Tialn Ball Nose End Mills Deliver Exceptional Results in Cast Iron Machining, Especially for Helical Interpolation. Their Titanium Aluminum Nitride Coating Provides Superior Hardness and Heat Resistance, Leading to Longer Tool Life and Cleaner Cuts.

Machining cast iron can be a tough job, and finding the right tool makes all the difference. If you’ve struggled with tools wearing out quickly or leaving rough finishes in cast iron, you’re not alone. Many beginners find cast iron to be a challenging material. But don’t worry! With the right end mill, like a Tialn ball nose end mill, you can achieve smooth, precise results with confidence. This guide will show you why these specific tools are a game-changer for cast iron and how to use them effectively.

Why TiAlN Ball Nose End Mills Excel in Cast Iron

Finding the right cutting tool for a material like cast iron is crucial for successful machining. Cast iron’s unique properties, such as its brittleness and abrasive nature, present specific challenges. Traditional end mills can struggle, leading to premature wear, poor surface finish, and increased machining time. This is where specialized tooling, like those with a TiAlN coating, shines.

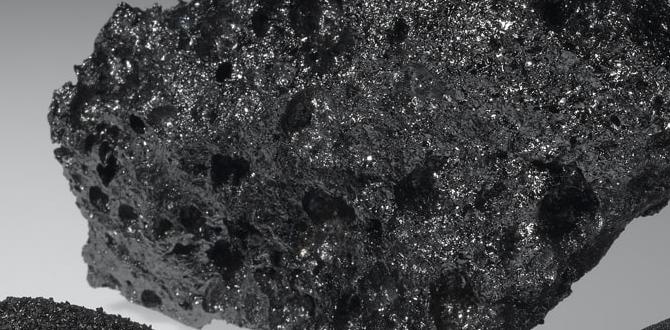

Understanding Cast Iron Challenges

Cast iron is an alloy of iron and carbon, typically with carbon content above 2%. This high carbon content gives it distinct characteristics compared to materials like aluminum or mild steel.

Brittleness: Cast iron is more brittle than steel, meaning it can fracture or chip rather than deform under stress. This requires careful control of cutting forces and avoiding shock loads.

Abrasiveness: The graphite (in grey and ductile iron) or carbon in its various forms acts like tiny abrasive particles within the metal matrix. This abrasive action can quickly wear down the cutting edges of standard tooling.

Heat Resistance: While not as prone to welding as some steels, cast iron can still generate significant heat during machining. Tools need to withstand this heat to maintain their edge and performance.

The Power of TiAlN Coating

TiAlN stands for Titanium Aluminum Nitride. This is a hard, thin-film coating applied to the surface of cutting tools, most commonly end mills. Here’s why it’s so effective for machining tougher materials like cast iron:

Exceptional Hardness: TiAlN is one of the hardest coatings available. This allows the end mill to cut through abrasive materials like cast iron with less wear on the cutting edge. Think of it like putting a tougher skin on your tool.

High Heat Resistance: During machining, friction creates heat. TiAlN coatings can withstand much higher temperatures than uncoated carbide or high-speed steel. This is vital for cast iron, helping to prevent the cutting edge from softening and degrading.

Reduced Friction: The coating also helps to reduce friction between the tool and the workpiece. This means less heat generated, lower cutting forces required, and a cleaner chip evacuation.

Oxidation Resistance: At high temperatures, many tool materials can start to oxidize (effectively burn away). TiAlN forms a protective aluminum oxide layer at elevated temperatures, further increasing its thermal stability.

The Ball Nose Advantage

A ball nose end mill has a hemispherical tip. This shape is perfect for creating rounded internal corners, complex 3D contours, and performing certain types of profiling.

3D Machining: Essential for creating sculpted surfaces, molds, and complex parts where sharp internal corners are not required.

Slotting and Profiling: Can be used for general profiling and creating slots, especially when a fillet radius is needed at the bottom.

Helical Interpolation: This is a key application where ball nose end mills excel. Helical interpolation is a process of machining a circular path to create holes, pockets, or threads using a continuous, upward spiral motion. A ball nose end mill’s geometry is well-suited for this, as it maintains a tangent cutting edge throughout the helical path, leading to smoother engagement and better surface finish. We’ll touch on this more later.

Why Use a 40-Degree TiAlN Ball Nose End Mill for Cast Iron?

The “40-degree” specification often refers to the helix angle of the flutes. While ball nose end mills are typically defined by their tip radius, the flute helix angle plays a significant role in performance, especially in certain applications like slotting or helical interpolation.

Understanding Helix Angle

The helix angle is the angle at which the flutes are twisted around the tool’s body. It affects chip evacuation and cutting action.

Lower Helix Angles (e.g., 0-30 degrees): Generally provide a more aggressive cut and better chip control in softer materials but can lead to chatter in harder materials.

Medium Helix Angles (e.g., 30-45 degrees): Offer a good balance between cutting aggressiveness and chip evacuation. They tend to be more stable.

