Imagine you are in a workshop, surrounded by machines that make incredible things. One of those machines is a metal lathe. Have you ever wondered how it works? The magic often happens thanks to something called the lathe gear ratio.

The lathe gear ratio is all about turning power into precision. It helps the lathe spin at just the right speed. But how does this affect the tools you make? Understanding the gear train can make a big difference!

Did you know that even small changes in the gear ratio can lead to big results? With the right setup, you can turn raw metal into beautiful shapes. This is why many craftsmen pay close attention to their lathe gear ratios!

Join us as we explore the fascinating world of lathe gear ratio and gear trains. Learn how they work together to transform your projects from ordinary to extraordinary!

Understanding Lathe Gear Ratio In Metal Lathe Gear Train Lathe Gear Ratios Play A Crucial Role In Determining The Performance And Efficiency Of Metal Lathes. Understanding How These Ratios Function Within A Gear Train Is Essential For Anyone Looking To Optimize Their Machining Projects. This Article Will Delve Into The Significance Of Lathe Gear Ratios, Their Impact On A Metal Lathe’S Capabilities, And How To Effectively Configure A Gear Train For Maximum Efficiency. What Is Lathe Gear Ratio? The Lathe Gear Ratio Refers To The Relationship Between The Input Speed Of The Motor And The Output Speed Of The Spindle. Essentially, It Defines How Many Times The Spindle Turns For Each Turn Of The Motor. A Higher Gear Ratio Indicates That The Spindle Will Turn More Slowly Compared To The Motor, Ideal For Cutting Harder Materials, Whereas A Lower Gear Ratio Results In A Faster Spindle Speed, Suitable For Softer Materials. The Role Of Gear Trains A Gear Train Is A System Of Gears That Transmits Power From One Component To Another. In Metal Lathes, Gear Trains Are Crucial For Adjusting The Lathe Gear Ratio. By Changing The Configuration Of Gears, Machinists Can Fine-Tune The Speeds And Torque Of The Spindle To Match The Requirements Of Different Workpieces. Understanding How These Gear Trains Operate Allows For More Precise Control Over The Machining Process, Enhancing Overall Productivity. Factors Affecting Lathe Gear Ratio Selection 1. **Material Type**: Different Metals Have Varying Hardness Levels, Which Require Specific Cutting Speeds. 2. **Tooling**: The Type Of Tools Being Used Also Influences The Ideal Lathe Gear Ratio. 3. **Desired Finish**: The Quality Of The Finish Desired On The Workpiece Can Dictate The Required Speeds. Conclusion Mastering The Lathe Gear Ratio And The Use Of A Metal Lathe Gear Train Is Essential For Achieving Optimal Performance During Machining Tasks. By Carefully Selecting And Configuring Gear Ratios, Machinists Can Greatly Enhance Their Operational Efficiency And The Quality Of Their Work. With A Thorough Understanding Of These Concepts, Anyone Can Improve Their Lathe Machining Skills, Leading To Better Results In Metalworking Projects.

Understanding Lathe Gear Ratio and Gear Train

Lathe gear ratios play a vital role in how metal lathes function. They determine the speed and torque, affecting your machining results. A higher ratio means more torque with less speed, perfect for heavy cutting. Did you know that adjusting these gears can make your projects run smoother? It’s like changing gears on a bike! Learning about lathe gear trains helps you master your lathe, leading to better workpieces and happier projects.What is a Lathe Gear Ratio?

Definition and importance of gear ratio in metal lathes. How gear ratio affects spindle speed and torque.A lathe gear ratio is a fancy way of saying how gears work together in a lathe machine. It’s like a teamwork event for gears! The gear ratio helps control the spindle speed, which is how fast the lathe spins. A higher gear ratio means a faster spin, while a lower gear ratio gives more torque, or turning power. So, if you want to turn a tough metal piece, you need that torque! Think of it like choosing between running fast and lifting heavy. Both are important, but you can’t do them at the same time!

