Looking for optimal speeds for your 3/8 inch ball nose end mill in cast iron? This guide offers precise, beginner-friendly settings to achieve fantastic results. We’ll cut through the confusion and give you the exact numbers you need for clean finishes and efficient machining, even if you’re new to milling cast iron.

Milling cast iron with a ball nose end mill can feel a bit like walking a tightrope. One minute you’re getting beautiful, smooth surfaces, and the next, you’re battling chatter, tool wear, or a finish that looks like it went through a rock tumbler. It’s a common frustration, especially when you’re just starting out or trying a new material. But don’t worry! Getting those “genius” speeds and feeds for your 3/8 inch ball nose end mill in cast iron is totally within your reach. We’ll break it down into simple, actionable steps so you can get back to making awesome parts with confidence.

Understanding the Basics: Why Speeds and Feeds Matter

Before we dive into specific numbers, let’s quickly touch on why these settings are so crucial. Think of your end mill as a tiny, high-speed cutting tool. The “speeds” refer to how fast the tool rotates (Spindle Speed, measured in RPM – Revolutions Per Minute). The “feeds” refer to how quickly the tool moves through the material (Feed Rate, usually measured in Inches Per Minute, IPM). Getting these two in sync is like tuning a guitar: too tight, and it buzzes unpleasantly (chatter, tool breakage); too loose, and it just doesn’t sound right (poor finish, slow cutting).

For cast iron, a material known for being abrasive and sometimes brittle, finding that sweet spot is even more important. It’s not as forgiving as aluminum, and it’s definitely tougher than wood. With a ball nose end mill, the unique geometry adds another layer because the cutting forces are constantly changing as it works its way into or out of a cut.

Key Factors for Cast Iron Machining

Several things influence the perfect speeds and feeds:

- Material Type: Cast iron isn’t just one thing! Ductile iron, gray cast iron, and malleable iron all have different machining characteristics. For this guide, we’ll focus on common gray and ductile cast irons.

- Tool Material: Are you using a High-Speed Steel (HSS) or a Tungsten Carbide end mill? Carbide is almost always the better choice for cast iron due to its hardness and heat resistance.

- Number of Flutes: This is how many cutting edges your end mill has. For cast iron, 2-flute or 4-flute carbide end mills are typical. 2-flute are great for slotting and high chip loads, while 4-flute can handle finishing and offer a smoother cut.

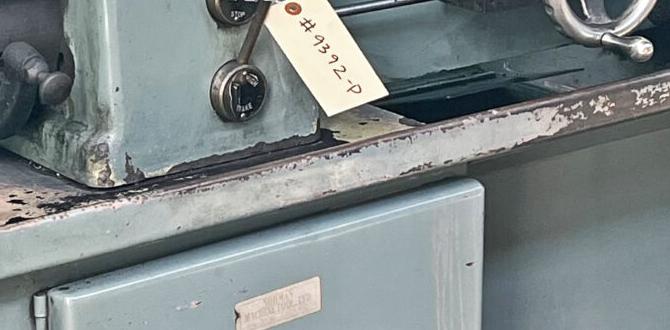

- Machine Rigidity: A mill that’s solid and doesn’t vibrate will handle higher speeds and feeds much better than a light-duty or wobbly machine.

- Coolant/Lubrication: Using a cutting fluid or mist system is highly recommended for cast iron. It cools the cutting edge, lubricates the cut, and helps evacuate chips, all of which extend tool life and improve finish.

- Depth of Cut (DOC) and Width of Cut (WOC): How deep and how wide you’re cutting significantly impacts the cutting forces. Smaller depths and widths generally allow for higher speeds.

Your 3/8 Inch Ball Nose End Mill: The Specs

A 3/8 inch ball nose end mill has a diameter of 0.375 inches and a perfectly hemispherical tip. This makes it ideal for creating concave shapes, fillets, and complex 3D contours. In cast iron, the abrasive nature of the material means carbide is your go-to. For this guide, we’ll assume you’re using a good quality two or four-flute uncoated or thin-film coated carbide ball nose end mill.

Tool Specifications we’ll reference:

- Diameter: 3/8″ (0.375″)

- Type: Ball Nose End Mill

- Material: Carbide (assumed)

- Flutes: 2 or 4 (we’ll provide options)

- Coating: Uncoated or TiN (Titanium Nitride) coating is common and works well here.

