!

What factors should I consider in milling?

Consider material hardness, desired finish, and machining time. All these will help you choose wisely between stepover and stepdown.

Tips for Optimizing Step-over and Step-down Techniques

Best practices for maximizing efficiency and quality. Common mistakes to avoid in milling operations.To achieve smooth milling operations, it’s key to balance your step-over and step-down settings. Keep the step-over small for delicate jobs, like trying to sneak a cookie from a jar without making a sound. But if you want speed, increase the step-down! Avoid going too deep in one go—think of it like biting into a giant sandwich all at once; you might choke!

| Tip | Common Mistake |

|---|---|

| Use proper feed rates | Too fast or too slow can lead to errors |

| Plan tool paths | Rushed paths can make a mess |

Remember, patience makes perfect! Overlooking these tips can lead to costly repairs and wasted material. Keep it fun and efficient!

Real-world Examples and Case Studies

Analysis of successful projects utilizing stepover. Analysis of successful projects utilizing stepdown.Using the right methods is key in milling projects. Here are some real-world examples:

- Stepover Success: A company improved part quality by using stepover. They optimized the path, which reduced waste and saved time.

- Stepdown Success: Another project focused on step-down. With deeper cuts, they shortened machining time and maintained strength.

These examples show how choosing the right strategy can make a big difference in milling projects.

How does stepover improve milling projects?

Stepover can increase efficiency by reducing the amount of material wasted, leading to faster completion times.

Why is step-down important in machining?

Step-down allows for deeper cuts that can speed up the process while maintaining product durability.

Future Trends in Milling Techniques

Innovations and technology advancements affecting stepover and stepdown. Predictions for the future of milling strategies.New technology is changing how we think about milling. Innovations like smart machines and automation help manufacturers work faster and better. These advancements make it easier to choose between step-over and step-down methods. Experts predict that in the future, milling will become even more precise. Machines will likely learn from their tasks to improve quality and efficiency.

- Use of AI to enhance decision-making.

- More eco-friendly practices to reduce waste.

- Increased speed and accuracy in milling processes.

What are possible future improvements in milling?

Future improvements in milling may include smarter tools, faster operations, and better energy use for efficiency.

Conclusion

In summary, step-over and step-down are important terms in milling. Step-over affects how wide your cuts are, while step-down determines how deep they go. Understanding both helps you make better cuts and improve your projects. Try experimenting with these techniques in your next milling task. For more tips, check out additional resources online!FAQs

Here Are Five Questions Related To The Topic Of Step-Over Vs. Step-Down In Milling:Sure! When we talk about step-over and step-down in milling, we mean how a machine moves while cutting. Step-over is how far the tool moves sideways after each pass. Step-down is how deep the tool goes into the material with each cut. Choosing the right way helps make smoother shapes and saves time. It’s like deciding how to walk side to side or move deeper when digging in the sand.

Sure! Please ask your question, and I will happily answer it for you in simple terms.

What Is The Primary Difference Between Step-Over And Step-Down In Milling Operations?In milling, step-over and step-down are different ways to move the cutting tool. Step-over is when the tool moves sideways a little bit after each cut. This helps cover a wide area. Step-down is when the tool moves straight down to cut deeper into the material. Each method helps make different shapes in the material.

How Do Step-Over Distances Affect The Surface Finish And Quality Of A Milled Part?Step-over distance is the space between each cut when we move the machine. When the step-over distance is small, we make smoother and nicer surfaces. If the distance is big, the surface can have bumps and look rough. So, we should choose a smaller distance for better quality parts. This makes them look and feel better when we use them.

In What Scenarios Would A Machinist Prefer To Use A Larger Step-Down Versus A Smaller Step-Down During A Milling Process?A machinist might use a larger step-down when cutting a big piece of metal quickly. This makes the work faster but can cause rough edges. You would use a smaller step-down for finer detail, like making smooth shapes or tight corners. It takes more time, but the finished piece looks nicer!

What Factors Should Be Considered When Determining The Optimal Step-Over Distance For A Specific Milling Project?When deciding the best step-over distance for milling, we should think about a few things. First, consider the material you’re cutting. Some materials need a smaller step-over for a smooth finish. Second, think about the tool’s size. Bigger tools can work with bigger step-overs. Finally, remember how fast you want to finish the job. A smaller step-over might take longer but gives a better look!

How Does The Choice Of Step-Over And Step-Down Impacts Tool Wear And Machining Efficiency In Cnc Milling?Step-over and step-down are like how deep and wide you cut when using a CNC milling machine. If you cut too deep or too wide, your tool can wear out faster. This makes the tool less sharp and can slow down the job. If you choose smaller steps, the tool stays sharper, and you finish the work more efficiently. So, making careful choices helps both the tool last longer and the work to go quicker.