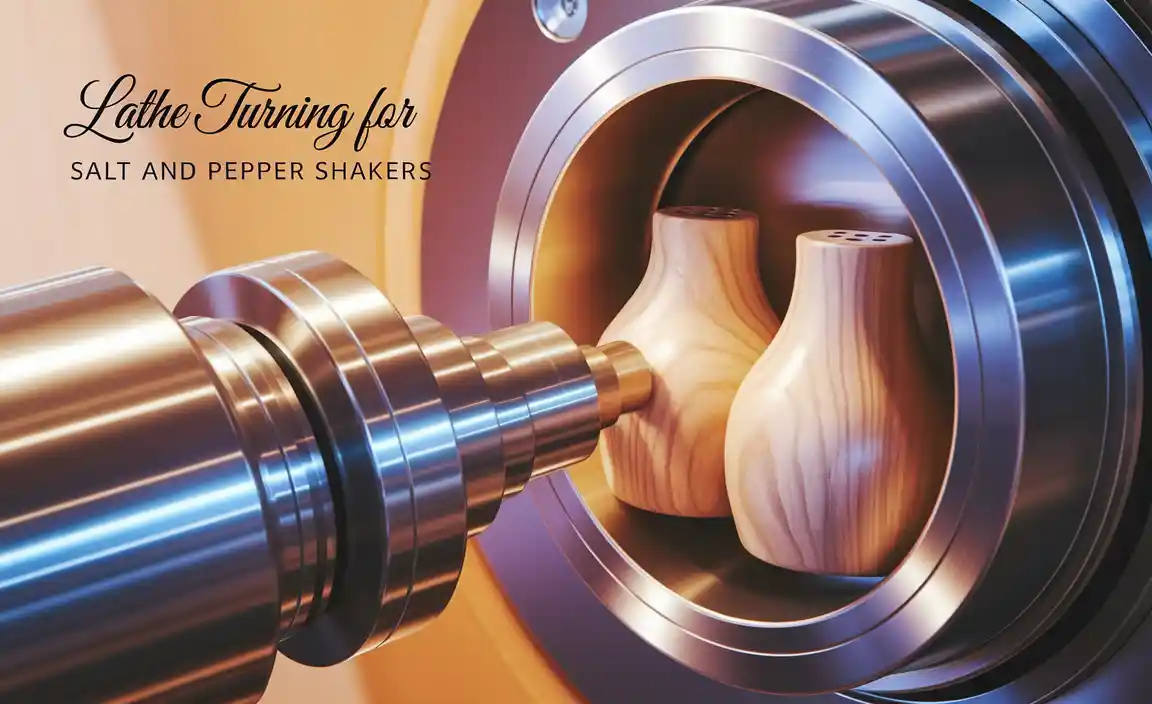

Wood Lathe Dust Shroud DIY: Effortless Setup for a Cleaner Workshop

Wood lathe dust shroud DIY: effortless setup is a game-changer for any woodturner seeking a cleaner, safer, and more enjoyable workspace. While the mesmerizing dance of wood against a spinning tool is an art form, it inevitably produces a significant amount of fine particulate matter and wood chips. This debris not only creates a mess but can also pose health risks due to inhalation and detract from the overall experience. Fortunately, crafting your own effective dust shroud is a surprisingly achievable project that can be completed with basic tools and materials, offering a significant upgrade to your workshop environment.

The benefits of a well-designed dust shroud extend far beyond mere cleanliness. Improved air quality is paramount. Fine wood dust, when airborne, can irritate the lungs and eyes, leading to respiratory issues and discomfort over time. A shroud effectively captures a substantial portion of this dust at its source, preventing it from dispersing into the air. This means less time spent cleaning and more time dedicated to the creative process. Furthermore, some woods can produce irritating or even toxic dust, making dust collection a safety necessity. Beyond health, a cleaner shop is simply a more pleasant place to work. Reduced dust means less residue coating your lathe, tools, and finished projects, preserving their pristine condition.

Designing Your Wood Lathe Dust Shroud: Key Considerations

When embarking on your wood lathe dust shroud DIY project, careful planning will ensure a functional and efficient design. The primary goal is to create a barrier that directs airborne dust and debris towards your dust collection system. Several design elements are crucial:

Coverage: The shroud needs to encompass the turning area as much as possible without impeding your ability to access the workpiece or controls. It should ideally extend from the lathe bed towards the tool rest and reach a reasonable distance along the bed to capture material expelled forward.

