Have you ever watched a lathe spin and wondered how it works? A lathe is a powerful tool that shapes metal into amazing forms. But did you know that keeping the lathe aligned is key to getting great results?

Imagine trying to carve a statue from stone. If you start with a crooked block, your statue won’t look right. The same goes for using a metal lathe. That’s where lathe alignment tips come into play.

One essential part of the lathe is the compound rest. This piece helps you make precise cuts. If it’s not aligned correctly, your work might not turn out as expected. Many people struggle with this, but it doesn’t have to be hard. With a few simple tricks, you can ensure your compound rest is perfectly aligned.

Ready to learn how to improve your metal lathe skills? Let’s dive into some tips that can make your work easier and more fun!

Essential Lathe Alignment Tips For Metal Lathe Compound Rest

Lathe Alignment Tips for Metal Lathe Compound Rest

Getting your lathe alignment right can be tricky but is crucial for good results. Start by checking that the compound rest sits flat. It should be parallel to the bed of the lathe. Did you know a small misalignment can lead to uneven cuts? Use a dial indicator for accurate measurement. A well-aligned lathe makes a huge difference in the quality of your work. So, are you ready to take your metalworking skills to the next level?Common Signs of Misalignment

Identifying symptoms of misalignment in the compound rest. Consequences of neglecting alignment.Misalignment in the compound rest can show a few clear signs. You might notice uneven cuts on your metal pieces. If the tool chatters or vibrates, that’s another warning. Ignoring these issues can lead to poor work quality and damage your lathe over time.

- Inaccurate dimensions

- Excessive wear on tools

- Poor surface finish

Why is alignment important?

Proper alignment ensures better accuracy and longer tool life. It helps produce smooth cuts and saves you from costly repairs.

Tools Required for Accurate Alignment

Essential tools for measuring and adjusting alignment. Recommended brands and models for metal lathe users.Getting the right tools makes lathe alignment easier. You will need some essential measuring tools to ensure everything is perfectly aligned. Here are a few recommended items:

- Dial Indicator: This tool measures small distances. Brands like Starrett or Mitutoyo are reliable.

- Feeler Gauges: These help measure gaps. Look for the Olsen brand for quality options.

- Precision Level: This checks surface flatness. Brands like Johnson are known for accuracy.

With these tools, you can improve your metal lathe’s accuracy and enjoy a smoother experience!

What tools are best for lathe alignment?

Dial indicators, feeler gauges, and precision levels are best for measuring and adjusting lathe alignment.

Step-by-Step Alignment Process

Detailed instructions for aligning the compound rest. Tips for checking alignment at various stages.Aligning your compound rest is like tuning a guitar. It needs to be precise, or else everything sounds off! Start by cleaning the area around the rest. Then, use a dial indicator to check if it’s level. Adjust as needed. After each adjustment, check your alignment again. Remember, practice makes perfect! A simple mistake can turn your project from masterpiece to disaster. Keep things light; if it doesn’t look right, maybe it’s a great spot for a rubber chicken impression!

| Step | Action |

|---|---|

| 1 | Clean the compound rest |

| 2 | Check with a dial indicator |

| 3 | Make necessary adjustments |

| 4 | Recheck alignment |

Adjusting the Compound Rest

Techniques for finetuning the compound rest alignment. Considerations for different lathe models.Fine-tuning the compound rest on your lathe helps you get better results. Here are some simple techniques to adjust it:

- Check the angle of the compound rest. Make sure it aligns with the lathe bed.

- Use a level to check if the surface is even.

- Adjust the locking screws carefully. They should be tight but not too tight.

- Test different lathe models. Some may require specific adjustments.

Small changes can make a big difference in how your projects turn out. Being precise is key to great work.

Why is Compound Rest Alignment Important?

Proper alignment helps achieve accurate cuts and smooth finishes. It can save material and time during your work.

Preventative Maintenance for Longevity

Best practices to maintain proper alignment over time. Routine checks and adjustments for optimal performance.Want your metal lathe to last longer? Regular maintenance is key! Start by checking the alignment of your compound rest frequently. Even small shifts can cause big headaches. Make adjustments as needed to keep everything running smoothly. Think of it as a workout—your lathe deserves some attention to stay fit! Remember to clean the parts regularly; dust won’t just dance, but it will also cause wear and tear. A happy machine makes for happy projects!

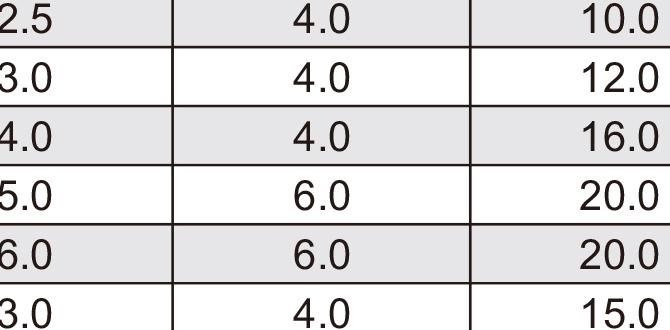

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Check Alignment | Weekly | Baby steps—make small adjustments! |

| Clean Components | After Each Use | Dust bunnies are not your friends! |

| Lubricate Moving Parts | Monthly | Use the right oil—keep it slick! |

Common Mistakes to Avoid

Pitfalls that can lead to misalignment. Tips on how to educate yourself on correct practices.Many beginners make simple mistakes that can disrupt lathe alignment. For instance, not checking the level of the lathe can cause misalignment. Another common pitfall is improper tightening of the compound rest. Learning correct practices is key. Read manuals, watch videos, and seek advice from experts. Here are some tips:

- Always ensure your lathe is on a flat surface.

