Would you like to learn about using a wood lathe? It’s fun to shape wood into beautiful pieces. Imagine making your own bowl or toy! To do this well, you need a wood lathe chuck. This holds the wood tightly while you work. But how do you install it? This wood lathe chuck installation guide will help you step by step. Let’s explore the world of woodturning together!

Key Takeaways

- Installing a chuck is key for safe woodturning.

- Follow a step-by-step guide for best results.

- A wood lathe chuck installation guide ensures correct setup.

- Clean tools improve your woodturning experience.

- Proper setup prevents accidents and makes projects easier.

Understanding Wood Lathe Chuck Parts

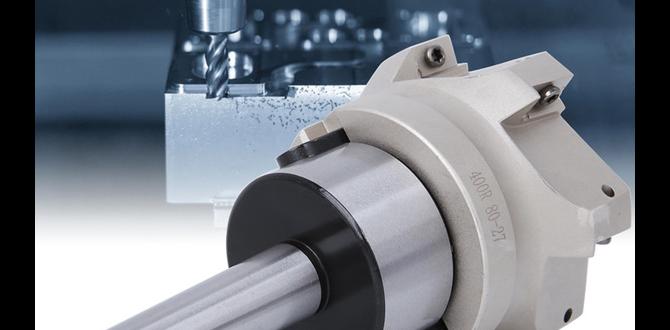

Before installing a chuck, know its parts. The chuck is like a hand. It grips wood so you can shape it. It has jaws that open and close. Most have four jaws. Some chucks are self-centering. This means the jaws move together to hold the wood in the middle. You need to attach the chuck to the lathe spindle. Each lathe may have a different spindle thread size. Make sure your chuck fits!

- Check the number of jaws on your chuck.

- Identify if it’s a self-centering chuck.

- Know your lathe’s spindle size.

- Match chuck type with your project needs.

- Understand chuck key functions for adjustments.

Understanding these parts helps you choose the right chuck for your project. It also ensures you can install it correctly. Using the wrong chuck can damage your lathe or project. Always double-check if your chuck matches your lathe’s spindle size. This prevents mishaps once you start working.

Fun Fact or Stats : The first lathe machine was invented in 1300 BC in Egypt!

What Are Chuck Jaws?

The jaws of a chuck are crucial for gripping wood. Think of them like fingers. They open and close to hold different sizes of wood pieces. Wouldn’t it be neat if you could adjust your fingers to fit any object? That is what chuck jaws do! They can change to hold large or small pieces alike. Choosing the right jaws depends on your project. For example, turning a small pen needs small jaws. Large bowls need bigger jaws. Many chucks come with different jaw sizes for this reason.

How Does Self-Centering Work?

Have you ever balanced a pencil on its tip? It’s tricky! Self-centering chucks make this easy. They find the center point of your wood automatically. This feature is handy for new woodturners. If your wood is off-center, it might spin unevenly. This can cause trouble or even be dangerous. A self-centering chuck saves time and keeps your work neat. It’s like having an invisible helper that makes sure everything is in place!

Choosing the Right Chuck for Your Lathe

Not all chucks fit every lathe. It’s like wearing shoes; the right size matters! Check your lathe for the spindle size. This ensures your chuck fits snugly. A loose chuck might wobble, damaging your project or lathe. Some chucks are for specific projects, like bowl-making. Others are versatile. It’s smart to choose a chuck that fits your lathe and your woodworking goals.

Preparing the Lathe for Chuck Installation

Preparing your lathe is like getting ready for a trip. First, ensure the lathe is off. Safety is important! Clean the spindle to remove dust and debris. Use a soft cloth or brush. Dirt can interfere with the chuck connection. If your lathe has a faceplate, remove it. You might need a wrench for this. Keep screws and parts in a safe spot. Check your lathe’s manual for specific instructions. Manuals often have tips tailored to your machine.

- Turn off the lathe before starting.

- Clean spindle with a soft cloth.

- Remove any existing faceplate carefully.

- Organize screws and parts safely.

- Consult the manual for specific instructions.

