Get a flawless mirror finish on carbon steel with a 3/16″ 8mm shank carbide end mill. This guide shows you how to select the right tool, set up your machine, and master the cutting techniques for that professional, reflective surface, making it simple even for beginners.

Ever looked at a perfectly polished metal surface and wondered how they achieve that incredible shine? It’s not magic, and it doesn’t have to be a frustrating mystery for us home machinists! Getting a mirror finish on materials like carbon steel can seem daunting, especially when you’re just starting out. But with the right tool and a few simple techniques, you can achieve those stunning results right in your own workshop. We’re going to break down exactly what you need to know about using a 3/16″ (or 8mm shank) carbide end mill to get that smooth, reflective surface. Let’s get started on achieving those professional-looking finishes!

Why a 3/16″ 8mm Carbide End Mill for Mirror Finishes?

When you’re aiming for that super smooth, almost liquid-metal look on your parts, the tool you choose is absolutely critical. For many beginner machinists and DIYers, the common question is: “What’s the best way to get a mirror finish, especially on materials like carbon steel?” The answer often leads us to a specific type of cutting tool: the carbide end mill, and often, the 3/16 inch or 8mm shank size is a sweet spot for many projects.

Carbide, short for tungsten carbide, is a super-hard material. This extreme hardness means carbide end mills can cut tougher metals like carbon steel much more effectively than their High-Speed Steel (HSS) counterparts. They also stay sharper for longer and can handle higher cutting speeds. When we talk about finishes, especially a mirror finish, the precision and rigidity of a carbide tool are key. A 3/16″ (or 8mm) shank size is popular because it offers a good balance of rigidity and reach for many common milling tasks on smaller machines or for delicate work, which is perfect for beginners focusing on accuracy.

The Magic of High-Quality Carbide

So, what makes carbide so special? It’s its incredible hardness and resistance to heat. When a cutting tool spins and removes material, it generates friction and heat. Carbide can withstand much higher temperatures than HSS without losing its hardness or getting damaged. This means it can maintain a sharp, precise cutting edge, which is essential for a smooth surface finish.

Why 3/16″ or 8mm Shank?

The shank is the part of the end mill that goes into your machine’s collet or tool holder. A 3/16 inch (which is roughly 4.76mm) or an 8mm shank offers a good balance.

Rigidity: Thicker shanks (like 8mm compared to a smaller 3mm or 1/8″ shank) mean less flex. Less flex translates to a more stable cut and a better surface finish.

Tool Holder Availability: 3/16″ and 8mm are common sizes for popular collet systems used on many benchtop milling machines and CNC machines often found in home workshops. This means it’s easier to find the right tool holder.

Versatility: This size is suitable for a wide range of smaller to medium-sized parts and detailed work where a larger end mill might be overkill or too aggressive.

When you combine the toughness of carbide with the stability of a 3/16″ or 8mm shank, you get a tool that’s well-suited for achieving that elusive, flawless mirror finish on carbon steel.

Selecting the Right 3/16″ 8mm Carbide End Mill for a Mirror Finish

Not all carbide end mills are created equal, especially when your goal is a mirror finish. For this specific task, you’ll want to look for a few key characteristics.

Key Features to Look For:

Number of Flutes: For finishing passes, especially to achieve a mirror-like surface, you generally want an end mill with a higher number of flutes.

2-Flute: Good for general-purpose milling and slotting, but can sometimes leave a rougher finish than higher flute counts.

3-Flute: A good compromise. Can work for finishing, but might struggle to clear chips effectively at very high speeds.

4-Flute or More: Ideal for finishing. More flutes mean more cutting edges engaging the material. This will result in a smoother surface and better chip evacuation at high speeds. For a mirror finish, 4 flutes are often recommended.

Coating: Some coatings can enhance performance and finish.

Uncoated: Often sufficient for general-purpose work and may even be preferred for some finishing applications depending on the material and your machine’s rigidity.

