Have you ever wondered how metal objects get those perfect threads? It’s all about using the right tools in a metal lathe. If you’re just starting out, a lathe application guide can be your best friend. Imagine making your own screws or bolts! It sounds exciting, right?

In this article, we will explore the metal lathe threading dial. This handy tool makes it easier to create accurate threads. It helps you measure and cut with precision. You can make various projects, from simple to complex, in your workshop.

Did you know that the lathe is one of the oldest machines still in use today? Its design has changed very little over the years. This shows how important it is to crafting. In our guide, you will learn tips and tricks for threading with your lathe.

Get ready to dive into the world of metal lathe threading dials! Your creativity and skills are about to shine.

Lathe Application Guide: Metal Lathe Threading Dial Explained

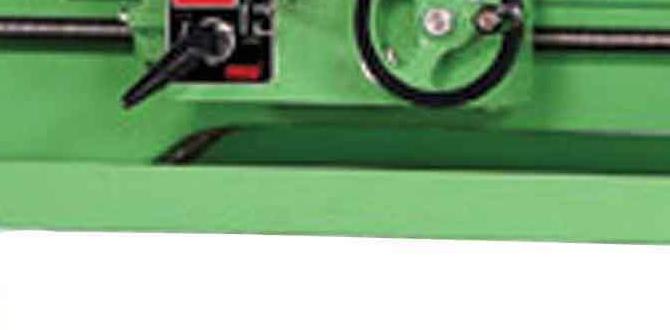

Lathe Application Guide: Metal Lathe Threading Dial

Metal lathes are essential tools in workshops. They help create precise parts. The threading dial is a handy feature that assists in threading operations. It shows the right point to start and end threads, making it easier for beginners. Imagine crafting a perfect screw! Understanding how to use this dial can save time and reduce mistakes. A well-used threading dial boosts productivity and quality in metalworking. Who wouldn’t want to make their projects smoother and more efficient?Importance of the Threading Dial

Role of the threading dial in achieving precise thread cutting. Advantages of using a threading dial over other methods.The threading dial is an important tool in metalworking. It helps you cut precise threads on your workpiece. With the threading dial, you can easily keep track of your measurements. This makes your threads more accurate than using other methods. Here are some key points about its advantages:

- Accuracy: You get a perfect fit every time.

- Ease of Use: Simple to read and adjust.

- Consistency: Produces the same results repeatedly.

Using a threading dial saves time and reduces errors. This makes it a valuable tool for anyone who works with metal.

Why is a threading dial better than other methods?

A threading dial provides better accuracy and ease of use compared to other methods. It ensures consistent results and minimizes mistakes, making your projects easier and faster to complete.

Setting Up Your Lathe for Threading

Stepbystep guide to prepare your metal lathe for threading operations. Essential tools and accessories needed for effective setup.Getting your lathe ready for threading is like prepping for a dance-off; you need the right moves! First, gather essential tools like a threading insert, a tool holder, and a dial indicator. These will help ensure everything is snug and accurate. Next, adjust your lathe’s speed; too fast, and you might just end up with a very expensive piece of scrap metal! Follow the steps below for a neat setup:

| Step | Action |

|---|---|

| 1 | Clean the lathe bed. |

| 2 | Install the proper tool holder. |

| 3 | Set the spindle speed. |

| 4 | Calibrate the threading dial. |

With these steps, you’ll be threading like a pro. Remember, safety goggles are a must—you don’t want shavings in your eyes while you’re threading your masterpiece!

Configuring the Threading Dial

Detailed instructions on calibrating the threading dial for different thread pitches. Common mistakes to avoid when configuring the threading dial.To configure the threading dial correctly, follow these steps: First, set the dial to zero. Then, measure the distance between threads for your chosen pitch. For example, if you’re setting a 10 threads per inch pitch, ensure the dial matches this measurement. Adjust it carefully using the locking lever. Always double-check your settings for accuracy.

Avoid these common mistakes:

- Forgetting to reset the dial to zero.

- Measuring thread pitch incorrectly.