Once ready, you can move on to installing the chuck. This preparation ensures a smooth installation process. It also lengthens the life of your lathe. Regular cleaning prevents build-up and makes your tools last longer. Remember, a clean workspace is a safe workspace!

Fun Fact or Stats : Over 80% of lathe accidents happen due to improper setup.

Why Is It Important to Clean the Spindle?

Imagine writing with a dirty pen. Your words might smudge or not show up. A dirty spindle can cause similar issues. Dust or debris can prevent the chuck from attaching properly. This might make it wobble during use. That’s why it’s crucial to clean the spindle before installation. It ensures a tight fit and smooth operation. A clean spindle also protects your tools. They last longer and work better without dirt in the way. It’s like giving your lathe a fresh start every time.

Steps for Removing the Faceplate

Removing the faceplate is easy with practice. First, double-check the lathe is off. Use a wrench to loosen screws holding the faceplate. Turn them counter-clockwise. Do this gently to avoid damage. Once loose, set screws aside safely. Then, slide the faceplate off the spindle. Keep a firm grip to prevent dropping it. Store the faceplate where you can find it later. Following these steps makes the process quick and simple!

Consulting the Lathe Manual

Each lathe is unique, like a fingerprint. The manual is your best friend for details. It tells you about your lathe’s parts and features. Curious about the spindle size? The manual has the answer. Need to know about maintenance? Check the manual! It can even help troubleshoot issues. Don’t worry if it seems complicated at first. With time, you’ll understand it better. Reading the manual gives you confidence to handle your lathe well.

