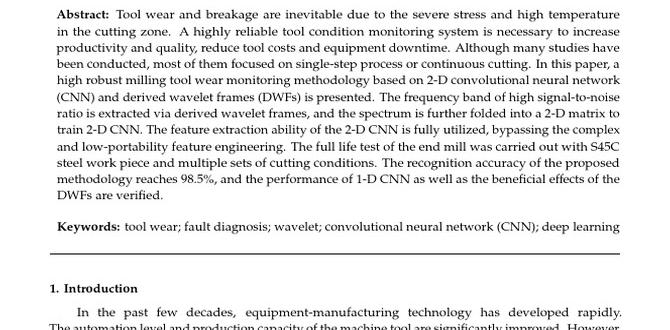

Quick Summary:

For clean, smooth cuts in MDF, a 3/16″ carbide end mill is essential. Look for one with excellent chip evacuation features, like a reduced neck, to prevent clogging and ensure a professional finish. This guide shows you the best choices and how to use them effectively.

Working with Medium-Density Fiberboard (MDF) can be a builder’s best friend and sometimes, a finishing nightmare. You want those crisp edges and precise inlays, but the dust and tear-out can really make you sweat. The good news? With the right tool, this frustration fades away. A specifically chosen 3/16″ carbide end mill can be your secret weapon for making MDF behave. We’ll dive into exactly what makes one of these end mills so special for MDF and how to pick the perfect one for your projects.

Why a 3/16″ Carbide End Mill is Your Go-To for MDF

MDF is a fantastic material. It’s smooth, consistent, and easy to machine. But it’s also made of fine wood particles held together with resin. When you cut it, especially with the wrong tool, this sticky resin can build up, leading to clogs, rough cuts, and even damage to your material and your machine. That’s where a high-quality carbide end mill comes in. Carbide is incredibly hard, meaning it stays sharp longer and can handle the abrasiveness of MDF better than many other materials.

The 3/16-inch size is particularly versatile for MDF. It’s small enough for detailed work, like creating intricate patterns or precise joinery, yet large enough to make good progress on larger cuts. Its size allows for a good balance between detail and speed, making it a staple in many CNC routing and manual milling setups for woodworkers and hobbyists.

The Magic of Carbide in MDF Machining

Carbide, or tungsten carbide, is a compound of tungsten and carbon atoms. It’s renowned for its exceptional hardness and wear resistance. When used in end mills, this means:

- Longer Tool Life: Carbide edges stay sharp for significantly longer periods compared to high-speed steel (HSS) when cutting materials like MDF, which can be abrasive due to the glue and fine dust.

- Higher Cutting Speeds: Because carbide can withstand higher temperatures generated by friction, you can often run your spindle at faster RPMs, leading to quicker machining times.

- Cleaner Cuts: A sharp carbide edge slices through MDF fibers cleanly, resulting in less chipping and tear-out, giving you that smooth finish straight off the machine.

- Less Heat Buildup: While cutting generates heat, carbide’s properties help dissipate it more effectively, further reducing the risk of melting the resin binder in MDF, which can cause gumming.

Key Features of the Best 3/16″ Carbide End Mills for MDF

Not all carbide end mills are created equal, especially when it comes to MDF. Several design features can make a huge difference in performance and longevity. Understanding these will help you choose the right tool for the job.

1. Flute Design: The Chip Evacuation Champion

Flutes are the helical grooves that run along the cutting end of the mill. Their primary job is to carry chips (the material being cut) away from the cutting edge. For MDF, excellent chip evacuation is paramount.

- High Helix Angle: Look for a high helix angle (often 30-45 degrees, sometimes even higher for specific MDF applications). This steep angle helps to pull chips up and out of the cut more efficiently.

- Polished Flutes: Some end mills feature polished flutes. This smooth surface finish reduces friction and prevents MDF dust and resin from sticking, which is a common problem that leads to clogging.

- Number of Flutes: For MDF, typically 2-flute or 3-flute end mills are preferred. More flutes mean more cutting edges, but they can also pack chips more easily. For MDF, especially in finer dust applications where chip evacuation is critical, fewer flutes (like 2) with a wider flute gullet (the space between flutes) are often best. A 2-flute design provides good chip clearance.

2. Coating: Added Protection and Performance

Coatings applied to carbide end mills can enhance their performance and durability. While not always necessary for basic MDF work, they can be beneficial for demanding tasks or to extend tool life.

- Uncoated: For many general MDF applications, a high-quality, uncoated carbide end mill is perfectly sufficient. The inherent hardness of carbide does most of the heavy lifting.

- Coated: Coatings like TiN (Titanium Nitride), TiCN (Titanium Carbonitride), or AlTiN (Aluminum Titanium Nitride) can provide extra hardness, lubricity, and heat resistance. For MDF, a coating that reduces friction and prevents material buildup is most beneficial. Uncoated or those with slick, low-friction coatings can be excellent.

