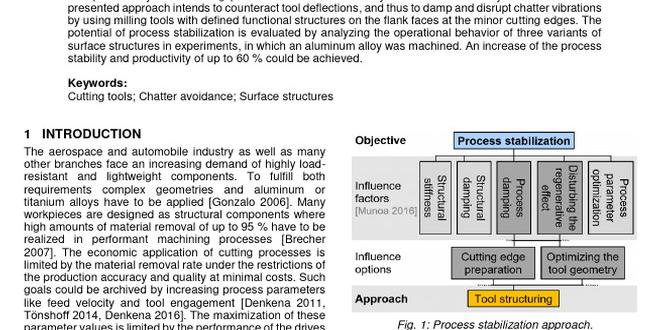

Carbide end mills are your go-to for hassle-free MDF cutting! This guide reveals how the right carbide end mill, especially a stub length one, dramatically improves chip evacuation, preventing frustrating clogs and ensuring clean MDF cuts for your projects.

Hey makers! Welcome back to Lathe Hub. If you’ve ever worked with MDF (Medium-Density Fiberboard), you know it can be a bit… messy. Those fine dust particles love to cling and clog, especially when you’re milling. It’s a common frustration that can slow down your work and lead to rough cuts. But what if I told you there’s a simple, effective solution that’s probably already in your toolbox? We’re talking about the humble yet mighty carbide end mill, and how choosing the right one can be the game-changer for your MDF projects. Stick around, and we’ll break down exactly why this tool is a proven winner and how you can use it to achieve cleaner cuts and a much happier workshop experience.

Understanding the MDF Machining Challenge

MDF is a fantastic material for many projects. It’s affordable, stable, and machines to a smooth finish. However, its composition – tiny wood fibers mixed with resin – creates a unique challenge when cutting, especially with CNC routers or milling machines. Unlike solid wood or plastics, MDF produces a fine, fluffy dust that behaves almost like a powder. This dust has a tendency to pack tightly into the flutes of your cutting tools.

When this happens, it’s called poor chip evacuation. Your end mill can’t effectively clear the chips (or dust, in this case) from the cutting area. This leads to:

- Increased heat: The packed dust acts as an insulator, causing friction and overheating the bit and material.

- Poor cut quality: Instead of cutting cleanly, the bit can rub or smolder, leaving a burnt or rough edge.

- Tool breakage: Overheating and excessive force can quickly wear down or even snap your end mill.

- Clutter and cleanup: Excess dust means more mess to deal with, reducing efficiency.

This isn’t just an annoyance; it directly impacts the quality and longevity of your work. Fortunately, the right cutting tool can make a world of difference. For MDF, a specially designed carbide end mill is often the best solution.

Why Carbide End Mills Shine for MDF

Carbide, specifically tungsten carbide, is a super-hard and dense material. Its properties make it ideal for cutting tools that need to withstand high temperatures and abrasion. Here’s why it’s a top choice for MDF:

Durability and Hardness

MDF dust is abrasive. Carbide is significantly harder than high-speed steel (HSS), meaning it resists wear much better. This translates to longer tool life and consistent cutting performance, even with materials that tend to clog.

Heat Resistance

Machining MDF can generate heat. Carbide can handle much higher temperatures than HSS before softening or degrading. This high heat resistance helps maintain the cutting edge, preventing it from dulling quickly and reducing the risk of burning the MDF.

Sharpness Retention

Carbide tools can be ground to a very fine, sharp edge. This sharpness is crucial for getting clean cuts in MDF, minimizing tear-out and splintering. A sharp tool also cuts more efficiently, requiring less force and producing better chips.

The Secret Weapon: Stub Length End Mills for MDF

While any good carbide end mill is a step up for MDF, a specific design often provides the best results: the stub length end mill. But what exactly makes it so good for this material?

What is a Stub Length End Mill?

A stub length end mill is characterized by a shorter flute length and overall length compared to standard end mills. Think of it as a more compact version designed for robustness and efficiency in specific applications. For instance, a 1/4-inch shank stub length end mill will have shorter cutting edges and a shorter body than a standard 1/4-inch end mill.

How Shorter Flutes Help Chip Evacuation

This is where the magic happens for MDF. Standard end mills have longer flutes, which can trap MDF dust. The fine, powdery nature of MDF dust can easily fill these longer flutes, leading to the packing and clogging issues we discussed earlier. Shorter flutes on a stub length end mill mean less space for the dust to accumulate and get stuck. It’s like having a more direct escape route for the chips!

The shorter flute length also means less material for the dust to adhere to and compact within. It promotes a more open cutting path, allowing the dust to be expelled more readily with each rotation of the tool.

Benefits of Using Stub Length End Mills on MDF:

- Improved Chip Clearance: Less dust gets trapped, reducing clogging.

- Reduced Heat Buildup: Better flow of material means less friction and heat.