- Not securing the dial after adjustment.

What is the best way to calibrate the threading dial?

Calibrating the threading dial involves measuring your thread pitch accurately and adjusting the dial accordingly. Always verify your adjustments to avoid mistakes.

Helpful Tips:

- Use a caliper for precise measurements.

- Practice on scrap metal before starting on the final piece.

Thread Cutting Techniques

Techniques for cutting internal and external threads using the lathe. Tips for maintaining thread quality and accuracy during cutting.Cutting threads can be fun and precise with the right techniques. For internal threads, use a fine cutting tool and ensure the lathe spindle rotates at a steady speed. To create external threads, adjust your tool’s position properly against the material. Maintaining thread quality is crucial. Always check the tool’s sharpness and keep the work area clean.

- Use cutting oil to reduce friction.

- Take light cuts for better accuracy.

- Measure threads regularly to ensure they fit perfectly.

What are the basic steps to cut threads using a lathe?

Start by setting the correct speed and feed rate. Then, position the cutting tool at the right angle. Engage the lathe slowly and watch the material closely. Check your progress often to ensure good results. This way, you’ll have clean and strong threads.

Safety Precautions When Using a Metal Lathe

Best practices for maintaining safety during lathe operations. Safety gear and equipment recommendations.Using a metal lathe can be fun and creative. However, safety should always come first. Follow these best practices:

- Wear safety glasses to protect your eyes.

- Use ear protection to guard against loud noises.

- Keep long hair tied back or tucked in a hat.

- Wear snug clothing and closed-toed shoes.

- Always check the machine before starting it.

Being careful helps prevent accidents. Stay alert and focused while using the lathe. Remember, safety gear is not just a suggestion but a must! Always think about keeping yourself safe!

What should I wear when using a metal lathe?

You should wear safety glasses, ear protection, and closed-toed shoes. Tying back long hair and wearing snug clothing can also help keep you safe.

Troubleshooting Common Threading Issues

Identifying and resolving common problems encountered during threading. Techniques for improving threading results when issues arise.Threading can be tricky, but don’t worry! Sometimes, the thread might look like a pretzel instead of a nice spiral. If your threads aren’t working, check the depth and alignment. A misaligned tool could throw everything off. Always make sure to use the right speeds—too fast and it could snap like a twig! To fix issues quickly, consider adjusting the threading dial or applying cutting oil for smoother action. Remember, practice makes perfect, but a little humor helps too; if all else fails, grab a snack and try again!

| Common Issue | Solution |

|---|---|

| Poor Thread Quality | Check depth and speed settings. |

| Chatter or Vibration | Tighten all machine parts. |

| Inconsistent Thread Pitch | Ensure correct tool alignment. |

Advanced Applications of Lathe Threading

Exploring advanced threading techniques for specialized projects. Examples of innovative uses of lathe threading in various industries.In advanced lathe threading, special techniques open doors for unique projects. Industries use these methods to create innovative designs. For example, custom screws and fittings are made using precise threading. This helps machines work better. Here are some exciting uses:

- Medical devices: Threading for small parts helps in surgeries.

- Aerospace: Strong threads withstand extreme conditions.

- Automotive: Custom threads improve engine performance.

These efforts show how lathe threading plays a big role in improving technology.

What are advanced threading techniques used for?

Advanced threading techniques create specialized parts. They enhance strength and precision in various fields, from medicine to aerospace.

Conclusion

In summary, a lathe application guide helps you use a metal lathe for threading. It makes the process easier and more efficient. Remember to always measure carefully and adjust the threading dial as needed. You can practice with scrap metal to improve your skills. For more tips, check out other guides and resources to enhance your lathe work!FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Threading Dials:Sure! Here are five related questions about metal lathe threading dials. 1. What is a metal lathe? A metal lathe is a machine that shapes metal into different parts. 2. How do threading dials work? Threading dials help you measure and cut threads on metal accurately. 3. Why are threading dials important? They make sure the threads are the right size, so parts fit together well. 4. Can I use a threading dial on all lathes? Not all lathes have threading dials. Check if yours does! 5. How do I read a threading dial? You read it like a ruler, using the numbers to guide your cuts.

