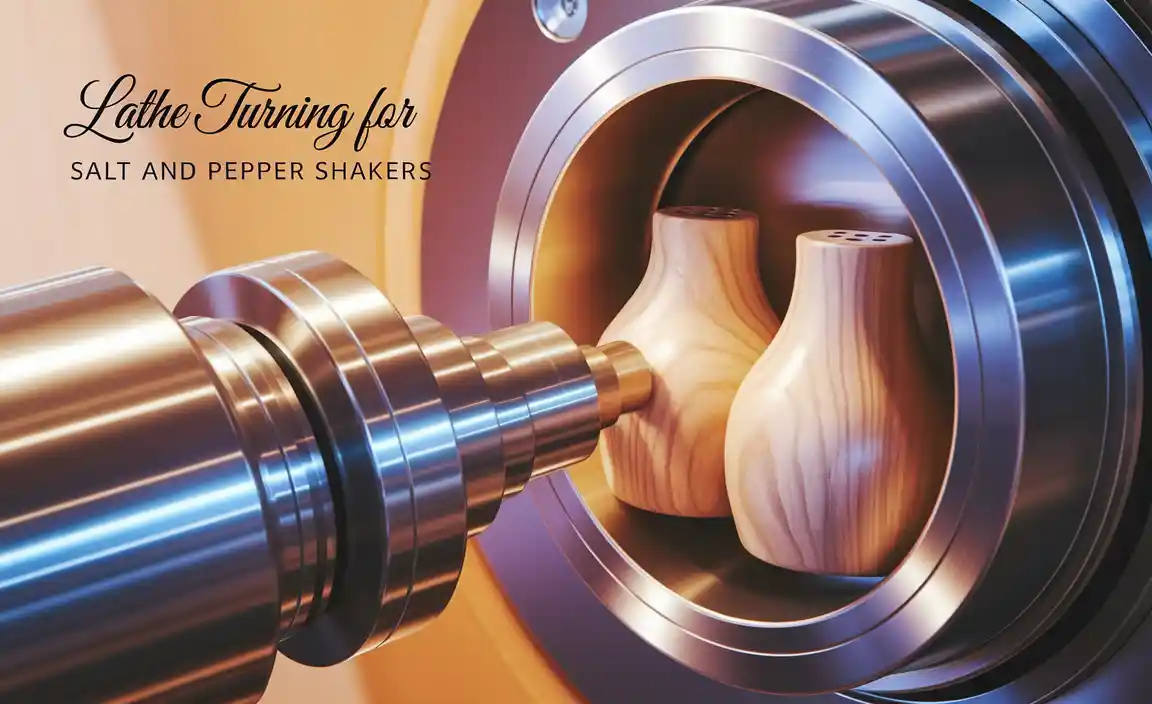

Have you ever watched a metal lathe in action? It’s like magic! With a simple setup, you can turn raw metal into precise shapes. But how do you get started with lathe machining?

Setting up a metal lathe may seem tricky. Many beginners feel overwhelmed by the machines and tools. However, learning the basics can be exciting and fun! Imagine creating your own metal parts for a project. That’s where the fun begins.

Here’s a fun fact: the lathe is one of the oldest tools used by humans. Ancient Egyptians used a form of it thousands of years ago! Today, it is still a vital machine in workshops around the world.

In this article, we will explore everything about lathe machining. We’ll guide you through a simple metal lathe setup. Soon, you’ll be ready to bring your ideas to life! Are you excited to learn more?

Lathe Machining: Essential Metal Lathe Setup Guide

Lathe Machining Metal Lathe Setup

Setting up a metal lathe involves several key steps to ensure precision. First, check that the lathe is on a level surface. Next, adjust the tailstock and tool rest for proper alignment. It’s essential to choose the right cutting tools based on material type. Did you know that a well-prepared setup can significantly reduce mistakes? Taking time with setup helps create smoother finishes. A simple setup leads to fantastic, accurate results in metalworking projects.Understanding Lathe Machining

Definition of lathe machining. Applications in various industries.Lathe machining is a process that shapes metal and other materials. A lathe tool turns the material, making it easier to cut, sand, or drill. This process is common in many industries, such as:

- Automotive

- Aerospace

- Manufacturing

- Construction

- Metalworking

Each industry uses lathe machining for making parts like gears, shafts, and rods. It’s important because it helps create precise and useful items.