| Gear Ratio | Spindle Speed | Torque |

|---|---|---|

| High Ratio | Fast | Low |

| Low Ratio | Slow | High |

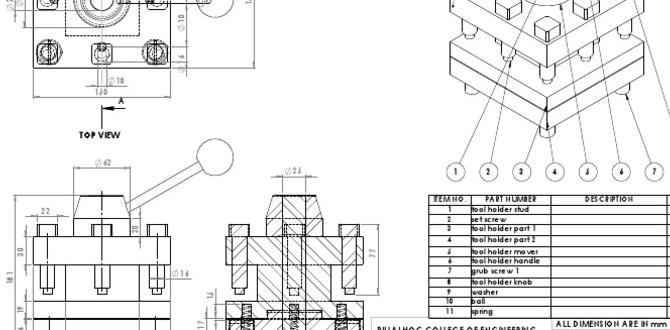

Components of a Lathe Gear Train

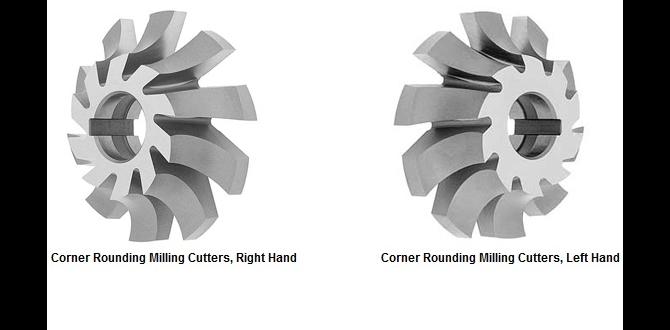

Breakdown of the parts involved in a gear train. Explanation of gear types used in a lathe (spur, bevel, etc.).A lathe gear train has several important parts that work together smoothly. These parts include gears, gears shafts, and pulleys. Each gear type has a special job. Here are the main types used in lathes:

- Spur gears: Simple and flat, they are used to transmit power directly.

- Bevel gears: They change the direction of rotation between different axes.

- Helical gears: These have angled teeth, which help with quiet and smooth operation.

Every gear plays a role in controlling speed and torque. Understanding these components helps you get better results while working with a lathe!

What are the main components of a lathe gear train?

The main components include gears, shafts, and pulleys, all designed to work together for smooth operation.

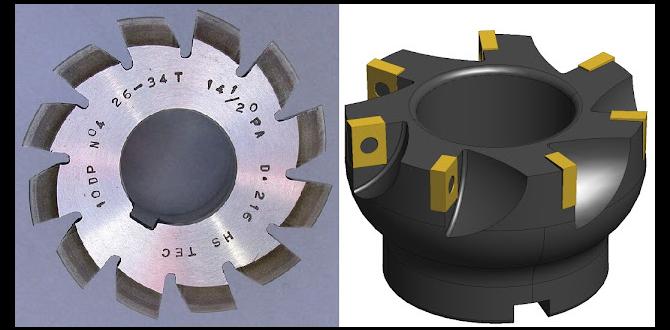

How to Calculate Lathe Gear Ratio

Stepbystep guide to calculating gear ratios. Examples demonstrating the calculation process.Figuring out how to calculate the lathe gear ratio is like baking cookies—follow the recipe! First, count the teeth on the drive gear and the driven gear. Let’s say you have 20 teeth on your drive gear and 60 on the driven gear. Your gear ratio is simply the teeth of the driven gear (60) divided by the teeth of the drive gear (20). So, 60/20 equals a ratio of 3:1. Easy-peasy!

Here’s a simple table to sum it up:

| Gear Type | Number of Teeth |

|---|---|

| Drive Gear | 20 |

| Driven Gear | 60 |

So, with a 3:1 gear ratio, your lathe runs smoother and faster! Now, go conquer that metal lathe gear train like a champ!

Effects of Gear Ratio on Metal Lathe Performance

Influence on cutting speed and surface finish quality. Understanding the relationship between gear ratios and material removal rates.The gear ratio in a metal lathe plays a big role in how well it works. A higher gear ratio can boost cutting speed, allowing the lathe to spin faster. This can help remove more material quickly. However, be careful! Too high a ratio can lead to a rough surface. A smooth finish usually needs a lower gear ratio for better control.

Here’s a simple table to illustrate how gear ratios impact performance:

| Gear Ratio | Cutting Speed | Surface Finish Quality |

|---|---|---|

| Low | Slow | Smooth |

| Medium | Moderate | Fair |

| High | Fast | Rough |

Understanding this balance helps you adjust the lathe for the best results. Remember, speed isn’t everything; quality matters too! Aim for that sweet spot to make your projects shine!

Adjusting Gear Ratios for Different Operations

Techniques for changing gear ratios on a metal lathe. Recommended ratios for various machining tasks (turning, facing, etc.).Changing gear ratios on a metal lathe is like dressing up for different occasions. You need the right outfit to impress! For turning, a common ratio is 4:1, giving a steady speed. But if you’re facing, switch to 2:1 for a smoother finish. To make adjustments, simply swap gears on the train. It’s like playing musical chairs, but with gears! Here’s a handy table to guide you:

| Operation | Recommended Gear Ratio |

|---|---|

| Turning | 4:1 |

| Facing | 2:1 |

Keep those gears happy, and your lathe will sing!

