A 1/8 inch, 10mm shank carbide end mill is your go-to tool for achieving precise cuts in various materials, especially when working with MDF. Its small size and robust carbide construction ensure clean, accurate results for intricate projects and tight tolerances, making it ideal for hobbyists and professionals alike.

Working with a new tool can feel a bit daunting, especially when you’re aiming for a perfectly smooth finish or a super-accurate cut. You might be looking at a tiny, yet mighty, tool like the 1/8 inch carbide end mill with a 10mm shank and wondering if it can really deliver the precision you need. It’s a common concern, especially when dealing with delicate materials like MDF or when chasing those tight tolerances. But don’t worry! This little powerhouse is designed for exactly these kinds of jobs. In this guide, we’ll break down everything you need to know about this end mill, from what makes it special to how you can use it safely and effectively to get those impressive results you’re after. Get ready to boost your confidence and your project quality!

Why the 1/8 Inch Carbide End Mill with a 10mm Shank is a Machinists’ Best Friend

When you first encounter a 1/8 inch carbide end mill with a 10mm shank, its compact size might seem limiting. However, this combination is actually a sweet spot for many machining tasks, offering a unique blend of agility and stability. Let’s dive into what makes this specific tool so valuable for achieving “Proven Precision.”

The Magic of Carbide

Carbide, or tungsten carbide, is a ceramic material renowned for its extreme hardness and wear resistance. This is a huge deal for cutting tools. Unlike high-speed steel (HSS), carbide can withstand higher temperatures generated during cutting without losing its sharp edge. This means:

Durability: Carbide tools last significantly longer than HSS tools, especially when cutting harder materials or at higher speeds. For a small tool like a 1/8 inch end mill, this means fewer tool changes and a more consistent cut over time.

Heat Resistance: The ability to handle heat means you can often run your milling machine at faster spindle speeds, speeding up your work without damaging the tool.

Surface Finish: Because carbide stays sharp and rigid, it tends to produce a cleaner, smoother surface finish on your workpiece compared to softer tool materials.

The Precision of 1/8 Inch

The 1/8 inch (approximately 3.175mm) diameter is not for roughing out large material. Instead, it excels at detailed work. Think intricate patterns, small grooves, delicate engraving, and cutting out small, precise shapes. In the world of CNC routing and milling, this size is perfect for:

Fine Detail: Creating intricate designs for models, signs, or decorative pieces.

Slotting and Grooving: Machining narrow slots or channels with high accuracy.

Edge Profiling: Following complex contours with minimal material removal per pass.

Close Tolerance Work: Achieving very precise dimensions, often required in functional parts or small assemblies.

The Stability of a 10mm Shank

Now, let’s talk about the 10mm shank. While the cutting diameter is tiny, the shank is the part that grips into your milling machine’s collet or tool holder. A 10mm shank offers a significant advantage over smaller shanks (like 1/8 inch or 3mm) when paired with a 1/8 inch cutting head. Here’s why:

Rigidity: A larger shank diameter provides more rigidity. This is crucial for minimizing tool deflection, especially when taking deeper cuts or cutting through tougher materials. Less deflection means more accurate dimensions.

Better Grip: A 10mm collet or chuck offers a more secure and stable grip on the tool, reducing the chance of slippage that can ruin a part or cause damage.

Vibration Reduction: The increased mass and rigidity of the 10mm shank can help dampen vibrations, leading to a smoother cut and a better surface finish.

This combination – the hardness of carbide, the fine detail capability of a 1/8 inch cutting diameter, and the robust stability of a 10mm shank – is what makes this specific end mill a powerful tool for achieving “Proven Precision.”

Applications: Where This Tiny Titan Shines

The 1/8 inch carbide end mill with a 10mm shank isn’t just a niche tool; it’s incredibly versatile. Its size and material properties make it perfect for detailed work across a range of crafting and machining disciplines.