Recommended Speeds and Feeds for Cast Iron

Finding the “genius” speeds and feeds isn’t about one magic formula, but rather a starting point based on best practices. These numbers are designed to keep your tool happy, your material cut cleanly, and your machine running smoothly. We’ll provide a table with recommended starting points. It’s always best to start conservatively and increase if your machine and setup can handle it.

Important Note: These are starting points. Always listen to your machine, watch your chips, and feel for chatter. Adjust as needed!

Carbide Ball Nose End Mill Speeds & Feeds for Cast Iron (3/8″)

| Tool Type | Spindle Speed (RPM) | Feed Rate (IPM) | Depth of Cut (DOC) – Axial | Depth of Cut (DOC) – Radial (WOC) | Notes |

|---|---|---|---|---|---|

| 2-Flute Carbide Ball Nose (Finishing) | 2000 – 3000 | 10 – 25 | 0.010″ – 0.020″ | 0.050″ – 0.100″ (Contour) / 0.015″ (Restricted) | Use for smooth contour passes and shallow cuts. Prioritize finish. |

| 2-Flute Carbide Ball Nose (Slotting/Roughing) | 1500 – 2500 | 8 – 15 | 0.020″ – 0.040″ | 0.1875″ (Full Slot) / 0.075″ (Partial Slot) | Higher chip load, watch for heat. Good chip evacuation is key. |

| 4-Flute Carbide Ball Nose (Finishing) | 2500 – 3500 | 15 – 30 | 0.005″ – 0.015″ | 0.075″ – 0.150″ (Contour) / 0.020″ (Restricted) | Excellent for smooth surfaces and 3D profiling. Can run slightly faster than 2-flute for finishing. |

| 4-Flute Carbide Ball Nose (Light Roughing/Profiling) | 2000 – 3000 | 12 – 25 | 0.015″ – 0.030″ | 0.125″ – 0.1875″ | Good balance between material removal and finish. |

Understanding DOC (Depth of Cut) and WOC (Width of Cut) for Ball Nose Mills:

- Axial DOC: This is how deep the ball tip cuts into the material. For finishing, you want it very shallow. For roughing, you can go deeper.

- Radial WOC: This is crucial for ball nose mills.

- Contour/Pencil Milling: When the ball tip is only engaging a small portion of its diameter (like tracing a line), WOC is small (e.g., 0.050″ to 0.150″).

- Slotting: When you’re cutting a full slot, WOC is equal to the tool diameter (0.375″).

- Restricted: When you need to remove material but can’t use the full diameter for engagement, WOC will be somewhere in between.

Choosing Your Cutting Strategy

The way you approach the cut makes a big difference. For ball nose end mills, especially on a 3D surface or for a fillet, you’ll mostly be using contouring strategies.

Finishing Passes:

- Use a shallow axial DOC (e.g., 0.010″ – 0.020″).

- Use a relatively small radial WOC for smooth stepovers (e.g., 0.050″ – 0.150″). The smaller the WOC, the smoother the surface finish, but the longer the machining time.

- Keep the spindle speed in the higher range recommended.

- Feed rate is critical for finish. Tune it to avoid chatter – a slightly slower feed rate can sometimes yield a better finish if chatter is an issue.

Roughing Passes:

- You can use a deeper axial DOC (e.g., 0.020″ – 0.040″).

- You can potentially use a larger radial WOC if your machine is rigid enough, but be mindful of chip thinning.

- Spindle speed might be a bit lower to manage heat and cutting forces.

- Feed rate can be higher, aiming for consistent chip formation.