Inlet Port: A critical component is the dust collection port. This is where your shop vacuum or dedicated dust collector will connect. The size and placement of this port will influence its effectiveness. A common recommendation is a 2.5-inch or 4-inch diameter port, depending on your dust collection capabilities. Consider positioning it so that the airflow created by your vacuum helps draw dust into the port, rather than fighting against the natural trajectory of the dust.

Visibility: You need to be able to see your work. The shroud should not obstruct your view of the turning operation. This might involve using transparent materials like clear acrylic or polycarbonate, or strategically placed cutouts.

Accessibility: Easy access to the workpiece for adjustments, measurements, and tool changes is essential. Hinged sections, removable panels, or a design that allows for quick detachment can be incorporated.

Material Choice: Durability, ease of cutting, and cost are key factors in material selection. Common choices include plywood, MDF, acrylic, polycarbonate, or even sturdy coroplast.

Building Your Wood Lathe Dust Shroud: A Step-by-Step Guide

Let’s dive into a practical approach for your wood lathe dust shroud DIY. This guide outlines a common and effective method using plywood and clear acrylic.

Materials You’ll Need:

Plywood (1/2 inch or 3/4 inch is suitable)

Clear Acrylic or Polycarbonate sheeting (⅛ inch or ¼ inch thick)

Wood screws

Hinges (optional, for access panels)

Dust collection port (a 90-degree sweep elbow or a pre-made dust collection fitting)

Tools: Saw (circular saw, jigsaw, or table saw), drill, measuring tape, pencil, sandpaper, clamps.

Construction Steps:

1. Measure and Template: Measure the dimensions of your lathe’s headstock, tailstock, and bed. Determine the desired footprint of your shroud. It’s often easiest to create cardboard templates first to refine the shape and fit before cutting your permanent materials.

2. Cut the Base and Sides: Cut your plywood into the necessary panels for the base and sides of your shroud. Consider a U-shaped design that fits around the lathe bed. The height of the sides will depend on how much dust capture you aim for, but typically a few inches above the top of the workpiece is sufficient.

3. Prepare the Acrylic Window: Cut your acrylic sheeting to create a viewing window. This can be a large panel that spans the front of the shroud or smaller windows strategically placed. Smooth the edges of the acrylic with fine-grit sandpaper or a cloth wheel to prevent cracking.

4. Attach the Acrylic: Secure the acrylic to the plywood frame. You can achieve this by creating a rabbet in the plywood for the acrylic to sit in, then securing it with screws and possibly a bead of silicone sealant for a better seal. Alternatively, you can create a simple frame and use screws to hold the acrylic in place.

5. Create the Dust Port Opening: Decide on the placement of your dust collection port. Cut an appropriate-sized hole in the plywood for your chosen port. This is often on the side or back of the shroud.

6. Install the Dust Port: Insert your dust collection port into the hole. Secure it with screws or epoxy, ensuring a good seal to prevent air leaks. If using a sweep elbow, you might need to fashion a fitting to connect it to your vacuum hose.

7. Assemble the Shroud: Assemble the plywood panels using wood screws. Ensure all joints are sturdy and as airtight as possible. If you’re incorporating access panels or doors, attach them with hinges now.

8. Mounting (Optional but Recommended): Consider how you will attach the shroud to your lathe. Some DIY designs simply rest on the lathe bed. Others might be secured with clamps, or even have dedicated mounting points that attach to the lathe bed. This prevents the shroud from shifting during operation.

Enhancing Your Wood Lathe Dust Shroud: Advanced Touches

Once your basic wood lathe dust shroud DIY is functional, there are several ways to elevate its performance and usability:

Dust Baffles: Adding internal baffles can help to slow down the airflow and encourage larger dust particles to fall out of suspension before reaching the dust port, reducing the load on your collection system.

Integrated Lighting: Consider adding a small LED light inside the shroud to improve visibility of intricate details on your workpiece.

Brush Seals: A flexible brush seal around the bottom edge of the shroud can further minimize dust escaping.

Quick-Release Mechanism: If you frequently need to remove the shroud, designing a quick-release mounting system can save significant time and effort.

Material Choice Refinements: For very fine dust or exotic woods, consider smoother, non-porous interior surfaces like melamine-coated particle board or even lining the inside with plastic sheeting to prevent dust from embedding into the wood fibers.

Implementing a wood lathe dust shroud is an investment in your health, your tools, and the overall enjoyment of your woodworking journey. The wood lathe dust shroud DIY: effortless setup described here offers a practical and effective solution that is well within the reach of most hobbyists, transforming your workshop into a cleaner, safer, and more productive space.