Quick Summary

For proven results cutting mild steel, a 3/16″ carbide end mill is an excellent choice. Look for high-quality carbide, an appropriate flute count (2-4 flutes are common for steel), and a helix angle suitable for chip evacuation. Proper speeds, feeds, and coolant will ensure smooth cuts and extend tool life for your projects.

Hey there, workshop warriors! Daniel Bates here from Lathe Hub. Ever stared at a block of mild steel, excited to get milling, only to wonder which tool will do the job best? It’s a common question, especially when you’re starting out. The sheer variety of cutting tools can seem overwhelming. But fear not! Today, we’re diving deep into one of the most reliable companions for your mild steel projects: the 3/16″ carbide end mill. We’ll break down exactly why this tool is a winner and how to get the most out of it, leading to clean, efficient cuts every time. Get ready to mill with confidence!

Why a 3/16″ Carbide End Mill is Your Go-To for Mild Steel

Mild steel is a fantastic material for beginners. It’s affordable, forgiving, and widely available. But to get those professional-looking results, you need the right cutting tool. That’s where a 3/16″ carbide end mill shines. Why this specific size and material? Let’s break it down.

Carbide: The Champion Material

Carbide, or more precisely, tungsten carbide, is a super-hard material. It’s made by sintering a fine powder of tungsten carbide with a binding metal, usually cobalt. This process creates a material that is incredibly hard and yet surprisingly tough. For machining steel, carbide offers several key advantages over traditional high-speed steel (HSS):

- Heat Resistance: Milling generates a lot of friction and heat. Carbide can withstand much higher temperatures than HSS without losing its cutting edge hardness. This means you can often run your machine faster, getting the job done quicker and more efficiently.

- Hardness: Tungsten carbide is significantly harder than steel itself. This allows it to cut through tough materials like mild steel with ease, leaving behind a clean, smooth surface finish.

- Wear Resistance: Because it’s so hard, carbide end mills resist wear much longer than HSS tools. This translates to a longer tool life, meaning fewer tool changes and less downtime.

- Rigidity: Carbide is a more rigid material, which can lead to less tool deflection. This is crucial for achieving tight tolerances and accurate dimensions in your parts.

The Mighty 3/16″ Size

The 3/16″ (or approximately 4.76mm) diameter is a sweet spot for many common machining tasks. It’s small enough for detailed work, like creating grooves, slots, or profiling intricate shapes, but substantial enough to remove material effectively without excessive chatter or vibration. For beginners, this size offers a good balance:

- Versatility: You can do a lot with a 3/16″ end mill – pocketing, contouring, facing, and even some light deburring. It’s a workhorse size.

- Manageability: Smaller end mills can be more prone to breaking if abused. The 3/16″ size is less delicate than, say, a 1/8″ end mill, offering a bit more forgiveness for slight errors in feed rate or depth of cut.

- Common Applications: Many DIY projects, hobbyist builds, and even some light industrial applications call for features that fall within the capability range of a 3/16″ end mill.

Optimized for Steel: What to Look For

Not all carbide end mills are created equal! When you’re specifically targeting mild steel, here are some features that make a big difference:

- Flute Count: For mild steel, 2-flute or 4-flute end mills are generally the best choices.

- 2-Flute: Excellent for chip evacuation, especially in slots and pockets. The two larger chip gullets allow chips to escape easily, preventing re-cutting and overheating. This is often preferred for aluminum and softer steels.

- 4-Flute: Provides a smoother finish and faster material removal when used for general milling and profiling (rather than deep slotting). The increased number of cutting edges means more cutting action per flute revolution, but also smaller chip gullets.

- Helix Angle: This is the angle at which the flutes spiral around the cutter.

- Standard (around 30 degrees): A good all-around helix angle suitable for many materials, including mild steel.

- High Helix (40-60 degrees): Offers excellent chip evacuation and can reduce vibration, leading to a better surface finish. These are particularly good for softer materials like mild steel and aluminum, allowing for higher feed rates.

