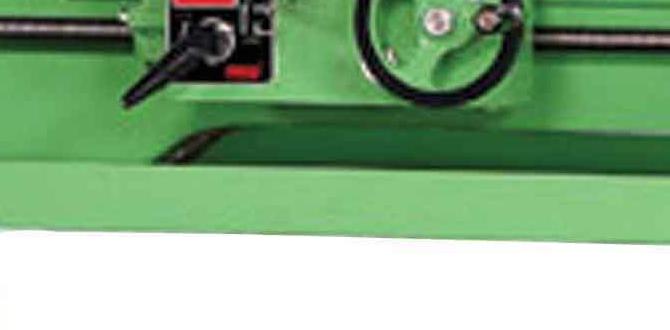

Bringing Precision to Your Woodturning: A DIY Wood Lathe Duplicator Attachment Guide

Bringing precision to your woodturning projects just became a whole lot more accessible with the creation of a DIY wood lathe duplicator attachment. For woodturners, whether seasoned professionals or enthusiastic hobbyists, the desire to replicate identical turned components is a frequent aspiration. From crafting matching sets of chair legs to duplicating intricate spindle designs for furniture restoration, the ability to achieve uniformity can elevate your work from merely functional to exquisitely crafted. While commercial duplicator attachments exist, they can often come with a hefty price tag. Fortunately, with a bit of ingenuity and a willingness to get your hands dirty, you can construct your own effective duplicator attachment, unlocking a new level of efficiency and repeatability in your workshop.

The fundamental principle behind a wood lathe duplicator is remarkably simple. It essentially acts as a template-following system. A stylus or tracer arm is guided along the contours of a master pattern. This movement is then mechanically transferred to a cutting tool, which mirrors the stylus’s path on a secondary workpiece mounted on the lathe. This allows for the rapid and accurate reproduction of shapes, saving countless hours of meticulous measurement and carving. Building your own version puts this powerful tool within reach of any woodworker equipped with basic tools and a creative spirit.

Understanding the Core Components of Your Wood Lathe Duplicator Attachment

Before diving into the construction, it’s crucial to grasp the essential elements that make a duplicator work. The primary components you’ll need to consider for your wood lathe duplicator attachment guide DIY project are:

The Template: This is your master shape. It can be made from a variety of materials, including plywood, MDF, hardwood, or even sturdy plastic. The key is that it’s dimensionally stable and has a clean, well-defined edge for the stylus to follow. It needs to be an exact representation of the desired final shape.

The Stylus/Tracer: This is the point of contact with your template. It needs to be robust enough to withstand repeated contact and glide smoothly along the template’s edge. A hardened steel pin, a ball bearing, or even a specialized carbide-tipped tracer can be used.

The Tool Holder/Cutting Mechanism: This is where your cutting tool (typically a standard lathe chisel) will be mounted. The critical aspect here is that the cutting tool’s cutting edge must be in a fixed, parallel relationship to the stylus. Any deviation will result in a distorted copy.

The Mounting System: This is how your duplicator attaches to your existing wood lathe. It needs to be secure and allow for precise alignment. You’ll need a method to attach it firmly to the lathe bed or tool rest, ensuring it remains stable during operation.

The Repulsion Mechanism (Optional but Recommended): This is often a spring-loaded system that gently pushes the stylus against the template. This ensures consistent contact and prevents the stylus from skipping or losing its place on the template, leading to a more accurate copy.

Designing Your DIY Wood Lathe Duplicator: Key Considerations

When planning your DIY wood lathe duplicator attachment, several design factors will influence its effectiveness and ease of use.

First, consider the range of workpiece sizes you intend to duplicate. Will you be working with small spindle blanks or larger table legs? This will dictate the overall size and rigidity of your duplicator’s frame and travel mechanism.

Secondly, material selection is paramount. For structural components, hardwoods like oak or maple, or even sturdy plywood, are excellent choices. For pivot points and sliding surfaces, consider using materials that offer low friction, such as brass bushings or even PTFE (Teflon) tape if available. The stylus should ideally be made from a hard, wear-resistant material.