What is lathe machining used for?

Lathe machining is used to make precise shapes and parts for machines and tools. This process helps create things we use every day.

Essential Components of a Metal Lathe

Core parts and their functions (bed, carriage, tailstock). Importance of each component in setup and operation.A metal lathe has three key parts that help it work well: the bed, carriage, and tailstock. Each of these parts plays an important role. The bed is the sturdy base. It holds everything in place. The carriage moves the cutting tool. This helps shape the metal. The tailstock supports the other end of the material. It’s crucial for stability during the job. Without these parts, a lathe won’t function properly.

- Bed: Provides a strong base for support.

- Carriage: Moves the tool to cut metal.

- Tailstock: Keeps the metal stable at both ends.

What are the main components of a metal lathe?

The main components include the bed, carriage, and tailstock. Each part is essential for efficient operation and setup.

Preparing Your Workspace for Lathe Machining

Key considerations for an efficient workspace layout. Safety measures to implement before setup.Before starting with lathe machining, it’s crucial to have a workspace that works for you. First, keep your tools organized and within reach. This helps you avoid the dreaded “Where did I put that wrench?” moment. Next, ensure you have enough space to move around safely. A cluttered area can turn into an obstacle course! Don’t forget safety measures. Always wear goggles and gloves. A little protection goes a long way—better safe than sorry! You wouldn’t want a flying metal chip giving you an unwanted haircut!

| Key Considerations | Safety Measures |

|---|---|

| Organize tools | Wear goggles |

| Clear workspace | Use gloves |

| Proper lighting | Keep first aid kit nearby |

Step-by-Step Guide to Setting Up a Metal Lathe

Initial inspection of the lathe before setup. Detailed instructions for aligning and calibrating the lathe.Before you start your metal lathe journey, take time for an initial inspection. Check for loose screws and ensure all parts are clean. A wobbly lathe is like a wobbly table – it’s a recipe for disaster! Next, align your lathe like you’re laying down the law. Use a dial indicator to calibrate it, ensuring it runs smoothly. If you want your metal pieces to look sharp, this step is key. Here’s a quick checklist:

| Step | Description |

|---|---|

| 1 | Inspect the lathe for any loose or damaged parts. |

| 2 | Clean the work area and the lathe itself. |

| 3 | Use a dial indicator to check alignment. |

| 4 | Calibrate the lathe to ensure proper functioning. |

Following these steps will set you up for success and make your lathe run as smooth as butter. Now, let’s create some shiny metal wonders!

Tools and Accessories for Optimal Lathe Setup

Musthave tools for metal lathe setup. Recommended accessories for enhancing functionality.For a successful lathe machining setup, certain tools and accessories can make your work easier. Must-have tools include a high-quality cutting tool, a steady tool rest, and a protective guard. These tools ensure safety and precision.

Adding recommended accessories enhances performance. Consider these items:

- Measuring tools, like calipers or micrometers

- Chucks for holding materials securely

- Lubricants for smoother operation

- Work lights for better visibility

Having the right setup helps produce better results!

What is essential for a lathe machine setup?

Essential tools include cutting tools, a tool rest, and a guard. Accessories like measuring tools, chucks, lubricants, and lights further improve the setup.

Common Challenges When Setting Up a Lathe

Typical issues faced during setup. Troubleshooting tips and solutions.Setting up a lathe can be tricky. Many people face similar problems. For example, you might have issues with alignment. Or, the machine may not spin correctly. Here are some troubleshooting tips:

- Check the power supply. Ensure it’s plugged in properly.

- Align the workpiece. Use a level to avoid wobbling.

