A 1/8 inch carbide end mill, especially one with a 1/2 inch shank and standard length for carbon steel, is crucial for precise cuts. With the right techniques, you can conquer chatter and achieve smooth finishes in your milling projects.

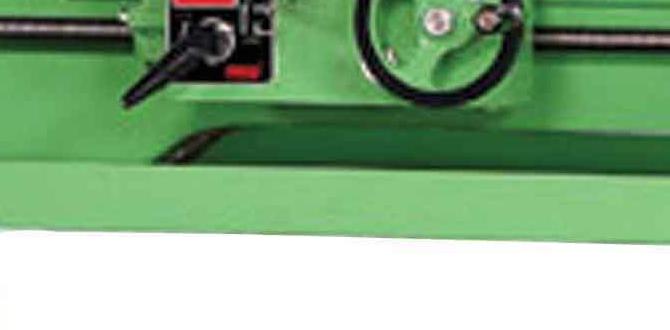

Hey there, fellow makers and tool enthusiasts! Daniel Bates here from Lathe Hub. Ever found yourself staring at a workpiece after a milling operation, only to see those ugly, wavy lines? That’s chatter, and it’s one of the most frustrating things beginners (and even experienced folks!) deal with. It makes your cuts look rough, wastes material, and can even damage your tools. Today, we’re zeroing in on a common culprit and a fantastic solution: the 1/8 inch carbide end mill. We’ll explore how to pick the right one, set it up correctly, and use proven techniques to banish chatter for good. Get ready to achieve those clean, professional finishes you’ve been aiming for!

Why Chatter Happens and Why a 1/8 Inch Carbide End Mill is Your Friend

Chatter, those nasty vibrations you see and hear during machining, can be a real headache. It happens when the cutting forces are unbalanced, causing the tool to repeatedly engage and disengage from the material. Think of it like a squeaky door hinge – constant friction and uneven movement. This vibration leads to poor surface finish, reduced tool life, and can even damage your workpiece.

Several factors contribute to chatter, including:

Tool Deflection: When the tool bends under cutting pressure.

Spindle Runout: Imperfect rotation of the milling machine spindle.

Machine Rigidity: A wobbly machine or workholding setup.

Cutting Parameters: Incorrect speed, feed rate, or depth of cut.

Tool Geometry: A dull or improperly designed cutting tool.

This is where a high-quality 1/8 inch carbide end mill shines. Carbide offers superior hardness and heat resistance compared to high-speed steel (HSS). This means it stays sharper longer and can handle the higher speeds and feeds required for efficient machining, without softening. For smaller diameter tools like the 1/8 inch, rigidity becomes even more critical. A solid, well-ground carbide end mill designed for the material you’re cutting can significantly reduce the chances of deflection and vibration, thus reducing chatter.

Choosing the Right 1/8 Inch Carbide End Mill for Carbon Steel

When you’re tackling carbon steel, specifically with a 1/8 inch end mill, a few features make all the difference. You’ll want to be looking for an end mill with a 1/2 inch shank for added rigidity, a standard length suitable for general-purpose work, and geometry optimized for steel.

Here’s what to look for:

Material: The Power of Carbide

As mentioned, carbide is king for machining steel. It’s much harder than HSS, allowing for faster cutting speeds and extended tool life. For carbon steel, a solid carbide end mill is the go-to choice. These are made entirely of carbide.

Number of Flutes

This is a key factor for reducing chatter and achieving a good surface finish.

2 Flutes: Generally good for softer materials and a wider chip gullet, which helps with chip evacuation. They can also be used in tougher materials, but can sometimes be more prone to chatter if not used correctly. For steel, they are often a good balance.

3 Flutes: A great all-around choice for steels. They offer a good balance between chip clearance and rigidity. They can often handle higher feed rates than 2-flute tools.

4 Flutes: Provide the most rigidity and a better surface finish. However, they have less chip clearance, making them better suited for lighter cuts or materials that don’t produce long, stringy chips. For a 1/8 inch end mill working in steel, 3 or 4 flutes are generally preferred for chatter reduction.

Pro Tip: For beginners struggling with chatter in carbon steel using a 1/8 inch end mill, starting with a 3-flute or 4-flute carbide end mill is usually the most effective route.

Coatings

Coatings add another layer of performance. For carbon steel, look for:

TiN (Titanium Nitride): A common, general-purpose coating that adds hardness and reduces friction. It’s a good starting point.

TiCN (Titanium Carbonitride): Harder than TiN, offering better wear resistance, especially in abrasive environments or for harder steels.

AlTiN (Aluminum Titanium Nitride): Excellent for high-speed steel machining and some stainless steels. It creates a protective oxide layer that helps resist heat, making it ideal for tougher cutting conditions. It’s a strong contender for carbon steel.

Helix Angle and Chip Breakers

Helix Angle: This is the angle of the flutes. A higher helix angle (e.g., 30-45 degrees) typically results in a smoother cut and better chip evacuation, which can help reduce chatter. For steel, a medium to high helix angle is often beneficial.

