Quick Summary: For precise cuts in bronze, a 3/16″ carbide end mill with an 8mm shank and standard length is your best bet. It offers superior hardness and heat resistance, leading to minimal deflection and cleaner finishes, making bronze machining achievable and repeatable for hobbyists.

Carbide End Mill 3/16″ Bronze: Proven Precision for Your Workshop

Hey everyone, Daniel Bates here from Lathe Hub! If you’ve ever tried to machine bronze, you know it can be a tricky material. It’s dense, can be a bit gummy, and leaves you wanting a cleaner cut than you sometimes get. The tool you choose makes a world of difference. Today, we’re diving deep into a specific hero for your workshop: the 3/16″ carbide end mill, especially when it’s configured for tackling bronze. We’ll explore why carbide is king for this job and how this particular size and type can bring precision to your projects, minimizing common frustrations. Get ready to unlock better results and more confidence in your machining!

Why Bronze Demands the Right End Mill

Bronze, an alloy of copper and tin (and sometimes other elements), is prized for its strength, corrosion resistance, and low friction. It’s commonly used in gears, bearings, marine hardware, and decorative items. However, from a machining perspective, bronze can be challenging.

Unlike softer metals, bronze has a higher tensile strength and can create long, stringy chips that cling to the cutting tool. This can lead to:

- Tool Loading: Chips getting stuck in the flutes, causing the tool to bind.

- Poor Surface Finish: Rough cuts and a gummy, uneven appearance.

- Increased Heat: Friction generates heat, which can dull tool edges faster and deform the workpiece.

- Deflection: The cutting forces can push the tool away from its intended path, resulting in inaccurate dimensions.

For beginners, these issues can be incredibly frustrating. You follow the steps, set your speeds and feeds, but the result isn’t what you imagined. The key is often in selecting the right cutting tool, and for bronze, that frequently means a carbide end mill.

Carrying the Torch: The Power of Carbide

When we talk about end mills, the material they’re made from is crucial. High-Speed Steel (HSS) is common, but for tougher materials like bronze, carbide is generally superior. Let’s look at why:

Hardness and Wear Resistance: Carbide is significantly harder than HSS. This means it maintains its sharp edge much longer, even when cutting harder materials or at higher speeds. For bronze, this translates to a tool that can chew through the material without quickly becoming dull and causing those frustrating chip issues.

Heat Resistance: Machining generates heat. Carbide can withstand much higher temperatures than HSS before softening. This is beneficial in bronze machining because it helps to dissipate heat away from the cutting edge into the chips and workpiece, reducing wear and tear on the tool.

Rigidity: Carbide is a denser, stiffer material. This means that a carbide end mill is less likely to flex or deflect under cutting forces compared to an HSS tool of the same size. This rigidity is paramount for achieving precise dimensions and clean finishes, especially with a smaller diameter tool.

Higher Cutting Speeds: Because of its hardness and heat resistance, you can often run carbide end mills at higher surface speeds (SFM) than HSS tools. This can lead to faster machining times, which is always a win in the workshop.

While carbide tools are generally more brittle than HSS (meaning they can chip or break if improperly used or subjected to shock), for precision work on materials like bronze, the benefits often outweigh this drawback when handled correctly by the user.

Why 3/16 Inch Matters for Bronze

The 3/16″ (which is approximately 4.76mm) size for a carbide end mill is a sweet spot for many common workshop tasks, especially those involving bronze. Here’s why this specific dimension is often a great choice:

- Versatility: A 3/16″ end mill is small enough for detailed work, slotting, pocketing, and profiling on smaller to medium-sized bronze parts. It’s not so large that you’re removing excessive material at once, which can be problematic with gummy materials.

- Heat Dissipation: Smaller diameter tools, when used correctly, can allow for quicker heat dissipation due to the chip load being managed. This helps prevent the aluminum oxide coatings on some end mills from breaking down prematurely, ensuring a longer tool life.

- Reduced Deflection Risk: While smaller tools are inherently more prone to deflection than larger ones, using a rigid carbide material in this size helps to mitigate that risk significantly. This is key for achieving the “Proven Precision” we’re aiming for.

When specifying a 3/16″ end mill for bronze, you might also encounter terms like “standard length.” This typically refers to a general-purpose length that provides a good balance between reach and rigidity. Too long, and deflection becomes a major issue. Too short, and you might not have enough flute engagement for efficient cutting.

The 8mm Shank Advantage

In many parts of the world, and particularly with imported tooling, you’ll find end mills specified with metric shank diameters. For a 3/16″ (approx. 4.76mm) cutter, an 8mm (approx. 0.315″) shank is a common and beneficial pairing. Why is this important?