- Tighten all the screws. Loose parts can cause problems.

- Consult the manual. It often has solutions for common issues.

Each problem has a solution. Don’t worry if things don’t work at first. Keep trying different fixes!

What are common problems during lathe setup?

Common problems include misalignment, power issues, and loose components. Always refer to the manufacturer’s guide for quick fixes.

Maintenance Tips for Longevity of Your Metal Lathe

Routine maintenance practices to follow. Importance of regular checks and balances.To keep your metal lathe in good shape, follow these simple maintenance tips. Regular care can help it work better and last longer. Check these points:

- Clean the machine often to remove dust and shavings.

- Lubricate moving parts to prevent rust and wear.

- Inspect belts and gears for signs of damage.

- Check alignment to ensure precision in your work.

Doing these routine checks helps find problems early. It’s like giving your lathe a health check-up! This way, it remains reliable for years.

How important is regular checking of the metal lathe?

Regular checks make sure your metal lathe runs smoothly and safely. Without them, small issues can become big problems.

Real-World Applications and Case Studies

Examples of successful metal lathe setups. Lessons learned from industry case studies.Many businesses use metal lathes successfully. For example, an auto shop improved its engine parts using a precise lathe setup. A furniture maker created beautiful table legs with smooth edges. These cases show how helpful good setups can be. Lessons learned include:

- Invest in quality tools for better results.

- Regular maintenance keeps machines running well.

- Training staff improves efficiency and safety.

These examples highlight real-world benefits. Proper lathe machining can lead to better products and happy customers.

What are some successful metal lathe setups?

Successful setups often include precise measurements and a focus on safety. Businesses see improved production and quality when they invest in good training and tools.

What lessons can we learn from industry case studies?

Industries show that maintenance, investment in quality, and staff training increase efficiency and product quality.

Conclusion

In conclusion, setting up a metal lathe is crucial for precise machining. You need the right tools, proper alignment, and safety measures. By understanding these basics, you can start creating great projects. Explore tutorials and practice regularly to improve your skills. Remember, every expert was once a beginner, so keep learning and experimenting with your lathe!FAQs

What Are The Essential Tools And Equipment Needed For Setting Up A Metal Lathe For Machining Operations?To set up a metal lathe, you need a few important tools. First, get a measuring tool, like calipers, to check sizes. You also need a tool post to hold the cutting tools in place. A chuck is necessary to grab the metal piece you want to shape. Lastly, having a good set of cutting tools will help you carve the metal into the right shape.

How Do You Properly Align And Level A Metal Lathe To Ensure Accurate Machining?To align and level a metal lathe, you start by placing it on a sturdy, flat surface. You can use a level tool to check if it’s even. Adjust the feet of the lathe until it sits perfectly flat. Then, check the lathe’s headstock and tailstock to make sure they line up straight. This helps your lathe cut smoothly and accurately.

What Safety Precautions Should Be Taken When Setting Up And Operating A Metal Lathe?When setting up and using a metal lathe, you should always wear safety goggles to protect your eyes. Make sure to tie back long hair and wear tight-fitting clothes. Keep your hands away from moving parts and use tools to handle metal pieces. Before starting, check that everything is secure and in place. Always follow the instructions for safe operation.

How Do You Select The Appropriate Cutting Tools And Speeds For Different Materials When Using A Metal Lathe?To choose the right cutting tools for a metal lathe, start by knowing the material you’re working with, like aluminum or steel. Different materials need different tools. For soft materials, use sharp tools that cut easily. For hard materials, you need tougher tools. Also, adjust the speed of the lathe based on the material; faster for soft materials and slower for hard ones. Always remember to check the lathe’s manual for help!

What Are The Common Troubleshooting Steps For Issues Encountered During The Setup Of A Metal Lathe?First, check the power supply to make sure the lathe is plugged in and turned on. Next, look for any loose wires or connections. You can also check the manual for setup help or error messages. If something isn’t working, try resetting the machine. Finally, ask someone with experience for help if you’re still stuck.