3. Neck Relief: Preventing Remachining and Binding

This is a critical feature often found on specialized end mills for softer materials like plastics and MDF. A neck relief, or reduced neck, means the shank (the part that goes into the tool holder) is slightly thicker than the cutting diameter of the flutes. In some designs, the cutting portion is also slightly narrower than the point where the flutes end, creating a taper.

Why is this important for MDF?

- Reduces Friction: The relief in the neck area means less surface area of the tool shank grinds against the sides of the cut, minimizing friction and heat.

- Prevents Binding: As chips are evacuated, a reduced neck allows for smoother passage, reducing the chance of the end mill getting stuck or binding in the material. This is especially helpful when cutting deep slots or making intricate paths where chip buildup would otherwise cause issues.

- Improved Chip Flow: The tapered relief behind the cutting edge encourages chips to flow more freely out of the flutes, further enhancing the chip evacuation capacity.

When looking for an end mill for MDF, keywords like “reduced neck” or “relief neck” on a 3/16″ carbide end mill are strong indicators that it’s designed for this type of work.

4. End Type: Flat vs. Ball vs. Ball Nose

The shape of the cutting end of the end mill influences the type of cuts you can make.

- Flat End Mills: These have a flat cutting surface at the end. They are ideal for pocketing (removing material from an area), profiling (cutting the outline of a shape), and general milling tasks. For most MDF applications, a 3/16″ flat end mill is the most versatile choice.

- Ball Nose End Mills: These have a rounded, ball-shaped tip. They are excellent for 3D carving, creating rounded fillets, and smooth surface finishing. A 3/16″ ball nose can be used for detailed carving on MDF.

- Corner Radius End Mills: These are a hybrid, having a flat end with slightly rounded corners. They offer the strength of a flat end mill but provide a small radius in the corners of pockets to reduce stress and improve tool life.

For beginner projects and general-purpose MDF cutting, a 3/16″ 2-flute flat end mill with a reduced neck is often the sweet spot. It offers the best balance of cutting performance, chip evacuation, and versatility.

Choosing the Right 3/16″ Carbide End Mill: Specifications to Look For

When you’re browsing online or in a tool shop, keep an eye on these specifications:

| Specification | Importance for MDF | What to Look For |

|---|---|---|

| Diameter | Essential for cut size. | 3/16″ (0.1875 inches) or metric equivalent (~4.76mm). Ensure the shank is a standard size like 1/4″ (6mm) or 3/8″ (8mm) for compatibility with common toolholders. |

| Material | Durability and sharpness. | Solid Carbide. |

| Flute Count | Chip evacuation and cut finish. | 2-flute or 3-flute. 2-flute is often preferred for better chip clearance in MDF. |

| Flute Type | Chip Removal. | High helix angle, polished or bright finish. |

| Coating | Wear resistance, friction reduction. | Uncoated is often fine. Low-friction coatings can be beneficial. |

| Neck Relief | Prevents binding and material buildup. | Look for “reduced neck,” “relief neck,” or “tapered relief” features. This is highly recommended for MDF. |

| End Type | Cut geometry. | Flat end for general use. Ball nose for carving. |

| Shank Diameter | Tool holder compatibility. | Common sizes are 1/4″ (6mm) or 8mm. 8mm shank versions are often found on tools marketed for CNC routers. |

A common and highly effective configuration you’ll find is a 3/16″ carbide end mill with an 8mm shank, reduced neck, and 2 flutes designed for plastics or soft materials. While marketed for plastics, these features translate exceptionally well to MDF due to the similar cutting challenges (resin, dust, chip buildup).

How to Use Your 3/16″ Carbide End Mill on MDF Safely and Effectively

Now that you know what makes a good end mill for MDF, let’s talk about putting it to work. Safety and proper technique are just as important as having the right tool.

Setting Up Your Machine

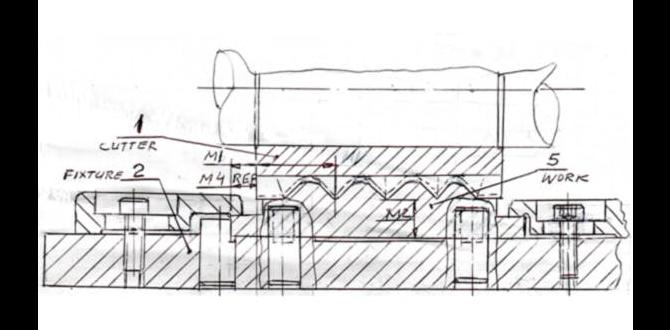

Whether you’re using a CNC router or a manual milling machine, proper setup is key.

- Secure Your MDF: Always clamp your MDF workpiece down firmly. Use methods like double-sided tape, clamps, or a spoilboard with a vacuum hold-down system. Vibration is the enemy of a clean cut.

- Clearance for Chips: Ensure there’s plenty of room for the chips to escape. If you’re using a CNC, make sure your dust collection system is working efficiently.