For the Woodworker and MDF Enthusiast

MDF (Medium-Density Fiberboard) is a popular material for its smooth surface, affordability, and ease of cutting. However, it can also be prone to chipping and burning if the wrong tools or settings are used. This is where our 1/8 inch end mill excels:

Intricate Signage: Cut out detailed lettering or decorative elements for custom signs with crisp, clean edges.

Inlays and Decorative Panels: Create precise recesses for inlay work or intricate patterns in cabinet doors and decorative panels.

Jigs and Fixtures: Machine small, precise components for shop-made jigs and fixtures that require tight tolerances.

Model Making: Produce fine details for architectural models, dioramas, or scale replicas where accuracy is paramount.

The hardness of carbide helps manage the heat generated against MDF, reducing the risk of burning, while the small diameter allows for tight corners and delicate curves without tearing. For MDF, it’s essential to use a quality end mill designed for wood or composite materials to ensure extended tool life and a superior finish.

For the Metal Machinist and Hobbyist

While often associated with softer materials, a carbide end mill of this size can also perform admirably in lighter metalworking tasks. It’s not for heavy-duty material removal, but for precision work, it’s invaluable:

Engraving: Create fine lines, serial numbers, or decorative patterns on metal parts.

Small Part Machining: Produce small, functional metal components where tight tolerances are required.

Prototyping: Machine small, detailed features on prototype metal parts.

Edits and Refinements: Make small adjustments or corrections to existing metal parts.

When working with metals, it’s crucial to use appropriate cutting fluids or lubricants and to understand the material’s properties. Even with carbide, aggressive cuts in harder metals can lead to tool breakage.

General Precision Machining Tasks

Beyond specific materials, this end mill is a workhorse for any task demanding fine detail:

Circuit Board Engraving: With precise CNC control, these can be used to mill traces on prototype PCBs.

Stamp and Mold Making: Machining detailed features for small stamps or part of a larger mold.

Plastic Machining: A go-to for intricate cuts in various plastics, from acrylics to acetal.

The key is understanding the tool’s limitations and matching it to the material and the task. For everything from delicate woodworking to precise metal engraving, the 1/8 inch carbide end mill with a 10mm shank offers a reliable path to achieving “Proven Precision.

Choosing the Right 1/8 Inch 10mm Shank Carbide End Mill

Not all end mills are created equal, and selecting the right one for your needs will significantly impact your results and the longevity of your tool. Here are key factors to consider to ensure you get the “Proven Precision” you’re looking for.

Material and Coating

Solid Carbide: This is the standard for high-performance end mills. It’s extremely hard and rigid.

Coatings: While solid carbide is excellent, coatings can further enhance performance for specific applications.

Uncoated: Good all-around, especially for wood, plastics, and softer metals at moderate speeds.

TiN (Titanium Nitride): A general-purpose coating that offers some added hardness and lubricity, improving tool life and surface finish. Good for a wide range of materials.

AlTiN (Aluminum Titanium Nitride): A more advanced coating that excels in higher-temperature environments and is ideal for machining harder metals like steel. It provides superior wear resistance.

ZrN (Zirconium Nitride): Often used for non-ferrous metals like aluminum and plastics, as it has a lower coefficient of friction and reduces material buildup.

For general-purpose use with MDF and occasional soft metals, an uncoated or TiN-coated end mill is often sufficient and cost-effective. If you plan on tackling harder metals frequently, an AlTiN coating would be a better investment.

Number of Flutes

The flutes are the helical grooves that run along the cutting edge of the end mill. The number of flutes affects how the tool chips away material and its suitability for different materials and operations.

2-Flute: These generally have more “chip clearance,” meaning there’s more open space between the flutes. This makes them excellent for softer materials like wood, plastics, and aluminum, as they can evacuate chips more efficiently, reducing the risk of clogging and melting. They can also be run at higher feed rates in these materials.