Common Problems with Lathe Gear Trains

Identification of typical issues (wear, slippage, misalignment). Solutions and maintenance tips to keep gear trains functioning optimally.Lathe gear trains can have some hiccups. Common problems include wear, where parts lose their shape over time, and slippage, which makes things go out of sync. Misalignment also causes trouble, like trying to fit a square peg in a round hole! To fix these issues, check for wear and adjust parts. Regular maintenance, like cleaning and lubrication, keeps everything running smoothly. Remember, a well-oiled machine is a happy one!

| Problem | Solution |

|---|---|

| Wear | Inspect parts and replace when needed. |

| Slippage | Adjust tension and check alignment. |

| Misalignment | Realign gears according to specifications. |

Upgrading and Modifying Lathe Gear Systems

Options for enhancing gear trains for better performance. Considerations for aftermarket gear modifications and their impacts.Want to boost your lathe’s performance? Upgrading your gear system could be the secret sauce! Enhanced gear trains can help you cut materials faster and with better precision. Think of it like swapping your bike gears for a turbo boost. Before you dive into aftermarket options, remember they can change how your lathe works. Choose wisely. Here’s a quick summary of options:

| Modifications | Benefits |

|---|---|

| Adding a new gear set | Improved speed and torque |

| Installing a gear ratio converter | Enhanced versatility |

| Switching to higher quality gears | Longer lifespan and better performance |

Choose what fits your needs best, and you’ll be on your way to transforming your metal lathe into a machine that even superheroes would envy!

Future Trends in Lathe Gear Technology

Emerging technologies in lathe gear systems. Predictions for developments in gear ratios and efficiency improvements.New technologies are changing how we create lathe gear systems. Innovations like smart sensors help machines communicate better. This makes adjustments easier. As machines get smarter, gear ratios will improve. Higher efficiency means less energy waste, saving money. Experts think future gear trains will be lighter and faster. Here are some trends to watch:

- Increased automation in gear production.

- Use of lightweight materials.

- Smart technology for real-time monitoring.

What is the future of lathe gear systems?

The future includes smarter machines and better materials. This will lead to more efficient gear ratios.Conclusion

In summary, understanding lathe gear ratios is important for using metal lathe machines effectively. Gear trains help control speed and torque, making your work easier. We can adjust these ratios to fit different tasks. If you want to learn more, check out beginner guides or videos on lathe gear systems. This knowledge will boost your skills and confidence in metalworking.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratios And Gear Trains In Metal Lathes:A lathe is a machine that helps us shape metal. Gear ratios show how fast one gear turns compared to another. If we change the gears, we can make the metal turn faster or slower. This helps us cut the metal better. By using different gears, we can create different shapes easily!

Sure! Please provide me with the question you’d like me to answer.

What Is The Significance Of Gear Ratios In A Metal Lathe, And How Do They Affect Spindle Speed And Torque?Gear ratios in a metal lathe help control how fast the spindle spins. A higher gear ratio makes the spindle spin faster but with less power. A lower gear ratio gives more power but makes it spin slower. This is important because you need different speeds and strengths for different jobs. So, by changing the gear ratio, you can choose the right speed and torque for your work.

How Can Adjusting The Gear Train In A Lathe Improve Machining Precision And Finish Quality?Adjusting the gear train in a lathe helps make better cuts. When you change the gears, you can control the speed more easily. This means you can cut the material just right, which makes it smoother. A smoother cut means a better finish on the piece you are making. So, with the right gears, you can create nicer and more accurate shapes!

What Are The Common Types Of Gearing Systems Used In Metal Lathes, And What Are Their Advantages And Disadvantages?Common types of gearing systems in metal lathes are belt drives, gear drives, and spindle drives. Belt drives are easy to use and quiet, but they may wear out quickly. Gear drives are strong and last a long time, but they can be noisy and heavy. Spindle drives offer good control but can be more complex to set up. Each type has its good and bad points.

How Do You Calculate The Gear Ratio For A Specific Gear Train Setup In A Lathe, And What Factors Should Be Considered?To calculate the gear ratio for a lathe, you need to count the teeth on the two gears. The gear ratio is the number of teeth on the drive gear divided by the number on the driven gear. For example, if the drive gear has 12 teeth and the driven gear has 36 teeth, the ratio is 12 divided by 36, which equals 1/3. We should also think about the speed you want and the force needed. Different gears can change how fast or strong the lathe works.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Efficiency Of A Lathe’S Gear Train System?To keep your lathe’s gear train system working well, you should clean it often. Dust and dirt can cause problems, so use a soft cloth. You should also check the oil levels to keep everything moving smoothly. Lubricate the gears regularly to prevent them from wearing out. Lastly, look for any broken parts and fix them right away.