Sure! Please ask your question, and I’ll be happy to help!

What Is The Primary Function Of A Threading Dial On A Metal Lathe?A threading dial helps you make grooves or patterns on metal pieces. It shows you when to move the cutting tool for making threads. You turn the dial to line up with the right number. This helps create strong and perfect threads on your metal project. Using the threading dial makes your work easier and more precise.

How Do You Properly Set Up The Threading Dial For Accurate Thread Cutting On A Lathe?To set up the threading dial on a lathe, first, make sure the machine is off. You need to start by choosing the right gear for the thread you want. Turn the dial until it shows zero, which helps you line everything up. Now, when the cutting tool moves to the right spot, you can start cutting. Keep an eye on the dial and repeat as needed for perfect threads!

What Are Some Common Issues That Can Arise When Using A Threading Dial, And How Can They Be Resolved?When using a threading dial, you might have trouble with the dial not lining up right. If this happens, you can try turning the knob a bit before starting. Another issue is if the thread gets stuck. You can fix this by gently pulling the thread to free it. Remember to check that the machine is clean too!

How Does The Threading Dial Interact With The Lead Screw During The Threading Process?The threading dial helps us cut threads on our workpiece. As we turn the handle, the lead screw moves the tool in and out. The threading dial shows us when to start and stop cutting. We line it up with a mark to get the right distance. This way, we make sure the threads are even and nice!

What Are The Differences Between A Mechanical Threading Dial And An Electronic Threading System On A Metal Lathe?A mechanical threading dial is a simple tool with numbers and a spinning dial. You turn it by hand to help cut threads on metal. An electronic threading system uses a computer. It is easier and can be more precise, but it needs power to work. So, one is like a simple clock, and the other is like a computer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions about metal lathe threading dials. 1. What is a metal lathe? A metal lathe is a machine that shapes metal into different parts. 2. How do threading dials work? Threading dials help you measure and cut threads on metal accurately. 3. Why are threading dials important? They make sure the threads are the right size, so parts fit together well. 4. Can I use a threading dial on all lathes? Not all lathes have threading dials. Check if yours does! 5. How do I read a threading dial? You read it like a ruler, using the numbers to guide your cuts.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of A Threading Dial On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A threading dial helps you make grooves or patterns on metal pieces. It shows you when to move the cutting tool for making threads. You turn the dial to line up with the right number. This helps create strong and perfect threads on your metal project. Using the threading dial makes your work easier and more precise.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up The Threading Dial For Accurate Thread Cutting On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up the threading dial on a lathe, first, make sure the machine is off. You need to start by choosing the right gear for the thread you want. Turn the dial until it shows zero, which helps you line everything up. Now, when the cutting tool moves to the right spot, you can start cutting. Keep an eye on the dial and repeat as needed for perfect threads!”}},{“@type”: “Question”,”name”: “What Are Some Common Issues That Can Arise When Using A Threading Dial, And How Can They Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a threading dial, you might have trouble with the dial not lining up right. If this happens, you can try turning the knob a bit before starting. Another issue is if the thread gets stuck. You can fix this by gently pulling the thread to free it. Remember to check that the machine is clean too!”}},{“@type”: “Question”,”name”: “How Does The Threading Dial Interact With The Lead Screw During The Threading Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial helps us cut threads on our workpiece. As we turn the handle, the lead screw moves the tool in and out. The threading dial shows us when to start and stop cutting. We line it up with a mark to get the right distance. This way, we make sure the threads are even and nice!”}},{“@type”: “Question”,”name”: “What Are The Differences Between A Mechanical Threading Dial And An Electronic Threading System On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A mechanical threading dial is a simple tool with numbers and a spinning dial. You turn it by hand to help cut threads on metal. An electronic threading system uses a computer. It is easier and can be more precise, but it needs power to work. So, one is like a simple clock, and the other is like a computer.”}}]}