Chip Breakers: Some end mills have “breaker grooves” ground into the cutting edges. These help to break up long, stringy chips into smaller, more manageable pieces. This is a HUGE advantage when milling steel, as packed chips are a prime cause of chatter and tool breakage.

Shank Diameter and Length

For a 1/8 inch cutting diameter, a 1/2 inch shank is highly recommended. The larger shank provides much more rigidity compared to a 1/8 inch shank, significantly resisting deflection and thus, chatter. This is a critical point for stability. Standard length is generally fine for most beginner applications. Avoid extra-long “reach” tools unless absolutely necessary, as they are more prone to vibration.

Example End Mill Specifications for Carbon Steel Chatter Reduction

Here’s a table to help visualize:

| Feature | Recommended for Carbon Steel Chatter Reduction (1/8″ Carbide) | Why it Helps |

|---|---|---|

| Material | Solid Carbide | Hardness, heat resistance, rigidity. |

| Cutting Diameter | 1/8 inch | Specific requirement of the task. |

| Shank Diameter | 1/2 inch | Maximizes rigidity to fight deflection and chatter. |

| Number of Flutes | 3 or 4 Flutes | Better rigidity and chip control than 2 flutes in many steel applications. 4 flutes offer most rigidity. |

| Coating | AlTiN or TiCN | Enhanced hardness, wear resistance, and heat tolerance for steel. |

| Helix Angle | 30° – 45° | Promotes smoother cutting and better chip evacuation. |

| Special Features | Chip Breakers (optional but recommended) | Breaks up chips, preventing packing and vibration. |

| Length | Standard | Maintains stiffness; avoid excessive reach. |

Setting Up for Success: Pre-Milling Checks

Before you even touch your machine, a few simple checks can prevent a world of chatter.

1. Secure Your Workpiece

This is non-negotiable. Your workpiece needs to be clamped down TIGHTLY. Any movement during the cut is a recipe for chatter and disaster.

Use clamps, vises, or fixtures: Ensure they are appropriate for your workpiece size and the forces involved.

Consider supports: For larger or thinner pieces, use parallels, risers, or jacks to support the underside and prevent flexing.

Check for tightness: Jiggle the workpiece. If there’s any play, tighten it down more.

2. Ensure Machine Rigidity

Your milling machine itself plays a big role.

Check Z-axis gibs: If your Z-axis (the quill or headstock movement) is loose, it will flex and cause chatter. Adjust the gibs to remove slop without making it too stiff to move.

Spindle check: Does your spindle run true? A worn spindle bearing or worn tooling holder can introduce runout, forcing the end mill to cut unevenly.

Table and saddle gibs: Ensure these are properly adjusted for smooth movement without excessive play.

3. Tool Holder and Collet Inspection

The connection between your machine spindle and the end mill is critical.

Clean your collet and holder: Any dirt, chips, or oil residue can prevent the collet chuck from gripping the shank evenly, leading to runout and vibration.

Use matching collets: Ensure your collet set is accurate and you are using the correct size collet for the 1/2 inch shank. A collet that’s too large or too small won’t grip properly.

Avoid runout: A worn collet or holder can introduce wobble. If you suspect issues, inspect or replace them. The ISCAR website has great resources on tooling holding solutions for milling.

4. The Tool Stick-Out (“Reach”)

This is crucial for a 1/8 inch end mill.

Keep it short: Whenever possible, set the distance the end mill sticks out of the collet and holder to the absolute minimum needed to clear the workpiece and any fixturing. For a 1/8 inch end mill, this is usually only a fraction of an inch.

Why? The longer the tool sticks out, the more it acts like a spring. It can deflect more easily under cutting pressure, leading directly to chatter. A shorter stick-out means a stiffer tool.

Mastering Cutting Parameters for Chatter-Free Cuts

Even with the perfect tool and setup, incorrect cutting speeds and feeds will cause chatter. This is often where beginners get stuck. Let’s break it down.

Surface Speed (SFM/SMM) and Spindle Speed (RPM)

Surface Speed (SFM): This is the speed at which the cutting edge of the tool moves across the material. It’s usually given in surface feet per minute (SFM) or surface meters per minute (SMM). Carbide tools can run much faster than HSS.

Spindle Speed (RPM): This is how fast your milling machine spindle rotates. You calculate RPM using the desired Surface Speed and the tool’s diameter.

The formula is:

RPM = (SFM 3.25) / Diameter (inches)

OR

RPM = (SMM 1000) / (Diameter (mm) π)

For a 1/8 inch (0.125 inch) carbide end mill in carbon steel, a good starting SFM range might be 200-400 SFM.

Example Calculation:

Let’s aim for 300 SFM with our 1/8 inch end mill:

RPM = (300 SFM 3.25) / 0.125 inches

RPM = 975 / 0.125

RPM = 7800 RPM

If your machine can achieve 7800 RPM (many smaller machines can!), that’s a good target. If not, use the highest RPM your machine can reliably provide in that range.

Beginner Tip: Always start conservatively. If you’re unsure, use the lower end of recommended SFM for your material and tool. You can always increase speed if things are going well.