Step-by-Step Guide to Machining Cast Iron

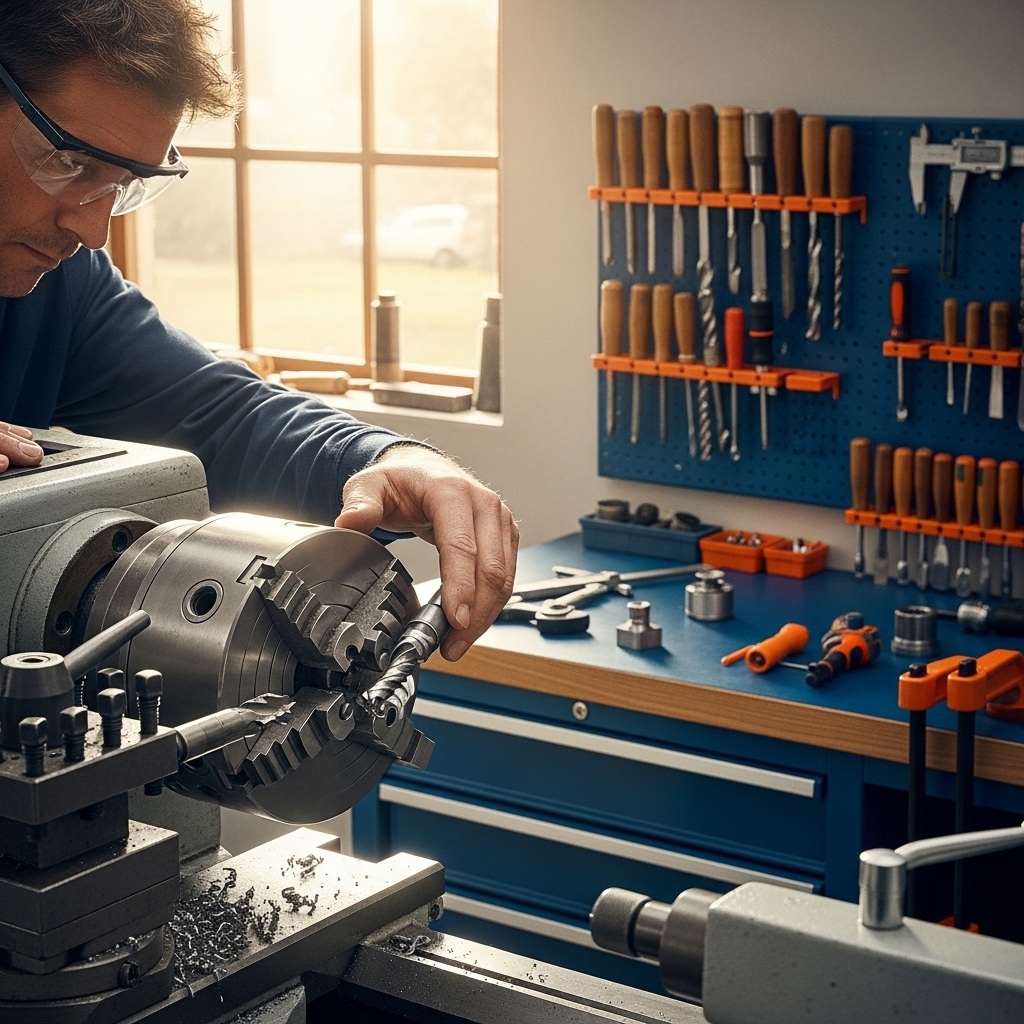

Here’s how to set up and run your 3/8 inch ball nose end mill on cast iron, step-by-step:

Step 1: Preparation is Key

- Secure the Workpiece: Ensure your cast iron part is well-clamped to the milling machine table. Use vises, clamps, or your fixture to prevent any movement during machining. Cast iron can be brittle, so avoid overtightening that could crack it.

- Set Up Your Machine: Make sure your milling machine is clean and in good working order. Check that gibs are properly adjusted for a rigid setup.

- Install the End Mill: Insert your 3/8 inch ball nose carbide end mill securely into a quality collet or tool holder. Ensure it’s seated properly to avoid runout.

- Coolant/Lubrication: Set up your coolant system. Flood coolant is ideal for cast iron, but a mist system or even a cutting paste can significantly help. A good cutting fluid for ferrous metals is recommended. You can find excellent data on cutting fluids from sources like the Machinery Lubricants magazine.

Step 2: Setting Your Speeds and Feeds

- Consult the Table: Review the table above. For a typical finishing pass, select a starting point for a 4-flute carbide ball nose end mill. Let’s say we choose:

- Spindle Speed: 3000 RPM

- Feed Rate: 25 IPM

- Axial DOC: 0.010″

- Radial WOC: 0.075″

- Program (or Set Manually): Input these values into your CNC controller or set them on your manual mill. If using a manual mill, control the feed rate carefully to match the programmed IPM as closely as possible.

