Have you ever wondered how craftsmen shape metal into amazing tools and parts? At the heart of this magic lies the lathe gear ratio. This simple device can turn raw metal into precise shapes. Understanding this gear ratio can help anyone who uses a metal lathe.

Imagine a skilled worker getting ready to create a custom piece. They select the right lathe and cutting tools for the job. But do they know how the gear ratio affects their project? A good gear ratio can make a big difference in speed and accuracy. Without it, they might struggle to achieve the desired results.

Did you know that even a small change in the gear ratio can lead to huge differences in cutting? The right settings let everyone, from hobbyists to professionals, produce high-quality work. So, if you’re curious about how to make the most of your metal lathe, keep reading. Understanding lathe gear ratios will open a world of possibilities for your projects!

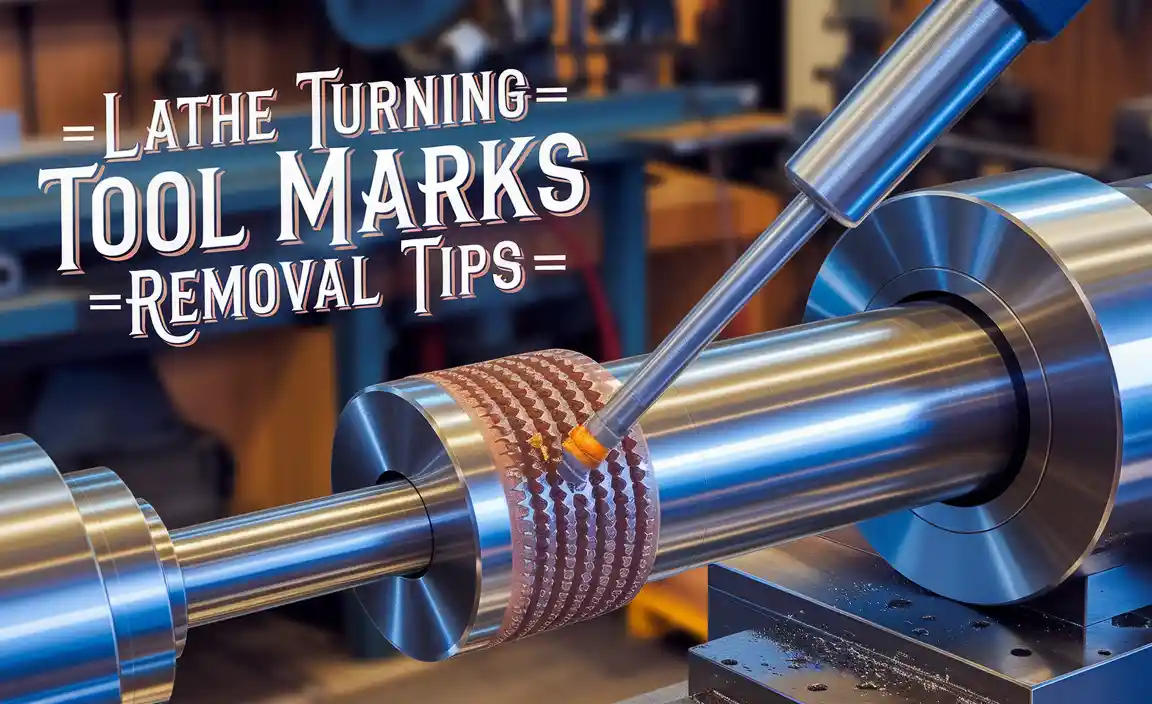

Understanding Lathe Gear Ratio For Metal Lathe Cutting Tools

Lathe Gear Ratio and Cutting Tools Explained

Understanding lathe gear ratios is key to any metalworking project. The gear ratio affects the speed and torque of the lathe, impacting how cleanly and efficiently cuts are made. Choosing the right metal lathe cutting tools is also essential. Different tools help achieve various finishes and precision levels. Did you know that a small change in gear ratio can lead to vastly different results? Experimenting with settings can unlock new possibilities in your projects!What is a Lathe Gear Ratio?

Definition of gear ratio in the context of lathes. Importance of gear ratio in metal cutting applications.A lathe gear ratio shows how the speed of the lathe’s motor is matched to the lathe’s cutting tools. It affects how fast or slow the machine spins. A proper gear ratio can improve cutting efficiency and precision. It plans the speed for different materials. Gear ratios are crucial in metal cutting. They help achieve smooth, clean cuts while protecting tools from damage. With the right gear, you get the best results.

Why is gear ratio important?

