Quick Summary: Effortlessly machine HDPE with a 3/16-inch carbide end mill featuring an 8mm shank. This guide reveals how to achieve tight tolerances and clean cuts, making HDPE projects simpler and more professional for beginners and hobbyists.

Working with High-Density Polyethylene (HDPE) can sometimes feel tricky, especially when aiming for precise shapes and smooth edges. You might have a project in mind that requires intricate cuts, and you’re wondering if your tools are up to the task. It’s a common frustration! Many beginners find that general-purpose end mills leave rough surfaces or struggle to maintain accuracy with this unique plastic. But what if there was a specific tool that made HDPE machining a breeze? Well, there is! This guide is your step-by-step solution. We’ll show you exactly how a particular type of carbide end mill can be your new best friend for HDPE, leading to fantastic results without the headache.

The Perfect Partner: Understanding the 3/16 Inch Carbide End Mill for HDPE

So, why is the 3/16-inch carbide end mill with an 8mm shank so special for HDPE? It’s all about the combination of size, material, and how it’s designed. Let’s break it down into simple terms.

Why Carbide?

Carbide is a super hard material. It’s much harder than the high-speed steel (HSS) often found in common cutting tools. This hardness means a carbide end mill stays sharp for longer, even when cutting tough materials like HDPE. For plastics, especially those that can melt or gum up on a dull tool, carbide’s durability is a massive advantage. It cuts cleaner and requires less effort, which is perfect when you’re just starting out.

The 3/16 Inch Diameter Advantage

The 3/16-inch size is a sweet spot for many HDPE projects. It’s small enough to allow for detailed work, like cutting out small parts, creating channels, or engraving. Yet, it’s substantial enough to remove material efficiently without being overly fragile. This size is often used for creating precise outlines or milling pockets where accuracy matters.

The 8mm Shank: A Secure Grip

The 8mm shank is the part of the end mill that fits into your milling machine’s collet or tool holder. An 8mm shank is a common size, offering a good balance between rigidity and compatibility with various machines. A secure fit is crucial for preventing chatter (vibrations) and ensuring that the tool spins true and cuts accurately. This stability is key to achieving those tight tolerances you’re after.

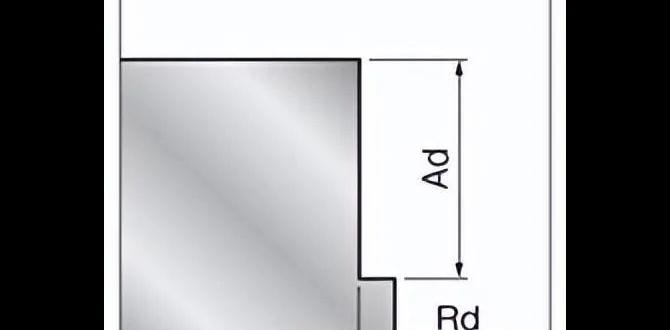

The “Reduced Neck” Design (Crucial for Tight Tolerances)

Now, for the secret sauce that truly makes this tool a “genius solution” for HDPE: the reduced neck. Not all 3/16-inch end mills have this feature, but it’s a game-changer. Imagine the cutting flutes of the end mill. The “neck” is the part of the shank just above the flutes. When this neck is slightly reduced in diameter, it allows the end mill to plunge deeper into a cut or get closer to a corner without the shank itself rubbing against the material.

This is incredibly important in HDPE because it can be a bit flexible. With a standard end mill, if you try to cut a tight internal corner or mill down into a deep pocket, the thicker shank might hit the sides of your workpiece before the cutting flutes can finish the job. This can lead to poor cut quality or even damage your workpiece. The reduced neck design eliminates this problem, allowing for cleaner cuts and significantly improved accuracy, especially in intricate designs.

For the keyword phrase “carbide end mill 3/16 inch 8mm shank reduced neck for hdpe tight tolerance,” this reduced neck is the key feature that enables you to achieve those specific tight tolerances in HDPE.

Why HDPE Can Be Challenging (And How This Tool Helps)

High-Density Polyethylene (HDPE) is a fantastic material for many applications, from signs and cutting boards to automotive parts and boat building. It’s durable, chemical-resistant, and easy to clean. However, when it comes to machining, it has a few characteristics that can make things a bit difficult for beginners using the wrong tools.

Melting and Gumming

One of the biggest challenges with machining plastics like HDPE is their tendency to melt. If your cutting tool is moving too slowly, not sharp enough, or generating too much friction, the plastic can heat up, melt, and stick to the cutting edges. This is called “gumming up.” When this happens, your cuts become rough, the tool can get clogged, and you might even damage your workpiece or your machine. The sharp edges of a carbide end mill, combined with the right cutting speeds and feeds, help to shear the plastic cleanly rather than melt it.