4-Flute: With more cutting edges, 4-flute end mills are better suited for harder materials like steel and stainless steel. They provide a smoother finish and can handle higher cutting forces. However, in softer materials, they can struggle with chip evacuation and may lead to overheating or chip welding.

For working primarily with MDF and similar materials, a 2-flute end mill is typically the preferred choice. If you plan on doing more precise metalwork, a 4-flute might be considered, but for a 1/8 inch tool, the 2-flute is generally the most versatile for fine detail.

Endmill Geometry

Beyond the basic flute count and material, there are subtle geometric features:

Square End: This is the most common type, designed for general-purpose milling, slotting, and profiling. It has a flat cutting surface at the tip. A “square end” end mill is what is typically meant by a standard end mill.

Ball End: The tip is rounded, forming a hemisphere. These are excellent for creating rounded profiles, 3D contouring, and general surface finishing in machining.

Corner Radius: A square end mill can have a small radius applied to its corners. This strengthens the cutting edges, making them less prone to chipping, and helps prevent sharp corners from burning when profiling. For precision work where you need square corners, you’d choose a true square end, but for general use and durability, a small corner radius (e.g., 0.010″ or 0.25mm) is often beneficial.

For beginners aiming for “Proven Precision,” a 2-flute, square-end solid carbide end mill is an excellent starting point. Consider a small corner radius for added durability if absolutely sharp inside corners aren’t critical for every job.

“Extra Long” Feature (If Applicable)

Some 1/8 inch end mills, especially those with a 10mm shank, might be advertised as “extra long.” This usually refers to the overall length of the tool or the length of the cutting edge.

Longer Cutting Length: This can be useful for cutting deeper slots or working with thicker materials. However, longer tools are also more prone to deflection and vibration.

Longer Overall Length: Can be helpful for certain tool changer setups or for providing clearance.

If your projects involve cutting deeper than a standard end mill allows, an “extra long” version might be necessary. However, for most intricate hobbyist and small-shop work, a standard length is usually sufficient. Always consider if the “extra long” feature genuinely benefits your specific applications and be prepared to manage potential deflection.

Key Specifications to Look For

When browsing for your 1/8 inch, 10mm shank carbide end mill, keep an eye on these specs:

| Specification | Typical Values | Importance |

| :——————- | :——————————————— | :—————————————————————————– |

| Cutting Diameter | 1/8 inch (3.175 mm) | Determines the width of cuts, grooves, and the smallest detail possible. |

| Shank Diameter | 10 mm | Provides rigidity and a secure grip in the collet/chuck. |

| Material | Solid Carbide, Micrograin Carbide | Hardness, wear resistance, heat tolerance. |

| Flute Count | 2 or 4 | Chip evacuation (2-flute for soft materials), strength (4-flute for metals). |

| Coating | Uncoated, TiN, AlTiN, ZrN | Enhances performance, wear resistance, and suitability for specific materials. |

| Helix Angle | Various (e.g., 30°, 35°, 45°) | Affects chip removal and surface finish. Steeper angles can be good for softer materials. |

| Overall Length | Standard, Extended | Clearance and depth of cut capabilities. |

| Cutting Length | Standard, Extended | Depth of cut. |

For MDF and tight tolerances, prioritize: Solid Carbide, 2 Flutes, and potentially an Uncoated or ZrN coating for best chip evacuation and reduced friction. A standard length is usually sufficient.

Reputable Brands and Resources

Investing in quality tools pays off. Look for reputable manufacturers known for their precision and material quality. Some well-regarded brands in the machining tool industry include:

Guhring: Known for high-quality industrial cutting tools.

IScar (Sandvik Coromant): A titan in the metal cutting industry, offering a vast range of carbide tools.

Heller: Specializes in carbide rotary tools and milling cutters.

Harvey Tool: Often praised for precision micro-tooling.

Maritool: Supplies quality end mills and tooling accessories.