The gear ratio is key for effective metal cutting. It allows for:

- Optimal Speed: Ensures tools cut at the right speed.

- Tool Protection: Reduces wear on cutting tools.

- Accuracy: Improves the quality of the cut.

The Role of Gear Ratio in Metal Lathes

How gear ratio affects spindle speed and torque. Influence of gear ratio on cutting tool performance and finishes.The gear ratio in metal lathes is like a secret recipe. It helps control how fast the spindle turns and how much power it has. A higher gear ratio means more torque, which is great for tough jobs. But too high can slow things down, like a tortoise running a race! The right gear ratio also decides how well the cutting tools perform. A good ratio gives smooth finishes, while a poor one might leave rough edges. It’s like choosing the right ice cream flavor; pick wisely!

| Gear Ratio | Spindle Speed | Torque |

|---|---|---|

| Low | High | Lower |

| High | Low | Higher |

Selecting the Right Gear Ratio for Cutting Tools

Factors to consider when choosing a gear ratio for specific cutting tasks. Recommendations for gear ratios based on material type and tool specifications.Choosing the right gear ratio can feel like picking a favorite flavor of ice cream—there are lots of options! First, think about the material you’ll cut. Softer materials need a different gear ratio than tough metals. For example, if you’re cutting aluminum, a lower ratio works well. But for steel, you may want a higher ratio to make it easier.

Here’s a quick guide to help:

| Material Type | Recommended Gear Ratio |

|---|---|

| Aluminum | 1:1 to 2:1 |

| Brass | 2:1 to 3:1 |

| Steel | 3:1 to 4:1 |

Remember, the right gear ratio can make cutting smooth and fun, like a slide in a park! So, pick wisely and avoid making it a headache!

Adjusting Gear Ratios for Enhanced Performance

Techniques for modifying gear ratios on existing lathes. Effects of adjusting gear ratios on cutting efficiency and precision.Modifying gear ratios is like giving your lathe a coffee boost! Simply change the gear teeth to adjust cutting speed and power. For example, using a larger gear can lower speed but increase torque, perfect for tougher materials. This tweaking can enhance efficiency and precision in cuts. Remember, a well-timed lathe is happier and produces better results! Here’s a quick look at common modifications:

| Modification | Effect on Cutting |

|---|---|

| Increase gear size | Higher torque, slower speed |

| Decrease gear size | Higher speed, less torque |

| Change gear material | Improved durability |

Fine-tuning your lathe’s gear ratio can make all the difference. Embrace it, and you’ll be cutting like a pro in no time!

Comparison of Gear Ratio Effects on Different Cutting Tools

Analysis of how gear ratios impact performance of various cutting tools (e.g., drills, end mills). Case studies demonstrating gear ratio influence on tool life and finish quality.Gear ratios can feel like magic in the world of cutting tools! They affect how well drills and end mills cut through metal. For example, a lower gear ratio offers more torque but less speed, leading to greater control. On the other hand, a higher gear ratio allows faster cutting but can wear out tools quicker. Imagine your drill having a caffeine boost—zooming through metal but getting tired soon!

| Cutting Tool | Best Gear Ratio | Tool Life | Finish Quality |

|---|---|---|---|

| Drill | Low | Longer | Smoother |

| End Mill | High | Shorter | Rougher |

One study found that a well-chosen gear ratio can double a tool’s lifespan! So, like picking the right shoes for a marathon, using the right gear ratio makes all the difference.

Innovations in Gear Ratio Technology for Modern Lathes

Latest advancements in gear ratio systems. Future trends and potential improvements in lathe gear technology.Modern lathes are getting better thanks to new gear ratio systems. These systems allow machines to work faster and more accurately. Recent advancements include electronic controls that adjust gear ratios automatically. This means less guesswork for users. In the future, we could see even smarter systems. Imagine lathes that predict the best gear ratio for a job!

- Improved precision

- Faster production times

- Less energy use

What are the latest trends in gear technology?

New trends include 3D printing of gear components and the use of materials that are lighter but stronger. This can help machines run better.

Troubleshooting Gear Ratio Issues

Common problems related to gear ratios in metal lathes. Solutions and maintenance tips to ensure optimal gear function.Gear ratio issues can cause problems in metal lathes. Common problems include inaccurate cuts and strange noises. These can happen if the gears are worn or misaligned. To fix these issues, check the gears regularly. Make sure they are clean and lubricated.

Use the right tools for repair. It’s important to replace any worn parts quickly. This keeps your lathe running smoothly and makes your work easier!

What are common gear ratio problems?

