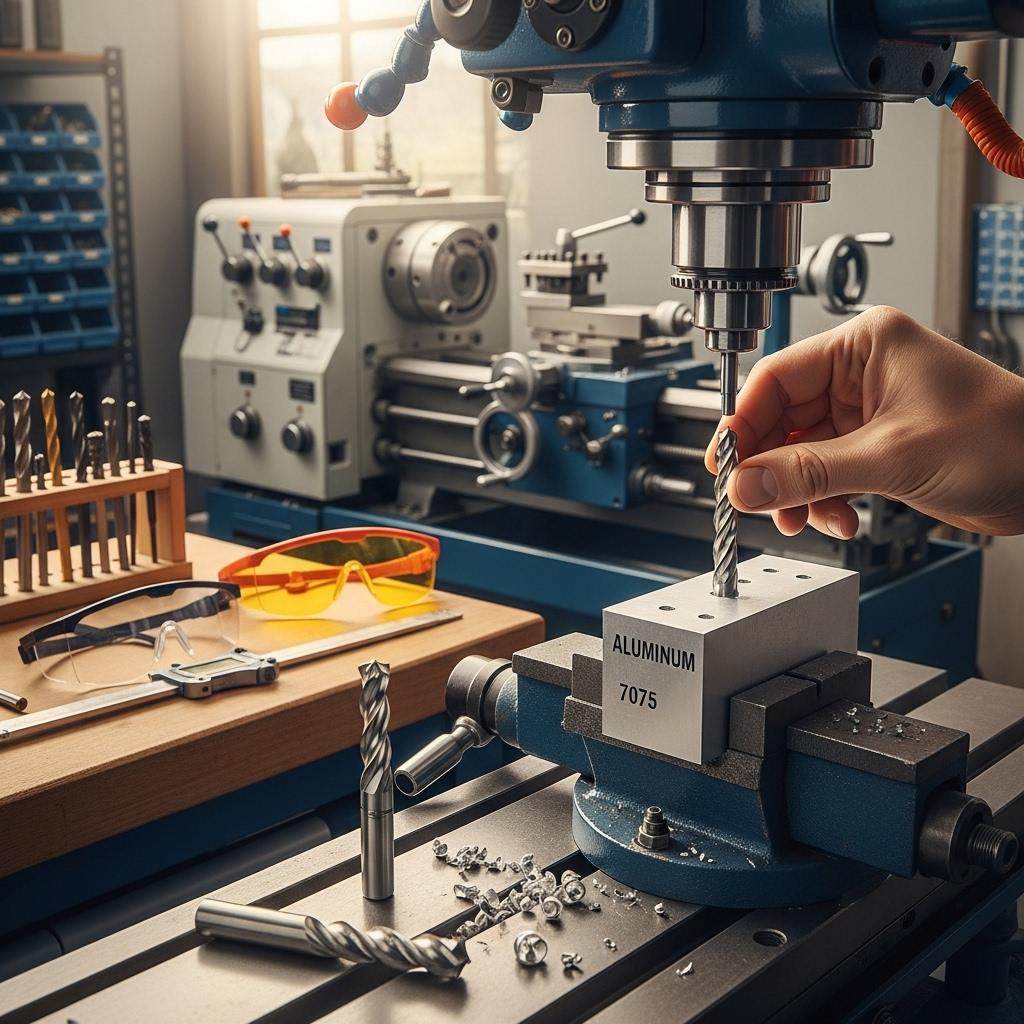

Quick Summary: For Aluminum 7075, a ball nose end mill is best for 3D contouring and smooth curves, while a corner radius end mill excels at creating sharp internal corners and maintaining tool strength for pocketing or slotting. Both are crucial, but their application depends on the desired geometry.

Hey everyone, Daniel Bates here from Lathe Hub! If you’re diving into the world of CNC machining, especially with a material as fantastic as Aluminum 7075, you’ve probably come across a couple of common tools: the ball nose end mill and the corner radius end mill. Deciding which one to use can feel a bit tricky, especially when both seem to work. But understanding their differences makes a huge impact on the finish quality and efficiency of your projects. We’ll break down exactly what makes each tool special and when to grab them. Let’s get your Aluminum 7075 projects looking smooth and precise!

