Carbide end mills excel at machining Inconel, offering superior hardness and heat resistance for this notoriously tough alloy. Selecting the right carbide end mill, like a reduced neck, 8mm shank variant for Inconel 625 with MQL, is key to achieving brilliant results and preventing tool failure.

Machining Inconel can feel like wrestling with a super-alloy. This material is tough, heat-resistant, and can quickly chew up standard cutting tools. If you’ve ever struggled with tool breakage or poor surface finish when working with Inconel, you’re not alone! The good news is that with the right tools and techniques, you can achieve brilliant machining results even in this challenging metal. One of the most powerful allies in your workshop for tackling Inconel is the carbide end mill. In this guide, we’ll explore why carbide is king for Inconel and how to pick the perfect carbide end mill to make your machining jobs shine. Get ready to turn those frustrating Inconel projects into triumphs!

Why Inconel is a Machining Challenge

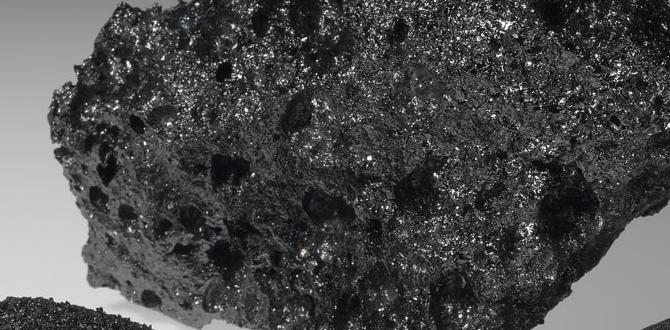

Inconel is a family of nickel-chromium-based superalloys. What makes them so special for high-temperature and corrosive environments also makes them incredibly difficult to machine. They possess a unique set of properties that engineers love, but machinists often find daunting:

- High Strength at Elevated Temperatures: Inconel retains its strength even when heated intensely, which happens during machining. This means it resists cutting forces much more than mild steel.

- Work Hardening: As you cut Inconel, the material immediately around the cut zone gets harder. This means subsequent passes have to cut through increasingly tough material, leading to rapid tool wear.

- Low Thermal Conductivity: Inconel doesn’t transfer heat away from the cutting zone very well. This causes heat to build up in the cutting tool, which can lead to thermal shock and premature tool failure.

- Gummy or Sticky Nature: Inconel tends to “gum up” or adhere to the cutting tool, leading to chip welding and a rough surface finish.

These properties mean that standard high-speed steel (HSS) end mills often struggle. They can’t withstand the heat and abrasion, leading to rapid dulling, chipping, and breakage. You need a tool that’s tougher, harder, and can handle significant heat.

The Brilliance of Carbide End Mills for Inconel

Carbide, specifically tungsten carbide, is a ceramic material renowned for its extreme hardness and wear resistance. When formed into an end mill, it brings several advantages crucial for machining Inconel:

- Superior Hardness: Carbide is significantly harder than HSS, allowing it to cut through tough materials like Inconel without dulling as quickly.

- High Heat Resistance: Carbide can withstand much higher temperatures than HSS before softening. This is vital because machining Inconel generates significant heat.

- Rigidity and Strength: Carbide end mills are generally more rigid, which helps in resisting the high cutting forces from Inconel and reducing chatter.

- Excellent Wear Resistance: The hard nature of carbide means it resists abrasion from the metal particles, leading to longer tool life, especially when machining abrasive materials like Inconel.

While carbide is more brittle than HSS and requires careful handling, its inherent toughness makes it the go-to material for machining difficult alloys like Inconel. For Inconel machining brilliance, a carbide end mill is your best bet.

Choosing the Right Carbide End Mill for Inconel

Not all carbide end mills are created equal, especially when it comes to Inconel. Here’s what to look for:

Material Grade and Coating

The specific grade of tungsten carbide and any coatings applied play a huge role.

- Carbide Grade: For Inconel, you’ll want a fine-grain carbide grade that balances hardness and toughness. Very fine grains offer supreme hardness but can be more brittle. A slightly coarser grade might offer better toughness for the shock and vibration inherent in Inconel machining.

- Coatings: Coatings add another layer of protection. For Inconel, consider:

- TiAlN (Titanium Aluminum Nitride): Excellent for high-temperature applications. It forms a protective aluminum oxide layer at high heat, providing superior thermal and oxidation resistance. This is a top choice for Inconel.

- AlTiN (Aluminum Titanium Nitride): Similar to TiAlN but often performs even better at the extreme temperatures generated by Inconel.

- ZrN (Zirconium Nitride): Offers good lubricity and wear resistance, helping to prevent chip welding.

End Mill Geometry

The shape and design of the end mill’s cutting edges are critical for managing Inconel’s properties.

- Number of Flutes: For Inconel, fewer flutes are generally better.