- Corner Radius: Some end mills have a sharp corner, while others have a small radius. A slight corner radius can add strength to the cutting edge, making it less prone to chipping, and can create a small fillet in the bottom of a slot. For general-purpose milling of mild steel, a square end mill (square corner) is very common and versatile. If you need a specific fillet, look for a radius.

- Coatings: While not always necessary for mild steel, specialized coatings like TiN (Titanium Nitride) or TiCN (Titanium Carbonitride) can further improve lubricity, wear resistance, and heat resistance, extending tool life. For general use, an uncoated carbide end mill is often perfectly adequate.

- Reduced Neck: Sometimes you’ll see “reduced neck” or “necked down” end mills. This means the shank (the part that goes into the collet or holder) is slightly smaller in diameter than the cutting head. This is particularly useful for reaching into deeper pockets or slots without the shank interfering with the walls of the pocket. For a 3/16″ end mill, this is often called an “8mm shank reduced neck” if we’re talking metric.

For optimal chip evacuation when slotting or pocketing mild steel, a 3/16″ carbide end mill with 2 flutes and a higher helix angle is often a fantastic choice.

Choosing Your 3/16″ Carbide End Mill: A Beginner’s Checklist

When you’re browsing online or in a tool store, keep this checklist handy. It will help you pick the right 3/16″ carbide end mill for your mild steel adventures.

- Material: Ensure it’s Tungsten Carbide.

- Diameter: Confirm it’s 3/16 inch (or 4.76mm).

- Shank Diameter: Most common will be 3/16 inch as well. For deeper reach, consider an 8mm shank if you have the tooling to hold it securely.

- Flute Count: For mild steel, 2 or 4 flutes are standard. 2-flute is great for chip clearing in slots. 4-flute is good for general surface milling.

- Coating: Uncoated is fine for many tasks, but a coating can add longevity if your budget allows.

- End Type: Square end for general work is most common. Radius end if you need a specific corner fillet.

- Manufacturer Reputation: Stick with reputable brands known for quality tooling.

Setting Up for Success: Speeds, Feeds, and Coolant

Having the right tool is only half the battle. Proper setup is crucial for getting those proven results and ensuring your end mill lasts. Let’s talk about speeds, feeds, and coolant.

Speeds and Feeds: The Magic Numbers

This is where things can get a bit technical, but we’ll keep it simple. Speeds and feeds determine how fast the tool spins (spindle speed) and how fast it moves through the material (feed rate).

Spindle Speed (RPM): This is the rotational speed of your milling machine spindle. A good starting point for a 3/16″ carbide end mill in mild steel is often between 8,000 and 15,000 RPM. The exact speed depends on the machine, the rigidity of your setup, and the specific carbide grade. Lower RPMs are generally safer for beginners and less rigid setups, while higher RPMs can be more efficient with the right machine and tooling.

Feed Rate (IPM or mm/min): This is how fast the cutting tool moves into and through the workpiece. A general rule of thumb for mild steel with a 3/16″ carbide end mill is to aim for a chip load of around 0.001″ to 0.003″ per flute. So, for a 2-flute end mill, your feed rate would be approximately:

Feed Rate (IPM) = Spindle Speed (RPM) Number of Flutes Chip Load (inches/flute)

Example:

Spindle Speed = 10,000 RPM

Number of Flutes = 2

Chip Load = 0.002″ per flute

Feed Rate = 10,000 2 * 0.002 = 40 IPM

Important Considerations:

- Start Conservatively: Always start at the lower end of the recommended speed and feed ranges. Listen to the cut. If it sounds smooth and the chips look good (they shouldn’t be wispy or powdery, nor should they be giant spaghetti strands), you can gradually increase the feed rate.