Flexibility and Chip Evacuation

HDPE can also be a bit flexible, especially in thin sheets. This means that if your tool isn’t cutting cleanly, it can snag and pull the material, leading to inaccuracies or broken parts. Furthermore, good chip evacuation (getting the cut-out material, or chips, away from the cutting area) is vital. If chips build up, they can reheat the material and cause melting. The flutes of an end mill are designed to help carry chips away. A well-designed end mill for plastics will have geometry that promotes efficient chip removal.

Achieving Tight Tolerances

For projects that need parts to fit together precisely, tight tolerances are essential. This means the dimensions of your cut need to be very close to the intended size. This requires a stable setup, a sharp tool, and a cutting process that doesn’t introduce errors. The rigidity of the 8mm shank, combined with the precise cutting action of the carbide and the clearance provided by a reduced neck, all contribute to achieving those critical tight tolerances.

Essential Tools and Setup for Machining HDPE

Before you fire up your mill, let’s make sure you have everything you need for a smooth and successful machining session with your 3/16-inch carbide end mill. Having the right setup ensures safety and better results.

Your Milling Machine

You’ll need a milling machine (a CNC router, a desktop CNC mill, or a proper vertical mill). Ensure it’s in good working order, with no excessive play in the Z-axis or spindle. For HDPE, even a desktop CNC router can do a fantastic job.

The Star of the Show: Your End Mill

- Carbide End Mill: 3/16 inch diameter, 8mm shank. Look for one designed for plastics or general-purpose use. A 2-flute end mill is often recommended for softer materials like plastics as it can provide better chip clearance than a 4-flute.

- Reduced Neck: Specifically seek out models with a reduced neck for internal cornering and deep pocketing.

Collets and Holders

You need the correct collet or tool holder that fits your machine’s spindle and accepts an 8mm shank. Make sure the collet is clean and provides a firm grip on the end mill. For precision, a good quality ER collet system is excellent.

Workholding Solution

This is crucial for safety and accuracy. You need to firmly secure your HDPE sheet to the milling bed so it doesn’t move during the cut. Options include:

- Clamps: Use low-profile clamps that won’t interfere with the end mill’s path.

- Double-Sided Tape: For thinner sheets and lighter cuts, strong double-sided tape can work, but ensure it’s robust enough. This is not recommended for demanding cuts or larger workpieces.

- Vacuum Table: If your machine has one, a vacuum table is an excellent, secure way to hold down plastics.

- Fixtures: For repeatable projects, creating a custom fixture is ideal.

Dust Collection

Machining HDPE creates plastic dust and small chips. While not as hazardous as metal dust, it’s best to have a dust collection system connected to your router or mill to keep your workspace clean and improve visibility. It also helps in preventing chips from melting back onto the workpiece.

Safety Gear (Non-Negotiable!)

Always prioritize your safety. You will need:

- Safety Glasses: To protect your eyes from flying debris.

- Hearing Protection: Milling can be noisy.

- Dust Mask: Especially if you don’t have robust dust collection.

Measuring Tools

For ensuring tight tolerances, have good measuring tools ready, such as calipers or a micrometer.

Step-by-Step Guide: Machining HDPE with Your 3/16 Inch End Mill

Let’s get cutting! This process is designed to be straightforward, ensuring you get good results even on your first try. Remember to always start with test cuts on scrap material.

Step 1: Prepare Your HDPE and Machine

- Clean the HDPE: Ensure the surface of your HDPE stock is clean and free from dirt or debris.

- Secure the Material: Firmly clamp or otherwise secure your HDPE sheet to the milling bed using your chosen workholding method. Double-check that it cannot move in any direction.

- Set Up Your Machine: Ensure your Z-axis is clear and your work surface is clean.

Step 2: Install the End Mill

- Select the Correct Collet: Choose the 8mm collet that fits your machine’s spindle.

- Insert the End Mill: Place the 3/16-inch carbide end mill into the collet. Ensure it’s inserted to the recommended depth (usually about two-thirds of the cutting flute length plus a bit more for shank engagement).

- Tighten the Collet: Secure the collet in your spindle according to your machine’s procedure. A properly tightened collet prevents the end mill from slipping, which is critical for accuracy and safety.

Step 3: Set Your Zero Points (Work Zero)

This is where you tell your machine where the workpiece is in relation to its movement. You’ll typically set:

- X and Y Zero: This is your starting point on the surface of the HDPE.

- Z Zero: This is the top surface of your HDPE. Use an edge finder or touch probe for accuracy. You can also carefully do this manually with a piece of paper under the spinning (but not cutting) end mill until it just grips the paper.

Step 4: Determine Cutting Speeds and Feeds

This is one of the most important parts for cutting plastic cleanly. Too fast, and you’ll melt; too slow, and you’ll get a rough cut or tear out.

For a 3/16-inch carbide end mill in HDPE, here are good starting points. Always test on scrap first!

