Do you love building things or tinkering with gadgets? If so, you might be curious about a CNC metal lathe. This powerful tool shapes metal into all kinds of amazing objects. Imagine turning a simple piece of metal into a beautiful part for a robot or a cool accessory for your bike.

CNC stands for Computer Numerical Control. It sounds complicated, but it’s really just a way to use a computer to guide the lathe. You can make precise cuts and create shapes that are hard to do by hand. Isn’t that cool? With a CNC metal lathe, you’re not just making pieces; you’re making your ideas come to life.

Did you know that CNC machines can make parts for everything from toys to airplanes? That’s right! Every time you see a high-tech gadget, a CNC lathe might have helped create it. So, if you’re interested in technology, or if you just want to play with cool tools, a CNC metal lathe could be your new favorite toy!

Exploring The Functionality And Benefits Of Cnc Metal Lathe

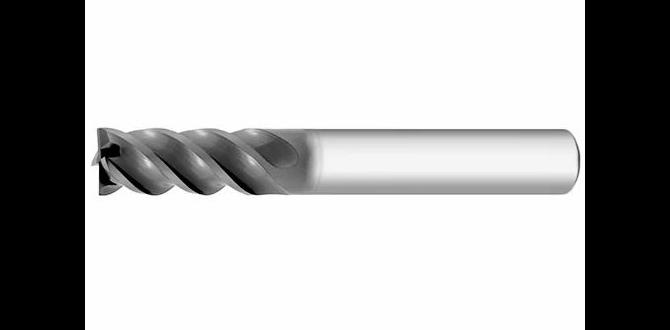

CNC metal lathes are amazing machines used in manufacturing. They shape metal with precision and speed. Have you ever wondered how complex parts are made? These lathes use computer programming to control cutting tools. This means they can create intricate designs without much human effort. Imagine a robot carefully turning metal just the way it needs to be! CNC lathes are essential for industries like automotive and aerospace, making them vital tools of modern technology.

What is a CNC Metal Lathe?

Definition and basic functionality of CNC metal lathes. Comparison between CNC lathes and traditional lathes.

A CNC metal lathe is a special machine that shapes metal. It uses computer control to make precise cuts. This helps create parts that are very accurate. In contrast, traditional lathes rely on manual operation. They need a person to turn knobs and guide the tool.

- Control: CNC lathes are automated, while traditional lathes are manual.

- Precision: CNC lathes produce more precise parts.

- Speed: CNC machines work faster than traditional lathes.

This technology makes it easier to create complex shapes. It revolutionizes how metal parts are made. With CNC lathes, businesses can produce high-quality products quickly.

What can CNC metal lathes create?

CNC metal lathes can create parts for cars, tools, and other machines. They are essential for making items that require exact sizes and shapes.

Key Features of CNC Metal Lathes

Detailed description of essential components (spindle, bed, tailstock). Importance of CNC controls and programming interfaces.

CNC metal lathes are powerful machines with key parts that make them special. The spindle spins the metal, creating the shape we want. The bed holds everything steady during work. The tailstock supports the other end of the metal piece. These components are essential for making quality parts.

Another important part is the CNC control. It acts like a brain for the lathe. With it, users can easily program tasks to get precise results. This technology helps in making complex shapes quickly and accurately.

What are the key parts of a CNC metal lathe?

- Spindle: Spins the workpiece.

- Bed: Supports and stabilizes the machine.

- Tailstock: Holds the other end of the metal piece.

Applications of CNC Metal Lathes

Industries that commonly use CNC metal lathes. Examples of specific parts and products manufactured.

CNC metal lathes are like magic wands in various industries. They spin to create precise parts for cars, airplanes, and even fancy gadgets. Imagine getting a perfect screw or a shiny gear all thanks to these machines! They help build items like engines and jewelry. Without them, we might still be chiseling things by hand, which sounds pretty tiring!

| Industry | Example Parts |

|---|---|

| Automotive | Axles, wheels |

| Aerospace | Landing gear, brackets |

| Manufacturing | Custom tools, fixtures |

| Jewelry | Rings, pendants |

Who knew that spinning metal could be so exciting? With CNC technology, parts are made quickly and accurately, which keeps everything running smoothly!

Benefits of Using CNC Metal Lathes

Advantages over manual machining processes. Impact on production efficiency and precision.

CNC metal lathes have many advantages over manual machining. They work faster and produce more parts. This boosts production efficiency. Also, these machines are more precise. They reduce errors, making the final products accurate. Each piece comes out the same every time. Here are some key benefits:

- Speed: Faster production times.

- Accuracy: Reduced errors equals better quality.

- Consistency: Same results every time.