- Listen to Your Machine: A good cut sounds like a continuous, gentle “shaving” sound. If you hear chattering, screaming, or any harsh noises, stop immediately! Your speeds, feeds, or depth of cut are likely wrong.

- Depth of Cut (DOC): For a 3/16″ end mill, a radial depth of cut (how much of the tool diameter is engaged sideways) of 50% is common for profiling. For axial depth of cut (how deep it cuts into the material vertically), a good starting point for light cuts is 0.100″ to 0.150. You can go deeper with rigid setups and lighter chip loads.

- Tooling Rigidity: The stiffer your machine, collet, and workpiece mounting, the faster you can push your speeds and feeds.

Don’t have a milling machine with adjustable RPM? Many hobby machines have fixed speeds. In that case, you’ll primarily adjust your feed rate. Start slow and find what works.

The Role of Coolant

While some machinists get by with dry machining, using a cutting fluid or coolant is highly recommended, especially for beginners and when working with steel. Coolant provides several benefits:

- Cooling: It significantly reduces the heat generated at the cutting edge, preventing the carbide from overheating and extending its life.

- Lubrication: It acts as a lubricant between the cutting edge and the workpiece, reducing friction and improving the surface finish.

- Chip Evacuation: It helps to wash chips away from the cutting zone, preventing them from being re-cut and causing tool wear or surface damage.

For mild steel, you have a few options:

- Flood Coolant: A constant flow of coolant directly onto the cutting area. This is ideal but requires a coolant system.

- Mist Coolant: A fine spray of coolant and air. Less coolant usage and can be effective.

- Cutting Fluid (Applied Manually): For simpler setups, you can use a brush or a spray bottle to apply a good quality cutting fluid directly to the cutting area. Look for soluble oils or synthetic coolants designed for ferrous metals.

- WD-40 (Temporary Fix): While not ideal for heavy machining, in a pinch for very light cuts on mild steel, an occasional spray of WD-40 can provide some lubrication and cooling. However, invest in proper cutting fluid for longer tool life and better results.

A great resource for machining data, including speeds and feeds, is the MetalForming association or resources from tool manufacturers like Sandvik Coromant or Kennametal.