High Helix Angles (e.g., 45+ degrees): Provide a shearing action, good for producing finer chips and reducing cutting forces, which is beneficial for harder materials and preventing chatter, but can sometimes have less robust chip evacuation for larger chips.

For cast iron, a 40-degree helix angle on a ball nose end mill often hits a sweet spot. It provides a good balance:

Good Chip Ejection: Helps to clear the abrasive cast iron chips effectively, preventing them from recutting and dulling the tool.

Stability: Offers improved stability over very high helix angles, reducing the risk of vibration or chatter, which is critical when working with brittle cast iron.

Cutter Engagement: Allows for a smooth engagement with the material, minimizing shock and stress on both the tool and the workpiece.

When you combine this 40-degree helix with the TiAlN coating and the ball nose geometry, you get a tool specifically designed to handle the demands of cast iron machining efficiently and effectively.

Helical Interpolation with a 40-Degree TiAlN Ball Nose End Mill

Helical interpolation is a powerful technique for creating internal features like holes, pockets, or even threads by feeding the end mill in a helical path. Using a 40-degree TiAlN ball nose end mill for this in cast iron offers several advantages:

Why It Works So Well

Controlled Engagement: The ball nose shape ensures that the cutting edge is always engaged in a controlled manner as it moves along the helix. This is much smoother than using a square end mill, which has sharp corners that can dig in.

Superior Surface Finish: The continuous cutting action and the TiAlN coating create a very clean and smooth wall finish inside the interpolated feature. This often eliminates the need for secondary finishing operations.

Reduced Tool Stress: By machining in a helical path, the cutting load is distributed more evenly. Combined with the TiAlN coating’s heat and wear resistance, this leads to a longer tool life compared to plunging or conventional milling for the same feature.

Versatility: You can create holes of various diameters (larger than the end mill itself) by simply adjusting the programmed radius of the helix. You can also create complex internal shapes or transitions.

Key Parameters for Success

For optimal results in helical interpolation with your 40-degree TiAlN ball nose end mill in cast iron, consider these parameters. These are general guidelines, and you should always refer to the tool manufacturer’s recommendations and perform test cuts.

| Parameter | Recommendation | Notes |

| :——————– | :————————————————– | :——————————————————————————————————- |

| Material | Cast Iron (e.g., Gray Iron, Ductile Iron) | TiAlN is excellent for these harder, abrasive materials. |

| Tool Material | Carbide Ball Nose End Mill | Provides the necessary rigidity and heat resistance. |

| Coating | TiAlN (Titanium Aluminum Nitride) | Essential for heat and wear resistance in cast iron. |

| Helix Angle | 40 Degrees (or manufacturer recommended for CI) | Balances chip evacuation, stability, and cutting action. |

| Spindle Speed (RPM) | 3,000 – 8,000 RPM | Varies significantly with tool diameter, machine rigidity, and specific cast iron alloy. Start lower. |

| Feed Rate (IPM/mm/min) | 0.002 – 0.006 in/flute (0.05 – 0.15 mm/flute) | Crucial for chip thinning and preventing tool breakage. Too fast = chatter; too slow = rubbing. |

| Depth of Cut (Axial)| 0.010″ – 0.060″ (0.25mm – 1.5mm) | For full ball nose interpolation, this is limited by the tool’s radius fitting the helix. |

| Stepover (Radial) | 0.005″ – 0.020″ (0.12mm – 0.5mm) | For creating a smooth wall. Smaller stepover = better finish but longer cycle time. |

| Coolant/Lubrication | Flood Coolant or Through Spindle Coolant (TSC) | Highly recommended to dissipate heat, lubricate, and clear chips effectively. Mist can work for light cuts. |

| Tool Holder | High-Quality Collet Chuck or Shrink Fit Holder | Ensures runout is minimized, which is critical for precision and tool life. |

| Workholding | Rigid and secure clamping to prevent vibration | Loose workholding will lead to chatter and poor results. |

Important Note: Always consult the specific tool manufacturer’s data for their recommended cutting parameters for TiAlN coated ball nose end mills in various grades of cast iron. These are general starting points.

Step-by-Step Helical Interpolation Process

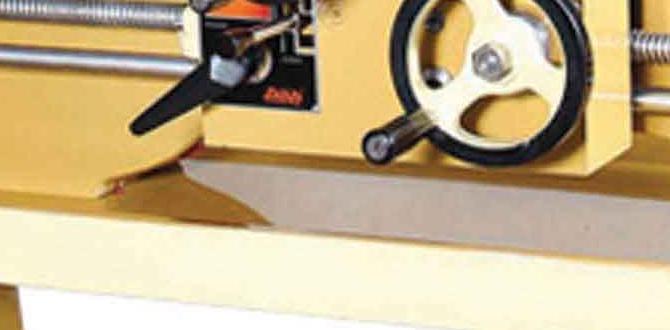

Let’s walk through the basic steps to perform helical interpolation. This assumes you have your CNC milling machine set up and know how to load a tool and set its work offsets.