- Cleaner Cuts: Prevents rubbing and burning associated with clogged bits.

- Longer Tool Life: Less stress on the cutting edges due to efficient chip removal.

- More Stable Tooling: Shorter tools are generally more rigid, reducing vibration and chatter, which is beneficial for achieving smooth finishes.

Choosing the Right Carbide End Mill: Key Features

When you’re specifically looking for a carbide end mill for MDF, pay attention to these critical features. We’ll focus on common sizes, like a 1/8 inch or 1/4 inch shank stub length, as these are very popular for smaller CNC routers and hobbyist machines.

1. Number of Flutes

This is crucial for MDF. Most standard end mills have 2, 3, or 4 flutes. For MDF, fewer flutes are generally better for chip evacuation. Why?

- 2 Flutes: Offers the largest chip gullet (the space between flutes) and is excellent for clearing large amounts of material and for softer materials like MDF. This is often the top recommendation.

- 3 Flutes: A good balance. It can still offer decent chip evacuation and provides a smoother finish than a 2-flute when used at optimal speeds and feeds.

- 4 Flutes: Generally not ideal for MDF. The flutes are too narrow, leading to rapid packing and poor chip clearance.

Recommendation for MDF: Prioritize 2-flute carbide end mills. If you need a better surface finish and can manage your feed rates and speeds meticulously, a 3-flute can work, but 2-flutes are usually more forgiving and effective for chip evacuation.

2. Helix Angle

The helix angle is the degree of the spiral on the cutting flute. Common angles are 30°, 45°, and 60°.

- Standard Helix (around 30°): Good all-around performance.

- High Helix (over 45°): Offers a more shearing action, which can lead to smoother finishes. However, it can sometimes lead to increased chatter and may not be as effective at clearing bulky chips.

- Low Helix/Straight Flutes: Unconventional for milling, but the flatter angle might offer some benefits in specific materials by allowing more flute volume.

For MDF, a standard or slightly higher helix angle (like 30-45°) is usually fine. The primary focus should remain on flute count and stub length for chip evacuation. Extremely high helix angles might not be necessary and could potentially be more prone to chatter which, while not directly a chip evacuation issue, impacts cut quality.

3. Coating

Some carbide end mills come with coatings designed to improve performance. For MDF, coatings aren’t as critical as flute design, but they can offer additional benefits:

- Uncoated: Perfectly suitable for MDF.

- TiN (Titanium Nitride): A common, general-purpose coating that adds some hardness and lubricity, helping reduce friction and wear.

- AlTiN (Aluminum Titanium Nitride): Offers superior heat resistance and hardness, excellent for high-temperature applications. Might be overkill for MDF but won’t hurt.

For MDF, an uncoated or TiN-coated end mill is usually sufficient and cost-effective.

4. Material (Carbide Grade)

Carbide itself comes in different grades (e.g., micro-grain, sub-micro-grain). For cutting wood composites like MDF, a good quality micro-grain carbide is excellent. It balances toughness with hardness, resisting chipping while maintaining a sharp edge.

5. Shank Diameter and Overall Length

This is where the “stub length” comes in. Common shank diameters for hobbyist CNCs are 1/8 inch, 1/4 inch, and 1/2 inch. For MDF, you might see stub length end mills specified as having ~1.5x or 2x the shank diameter for their flute length, compared to standard mills which might have flute lengths of 3x or 4x the shank diameter.

A 1/4 inch shank stub length end mill is a very popular choice for CNC routers and smaller milling machines. It offers a good balance of rigidity, cutting capacity, and manageable dust evacuation compared to longer bits.

Specific Keyword Focus: Carbide End Mill 1/8 Inch 1/4 Shank Stub Length for MDF Chip Evacuation

When searching for the ideal tool, using terms like “carbide end mill 1/8 inch 1/4 shank stub length for MDF chip evacuation” can help narrow your search. This indicates you need:

- Carbide End Mill: The material for durability.

- 1/8 Inch / 1/4 Shank: The diameter of the tool holder (collet or chuck) it fits into.

- Stub Length: Shorter flutes crucial for MDF.

- MDF Chip Evacuation: The specific problem you’re solving.

Look for tools specifically advertised for non-ferrous materials or plastics, as these often share similar characteristics to MDF. For example, a 1/4″ shank, 2-flute, stub length, solid carbide end mill is often a great starting point.

Setting Up Your Machine for Success with MDF

The tool is only half the equation. Proper machine setup and cutting parameters are vital for effective chip evacuation and a great finish on MDF. Here’s how to get it right:

Speeds and Feeds

This is probably the most critical part of CNC machining. Getting your spindle speed (RPM) and feed rate (inches or millimeters per minute) correct ensures the end mill cuts efficiently, clearing chips as it goes. Too slow a feed rate for the RPM, and you’ll pack chips. Too fast, and you’ll overload the bit.