For hobbyists and smaller workshops, brands like PreciseBits or even well-sourced options from V-Tool or other specialized CNC tooling suppliers can offer excellent value. Always check reviews and specifications carefully.

Setting Up for Success: Using Your 1/8 Inch End Mill

Getting the most out of your 1/8 inch carbide end mill, especially when aiming for precision, involves proper setup and careful operation. This section will guide you through the essentials, ensuring you get those “Proven Precision” results.

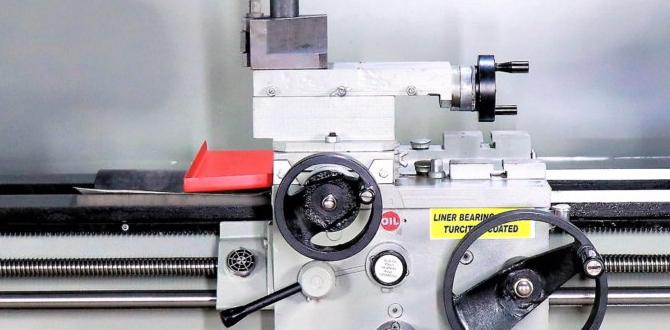

Securing the Tool: The Collet is Key

The 10mm shank of your end mill needs to be held very securely in your milling machine’s spindle. This is where the collet system comes in.

Collet Type: Most CNC machines and many manual milling machines use collets. Ensure you have a 10mm collet that fits your machine’s spindle taper (e.g., ER-style collets are very common).

Cleanliness: Before inserting the end mill, clean both the shank of the end mill and the inside of the collet. Any dirt, dust, or oil can prevent the collet from gripping the shank properly, leading to runout (wobble) or slippage.

Proper Insertion: Insert the end mill into the collet, but don’t push it all the way to the bottom. Leave a small amount of clearance. Then, insert the collet with the end mill into the spindle’s collet nut.

Tightening: Tighten the collet nut evenly. For small-diameter end mills, it’s often recommended not to overtighten, as this can distort the collet and cause runout. Snug is usually sufficient with a quality collet. Check your machine’s manual for specific recommendations.

Setting Your Workpiece Zero

Accurate work offset setting is paramount for precision. This tells your CNC machine (or you, on a manual machine) where the workpiece is in relation to the tool.

Edge Finder or Probe: For CNC machines, use a touch probe or an edge finder. For manual machines, a dial indicator or a simple piece of paper can help.

X, Y, and Z Zero:

X and Y: Typically set to a corner or center of your workpiece.

Z Zero: This is critical. It defines the top surface of your material. Use an edge finder, a touch plate, or carefully “kiss” the surface with the tip of the end mill (slowly lowering it until it just makes contact, often indicated by a slight drag or a spark if working with metal and power on). For MDF, a touch plate is ideal for consistent Z-zeroing.

Feeds and Speeds: The Sweet Spot

This is where many beginners struggle. Incorrect feeds and speeds can lead to poor surface finish, tool breakage, or burned material. For a 1/8 inch carbide end mill, especially on MDF, you’ll generally use higher spindle speeds and moderate feed rates.

General Starting Points for 1/8″ Carbide End Mill on MDF:

Spindle Speed (RPM): 18,000 – 24,000 RPM is a common range for 1/8″ carbide end mills on MDF. Always start at the lower end and increase if needed.

Feed Rate (IPM – Inches Per Minute): This depends heavily on your machine’s rigidity and the depth of cut. For a CNC router on MDF, a good starting point might be 30-60 IPM. For manual machines, you’ll be manually controlling this.

Depth of Cut (DOC): For a 1/8″ end mill, especially with a 10mm shank for rigidity, you can often take a decent shallow cut. For roughing, start with around 0.100″ to 0.125″ (2.5mm to 3mm). For finishing passes, much shallower cuts (0.010″ – 0.030″) are common to get a perfect surface.

Important Considerations:

*