Feed Rate (IPM/MM/min)

The feed rate determines how much material the end mill advances into the workpiece with each revolution. It’s often expressed in inches per minute (IPM) or millimeters per minute.

Chip Load: A more useful concept for beginners is chip load. This is the thickness of the chip that each cutting edge (flute) removes. Like SFM, chip load has a recommended range for different tool sizes and materials.

Feed Rate (IPM) = Chip Load (inches/tooth) Number of Flutes RPM

For a 1/8 inch carbide end mill in carbon steel, a starting chip load might be 0.001 to 0.003 inches per tooth.

Example Calculation (using 3 flutes, 7800 RPM, and 0.002″ chip load):

Feed Rate = 0.002 inches/tooth 3 flutes 7800 RPM

Feed Rate = 0.006 7800

Feed Rate = 46.8 IPM

Beginner Tip: A feed rate that’s too slow (too small a chip load) can cause rubbing instead of cutting, leading to heat buildup and chatter. A feed rate that’s too fast can overload the tool and cause breakage or chatter. Aim for a chip that exits the cut cleanly, not wispy or packed.

Depth of Cut (DOC) and Stepover

Depth of Cut (DOC): This is how deep the end mill cuts into the material in the Z-axis. For a 1/8 inch end mill, especially in harder materials, it’s generally best to take lighter depths of cut. A common recommendation is to keep the DOC about 25-50% of the tool diameter when plunging or doing full-width cuts, and potentially a bit more on the radial cut (stepover).

Stepover (Radial Depth): This is how much the end mill moves sideways (X or Y axis) in each pass. A smaller stepover (e.g., 20-50% of the tool diameter) will create a much smoother surface finish and is less taxing on the tool, reducing chatter potential.

Crucial for Chatter Reduction:

For 1/8 inch end mills, especially when milling slots or pockets where the end mill engages the full width of its diameter, avoid full-width cuts if possible. Instead, use a smaller stepover (e.g., 1/8 inch end mill, 0.050″ – 0.100″ stepover) and take multiple passes. This is often called “climb milling” with a reduced radial engagement.

Proven Techniques to Prevent Chatter with Your 1/8 Inch End Mill

Beyond just picking the right tool and settings, employing specific machining strategies is key.

1. Climb Milling vs. Conventional Milling

This is one of the most impactful techniques for chatter reduction.

Conventional Milling: The cutter rotates against the feed direction. This tends to lift the tool and workpiece, increasing vibration and chatter. It’s often used on older or less rigid machines.

Climb Milling: The cutter rotates in the same direction as the feed. This pulls the tool into the workpiece, resulting in a cleaner cut, better surface finish, and significantly less chatter. This is the preferred method whenever possible.

How to Apply for Chatter Reduction:

When milling pockets or contours with your 1/8 inch end mill, always orient your toolpath so that the machine is climb milling. This means the cutter is feeding into the material in the direction of its rotation. For example, if milling a slot, you’d typically want to engage the wall where the tool rotates downwards and into the material.

Important Note: Climb milling requires a machine with minimal backlash in the lead screws or a modern CNC with precise control. If your machine has significant backlash on the axis you are climb milling, you might experience chatters as the cutter “falls” into the backlash. For manual milling, use your handwheel to maintain consistent feed pressure against the direction of rotation.

2. High-Helix End Mills for Steel

As mentioned in tool selection, end mills with a higher helix angle (30-45 degrees) are designed to cut more smoothly. The steeper angle shears the material more effectively and helps to “lift” the chip up and out, reducing the chance of it getting packed and causing vibration.

3. Variable Helix / Variable Pitch End Mills

These advanced tools have flutes that are ground with slightly varying angles or spacing. This “breaks up” the harmonic vibrations that cause chatter. Imagine having slightly out-of-sync drummers – the overall rhythm becomes less pronounced. While often found on larger diameter tools, some manufacturers offer variable helix 1/8 inch end mills. They are an excellent, albeit often more expensive, solution for chatter.

4. Use a High-Quality Tool Holder and Collet System

This cannot be stressed enough. Even the best end mill will chatter if it’s not held securely and run true. A precision collet chuck system is ideal. Make sure your collets are clean and matched to the tool shank. A system like a Weldon shank holder might be more rigid but can sometimes be less forgiving with slight runout than a good collet. The general rule of thumb is: the smaller the tool and the higher the speed, the higher the precision needed in the tooling system.

5. Lighten Up Those Cuts!

When in doubt, reduce your parameters.

Depth of Cut (DOC): If you’re getting chatter, reduce the amount of material you’re removing in the Z-direction. Try cutting at 10-20% of the tool diameter.

Stepover (Radial): Reduce the sideways engagement. Instead of 50% of the tool diameter, try 20-30%. This means more passes, but each pass will be lighter and less prone to chatter.

* Feed Rate: If chatter persists, try a slightly slower feed rate. This means a smaller chip load. Be careful here, as too slow a feed can cause rubbing and heat.

6. Use Lubrication and Coolant

Machining steel generates heat. Heat leads to tool wear and poor chip formation,