- Tool Holder: Use a clean and appropriate tool holder to grip the end mill’s shank. A worn or dirty collet can lead to runout (the tool wobbling), resulting in poor cut quality and potentially breaking the end mill.

Spindle Speed (RPM) and Feed Rate

This is where things get a bit technical, but we’ll keep it simple. The combination of how fast the tool spins (RPM) and how fast it moves through the material (feed rate) is crucial for getting good results and preventing tool damage.

General Guidelines for 3/16″ Carbide End Mill on MDF

These are starting points, and you may need to adjust them based on your specific machine, MDF density, and the end mill’s exact geometry. It’s always best to consult the end mill manufacturer’s recommendations if available.

- Spindle Speed (RPM): For a 3/16″ carbide end mill, a common starting point is between 12,000 and 18,000 RPM. Lower RPMs can cause the MDF resin to melt and gum up the tool, while excessively high RPMs can generate too much heat and dust.

- Feed Rate: This is typically measured in inches per minute (IPM) or millimeters per minute (mm/min). A good starting point for roughing cuts might be 30-60 IPM (760-1520 mm/min). For finishing passes, you might slow down to 20-40 IPM (500-1000 mm/min) to achieve a finer surface finish. The feed rate is also closely tied to the depth of cut.

- Depth of Cut (DOC): Don’t try to cut through the entire thickness of the MDF in one pass. For a 3/16″ end mill, taking a depth of cut of around 0.125″ to 0.250″ (3mm to 6mm) per pass is a good rule of thumb for roughing. You can use a shallower DOC for finishing passes.

The Golden Rule: Always perform a test cut on a scrap piece of MDF. Listen to the sound the machine is making. If it sounds like it’s straining or chattering, adjust your feed rate (usually slower) or depth of cut (shallower). If it’s just smoothly cutting and evacuating chips, you’re likely in the right zone.

For more precise information, you can explore resources on CNC machining parameters. Websites like the Machinery.com Guide to CNC Router Speeds and Feeds offer valuable insights into calculating optimal settings, though you’ll need to adapt them for your specific 3/16″ end mill and MDF type.

Cutting Strategies

How you move the tool matters. For CNC routing, common strategies include:

- Climb Milling vs. Conventional Milling:

- Conventional Milling: The cutter rotates against the direction of feed. This is generally safer for beginners as it’s less likely to grab the material.

- Climb Milling: The cutter rotates in the same direction as the feed. This imparts less stress on the tool and can result in a smoother finish, but requires a more rigid machine and careful feed rate control to avoid accidents. For MDF, conventional milling is often sufficient and easier to manage.

- One-Way vs. Two-Way Passes: When profiling a part, a common technique is to set up two passes. The first pass cuts to about 90% of the final depth, leaving a thin “skin.” The second pass cuts the remaining material at the full depth. This second pass is often done at a slower feed rate for a cleaner edge finish.

Maintaining Your End Mill

Even the best carbide end mill will eventually wear out or get clogged.

- Clean After Use: Always clean your end mill after each project. Compressed air is great for blowing away dust. A stiff brush can help remove any stubborn buildup. You can also use a small amount of non-flammable, low-VOC solvent to clean off resin residue if needed, but ensure it’s completely dry before storage.

- Inspect for Wear: Look at the cutting edges. If they appear chipped, dulled, or rounded over, it’s time to replace the end mill.

- Proper Storage: Store your end mills in a protective case. Dropping them or allowing them to bang against other tools can damage the delicate cutting edges.

Comparing Different Types of 3/16″ Carbide End Mills for MDF

Let’s look at some common types you might encounter and their pros/cons for MDF:

1. Standard 2-Flute Flat End Mill

- Pros: Versatile, good for pocketing and profiling, generally affordable, decent chip clearance with 2 flutes.

- Cons: Can be prone to clogging if not designed for soft materials, edges might not be as clean as specialized types without careful parameter tuning.

2. “O-Flute” or “Plastic” End Mill (Often 1 or 2 Flute)

These are often designed with very large, polished flute gullets specifically to evacuate chips from materials like plastics and MDF, which have a tendency to melt and clog.

- Pros: Excellent chip evacuation, greatly reduces sticking and gumming, produces super clean cuts on MDF, often has a polished finish on flutes and cutting edges.

- Cons: Can be more expensive, might be slightly less durable than standard designs if the flute walls are very thin.

3. “On Edge” or “Spiral Upcut/Downcut” End Mills

While less common in this exact size for MDF, these refer to how the cutting edges are presented. Most standard end mills cut “on edge.” Spiral upcut and downcut refers to the direction of the flutes relative to the tool holder. For MDF, you’ll primarily be looking at upcut spirals for chip evacuation.

- Upcut Spiral: Flutes spiral upwards. This pulls chips up and out of the cut, which is generally ideal for MDF to keep the cutting area clear.

- Downcut Spiral: Flutes spiral downwards. This pushes chips down, which is good for holding material down and getting a clean top surface, but can lead to chip packing in the cut. Less ideal for general MDF work.