Rigidity Reinforcement: An 8mm shank is substantially larger than the cutting diameter of the 3/16″ end mill. This larger shank provides a very strong anchor for the carbide cutting head. When the cutter is engaged in the bronze, a robust shank means less flex, less vibration, and therefore, vastly improved precision and surface finish. This is crucial for minimizing deflection.

Tool Holder Fitment: Many common milling machine collet systems and tool holders are designed around standard metric shank sizes like 8mm. Having an 8mm shank ensures that your new end mill will fit securely and accurately into commonly available tooling solutions.

Comparison: Imagine trying to hold a thin stick securely versus a much thicker dowel. The thicker dowel will resist bending far better. The 8mm shank acts like that thicker dowel for your 3/16″ cutting head, providing the necessary support for the cutting forces exerted on bronze.

Key Features of a Quality Carbide End Mill for Bronze (3/16″ x 8mm)

When you’re on the hunt for the perfect tool, here are the specific features to look for in a 3/16″ carbide end mill with an 8mm shank bundle, optimized for bronze:

| Feature | Why it Matters for Bronze | Beginner Tip |

|---|---|---|

| Material: Solid Carbide | Offers superior hardness, wear resistance, and heat tolerance compared to High-Speed Steel (HSS), crucial for cutting dense materials like bronze. | Carbide is more brittle than HSS. Avoid heavy shock or side loading. |

| Diameter: 3/16″ (approx. 4.76mm) | Ideal for intricate work, smaller parts, and controlled material removal. Good balance between cutting capability and tool rigidity for this size. | This size is versatile for many DIY and hobbyist projects. |

| Shank Diameter: 8mm (approx. 0.315″) | Provides significant rigidity and a secure grip in the collet chuck, drastically reducing deflection and improving accuracy. | Ensure your collet or tool holder can accept an 8mm shank. |

| Flute Count: 2 or 4 Flutes | 2-Flute: Best for softer metals and allows for higher feed rates, ideal for clearing chips more effectively in gummy materials like bronze. It offers better chip evacuation. 4-Flute: Generally better for harder materials and provides a smoother finish. For bronze, 2-flute is often preferred initially. |

Start with a 2-flute end mill for bronze. You can explore 4-flutes later if needed. |

| Coating: Uncoated or TiN (Titanium Nitride) | Uncoated: Good performance in softer materials like bronze. TiN: Adds a slight hardness and lubricity, helping with chip flow and slightly extending tool life. |

Uncoated is usually sufficient and more cost-effective for beginner bronze work. TiN is a nice upgrade if available. |

| End Type: Square End | The standard for milling slots, pockets, and contours. Provides sharp 90-degree internal corners. | This is the most common type for general milling. |

| Length: Standard Length | Balances reach with rigidity. Avoid excessively long end mills that invite deflection. A “standard” length is typically 1.5 to 2 times the diameter. | Check the “overall length” and “flute length” specifications. |

Setting Up for Success: Speeds, Feeds, and Coolant

Even with the right tool, improper setup can lead to trouble. For machining bronze with a 3/16″ carbide end mill, consider these general guidelines. Always check the manufacturer’s recommendations for specific tools and materials if available!

Surface Speed (SFM)

Surface speed is the linear speed of the cutting edge as it moves across the workpiece. For carbide end mills in bronze, a good starting point is often in the range of 200-400 SFM (Surface Feet per Minute).

Calculation:

SFM = (Diameter in inches RPM) / 3.14

Or, to find RPM:

RPM = (SFM 3.14) / Diameter in inches

For a 3/16″ (0.1875″) end mill:

- At 250 SFM: RPM = (250 3.14) / 0.1875 ≈ 4187 RPM

- At 350 SFM: RPM = (350 3.14) / 0.1875 ≈ 5861 RPM

Beginner Tip: Start at the lower end of the recommended SFM range and increase gradually if the cut is clean and the tool sounds happy. Listen to your machine!

Chip Load (IPR – Inch Per Revolution)

Chip load is the thickness of the material removed by each tooth of the end mill with every revolution. This is critical for preventing tool overload and ensuring good chip evacuation when machining bronze. A common starting point for a 3/16″ carbide 2-flute end mill in bronze might be around 0.001″ to 0.002″ IPR.

Calculation:

Feed Rate (IPM) = RPM Chip Load (IPR) Number of Flutes

Using our 4187 RPM example (250 SFM):

- With 0.0015″ IPR and 2 flutes: Feed Rate = 4187 0.0015 2 ≈ 12.56 IPM

- With 0.002″ IPR and 2 flutes: Feed Rate = 4187 0.002 2 ≈ 16.75 IPM

Beginner Tip: Make initial cuts with a lighter chip load. If the chips are small and dusty, increase the chip load slightly. If they are very large or you hear chattering, reduce the chip load.