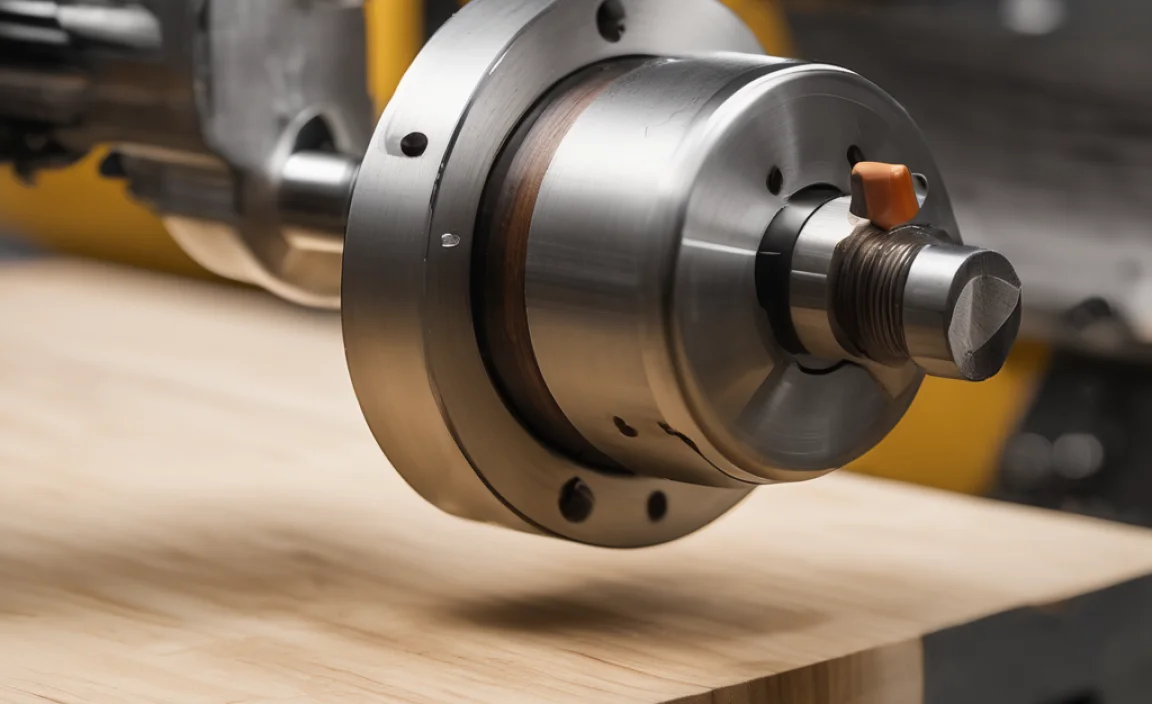

Installing the Wood Lathe Chuck

Now it’s time to install the chuck. Begin by holding the chuck near the spindle. Align it carefully with the threads. Turn the chuck clockwise to attach it. It should fit snugly. Use a chuck key to tighten it further. This ensures the chuck holds firmly. Double-check that it’s secure before you start turning. A loose chuck can be dangerous. Following this wood lathe chuck installation guide is crucial for safety and success.

- Align chuck with spindle threads.

- Turn chuck clockwise to attach.

- Use chuck key to tighten securely.

- Check for a snug fit on the spindle.

- Ensure no movement or wobble before starting.

With the chuck installed, you’re ready to begin woodturning. Always double-check your work. Tighten any loose parts. Safety is key to enjoying your new hobby. A securely installed chuck makes your turning projects easier and more fun!

Fun Fact or Stats : Lathes can spin at over 3,000 revolutions per minute!

Aligning the Chuck with the Spindle

Aligning the chuck is like threading a needle. It takes patience and precision. Hold the chuck close to the spindle. Look closely at the threads. Gently turn the chuck until it catches the thread. Once aligned, the chuck should screw on easily. Avoid forcing it. Forced connections can strip the threads. This may damage the spindle or chuck. Alignment ensures a smooth and safe connection every time.

Using the Chuck Key

Have you ever turned a lock with a key? It feels satisfying when it clicks open. The chuck key works similarly. After aligning the chuck, use the key to tighten it. Insert the key into the chuck’s hole. Turn it clockwise. Listen for a click or feel for tightness. The chuck should not wobble. A firm connection helps you work safely. Never leave the key in the chuck. Doing so can be dangerous when the lathe starts spinning.

Checking Chuck Security

Checking security is like testing a seatbelt before driving. It ensures safety. Once the chuck is on, wiggle it gently. It should not move much. A tight chuck means a secure connection. If it moves, tighten it again. A secure chuck prevents accidents. It also makes woodturning smooth and fun. Safety checks are important every time you use the lathe. They give you peace of mind to focus on creativity.

Testing the Installed Chuck

Now that your chuck is installed, it’s time to test it. Before turning on the lathe, double-check the chuck’s security. Use a piece of scrap wood for testing. Place it in the chuck’s jaws and tighten them. Turn the lathe on at a low speed. Watch the wood closely. It should spin smoothly. If it wobbles, stop the lathe. Tighten or adjust the jaws as needed. This ensures everything is working well.

- Use a scrap wood piece for the test.

- Ensure jaws are securely tightened.

- Turn on lathe at a low speed.

- Check for smooth spinning of wood.

- Adjust if any wobbling occurs.

Testing is an important final step. It confirms that your installation is done right. This step also prepares you for future projects. With a secure setup, you can focus on making amazing creations!

Fun Fact or Stats : Woodturning dates back to ancient Egypt and is over 3,000 years old!

Using Scrap Wood for Safety

Scrap wood is a woodturner’s best friend. It’s perfect for testing the chuck. Why risk a special piece when you can test safely? Place the scrap wood in the jaws. Tighten them as you did during installation. Turn the lathe on at a slow speed. Watch the wood’s movement. Is it smooth? Does it wobble? Adjust the jaws if needed. Scrap wood saves your good pieces and keeps your setup safe.

Observing the Wood’s Movement

Have you ever watched a top spin? It moves smoothly when balanced. Observe the wood in the lathe like this. If the wood spins without wobbling, the chuck is tight. If it wobbles, the jaws need adjustment. A smooth spin means the setup is secure. It ensures your projects will be precise. Testing wood movement is quick and easy. It’s a small step for big safety!

