Wood Lathe DRO: Accurate & Effortless

Achieving precision and ease on your wood lathe has never been more accessible thanks to the advent of the wood lathe digital readout system, often referred to as a DRO. For woodturners of all skill levels, from hobbyists seeking to improve their project consistency to seasoned professionals demanding absolute accuracy, a DRO can be a transformative addition to their workshop. Gone are the days of painstakingly measuring and remeasuring, or relying on the subjective feel of a caliper against spinning wood. A DRO offers immediate, unambiguous feedback, allowing you to replicate diameters, set depths with confidence, and execute complex tapers and curves with unparalleled control.

The fundamental principle behind a wood lathe DRO is elegantly simple yet remarkably effective. It comprises a series of sensors and a digital display. Typically, one sensor is mounted to the lathe bed, acting as a reference point, while another sensor moves along the carriage, precisely tracking the tool’s position. This movement is translated into numerical data displayed on a sleek, easy-to-read screen. This constant stream of information empowers the woodturner to make informed adjustments in real-time, rather than guessing or relying on memory. The benefits extend beyond just accuracy; a DRO significantly reduces the mental load, freeing up cognitive energy to focus on the creative process and the aesthetic nuances of the turning.

Understanding the Components of Your Wood Lathe Digital Readout System

Before diving into the advantages, it’s helpful to understand the core components of a typical wood lathe digital readout system installation. Most systems consist of:

Linear Scales (Sensors): These are the workhorses, designed to be mounted to fixed parts of the lathe, usually the bed. They contain a sensing element that reads a coded track on a movable magnetic strip or glass encoder. The accuracy of the DRO is directly tied to the precision of these scales.

Readhead/Encoder: Attached to the moving carriage of the lathe, this component reads the data from the linear scale. As the carriage moves, the readhead interprets the changes in the scale’s coded pattern and transmits this information.

Digital Display Unit (Console): This is the user interface of the DRO. It receives the data from the readheads and presents it in a clear, digital format. Most consoles allow for zeroing out the display at any point, which is crucial for setting reference points and measuring incremental movements. They often also offer functions like inch/millimeter conversion and absolute/incremental modes.

Mounting Hardware: This includes brackets, fasteners, and protective covers to securely install the scales and readheads onto the lathe without interfering with its operation.

The installation process itself can vary depending on the lathe model and the specific DRO kit chosen. However, most manufacturers provide detailed instructions and sometimes even pre-fabricated mounting brackets to simplify the setup. While some technically inclined individuals may find it a straightforward DIY project, others might prefer professional installation to ensure optimal alignment and performance.

Enhancing Your Woodturning with a Wood Lathe DRO

The impact of a wood lathe digital readout system on your turning endeavors can be profound. Let’s explore some of the key benefits:

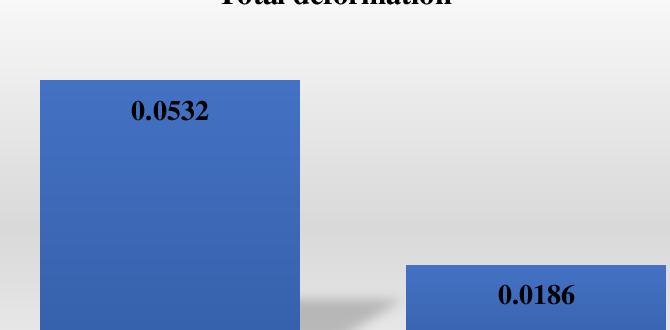

Unrivaled Accuracy and Consistency: This is the most significant advantage. Whether you’re turning identical legs for a table, creating finely tuned bowls with precise wall thicknesses, or replicating complex decorative elements, a DRO eliminates guesswork. You can set a target diameter and turn down to it with confidence, knowing exactly where your tool is in relation to the workpiece. This leads to higher quality finished products and significantly reduces material waste due to over-turning.

Effortless Replication: Imagine making multiple identical components. With a DRO, you can measure the first component, zero the display, and then use that read-out as your guide for subsequent pieces. This is invaluable for furniture making, spindle turning, and any project requiring uniformity.

Simplified Spindle Turning and Tapers: Creating smooth, consistent tapers can be a challenge for many woodturners. A DRO allows you to measure the exact taper angle by observing spindle movement and tool position. You can input your desired taper dimensions and make precise adjustments as you turn, achieving perfect profiles every time.

Reduced Measurement Interruptions: Traditionally, checking dimensions requires stopping the lathe, taking calipers or a measuring tape to the workpiece, and then restarting. This cycle can be time-consuming and can lead to slight errors if the workpiece moves or if the measurement isn’t taken accurately. A DRO provides continuous, on-the-fly measurement, allowing you to keep the lathe running and maintain momentum, leading to a smoother and more efficient workflow.

Improved Learning Curve for Beginners: For individuals new to woodturning, the learning curve can be steep. A DRO demystifies the process of controlling tool position and achieving specific dimensions. It provides immediate feedback on their actions, allowing them to quickly understand how their movements translate into material removal and shape creation. This can significantly accelerate their skill development and build confidence.

Enhanced Safety: While not its primary function, a DRO can indirectly contribute to safety. By reducing the need for frequent stopping and starting to measure, and by providing clear, unambiguous positional data, it can lead to a more focused and less interrupted turning session. This can minimize distractions and improve overall control of the machine.

Choosing the Right Wood Lathe Digital Readout System

When selecting a wood lathe digital readout system, consider a few key factors:

Lathe Size and Travel: Ensure the DRO system is designed for the size and travel distance of your lathe. Scale lengths need to accommodate the full range of movement of your carriage and tailstock.

Accuracy Requirements: DROs come with varying levels of accuracy. For most woodturning applications, a resolution of 0.01mm or 0.0005 inches is more than sufficient.

Durability and Environmental Resistance: Wood dust and chips are pervasive in a workshop environment. Look for systems with robust construction and seals that can withstand these conditions.

Ease of Installation and Use: Consider your own technical comfort level and whether the system is known for straightforward installation and an intuitive display.

* Brand Reputation and Support: Research different brands and read reviews from other woodturners to gauge reliability and customer support.

In conclusion, a wood lathe digital readout system is an investment that pays dividends in accuracy, consistency, and efficiency. It empowers woodturners to elevate their craft, transforming challenging tasks into effortless processes. By providing clear, real-time positional data, a DRO allows you to focus on the artistic aspects of your work, confident that your measurements are precise and your results are repeatable. For anyone serious about achieving superior results on their wood lathe, a DRO is no longer a luxury, but an essential tool.