Step-by-Step: Using Your 3/16″ Carbide End Mill on Mild Steel

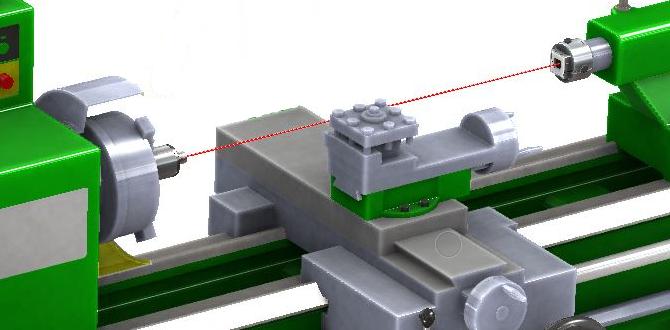

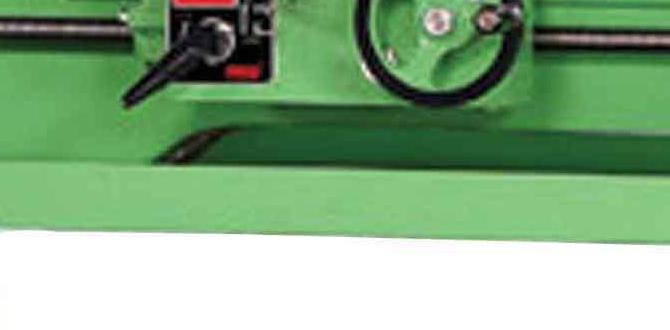

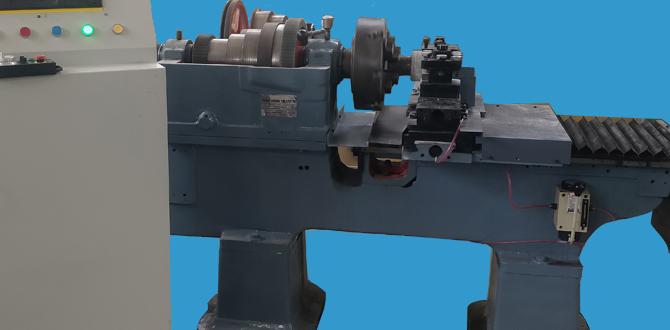

Let’s walk through a typical milling operation using your 3/16″ carbide end mill on mild steel. We’ll assume you’re using a small, benchtop milling machine (like a Grizzly G0704 or similar). Safety first!

Safety First!

Before you even touch the machine:

- Eye Protection: Always wear safety glasses or a face shield. Metal chips can fly.

- Appropriate Clothing: No loose clothing, jewelry, or long hair that can get caught.

- Secure Workpiece: Make sure your workpiece is clamped TIGHTLY. Use a vise with soft jaws if necessary to protect the surface.

- Secure Tool: Ensure the end mill is securely held in the collet or chuck.

- Stable Machine: Ensure your milling machine is on a stable surface and properly grounded.

- Know Your E-Stop: Be aware of where your emergency stop button is.

Step 1: Prepare Your Workpiece

Ensure your piece of mild steel is clean, flat, and securely fixtured in your milling machine vise or on the table. For beginners, it’s best to start with a piece that is already reasonably flat and square.

Step 2: Select and Install Your End Mill

Choose the appropriate 3/16″ carbide end mill (e.g., 2-flute, regular helix). Securely insert it into a properly sized collet or end mill holder. Make sure the shank is inserted deep enough into the collet for good support, but not so deep that the flutes are obscured.

Step 3: Set Up Your Machine

Spindle Speed: Set your spindle to a conservative speed, say 8,000 RPM. If your machine has a dial, use it. If it’s a fixed speed, use that.

Coolant: Get your coolant ready. If using flood or mist, turn it on. If using manual application, have your spray bottle or brush handy.

Step 4: Zero Your Axes

You need to tell the machine where Z=0 (the top surface of your material) and where X and Y will start.

- Z-Axis: Use a probe, edge finder, or a piece of paper to find the top surface of your workpiece. Jog the spindle down until the end mill just touches the surface. You can often feel this with the paper – when it just starts to drag, you’re at Z=0. Set your Z-axis DRO (Digital Readout) to 0.

- X and Y Axes: Use an edge finder or the spindle itself to find the edge of your workpiece. Set your X and Y DROs to 0 at your desired starting point for the cut.

Step 5: Set Your Depth of Cut (DOC)

For a pocketing or slotting operation:

- Decide how deep you want to cut. Let’s say 0.125″ (1/8 inch).

- From your Z=0 setting, jog the spindle down to Z=-0.125.

- Ensure your DRO is zeroed at the top surface before you start jogging.

Step 6: Program or Manually Set Your Feed Rate

Calculate your feed rate based on your chosen RPM and chip load. Aim for around 40-60 IPM as a starting point for our example (10,000 RPM, 2-flute, 0.002-0.003″ chip load). If you are using a CNC, you’ll enter this into your program. If you are using a manual mill, you will manually turn the handwheel. Start slow! It’s much better to feed too slowly than too fast.

Step 7: Make the Cut

Engage the spindle at your chosen RPM.

Apply coolant.

Manually (or via program) engage the X or Y axis feed. Start moving the tool into the material. If manual, use smooth, consistent pressure on the handwheel. Listen carefully to the sound of the cut.

Observe the Chips: You want to see small, well-formed chips being evacuated. If they are dusty and fine, you might be feeding too slowly or the part is burning. If they are long, stringy, or re-cut, you might be feeding too fast or not enough coolant.

Complete the Cut: Continue feeding until you reach your desired depth and travel the programmed path.