Understanding Aluminum 7075

Before we dive into the specifics of end mills, let’s quickly chat about Aluminum 7075. This alloy is like the superhero of aluminum! It’s incredibly strong, often compared to many steels, yet it remains relatively lightweight. This makes it a favorite for high-performance applications, such as aerospace components, sporting goods, and high-end industrial parts. Machining 7075 can be a bit more challenging than softer aluminum alloys because of its hardness and tendency to work-harden. This is where choosing the right cutting tool becomes super important. Using the wrong tool or machining parameters can lead to poor surface finish, tool breakage, or frustratingly slow work. So, let’s make sure we’re picking the right tools for the job!

Ball Nose End Mill: The Sculptor of Curves

Imagine you need to create a perfectly rounded surface, a smooth transition between different planes, or a complex 3D shape. That’s where the ball nose end mill shines. As the name suggests, its cutting tip is a perfect hemisphere, like the end of a ball. This rounded shape means it can cut in any direction on the XY plane and also engage the workpiece with its full radius when plunging or moving vertically.

What is a Ball Nose End Mill?

A ball nose end mill, also sometimes called a ball end mill, has a fully radiused tip that forms a perfect half-sphere. The radius of this sphere is consistent across the entire tip. They come in various sizes, measured by their diameter, and their corresponding ball radius can range from very small to quite large. The key characteristic is that the cutting edges on the tip are curved, not flat or chamfered.

How Does It Work on Aluminum 7075?

When you use a ball nose end mill on Aluminum 7075, its rounded tip creates a smooth, swept-out surface. In 3D contouring operations, the CNC machine moves the tool along a path, and the ball shape naturally blends any transitions. This is fantastic for creating fillets, rounded pockets with no sharp internal corners at the bottom, and organic shapes often found in molds or intricate designs. Because the entire surface of the hemisphere can engage, it allows for very fine step-overs (the distance the tool moves sideways between passes) to achieve a mirror-like finish, especially in aluminum.

Key Applications for Ball Nose End Mills:

- 3D Contouring: Creating complex, curved surfaces.

- Fillet Creation: Machining rounded internal wall transitions.

- Mold Making: Producing the smooth features required for injection molds.

- Engraving: When a rounded, flowing line is desired.

- Slotting with Rounded Bottoms: If you need a slot that is rounded at its base rather than having sharp 90-degree internal corners.

Pros and Cons of Ball Nose End Mills for Aluminum 7075

Here’s a quick rundown:

Pros:

- Excellent for 3D Surfaces: Unmatched for creating smooth, flowing contours.

- Good Surface Finish: With small step-overs, can produce a highly polished appearance.

- Versatile in 3D Machining: Can cut in multiple directions without leaving sharp corners at the bottom of its axial cut.

- Reduces Post-Machining Work: Minimizes the need for manual deburring or polishing on curved surfaces.

Cons:

- Weaker at the Tip: The curved tip is inherently less rigid than flat edges, making it prone to deflection or breakage under heavy cutting forces, especially in harder materials.

- Not Ideal for Sharp Internal Corners: Will always leave a radius at the bottom of a hole or pocket it cuts.

- Can be Slower for 2D Pocketing: For simple flat-bottomed pockets, a flat-end mill is often more efficient.

- Potential for Chatter: The curved cutting edge can sometimes induce vibration if not used with appropriate speeds and feeds, especially on Aluminum 7075.

Corner Radius End Mill: The Master of Strong Corners

Now, let’s talk about the corner radius end mill. This tool looks a lot like a standard flat-end mill, but with a crucial difference: its corners are rounded off. This radius is not a full hemisphere; it’s a specific, often smaller, radius applied to the edge where the side cutting flutes meet the end cutting face. Think of it as a beefed-up flat-end mill that can handle corner details better.

What is a Corner Radius End Mill?

A corner radius end mill is designed with a small radius applied to its cutting edges. This radius can be a consistent value (e.g., 0.030″ radius) across all its cutting flutes at the bottom. Unlike a ball nose end mill, the corner radius end mill has flat sections on its sides and a relatively flat cutting face adorned with this radius. This design offers a balance between the strength of a flat end and the ability to create a controlled radius.