- Regularly inspect and clean your tools.

- Practice proper tightening techniques.

Remember, gaining knowledge prevents errors!

What are some common mistakes in lathe alignment?

Common mistakes include not leveling the lathe properly and failing to secure the compound rest tightly. These issues can lead to poor cuts and wasted materials.

Real-World Applications of Proper Lathe Alignment

Examples of projects that benefit from precise alignment. Success stories from seasoned machinists.Proper lathe alignment can make a massive difference in metalworking projects. For example, crafting a bicycle frame requires perfect alignment to ensure a smooth ride. A local machinist once shared how proper setup helped him create a flawless part for a trophy—a win-win!

| Project Type | Benefit of Alignment |

|---|---|

| Bicycle Frame | Smooth ride |

| Trophy Part | Flawless finish |

| Car Engine | Better performance |

Seasoned machinists know the joy of achieving precise results. Proper alignment not only saves time but also makes work more enjoyable. Who wouldn’t want less hassle and more success in their projects?

Conclusion

In summary, aligning your metal lathe’s compound rest is crucial for precision. Start by checking the bed alignment and adjusting as needed. Regularly inspect the dovetail and ensure smooth movement. Remember, a well-aligned lathe helps you create better parts. For more tips, explore resources on lathe maintenance. Take your skills to the next level by practicing these simple steps!FAQs

Here Are Five Related Questions On The Topic Of Lathe Alignment, Specifically Focusing On The Compound Rest Of A Metal Lathe:To keep the compound rest of a metal lathe aligned, check if it moves smoothly. Make sure the screws are tight but not too tight. You can use a level to see if it’s straight. If it’s off, adjust the screws until it’s right. Regular checks will help your lathe work better.

Sure! Please provide the question you want me to answer.

What Are The Key Steps To Properly Align The Compound Rest On A Metal Lathe?To properly align the compound rest on a metal lathe, first, make sure the lathe is off. Next, check that the bed is clean and free of dirt. Then, adjust the compound rest so it sits perfectly flat. After that, use a level to check if it’s straight. Finally, tighten all the screws to keep it in place.

How Can Misalignment Of The Compound Rest Affect The Precision Of Machining Operations On A Lathe?If the compound rest on a lathe is not lined up correctly, it can cause problems. You might end up cutting the material at the wrong angle. This can make the pieces not fit together right. It can also create rough edges that need more work. So, keeping the compound rest aligned helps us make better and more accurate parts.

What Tools Are Recommended For Checking And Adjusting The Alignment Of The Compound Rest?To check and adjust the alignment of the compound rest, you can use a few simple tools. A straightedge helps you see if the parts are straight. A dial indicator shows tiny movement changes very well. You might also need a square to check right angles. These tools help you make sure everything is lined up correctly.

How Often Should The Alignment Of The Compound Rest Be Checked And Maintained For Optimal Lathe Performance?You should check the alignment of the compound rest on your lathe often. It’s best to do this every few uses. This way, you can catch any problems early. A good alignment helps your lathe work better and creates nicer pieces. Regular checks keep everything running smoothly!

What Common Signs Indicate That The Compound Rest May Be Misaligned And Requires Adjustment?If the compound rest is misaligned, you might notice that your cuts are uneven or wobbly. The tool may also feel loose or shake while you use it. If you can’t get a straight edge or the pieces don’t fit correctly, that’s another sign. We should check it and make adjustments to get better results.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Alignment, Specifically Focusing On The Compound Rest Of A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the compound rest of a metal lathe aligned, check if it moves smoothly. Make sure the screws are tight but not too tight. You can use a level to see if it’s straight. If it’s off, adjust the screws until it’s right. Regular checks will help your lathe work better.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Steps To Properly Align The Compound Rest On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To properly align the compound rest on a metal lathe, first, make sure the lathe is off. Next, check that the bed is clean and free of dirt. Then, adjust the compound rest so it sits perfectly flat. After that, use a level to check if it’s straight. Finally, tighten all the screws to keep it in place.”}},{“@type”: “Question”,”name”: “How Can Misalignment Of The Compound Rest Affect The Precision Of Machining Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the compound rest on a lathe is not lined up correctly, it can cause problems. You might end up cutting the material at the wrong angle. This can make the pieces not fit together right. It can also create rough edges that need more work. So, keeping the compound rest aligned helps us make better and more accurate parts.”}},{“@type”: “Question”,”name”: “What Tools Are Recommended For Checking And Adjusting The Alignment Of The Compound Rest?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check and adjust the alignment of the compound rest, you can use a few simple tools. A straightedge helps you see if the parts are straight. A dial indicator shows tiny movement changes very well. You might also need a square to check right angles. These tools help you make sure everything is lined up correctly.”}},{“@type”: “Question”,”name”: “How Often Should The Alignment Of The Compound Rest Be Checked And Maintained For Optimal Lathe Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the alignment of the compound rest on your lathe often. It’s best to do this every few uses. This way, you can catch any problems early. A good alignment helps your lathe work better and creates nicer pieces. Regular checks keep everything running smoothly!”}},{“@type”: “Question”,”name”: “What Common Signs Indicate That The Compound Rest May Be Misaligned And Requires Adjustment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the compound rest is misaligned, you might notice that your cuts are uneven or wobbly. The tool may also feel loose or shake while you use it. If you can’t get a straight edge or the pieces don’t fit correctly, that’s another sign. We should check it and make adjustments to get better results.”}}]}