TiN (Titanium Nitride): A golden coating that improves hardness and reduces friction. Good for general use.

AlTiN (Aluminum Titanium Nitride): Excellent for high-temperature applications and harder materials like stainless steel. Can also contribute to a good finish.

ZrN (Zirconium Nitride): Often used for superalloys and can provide a very slick surface that helps with chip evacuation and finish.

DLC (Diamond-Like Carbon): Very hard and has excellent lubricity, which can lead to superior surface finishes.

For a straightforward mirror finish on carbon steel, an uncoated or TiN-coated 4-flute carbide end mill will often serve you very well.

Material: Ensure it’s genuine tungsten carbide. Reputable manufacturers will clearly state this.

Cutting Edge Geometry: Look for end mills designed for finishing. These often have sharper, more refined cutting edges. Some might have a slight radius or a chamfer on the edge. For a true mirror finish, you’re often looking for a tool with a very sharp, clean edge.

Standard Length: For most general milling and finishing operations where you’re not plunging deep into a part, a “standard length” or “stub length” end mill is perfectly fine. Being shorter, they are generally more rigid, which benefits finish quality.

Where to Find Them:

You can find these specialized end mills at:

Online tool suppliers (e.g., McMaster-Carr, MSC Industrial Supply, G&G Tools, Harvey Tool)

Local industrial supply stores

Specialty machining shops

Example Specifications for a Mirror Finish End Mill:

Let’s consider what you might type into a search bar:

“Carbide end mill 3/16 inch shank, 4 flute, uncoated, standard length”

OR

“Carbide end mill 8mm shank, 4 flute, TiN coated, standard length”

You’ll see options from brands like YG-1, Widia, Sandvik Coromant, and many others. For beginners, starting with a well-known, reputable brand is usually a safe bet.

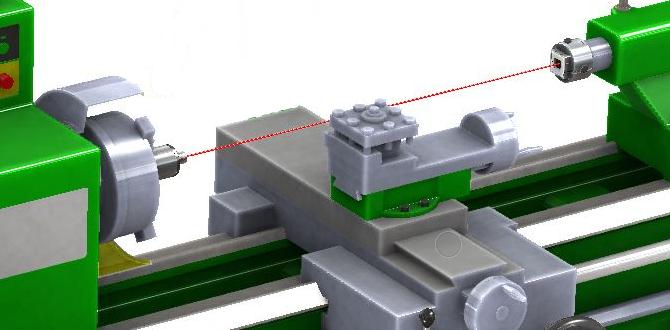

Machine Setup for a Smooth Finish

Getting the perfect surface finish isn’t just about the end mill; how you set up your milling machine plays a huge role too! Even the best tool can produce a rough surface if your machine isn’t dialed in.

Essential Checks and Preparations:

Before you even think about cutting, let’s make sure your machine is ready to deliver that silky smooth surface.

1. Rigidity is King:

Secure the Workpiece: Your workpiece MUST be held down firmly. Use strong clamps, a vise that’s snug against the machine table, or appropriate fixtures. Any vibration or movement here will ruin your finish.

Minimize Overhang: If possible, use the shortest possible workholding setup. A long, wobbly vise jaw is the enemy of a good finish.

Machine Stability: Ensure your milling machine itself is on a solid base, like a heavy workbench or a dedicated machine stand. Avoid flimsy setups.

2. Cleanliness Matters:

Machine Table: Make sure the T-slots and the surface of your milling machine table are clean and free of debris.

Tool Holder: Your collet or tool holder must be spotlessly clean. Any swarf or oil inside can cause runout and vibration. Clean it with a shop towel and maybe some alcohol.

Workpiece Surface: Ensure the surface of the carbon steel you’re milling is brushed or cleaned to remove any heavy scale or rough patches. A clean starting surface helps immensely.