How do CNC metal lathes improve production?

CNC metal lathes improve production by increasing speed and precision. This allows businesses to make more parts quickly and accurately.

Maintenance and Care for CNC Metal Lathes

Essential maintenance practices to ensure longevity. Common issues and troubleshooting tips.

Keeping a cnc metal lathe in great shape takes some care. Regular cleaning is a must. Wipe off dust and grease to keep it shiny! Check the oil levels often; dry machines are sad machines. If something feels off, like strange noises, don’t ignore it. It could be a sign of trouble. Here’s a quick table with some tips to help you out:

| Common Issues | Troubleshooting Tips |

|---|---|

| Rust on parts | Use a rust remover and apply oil. |

| Inaccurate cuts | Check the tool settings and alignment. |

| Strange noises | Inspect belts and bearings for wear. |

If you treat your cnc metal lathe well, it will serve you for years. Remember, a happy lathe makes happy projects!

Future Trends in CNC Metal Lathing Technology

Innovations in CNC technology (automation, IoT integration). Predictions for the evolution of CNC metal lathes in manufacturing.

New changes in CNC metal lathing technology are exciting! Innovations like automation allow machines to work without much help. They can run faster and make fewer mistakes. Also, IoT integration helps machines talk to each other. This makes it easy to track and control the process.

Experts believe that these upgrades mean CNC metal lathes will be smarter and more precise. Predicting the future, they expect:

- More efficiency in production.

- Lower costs for manufacturers.

- Improved workplace safety.

With these advancements, CNC metal lathes will change how things are made forever!

What is the future of CNC metal lathes?

The future holds smarter machines that work faster and more safely. New trends in technology will help create a better manufacturing process.

Resources for Learning CNC Metal Lathing

Recommended courses, books, and online platforms. Communities and forums for CNC machinists and enthusiasts.

Learning about CNC metal lathing can be exciting! To get started, check out these resources:

- **Courses:** Look for classes at local community colleges or online sites like Coursera and Udemy.

- **Books:** Find beginner books such as “CNC Machining Handbook” by Chris B. and “CNC Programming” by Peter Smid.

- **Online Platforms:** Websites like YouTube have many free tutorials.

- **Communities:** Join forums like CNCZone or Reddit where you can ask questions and share tips.

These tools are great for learning and improving your skills.

Where can I find CNC metal lathe courses?

You can find courses on platforms like Coursera, Udemy, or even local community colleges. They often have beginner-friendly classes.

Conclusion

In conclusion, a CNC metal lathe is a powerful machine that shapes metal with precision. It automates tasks, making work easier for you. Understanding its features and functions helps you in many projects. If you’re interested, explore how CNC lathes can enhance your skills. Dive deeper into CNC technology and consider trying out a local class or workshop!

FAQs

What Are The Key Features To Look For When Selecting A Cnc Metal Lathe For A Machining Shop?

When choosing a CNC (Computer Numerical Control) metal lathe, look for these key features. First, check the size of the lathe. Make sure it fits your workspace. Next, look for the power of the motor. A stronger motor can handle tougher metal. Also, consider the types of tools it can use. Some lathes work with more tools, which gives you more options. Finally, check how easy it is to use. A simple control system makes your work easier.

How Does A Cnc Metal Lathe Differ From A Traditional Manual Lathe In Terms Of Precision And Efficiency?

A CNC metal lathe is like a robot that helps us shape metal very precisely. It can make the same part over and over without mistakes. In contrast, a traditional manual lathe needs a person to control it, so it’s easier to make errors. This makes the CNC lathe not only more accurate but also quicker at making parts. So, if you want high quality and speed, the CNC lathe is the better choice!

What Types Of Materials Can Be Effectively Machined Using A Cnc Metal Lathe?

You can machine many different materials using a CNC metal lathe. This includes metals like steel and aluminum. You can also use softer materials, like brass and copper. Most of these materials are strong and great for making parts. It’s like crafting shapes using a spinning tool!

What Are Some Common Programming Languages Or Software Used To Operate Cnc Metal Lathes?

To operate CNC (Computer Numerical Control) metal lathes, we often use special programming languages. Some common ones are G-code and M-code. G-code tells the machine how to move and cut metal. We also use software like Mastercam and SolidWorks to design parts before making them. These tools help us create accurate shapes easily.

How Can Regular Maintenance And Calibration Improve The Longevity And Performance Of A Cnc Metal Lathe?

Regular maintenance and calibration make a CNC metal lathe work better and last longer. When we clean and check the machine, it runs smoothly. This prevents problems that can break parts. Regularly adjusting it ensures it cuts metal accurately. Taking care of it helps us make great projects for a long time!