General Guidelines for MDF (using 1/4 inch 2-flute carbide end mill):

- Spindle Speed (RPM): Often in the range of 18,000 – 24,000 RPM. Higher RPMs can help clear chips faster, but too high can cause burning if not matched with feed rate.

- Feed Rate (IPM): This is highly dependent on your machine’s rigidity and the material thickness. A good starting point might be 30-60 IPM for a 1/4-inch bit. You’ll need to experiment!

- Plunge Rate: Should be significantly slower than your feed rate (e.g., 50% or less).

Important Note: Always consult the end mill manufacturer’s recommendations or use online calculators (like this one from a reputable tool supplier) as a starting point. Then, perform test cuts on scrap material. Listen to the machine! A smooth cutting sound is good; screaming or chattering indicates issues.

Depth of Cut (DOC) and Stepover

How much material you remove with each pass makes a big difference.

- Depth of Cut (DOC): For MDF, take lighter passes. A common recommendation is to set your DOC to no more than 0.5 times the diameter of the end mill. For a 1/4-inch bit, this means cutting no more than 1/8 inch deep per pass. This allows the tool to clear chips more effectively.

- Stepover: This is the amount the tool moves sideways for each pass when cutting pockets or profiles. A stepover of 40-50% of the tool diameter is typical for good balance between speed and finish. For MDF, you might consider slightly larger stepovers if chip evacuation is still challenging, as it reduces the total volume of material being processed at once.

Workholding and Dust Extraction

- Secure Workholding: Ensure your MDF is firmly secured to your machine bed. Any movement can lead to inaccurate cuts and potentially dangerous situations. Vacuum tables or strong clamps are essential.

- Dust Extraction: This is NON-NEGOTIABLE for MDF. Your CNC router should have a dust collection system connected closely to the spindle. While the stub length end mill helps evacuate chips from the cut, a good vacuum system removes them from the machine and your workshop, improving visibility and air quality. The Occupational Safety and Health Administration (OSHA) highlights the health risks associated with wood dust exposure, so proper collection is crucial.

Step-by-Step: Using Your Carbide End Mill for MDF

Let’s walk through the process of setting up and cutting MDF with your new stub length carbide end mill.

- Select Your End Mill: Choose a 2-flute, stub length, solid carbide end mill. A common choice for many hobbyist CNC machines would be a 1/4 inch shank (or 1/8 inch if your machine uses smaller collets), with a suitable cutting diameter for your project (e.g., 1/8″, 1/4″, 1/2″).

- Install the End Mill: Insert the end mill into your machine’s collet or chuck. Ensure it’s properly seated and tightened. Use the correct size collet for your shank diameter to ensure a secure grip and minimize runout.

- Secure Your MDF: Place your piece of MDF on your machine bed and secure it firmly using clamps, spoilboard screws, or a vacuum table.

- Set Up Toolpaths in CAM Software:

- Input the correct tool diameter.

- Select appropriate cutting strategies (e.g., pocketing, contouring).

- Define your Speed and Feed settings (start with general guidelines and adjust).

- Set Depth of Cut (DOC) to be conservative (e.g., max 0.5x tool diameter).

- Define Stepover (e.g., 40-50%).

- Set Plunge Rate to be slow (e.g., 50% of feed rate).

- Zero the Machine: Using your CAM software’s commands and your machine’s jogging controls, set the X, Y, and Z zero points on your MDF workpiece. Ensure the Z-zero is set correctly on the top surface of the material.

- Connect Dust Extraction: Turn on your dust collection system. Ensure the hose is positioned to effectively capture dust from the cutting area.

- Perform a Test Cut: If possible, run the program on a scrap piece of MDF or a designated test area. Observe the dust evacuation. Listen to the sound of the cut. If you hear excessive screeching or see smoke, stop the machine and re-evaluate your speeds and feeds.

- Run the Job: Once you’re confident with the test cut, run the full program on your project material. Monitor the process, especially during the initial passes.

- Inspect and Clean: After the cut is complete, carefully remove the workpiece. Inspect the cut edges for quality. Clean up any residual dust from the machine and your workbench.

Troubleshooting Common MDF Cutting Issues

Even with the right tool, you might run into problems. Here’s how to fix them:

Issue: Burning or Smoldering Edges

Cause: Insufficient chip evacuation, dull tool, or feed rate too slow for the RPM.

Solution:

- Check your feed rate – try increasing it slightly.

- Ensure your dust collection is excellent.

- Verify your MDF is clean and free of debris.

- Try a 2-flute end mill if you’re not already using one.

- Consider a lighter Depth of Cut.

- Inspect your end mill for wear; a dull bit will cause burning.

Issue: Excessive Dust Buildup in Flutes

Cause: Feed rate too slow, DOC too deep, or end mill design not optimized for MDF.

Solution:

- Increase feed rate.