Common problems include incorrect cutting speeds, unusual noises, and uneven finishes.

How can I maintain my lathe gears?

- Check for wear and tear regularly.

- Keep the gears clean and lubricated.

- Replace any damaged parts promptly.

Conclusion

In summary, understanding the lathe gear ratio helps you control the speed and torque when using metal lathe cutting tools. A good gear ratio can lead to better precision and smoother cuts. We encourage you to explore different gear ratios and practice with various tools. This hands-on experience will improve your skills and confidence in metalworking. Happy crafting!FAQs

What Is The Significance Of Gear Ratio In A Metal Lathe And How Does It Affect Cutting Speed?The gear ratio in a metal lathe helps us decide how fast the machine spins. A higher gear ratio means faster spinning, which gives us a quicker cutting speed. When we change the gear ratio, we can cut different materials better. So, it’s important to choose the right gear ratio for the best results!

How Can I Determine The Appropriate Gear Ratio For Different Metal Cutting Tasks On A Lathe?To find the right gear ratio for cutting metal on a lathe, start by checking the type of metal you’re using. Softer metals need a higher speed, while harder metals require lower speed. Next, look at your lathe’s manual; it usually has suggestions for different tasks. Finally, experiment with different settings until you find what works best. Remember, safety first!

What Types Of Cutting Tools Are Most Commonly Used With Metal Lathes, And How Do They Interact With The Lathe’S Gear Ratio?The most common cutting tools used with metal lathes are turning tools, drill bits, and parting tools. Turning tools shape the metal by removing bits as it spins. Drill bits make holes, and parting tools cut off pieces of metal. The lathe’s gear ratio helps control the speed of spinning. This way, we can change how fast the tools cut the metal.

How Do Changes In Gear Ratio Impact The Torque Produced By A Metal Lathe During Cutting Operations?Changing the gear ratio on a metal lathe affects how hard the machine can push while cutting. A lower gear ratio makes the lathe spin slower but gives more power, or torque. This is great for cutting tough metal. A higher gear ratio makes the lathe spin faster, but with less power. So, choosing the right gear ratio helps you cut better!

What Are Some Common Troubleshooting Tips For Issues Related To Gear Ratio And Cutting Performance On A Metal Lathe?If you’re having trouble with your metal lathe, check the gear ratio first. Make sure it matches the type of work you’re doing. If the cutting feels rough, try using a sharper tool. Also, ensure the lathe is clean and well-lubricated. This will help it work better and make smoother cuts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Significance Of Gear Ratio In A Metal Lathe And How Does It Affect Cutting Speed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear ratio in a metal lathe helps us decide how fast the machine spins. A higher gear ratio means faster spinning, which gives us a quicker cutting speed. When we change the gear ratio, we can cut different materials better. So, it’s important to choose the right gear ratio for the best results!”}},{“@type”: “Question”,”name”: “How Can I Determine The Appropriate Gear Ratio For Different Metal Cutting Tasks On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right gear ratio for cutting metal on a lathe, start by checking the type of metal you’re using. Softer metals need a higher speed, while harder metals require lower speed. Next, look at your lathe’s manual; it usually has suggestions for different tasks. Finally, experiment with different settings until you find what works best. Remember, safety first!”}},{“@type”: “Question”,”name”: “What Types Of Cutting Tools Are Most Commonly Used With Metal Lathes, And How Do They Interact With The Lathe’S Gear Ratio? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The most common cutting tools used with metal lathes are turning tools, drill bits, and parting tools. Turning tools shape the metal by removing bits as it spins. Drill bits make holes, and parting tools cut off pieces of metal. The lathe’s gear ratio helps control the speed of spinning. This way, we can change how fast the tools cut the metal.”}},{“@type”: “Question”,”name”: “How Do Changes In Gear Ratio Impact The Torque Produced By A Metal Lathe During Cutting Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Changing the gear ratio on a metal lathe affects how hard the machine can push while cutting. A lower gear ratio makes the lathe spin slower but gives more power, or torque. This is great for cutting tough metal. A higher gear ratio makes the lathe spin faster, but with less power. So, choosing the right gear ratio helps you cut better!”}},{“@type”: “Question”,”name”: “What Are Some Common Troubleshooting Tips For Issues Related To Gear Ratio And Cutting Performance On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you’re having trouble with your metal lathe, check the gear ratio first. Make sure it matches the type of work you’re doing. If the cutting feels rough, try using a sharper tool. Also, ensure the lathe is clean and well-lubricated. This will help it work better and make smoother cuts.”}}]}