- 2-Flute End Mills: These provide the best chip clearance. With Inconel’s tendency to produce long, stringy chips that can weld to the tool, ample space for chips to escape is paramount.

- 3-Flute End Mills: Can offer a balance between chip evacuation and tool rigidity. Suitable for lighter cuts or finishing passes.

- 4-Flute End Mills: Generally not recommended for roughing Inconel as they offer poor chip clearance and can lead to chip packing and overheating. Use for finishing or specific applications where rigidity is key and chip buildup isn’t a major concern.

- Helix Angle: A higher helix angle (e.g., 30-45 degrees) helps to shear the material more effectively, reduce cutting forces, and improve chip evacuation.

- Core Diameter: A larger core diameter provides more rigidity, which is essential for resisting the forces when cutting Inconel.

- Corner Radius or Chamfer: A small corner radius or a chamfered edge can help to strengthen the cutting edge and distribute forces, reducing the risk of chipping.

Specific Considerations: Reduced Neck, 8mm Shank for Inconel 625 MQL Friendly

Let’s break down a specific example often encountered when working with Inconel 625, especially in precision applications:

- Reduced Neck: This feature means the diameter of the non-cutting shank is smaller than the cutting diameter. This is incredibly useful for reaching into pockets or features where a standard shank would collide with the workpiece or fixturing. For Inconel 625, a reduced neck allows access to complex geometries without compromising the cutting diameter’s integrity.

- 8mm Shank: A standard shank size in metric systems, an 8mm shank is common for smaller diameter end mills. When paired with Inconel machining, it implies precision work where tool diameter is often controlled. It’s a practical size for many smaller CNC machines and milling attachments.

- Inconel 625: This specific grade of Inconel is known for its excellent corrosion resistance and strength, especially at high temperatures. Machining it requires tools that can handle its high tensile strength and tendency to work harden.

- MQL Friendly: MQL stands for Minimum Quantity Lubrication. This system uses a very small amount of coolant and air, delivered directly to the cutting zone. An MQL-friendly end mill is designed to work efficiently with this system. Benefits include:

- Superior Cooling: The air component of MQL helps to evacuate heat rapidly, keeping the tool and workpiece cooler.

- Improved Lubrication: The fine mist of coolant lubricates the cutting edge, reducing friction and preventing chip welding.

- Environmental Benefits: MQL uses significantly less coolant than traditional flood coolant systems, leading to reduced waste and easier cleanup.

- Visibility: The reduced mist allows for better visibility of the cutting process.

For Inconel, where heat management is critical, MQL can be a game-changer, and an end mill designed for it will perform exceptionally well.

When searching for an end mill, look for descriptions like “Carbide End Mill 3/16 Inch 8mm Shank Reduced Neck for Inconel 625 MQL Friendly” to find tools specifically suited for these challenging conditions and precision needs.

Recommended Carbide End Mill Features for Inconel

Based on the needs of Inconel, here are key features to confirm when selecting your carbide end mill.

| Feature | Why it’s Important for Inconel | Recommended Specification |

|---|---|---|

| Material | Hardness and heat resistance are paramount. | Solid Carbide (Tungsten Carbide) |

| Coating | Protects against extreme heat and abrasion. | TiAlN, AlTiN, or ZrN variants. Zirconium Nitride (ZrN) coatings are particularly good for reducing friction and preventing chip welding. |

| Flute Count | Chip evacuation is critical to prevent heat buildup and tool breakage. | 2 or 3 flutes for roughing and general machining. 4 flutes can be used for finishing passes where chip load is lower. |

| Helix Angle | Improves shearing action and chip removal. | 30° to 45° (High Helix) |

| Corner Configuration | Strengthens the cutting edge and reduces chipping. | Slight corner radius or chamfer |

| Coolant/Lubrication | Essential for managing heat and preventing welding. | Through-coolant holes (if available) and designed for MQL or high-pressure coolant. |

Steps for Successful Inconel Machining with Carbide End Mills

Picking the right tool is only half the battle. Here’s a step-by-step approach to machining Inconel with your carbide end mill to ensure brilliant results:

1. Rigidity is Key: Secure Your Workpiece and Tooling

Inconel demands a rigid setup. Any flex in your machine, vise, or tooling will lead to chatter, poor surface finish, and premature tool failure.

- Ensure your milling machine is sturdy and well-maintained.

- Use a robust vise or fixture to clamp the Inconel workpiece securely. Avoid overhanging the workpiece excessively.

- Use the shortest possible tool length to minimize deflection. If using an extended reach tool (like with a reduced neck), ensure it’s appropriate for the depth.

- Securely fasten the end mill in a high-quality collet chuck. Avoid standard chucks if possible, as they offer less runout accuracy and rigidity.

2. Set Your Cutting Parameters Wisely

This is where many beginners struggle. Inconel generally requires lower surface speeds than steels. The key is to maintain a consistent chip load and avoid dwelling in the cut.