Step 3: Initiating the Cut

- Tool Length Offset: Accurately set your Z-axis tool length offset. This is critical for the correct depth of cut.

- X and Y Zero: Set your X and Y zero points on your workpiece according to your CAM program or manual setup.

- First Pass Check: Start the spindle and carefully bring the tool down to engage the material. Watch and listen. Are chips forming? Is the machine noisy?

- Observe Chip Load: For cast iron, you want to see small, manageable chips, not fine dust (which indicates rubbing and heat) or large, stringy chips (which can clog flutes). The chips should be coming off cleanly.

Step 4: Monitoring and Adjusting

- Listen for Chatter: Any high-pitched squealing or irregular vibration means your speeds or feeds are off, or your setup isn’t rigid enough.

- Too Fast Feed: If you get chatter, try slightly reducing the feed rate (e.g., from 25 IPM down to 20 IPM).

- Too Slow Feed: If the tool seems to be rubbing, you might be able to increase the feed rate slightly.

- Spindle Speed: If chatter persists, experiment with spindle speed. Sometimes a little higher or lower can make a big difference.

- Check Tool Temperature: The tool and the workpiece should be warm, but not excessively hot to the touch. Excessive heat is a sign of too much friction, often caused by insufficient feed rate or poor chip evacuation.

- Examine the Finish: After completing a pass, inspect the surface. Is it smooth? Are there any ridges from tool runout or chatter? A good finishing pass should leave a clean, consistent surface.

- Adjust Radial WOC for Finish: If you need a super-smooth surface, you can reduce the radial WOC. This means the tool will take smaller, overlapping steps. For example, reducing WOC from 0.075″ to 0.040″ for a finishing pass will result in a finer surface finish but take longer.

Step 5: Advanced Considerations (for when you’re comfortable)

- High-Speed Machining (HSM): For more advanced setups, you might explore HSM techniques. This often involves much higher spindle speeds and much lower chip loads (which translates to a higher feed rate as the tool engages less material per revolution). However, this requires a machine capable of high RPMs and rigidity.

- Variable Helixes: Some CAM software offers tools with variable helix angles. These can help break up the cutting harmonics and reduce chatter, especially in tougher materials. Refer to your tool manufacturer’s recommendations, like those found on websites from leading tooling suppliers.

- Tool Wear: Keep an eye on your end mill. In cast iron, the abrasive nature can cause premature wear. If finishes start to degrade, it might be time for a new tool. The Sandvik Coromant website offers a wealth of information on tool wear evaluation and machining strategies.

Troubleshooting Common Problems

Even with the best settings, you might run into issues. Here’s how to tackle them:

Problem: Excessive Chatter or Vibration

- Cause: Tool rigidity, spindle speed, feed rate, machine rigidity, workpiece clamping.

- Solution:

- Reduce feed rate.

- Slightly reduce spindle speed or find a “sweet spot” where vibration is minimized.

- Check tool length projection – shorter is stiffer.

- Ensure workpiece is clamped very securely.

- Make shallower depths of cut.

Problem: Poor Surface Finish (Scalloping, Ridges)

- Cause: Tool runout, incorrect feed rate, tool wear, insufficient coolant.

- Solution:

- Ensure the collet and tool holder are clean and runout is minimal.

- Reduce radial WOC for finishing passes.

- Use a higher spindle speed (if possible) with a suitable feed rate.

- Check for tool wear.

- Ensure adequate coolant flow.

Problem: Tool Breakage

- Cause: Too aggressive feed rate, too deep of a cut (axial or radial), insufficient rigidity, chip recutting.

- Solution:

- Significantly reduce feed rate and DOC.

- Ensure the machine and workpiece are rigid.

- Verify tool condition – a chipped or dull tool is more prone to breaking.

- Make sure chips are clearing the flute; a chip jam can shock-load the tool.

Problem: Overheating/Burning

- Cause: Insufficient feed rate (tool rubbing), lack of coolant, dull tool.

- Solution:

- Increase feed rate for higher chip load.

- Ensure effective coolant delivery directly to the cutting zone.

- Use a sharp tool.

Safety First!

Always remember that machining involves powerful tools and forces.:

- Eye Protection: Always wear safety glasses or a face shield.