How Does It Work on Aluminum 7075?

When you use a corner radius end mill on Aluminum 7075, it’s excellent for clearing out pockets and slots while leaving a defined, internal radius. This radius prevents stress concentrations, which is critical for parts that will experience loads. In Aluminum 7075, which can be prone to stress cracking, having controlled radii at internal corners is a significant advantage. It also offers more rigidity than a ball nose end mill, especially during deeper cuts, leading to better accuracy and a cleaner cut in Aluminum 7075.

Key Applications for Corner Radius End Mills:

- Pocketing and Slotting: Creating internal features with well-defined corners that have a specific radius.

- Creating Stress-Relief Radii: Essential for parts that need to withstand mechanical stress without cracking.

- Shoulder Milling: Where a specific corner radius is required at the bottom of a cut.

- Roughing Operations: Their strength makes them good for removing material efficiently on Aluminum 7075.

- Transitioning Between Planes: Can be used to create smooth transitions, but the resulting edge will have the specified radius.

Pros and Cons of Corner Radius End Mills for Aluminum 7075

Here’s a breakdown:

Pros:

- Increased Rigidity: The presence of the radius at the corner makes these end mills stronger and less prone to breaking than ball nose end mills, especially during aggressive cutting.

- Controlled Radii: Provides a specific, predictable radius at internal corners, which is crucial for stress management and design requirements.

- Efficient Material Removal: Can often be used for more aggressive depths of cut and feed rates compared to ball nose end mills in similar aluminum alloys.

- Good for 2D Machining: Ideal for clearing out pockets, creating slots, and machining profiles where a specific internal radius is desired.

Cons:

- Not for True 3D Sculpting: Cannot create fully rounded, continuous 3D surfaces like a ball nose end mill.

- Leaves Radii at Bottom of Cuts: If a perfectly sharp internal corner is needed at the bottom of a pocket or slot, this tool won’t achieve it without a secondary operation or a very small radius tool.

- Limited Directional Cutting: While versatile, their strength is optimized for milling along defined paths, not necessarily for complex freeform surface engagement like a ball end mill.

Ball Nose End Mill VS Corner Radius End Mill for Aluminum 7075: Direct Comparison

Let’s put these two tools head-to-head, specifically for Aluminum 7075. It’s not about one being “better” than the other overall, but about which one is better for your specific task.

| Feature | Ball Nose End Mill | Corner Radius End Mill |

|---|---|---|

| Tip Geometry | Full hemispherical radius | Flat edges with a specific corner radius (smaller than hemisphere) |

| Primary Use Case | 3D contouring, sculpting, smooth curved surfaces | Pocketing, slotting, creating controlled internal radii |

| Internal Corner Result | Always leaves a radius equal to the tool’s ball radius. | Leaves a radius equal to the tool’s specified corner radius. |

| Strength/Rigidity | Less rigid, especially at the tip. Prone to deflection. | More rigid due to flat sections. Better for aggressive cuts. |

| Surface Finish Capability | Excellent for smooth, flowing 3D surfaces with small step-overs. | Good for smooth 2D surfaces and flat areas. |

| Workpiece Material Consideration (Aluminum 7075) | Requires careful feed and speed to avoid chatter and deflection due to its hardness. Good for finishing passes. | Handles the hardness of 7075 better for roughing and semi-finishing due to increased strength. |

| Tool Life | Can be shorter if used improperly or for aggressive material removal due to tip weakness. | Generally better tool life in demanding operations due to stronger design. |

Choosing the Right Tool for Aluminum 7075

When you’re working with Aluminum 7075, your choice depends entirely on the geometry you need to achieve:

When to Choose a Ball Nose End Mill:

- You need smooth, flowing curves: If your design calls for contoured surfaces, rounded transitions, or organic shapes, a ball nose is your go-to.

- You’re doing 3D surfacing: This is its specialty. Think mold cavities, aerodynamic shapes, or artistic carvings.

- You need a very fine, polished finish on complex surfaces: By using very small step-overs (e.g., 0.005″ – 0.010″), you can achieve stunning results.

- You need rounded internal fillets: If a radius at the bottom of a pocket or a wall intersection is acceptable and desired.