- Surface Speed (SFM or m/min): Start conservatively. For Inconel 625, typical starting points might be 30-60 SFM (9-18 m/min). Always refer to manufacturer recommendations for specific end mills and coatings as these can vary significantly.

- Feed Rate (IPM or mm/min): This is directly tied to your surface speed and the diameter of your end mill. The goal is to achieve an adequate chip load. A good starting point for chip load per tooth might be 0.001-0.003 inches (0.025-0.076 mm) depending on the tool diameter. Many advanced CAM software packages will help calculate this.

- Depth of Cut (DOC) and Stepover: For roughing Inconel, shallow depths of cut (e.g., 0.050-0.100 inches or 1.25-2.5 mm) and a reasonable stepover (e.g., 30-50% of tool diameter) are often best. This helps manage heat and cutting forces. For finishing, you’ll use much shallower depths and smaller stepovers.

Pro Tip: Consult a machining calculator or your CAM software for precise feed and speed recommendations. Resources like the NIST Manufacturing Data may offer insights into material properties and machining parameters.

3. Implement Effective Lubrication and Cooling

As discussed, heat is the enemy. Proper cooling and lubrication are non-negotiable for Inconel.

- MQL: If your end mill is MQL friendly, set up your MQL system to deliver a fine mist of coolant and air directly to the cutting zone.

- High-Pressure Coolant: If using flood coolant, ensure it’s high-pressure and directed precisely at the cutting edges.

- Through-Coolant Holes: If your end mill has through-coolant holes, ensure your machine’s coolant system can supply fluid at adequate pressure to utilize them effectively.

- Cutting Fluid: Use a high-quality synthetic or semi-synthetic coolant specifically designed for machining nickel alloys or difficult-to-machine metals.

4. Optimize Chip Evacuation

Preventing chip buildup is crucial to avoid re-cutting chips, which generates excessive heat and dulls the tool. This is why 2-flute end mills are often favored for roughing Inconel.

- Peck Drilling/Engaging: When plunging the end mill, use a “peck” cycle to retract the tool periodically and clear chips from the hole.

- Toolpath Strategy: In your CAM software, use strategies like “high-efficiency milling” (HEM) or trochoidal milling, which maintain a consistent chip load throughout the cut and minimize the time the tool spends engaging with hot material.

- Air Blast: Even with MQL or flood coolant, an intermittent air blast can help blow chips away from the cutting zone.

5. Monitor and Adjust

Machining Inconel is an iterative process. Pay close attention to the sound of the cut, visual cues, and chip formation.

- Listen: A healthy cut sounds consistent. A loud, chattering, or “singing” sound often indicates rigidity issues or incorrect parameters.

- Look: Observe chip formation. Chunks of aluminum-like material mean you’re likely taking too big a bite or not cooling/lubing enough. Small, well-formed chips are ideal.

- Feel: With the machine stopped, carefully feel the tool and workpiece. Excessive heat is a sign that parameters need adjustment.

- Adjust: If you notice signs of tool wear or difficulty, slightly reduce your surface speed or feed rate, or increase your coolant flow.

Benefits of Using the Right Carbide End Mill for Inconel

When you get your Inconel machining right with the correct carbide end mill, the rewards are immense:

- Extended Tool Life: Instead of burning through expensive end mills, they last significantly longer.

- Improved Surface Finish: Achieve smooth, precise surfaces without the rough imperfections caused by tool wear or chip welding.

- Increased Productivity: You can machine faster and more reliably, reducing cycle times.

- Reduced Machining Costs: Less tool breakage and scrap means lower overall project costs.

- Greater Design Freedom: Successfully machining Inconel opens up possibilities for complex parts in demanding applications, from aerospace to medical devices.

Common Mistakes to Avoid

Even with the best tools, some common pitfalls can derail your Inconel machining efforts:

- Using the wrong end mill: Trying to machine Inconel with a general-purpose end mill is a recipe for frustration.

- Running too fast: Excessive spindle speed is detrimental. It generates too much heat and can cause the carbide to fail prematurely.

- Chip packing: Poor chip evacuation is a primary cause of tool breakage and surface damage.

- Insufficient lubrication/cooling: Inconel will not tolerate dry machining or inadequate coolant.

- Lack of rigidity: Flex in the system is fatal to cutting tools when tackling superalloys.

- Taking too deep a cut: Attempting to remove too much material in a single pass will overload the tool.

FAQ: Your Carbide End Mill & Inconel Questions Answered

Q1: What is the biggest challenge when machining Inconel?

A1: The biggest challenge is managing the material’s extreme hardness, tendency to work-harden, and low thermal conductivity. These factors create immense heat and stress on the cutting tool.

Q2: Can I use a standard carbide end mill for Inconel?

A2: While a standard solid carbide end mill is better than HSS, it’s not ideal. You’ll achieve much better results with a carbide end mill specifically designed for tough