1. Tool Selection and Setup:

Choose a 40-degree helix TiAlN coated ball nose end mill of appropriate diameter for your desired hole size. Remember, a ball nose end mill can create a hole larger than its own diameter.

Verify the end mill is sharp and undamaged using a toolmaker’s microscope or by careful visual inspection.

Securely install the end mill into a high-quality tool holder (e.g., ER collet chuck, shrink fit holder) installed in your machine’s spindle. Ensure it’s properly seated and tightened to prevent runout.

2. Machine Setup:

Securely clamp your cast iron workpiece to the milling machine table. Ensure it’s rigid and won’t move during the cutting process.

Install and zero your work offsets as you normally would.

Set up your coolant system. Flood coolant is generally preferred for cast iron to manage heat and remove chips effectively.

Load your CNC program into the machine controller.

3. Program Verification (Dry Run):

Before cutting into your workpiece, perform an air cut (dry run) of your program. This means running the tool path above the workpiece to visually check:

Tool clearance on all axes

The helical path geometry

Programmed speeds and feeds

Coolant activation

Ensure the programmed path correctly generates the desired hole diameter and depth. For a ball nose end mill, the programmed radius of the helix will determine the diameter of the hole. The distance from home position to where the center of the tool starts its helix determines the effective hole diameter.

4. Setting Cutting Parameters:

Refer to the table of general parameters above, or your tool manufacturer’s recommendations.

For your first attempt, it’s wise to start at the lower end of the recommended speed and feed rates, especially for RPM. You can always increase them if the cut is too light and the tool isn’t efficiently removing material.

5. Initiating the Cut:

Ensure the workpiece is clear.

Start the spindle and bring it up to the programmed RPM.

Turn on the coolant.

Initiate the cutting cycle for the helical interpolation.

Observe the cut closely. Listen for any unusual noises like chatter or scraping. Watch chip formation: they should be relatively small, consistently sized, and being ejected cleanly.

6. Monitoring During Machining:

Continue to monitor the process. Look for signs of excessive heat, poor chip evacuation, or tool chatter.

If you see any issues, be prepared to pause or stop the machine and re-evaluate your parameters. Often, a slightly higher feed rate or improved coolant flow can resolve minor problems.

7. Cycle Completion and Inspection:

Once the program completes, allow the spindle to stop and retract the tool.

Turn off the coolant.

Carefully inspect the machined feature. Check for:

Correct diameter and depth

Smoothness of the wall finish

Absence of burrs or sharp edges

* Signs of tool wear (if possible to check without removing the part)

Best Practices for Optimizing Tool Life

Getting the most out of your TiAlN ball nose end mill in cast iron involves more than just setting the right parameters. Here are some tips to maximize its lifespan and achieve consistent results:

- <li><strong>Use Quality Workholding:</strong> A rigid setup is paramount. Any movement or vibration will quickly dull the tool’s cutting edges, especially with a brittle material like cast iron.</li>

- <li><strong>Effective Chip Evacuation:</strong> Don’t let chips build up. Ensure your coolant flow is adequate and directed to the cutting zone to wash away chips and prevent them from being recut.</li>

- <li><strong>Minimize Runout:</strong> A precise tool holder and a well-maintained spindle are critical. Even a small amount of runout dramatically increases wear and can cause chatter.</li>

- <li><strong>Avoid Re-engagement on Dwell:</strong> If possible, program your tool path so it doesn’t dwell in the cut at the end of a pass, then re-engage. A slight retract and reposition can save the edge.</li>

- <li><strong>Manage Heat:</strong> While TiAlN is heat-resistant, excessive heat can still degrade the coating and the tool material. Proper coolant use is your best defense.</li>

- <li><strong>Consider Tool Diameter vs. Hole Size:</strong> For larger holes, you might need to use a smaller end mill and perform multiple passes or a larger end mill if it fits. Understand the geometry limitations.</li>

- <li><strong>Cleanliness is Key:</strong> Keep your machine and tooling clean. Metal chips and grit can act as abrasives and damage both the workpiece and the cutting tool.</li>

Comparison: TiAlN vs. Uncoated Carbide for Cast Iron

Choosing coated tooling is often a significant upgrade. Let’s look at why TiAlN stands out against uncoated carbide for this specific application.

| Feature | TiAlN Coated Carbide Ball Nose End Mill | Uncoated Carbide Ball Nose End Mill |

|---|---|---|

| Hardness | Very High (due to coating) | High (carbide material) |

| Heat Resistance | Excellent (up to 800-900°C / 1470-1650°F) | Good (becomes softer significantly above 500°C / 930°F) |

| Tool Life in Cast Iron | Significantly Longer | Shorter |

| Surface Finish in Cast Iron | Smoother, Cleaner | Can be rougher due to faster wear |