Adjusting Jaws if Needed

If the wood wobbles, don’t worry. Adjusting the jaws is simple. Turn the lathe off first. Loosen the jaws slightly. Reposition the wood and tighten the jaws again. Turn the lathe back on. Check the wood’s movement. Repeat if necessary. Adjusting ensures the chuck holds the wood tightly. A little patience goes a long way in woodturning. With practice, you’ll adjust jaws like a pro!

Maintaining the Wood Lathe Chuck

Maintaining your chuck keeps it working well. After each project, clean the chuck. Remove any wood shavings or dust. Use a brush or cloth. Check for rust or wear on the jaws. If the chuck feels loose, tighten any screws. Lubricate moving parts with oil. This prevents them from sticking. Regular maintenance extends the life of your chuck. It also ensures your projects run smoothly and safely.

- Clean chuck after each use.

- Check for rust or wear on jaws.

- Lubricate moving parts regularly.

- Tighten any loose screws.

- Store chuck in a dry place to avoid rust.

Maintaining your tools is like caring for a garden. It requires regular attention. This attention ensures everything grows and works well. A well-maintained chuck makes woodturning enjoyable and efficient. You’ll also save money by avoiding replacements. Remember, treated well, your chuck will last for years.

Fun Fact or Stats : Regular maintenance can double the lifespan of your tools!

Cleaning the Chuck

Cleaning is key to a happy chuck. After each use, remove wood shavings and dust. A small brush works well for this. Dust can build up and cause issues. Have you ever tried to draw with a pencil covered in dust? It doesn’t work well. The same goes for a dusty chuck. Clean it often to keep it in top shape. This simple habit makes a big difference in how your chuck performs.

Checking for Rust

Rust is a chuck’s enemy. It makes metal parts rough and hard to use. To check for rust, look closely at the jaws and screws. Do you see any brown spots? If so, clean them off. Use a rust remover or sandpaper. Keeping rust away ensures smooth operation. It also prevents damage to your wood pieces. Regular checks help catch rust early. This keeps your chuck in great condition.

Lubricating Moving Parts

Lubricating moving parts keeps them smooth. Do you remember oiling a squeaky door hinge? It suddenly swung quietly. The same goes for your chuck. Apply a few drops of oil to moving parts. This prevents them from sticking. It also reduces wear over time. A well-oiled chuck makes woodturning easier. It ensures everything runs quietly and smoothly.

Conclusion

In this guide, we explored everything about installing a wood lathe chuck. From understanding its parts to proper maintenance, each step is key. Following this wood lathe chuck installation guide makes woodturning safe and fun. Always ensure each step is done right. Enjoy creating amazing wood pieces and keep practicing!

FAQs

Question: Why is a wood lathe chuck important?

Answer: A wood lathe chuck holds wood pieces securely on the lathe. It ensures the wood spins evenly for precise shaping. Without a chuck, the wood might wobble or fly off, making it unsafe to work.

Question: Can I use any chuck on my lathe?

Answer: Not every chuck fits all lathes. Check your lathe’s spindle size before choosing a chuck. This ensures a proper fit. Using the wrong chuck can cause damage or unsafe conditions during use.

Question: How often should I clean my chuck?

Answer: Clean your chuck after each use. This helps remove dust and debris. Regular cleaning prevents build-up that can affect performance. It also prolongs the life of your chuck.

Question: What should I do if my lathe chuck becomes rusty?

Answer: If rust appears, clean it off immediately. Use a rust remover or sandpaper to polish rusty areas. Regular checks help catch rust early. Keeping your chuck clean and dry prevents rust from forming.

Question: Is it difficult to install a wood lathe chuck?

Answer: With a proper wood lathe chuck installation guide, it’s not difficult. Follow step-by-step instructions to align, attach, and secure the chuck properly. Practice makes it easier over time, ensuring a safe and enjoyable woodturning experience.

Question: What safety measures should I take when using a lathe?

Answer: Always wear safety goggles to protect your eyes. Keep sleeves rolled up and tie back long hair. Ensure the chuck is securely fastened before starting the lathe. Follow all manual instructions and never leave the lathe unattended while in use.