3. Tool Holder and Spindle:

Runout: This is a critical concept. Runout is the wobble of the cutting tool as it spins. Even a tiny amount of runout (the amount the center of the cutting tool deviates from the exact center of rotation) can cause an uneven, bumpy surface finish.

Use a Good Collet System: Invest in quality ER collets or a milling chuck designed for low runout.

Check Runout: Many machinists use an indicator to measure runout. Ideally, you want less than 0.0005″ (0.0125mm) for good finishing. For a true mirror finish, aiming for even less is better.

Spindle Cleanliness: Ensure the spindle taper is clean and free of any debris.

4. Coolant/Lubrication:

Why Use It: For carbon steel, a coolant or lubricant is almost always recommended, even for finishing. It helps:

Reduce friction and heat buildup.

Lubricate the cutting edge, allowing it to glide smoothly.

Flush away chips, preventing them from being re-cut and damaging the finish.

What to Use:

Cutting Fluid: Specifically designed for metal cutting. Available as neat oils or water-soluble emulsions.

Cutting Paste/Stick: Concentrated lubricants that can be applied directly to the cutting edge. Great for lighter-duty machines or when a full coolant flood isn’t practical.

WD-40 (with caution): For very light cuts and less demanding materials, some might use WD-40. However, it’s not a true cutting lubricant for heavy work and can sometimes contribute to sticky chip issues on harder steels. Always use a dedicated cutting fluid if you can.

Application: Apply coolant directly to the cutting zone as the end mill is working.

Mounting the End Mill:

1. Ensure the collet and collet nut are clean.

2. Insert the 3/16″ or 8mm shank carbide end mill into the collet. Make sure it’s seated properly and doesn’t extend too far out from the collet nut. A longer overhang reduces rigidity.

3. Tighten the collet nut securely in the tool holder or directly into the spindle if it has an integrated collet system.

4. Insert the tool holder into the spindle. Make sure it’s seated correctly.

By ensuring your machine and setup are rigid, clean, and properly equipped, you’re setting yourself up for success. A stable machine is the foundation for any good finish.

Mastering the Cut: Cutting Parameters for a Mirror Finish

This is where the rubber meets the road! The settings you use—speed, feed, and depth of cut—will directly impact the surface finish you achieve. For a mirror finish, we’re looking for very specific parameters.

Understanding Speed and Feed

Spindle Speed (RPM): This is how fast your cutting tool rotates. Measured in revolutions per minute (RPM).

Feed Rate: This is how fast the tool moves into the material. Measured in inches per minute (IPM) or millimeters per minute (mm/min).

Depth of Cut (DOC): How deep the end mill cuts into the material with each pass.

For a mirror finish, we are generally talking about a light finishing pass. This means shallow depths of cut and taking multiple passes if necessary, rather than trying to hog out material in one go.

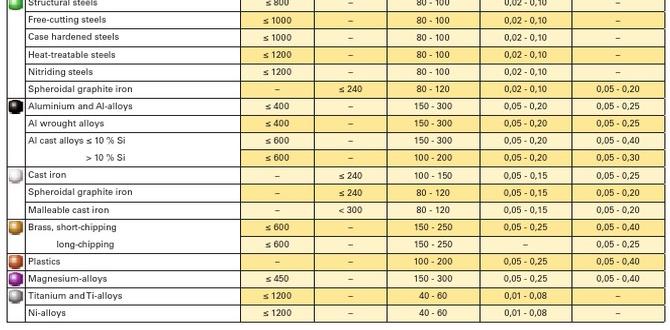

Recommended Parameters for Carbon Steel (Approximate)

Finding the exact perfect numbers depends on your specific end mill, machine rigidity, and coolant. However, here are some starting points for a 3/16″ (4.76mm) or 8mm shank, 4-flute carbide end mill on carbon steel. These are generally conservative numbers to help you achieve a good finish without damaging the tool.