Thirdly, pivot points and linear movement must be smooth and precise. If your duplicator relies on pivoting arms, ensure the pivot pins are well-aligned and minimize any wobble. If you’re incorporating a sliding mechanism, consider using linear bearings or carefully machined channels with smooth mating surfaces to ensure effortless movement without play.

Finally, safety features should not be overlooked. While the inherent nature of woodturning requires caution, a duplicator adds another layer of complexity. Ensure all components are securely fastened and that there are no exposed sharp edges or pinch points that could snag clothing or skin. Regularly inspect your attachment for wear and tear.

Building Your Woody Lathe Duplicator: A Step-by-Step Approach (Conceptual)

While specific dimensions and construction methods will vary based on your lathe and available materials, here’s a conceptual breakdown of how you might approach building your duplicator:

1. Construct the Base/Mounting Bracket: This component will attach directly to your lathe. It needs to be robust and allow for adjustable positioning. Consider using angle iron, thick steel plate, or a precisely machined wooden block.

2. Fabricate the Pivoting Arm(s): This is the heart of the duplicator. You’ll likely need at least two arms: one for the stylus and one for the tool holder. These arms should be rigidly connected, maintaining a fixed distance and orientation between the stylus and the cutter. Consider using sturdy metal tubing or precisely cut hardwood.

3. Incorporate the Stylus and Tool Holder: Mount your chosen stylus securely to one arm. On the other arm, create a robust clamp or mounting system for your lathe chisel. This needs to be adjustable to accommodate different chisel sizes and to ensure precise alignment relative to the stylus.

4. Develop the Linear Movement/Pivot System: If your design utilizes a sliding mechanism, create the rails and mating surfaces that allow for smooth, unhindered travel parallel to the lathe’s bed. If it’s a pivoting design, ensure the pivot points offer minimal friction and wobble.

5. Add the Repulsion Spring (If Applicable): Design a simple system to mount a spring that applies gentle pressure, pushing the stylus against the template. This could involve a spring-loaded plunger or a tensioned spring attached to the arms.

6. Create and Mount the Template: Cut your template accurately to the desired shape. You’ll need a method to securely attach the template to the lathe, typically to the headstock end, allowing it to rotate in sync with the workpiece. This might involve a custom-made faceplate or mounting bracket.

7. Assembly and Alignment: Carefully assemble all components, ensuring smooth operation and verifying that the stylus and cutting tool remain perfectly parallel throughout their entire range of motion. This is the most critical step for accuracy.

Using Your DIY Wood Lathe Duplicator Effectively and Safely

Once your wood lathe duplicator attachment guide DIY project is complete and functioning, safe and effective operation is key.

Template Preparation: Ensure your template is smooth, free of any burrs or imperfections that could snag the stylus.

Workpiece Mounting: Securely mount your workpiece to the lathe.

Initial Setup: Position the duplicator so the stylus is in contact with the starting point of your template. Position your cutting tool to make a very light initial cut or to just touch the blank.

Slow and Steady Wins the Race: Begin turning at a low speed, especially for initial passes. Allow the stylus to guide the cutting tool on the blank.

Gradual Material Removal: Make multiple light passes rather than attempting to remove large amounts of material at once. This is crucial for preventing tear-out and ensuring accuracy.

Tool Sharpness: Keep your lathe chisels exceptionally sharp. A dull tool will struggle to follow the template accurately and will result in a poor finish.

Regular Inspection: Periodically check your DIY attachment for any signs of wear, loose bolts, or excessive play. Address any issues immediately.

* Personal Safety: Always wear appropriate safety gear, including eye protection. Be mindful of rotating parts and avoid loose clothing.

By investing the time and effort into building your own wood lathe duplicator attachment, you’re not just saving money; you’re gaining a deeper understanding of the mechanics of woodturning and acquiring a valuable tool that will expand your creative possibilities and enhance the precision of your craft. Happy turning!