Depth of Cut (DOC) and Width of Cut (WOC)

For bronze, it’s often best to use a shallower Depth of Cut (DOC) and a moderate to light Width of Cut (WOC) to manage forces and heat.

- DOC: Start with a DOC of around 0.060″ to 0.100″ (roughly 1/3 to 1/2 of the end mill diameter).

- WOC: For full slotting, WOC = Diameter (0.1875″). For pocketing or profiling, aim for a WOC that’s about 20-50% of the diameter (e.g., 0.035″ to 0.090″). This is often called “high-efficiency machining” or “adaptive clearing” where possible, which is great for chatter reduction.

Beginner Tip: Taking lighter cuts is always safer and often leads to a better finish. You can always go back and take more material off if needed.

Coolant and Lubrication

Bronze machining generates heat. While carbide handles it better than HSS, using a coolant or lubricant is highly recommended.

- Flood Coolant: The most effective for removing heat and flushing chips.

- Mist Coolant: A good alternative, provides lubrication and cooling without excessive mess.

- Cutting Fluid/Oil: For manual machining, a good quality cutting oil applied directly to the tool/workpiece interface is essential.

Why it helps: It cools the cutting edge, lubricates the cut, helps flush chips away from the flutes, and prevents the workpiece material from galling onto the cutter. This translates directly to a better finish and longer tool life.

Machinery Lubricants has excellent resources on understanding metalworking fluids and their importance.

Step-by-Step: Making it Happen on Your Mill

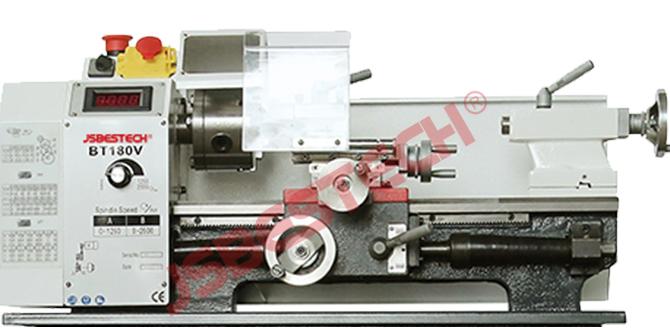

Let’s break down how to use your 3/16″ carbide end mill for precision work in bronze. We’ll assume you’re using a typical R8 collet system or similar on a milling machine.

Step 1: Preparation and Safety First

- Wear Safety Glasses: Always! Even with a chip guard, flying chips are a hazard.

- Secure Your Workpiece: Ensure the bronze block or part is firmly clamped in a vise or on the milling table. Use parallels if needed to keep it flat and stable.

- Secure the Tool: Insert the 3/16″ 8mm shank carbide end mill into an appropriate collet (e.g., an 8mm R8 collet). Tighten the collet securely in your milling machine’s spindle.

- Set Zero Z-Axis: Bring the tip of the end mill down to gently touch the top surface of your workpiece. Use a piece of paper or a touch probe to accurately find the surface, then set your Z-axis position to zero.

Step 2: Roughing Passes (If Necessary)

If you need to remove a significant amount of material, start with slightly more aggressive settings, but still within reasonable limits for bronze.

- Engage the Spindle: Start the spindle at your calculated RPM.

- Apply Lubricant: Start your coolant or apply cutting fluid to the cutting area.

- Plunge or Step In: For plunge cuts, ease the tool down to your desired Depth of Cut (DOC) using the Z-axis handwheel. For stepping in from the side, use your X or Y-axis handwheel.

- Make the Cut: Feed the workpiece into the rotating end mill using your X and Y-axis handwheels. Maintain a consistent feed rate.

- Clear Chips: Periodically retract the tool to clear accumulated chips, especially if not using flood coolant.

- Repeat: Make shallow passes, incrementally increasing the DOC towards your target depth.

Step 3: Finishing Passes

Once you’re close to your final dimensions, switch to lighter, more precise settings for a superior finish.

- Reduce DOC: Set your Depth of Cut to a shallower value, perhaps 0.020″ to 0.040″ for the final passes.

- Adjust Feed Rate: You might slightly slow down the feed rate or maintain it if the cutting action is smooth.

- Use Climb Milling (If Appropriate): On many modern CNC machines, climb milling (where the cutter rotates in the same direction as the feed) can provide a better finish and reduce cutting forces. For manual mills, conventional milling is more common and generally requires heavier cuts. When possible, aim for a finish pass that leaves minimal material.

- Focus on Surface Finish: Make your final pass with a very light DOC (e.g., 0.005″ to 0.010″) at a good feed rate to achieve a mirror-like surface.

Step 4: Inspection and Next Steps

- Clean the Part: Thoroughly clean the workpiece and the tool to remove any residual chips or coolant.