Recommended Starting Speeds and Feeds for HDPE (3/16″ Carbide End Mill, 8mm Shank)

| Parameter | Typical Value | Notes |

|---|---|---|

| Spindle Speed (RPM) | 15,000 – 20,000 | Higher speeds are often better for plastics to reduce friction. Your machine’s max speed may vary. |

| Feed Rate (IPM or mm/min) | 20 – 40 IPM (approx. 500 – 1000 mm/min) | This is the speed the tool moves through the material. Start slower and increase if cuts are clean. |

| Depth of Cut (DOC) | 0.1 – 0.2 inches (approx. 2.5 – 5 mm) per pass | Take multiple shallow passes rather than one deep one. |

| Stepover (Width of Cut) | 30 – 50% of tool diameter (0.057 – 0.095 inches) | For facing or pocketing. Lower stepover for smoother finish. |

Important Note: These are general guidelines. Actual optimal settings depend on your specific machine rigidity, material batch, and end mill geometry. Always listen to the sound of the cut and watch the chips being produced. If you hear squealing or see melting, slow down the feed rate or reduce the depth of cut.

You can find more technical information on cutting plastics from resources like The Plastics Industry Association, though they may be more industry-focused than beginner machining.

Step 5: Program Your Toolpath (or Manually Control)

If you’re using a CNC machine, this is where you’ll input your design and cutting parameters into your CAM software or directly into the machine controller. For manual milling, you’ll be controlling the X, Y, and Z axes by hand.

Key considerations for your toolpath:

- Climb vs. Conventional Milling: For plastics, climb milling (where the cutter rotates in the same direction as its feed) often yields better surface finishes and reduces the tendency for the material to be pushed around.

- Contour Passes: When cutting out a part, you’ll often use a contour path. Ensure the path is set to cut outside the intended part outline if you want the part to be the exact dimension, or inside if you want the contour to be exact.

- Pocketing: When milling out an area, use a pocketing strategy.

- Reduced Neck Utility: Remember to leverage the reduced neck feature by programming internal corners and deep pockets. Your CAM software might have specific settings to account for tool shank radius.

Step 6: Perform Test Cuts

As mentioned, always test on a scrap piece of HDPE first.

Make a simple cut, like a square or a circle, to check:

- Dimensional Accuracy: Measure the cut feature with calipers to ensure it’s the correct size.

- Surface Finish: Look for smooth edges and a clean surface.

- Chip Formation: Are the chips small and powdery, or are they melting and stringy?

Adjust your speeds and feeds based on the test results. If melting occurs, try increasing the feed rate or decreasing the spindle speed slightly. If the cut feels rough, you might try a slightly slower feed rate or a shallower depth of cut.

Step 7: Execute Your Project Cut

Once your test cuts are successful, you’re ready to machine your actual project.

Follow your programmed toolpath or manual machining plan carefully.

Keep an eye on the cutting process:

- Listen: Unusual noises can indicate problems.

- Watch: Observe chip formation and surface finish.

- Check for Melting: If you see signs of melting, pause the machine and address the issue (often adjusting feed or speed).

Step 8: Finishing Touches

After the cut is complete, carefully remove the finished part from the machine.

- Deburr: Some minor burrs might remain. These can usually be removed with a deburring tool, a sharp knife, or sandpaper.

- Inspect: Measure critical dimensions one last time to confirm your tight tolerances were met.

Common Issues and Troubleshooting

Even with the best tools, you might encounter a few hiccups. Here’s how to fix them.

Issue: Melting or Gumming Up

- Cause: Too much heat generated. This usually means the cutting speed is too slow OR the feed rate is too slow, OR the depth of cut is too high.

- Solution: Increase feed rate, reduce depth of cut, or increase spindle speed slightly. Ensure good chip evacuation. If using a CNC, engage coolant or air blast if available and appropriate.

Issue: Rough Surface Finish

- Cause: Dull end mill, incorrect feed/speed, excessive tool runout, or material vibration.

- Solution: Ensure your end mill is sharp. Adjust feed rate (sometimes slightly faster or slower can help). Check that the end mill is properly seated in the collet and that your machine has minimal play. Try reducing the depth of cut or stepover.

Issue: Poor Dimensional Accuracy / Not Meeting Tight Tolerances

A 3/16-inch carbide end mill with an 8mm shank and reduced neck is designed to help here, but other factors contribute.

- Cause: Material not held securely, inadequate tool rigidity, excessive cutting forces, deflection of the workpiece or tool.

- Solution: Ensure your HDPE is very securely fixtured. Use the shallowest possible depth of cut. Use climb milling. Ensure your end mill is sharp and properly gripped. For deep pockets, the reduced neck is essential to prevent shank rubbing.

Issue: Chipping or Tear-Out on Edge

- Cause: The tool is