When to Choose a Corner Radius End Mill:

- You need to maintain tool strength for heavier cuts: For clearing out pockets or slots efficiently in tough Aluminum 7075, the rigidity of a CR end mill is vital.

- You require sharp-looking, but radiused, internal corners: For parts that will undergo stress, a defined radius is often mandatory to prevent cracks from forming. A CR end mill gives you precise control over this radius.

- You are performing 2D pocketing or slotting: For most flat-bottomed features where a specific radius is acceptable at the inside corners.

- You need to balance strength, speed, and finish: For a workhorse tool that can handle material removal well and still provide a decent finish.

A fascinating aspect of machining Aluminum 7075 is its machinability when using the right parameters. According to resources like The Aluminum Association, proper speed, feed, and tool selection are key to achieving good results and preventing issues like work hardening and chip welding. This reinforces why picking the right end mill is so foundational.

Machining Parameters for Aluminum 7075

For both ball nose and corner radius end mills, using appropriate machining parameters is critical for Aluminum 7075 to prevent issues and achieve a good finish. Here are some general guidelines. Always start conservatively and adjust based on your machine, tool, and specific results.

Speeds and Feeds Primer

Getting speeds and feeds right is like finding the sweet spot. Too slow, and you’ll rub and overheat. Too fast, and you’ll break tools or get a bad finish. For Aluminum 7075:

Surface Speed (SFM):

This is how fast the cutting edge moves across the material. For Aluminum 7075, a good starting point for carbide tools is often between 300-800 SFM depending on the specific alloy grade variant and whether it’s coated.

Chip Load:

This is the thickness of the material each cutting flute removes with each revolution. It’s crucial for preventing chip recutting and for getting a good finish. For Aluminum 7075, chip loads can range from 0.001″ to 0.005″ or more, depending on the tool diameter and number of flutes.

Spindle Speed (RPM):

Calculated by: RPM = (SFM 3.82) / Tool Diameter (inches). This is what you’ll set on your machine.

Feed Rate (IPM):

Calculated by: Feed Rate (IPM) = RPM Chip Load * Number of Flutes. This is how fast your machine moves the tool through the material.

Ball Nose End Mill Specifics for Aluminum 7075

Due to the curved tip, it’s best to use smaller step-overs for finishing and avoid aggressive radial engagement when possible.

- Finishing Passes:

- Axial Depth of Cut: 0.010″ – 0.050″

- Radial Step-over: 0.005″ – 0.020″ (smaller for finer finishes)

- Spindle Speed: Typically higher end of your tool’s recommendation.

- Feed Rate: Adjusted based on chip load and small step-over.

- Roughing Passes (Use with Caution):

- Axial Depth of Cut: 0.050″ – 0.150″

- Radial Step-over: 0.050″ – 0.150″

- Spindle Speed: Moderate, adjust for rigidity.

- Feed Rate: Moderate, watch for chatter and deflection.

Corner Radius End Mill Specifics for Aluminum 7075

Their increased rigidity allows for more aggressive parameters, especially with the corner radius.

- Roughing/Semi-Finishing:

- Axial Depth of Cut: 0.100″ – 0.500″ (or more if machine allows)

- Radial Step-over: 0.050″ – 0.200″

- Spindle Speed: Moderate to higher end of range.

- Feed Rate: Can be higher due to rigidity.

- Finishing Passes:

- Axial Depth of Cut: 0.020″ – 0.100″

- Radial Step-over: 0.010″ – 0.050″

- Spindle Speed: Moderate to higher end.

- Feed Rate: Adjusted for good chip formation.

Important Considerations:

- Tool Coating: For Aluminum 7075, AlTiN (Aluminum Titanium Nitride) or ZrN (Zirconium Nitride) coatings can improve performance and tool life by reducing friction and heat. Uncoated carbide is also common.

- Number of Flutes: For aluminum, 2-flute or 3-flute end mills are often preferred. They provide more chip clearance, which is crucial for preventing chip recutting and welding. 4-flute tools can sometimes be used for finishing if chip evacuation is excellent but are more prone to clogging in softer materials.

- Coolant/Lubrication: While some