General Rule of Thumb: For finishing, you want to move to the higher end of the recommended speed range and the lower end of the feed rate range to achieve a smooth surface.

| Parameter | Recommendation for Carbon Steel (e.g., 1018, mild steel) | Notes for Mirror Finish |

| :———————- | :——————————————————- | :———————————————————————————————————————————————————————————————————————————————– |

| Spindle Speed (RPM) | 6,000 – 15,000+ RPM | Higher RPM is generally better for finish. Aim for the higher end. The exact speed will depend on the end mill manufacturer’s recommendation and what your machine can achieve. A higher speed means the cutting edge engages with the material for a shorter, cleaner bite, reducing tearing. |

| Feed Rate (IPM / mm/min) | 10 – 30 IPM (approx. 250 – 760 mm/min) | Lower feed rate is key. This ensures that each cutting edge takes a very small chip. A common rule of thumb for finishing is to aim for chip loads between 0.001″ – 0.003″ (0.025mm – 0.075mm) per flute. |

| Depth of Cut (DOC) | 0.005″ – 0.020″ (0.1mm – 0.5mm) | Very shallow cuts are essential. For a true mirror finish, you might even go down to 0.001″ – 0.002″ (0.025mm – 0.05mm) on the final pass. Multiple light passes are better than one aggressive pass. |

| Axial Depth of Cut (Plunge) | N/A (if facing) or shallow for pocketing | If plunging, consider a slow plunge rate and pecking. For finishing, avoid plunging directly into features if possible; instead, ramp or spiral in. |

| Engagement Angle | N/A (if facing) | For pocketing or profiling, a shallow engagement angle (ramping) is much better for finishing than a square, 90-degree entry. |

Important Considerations for Mirror Finish:

Chip Load: This is the thickness of the chip removed by each cutting edge. For a mirror finish, you want a very small chip load. You can calculate it:

`Chip Load = Feed Rate (IPM) / (RPM Number of Flutes)`

`Chip Load = Feed Rate (mm/min) / (RPM Number of Flutes)`

For example, if you’re running at 10 IPM, 8000 RPM, with a 4-flute end mill:

`Chip Load = 10 IPM / (8000 RPM 4) = 0.0003125″` per flute. This is a very light chip load, perfect for finishing.

Climb Milling vs. Conventional Milling:

Climb Milling: The tool rotates in the same direction as it moves into the material. This generally produces a smoother finish and reduces cutting forces. Often preferred for finishing.

Conventional Milling: The tool rotates against the direction of material feed. This can cause more chatter and a rougher finish.

For mirror finishing, always try to climb mill if your machine setup allows it. This typically means the CNC controller handles it automatically, or on a manual mill, you need to ensure the table feed is set up to push the workpiece into the cutter in the direction it’s spinning.

Surface Speed (SFM): Some end mill manufacturers provide recommended Surface Feet per Minute (SFM) instead of RPM. You can convert SFM to RPM using this formula:

`RPM = (SFM 3.82) / Diameter (inches)`

`RPM = (SM 1000) / (3.14159 Diameter (mm))`

For a 3/16″ (0.1875″) end mill and a target SFM of, say, 500 SFM:

`RPM = (500 3.82) / 0.1875 = 10186 RPM`. This is a good reference point.

Step-by-Step Cutting Process for Mirror Finish:

1. Initial Roughing (if needed): If your part has significant material to remove, do this first with a larger, more aggressive end mill. Don’t try to achieve a mirror finish in the first pass.

2. Pre-Finishing Pass: After roughing, use your 3/16″ 8mm carbide end mill for a slightly deeper pass (e.g., 0.010″ – 0.020″) at a moderate speed and feed rate, still using climb milling and coolant. This will clean up the surface and prepare it for the final mirror pass.

3. Final Mirror Pass:

Set your depth of cut to be extremely shallow, as low as 0.001″ to 0.002″ (0.025mm to 0.05mm).

Increase your spindle speed to the higher end of the recommended range.

Ensure your feed rate is set for a very light chip load (use the formula above to check).

*