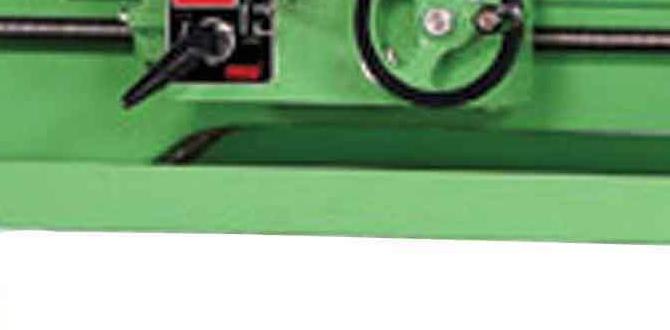

Have you ever wondered how people create precise shapes from metal? One tool that makes this possible is the lathe parting tool. This special tool is crucial for anyone using a metal lathe bench. It helps cut and shape metal pieces with great accuracy.

Imagine a craftsman working diligently at his bench. He carefully uses his lathe parting tool. With each turn, he transforms a dull metal block into something beautiful and useful. Isn’t that fascinating?

In the world of metalworking, efficiency is key. A lathe parting tool aids in quick and clean cuts. With the right skills and tools, even a beginner can create impressive projects.

Join us as we explore the exciting world of lathe parting tools and how they enhance your metal lathe bench experience. You’ll learn tips and tricks that can make your projects easier and more enjoyable!

Essential Guide To Lathe Parting Tool For Metal Lathe Bench

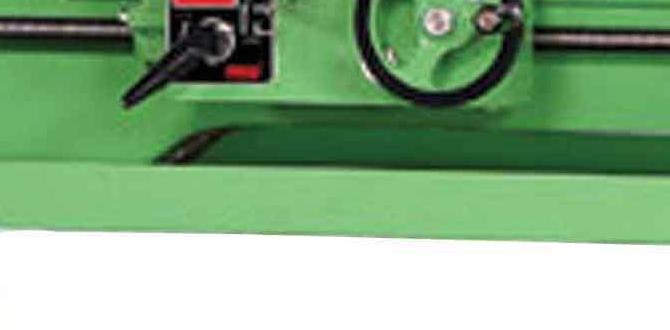

Lathe Parting Tool for Metal Lathe Bench

A lathe parting tool is essential for any metal lathe bench. It helps you create precise cuts and shapes in metal. Think about how much easier your projects could be with the right tool. Did you know a sharp parting tool can make smoother edges? Using this tool properly enhances your skills and boosts your confidence. Whether you’re a beginner or advanced, mastering this tool can transform your creations. It’s all about precision and quality in your work!

Understanding Lathe Parting Tools

Definition and purpose of parting tools in metal lathes. Common materials used in parting tool construction.

Parting tools are the superheroes of metal lathes. They help cut off pieces of material smoothly and accurately, making sure your project looks great. Think of them as the scissors of the metal world! Most parting tools are made from strong materials like high-speed steel or carbide. These materials can handle tough jobs while staying sharp. Plus, they resist wear and tear, like a superhero’s armor.

| Material | Features |

|---|---|

| High-Speed Steel | Easy to sharpen; great for general use |

| Carbide | Super tough; holds its edge longer! |

Selecting the Right Parting Tool

Key factors to consider when choosing a parting tool. Recommended brands and models for different projects.

Picking the right parting tool can feel like choosing ice cream flavors! First, think about the material you’ll work with. Some tools shine on metal, while others love wood. Next, consider the size you need. Bigger isn’t always better—trust me on that! Popular brands like Grizzly and Tormach offer great options for newbies and pros alike.

| Brand | Model | Best For |

|---|---|---|

| Grizzly | G8689 | Beginners |

| Tormach | Tooling Pack | Advanced Projects |

| Holloway | Parting Tool | General Use |

With these tips, you can slice through your project like butter. Happy turning!

Setting Up a Metal Lathe for Parting Operations

Stepbystep guide to prepare a lathe for parting work. Importance of proper tool height and alignment.

Before using a metal lathe for parting, follow these steps for best results. Start by ensuring the machine is turned off. Check the tool height to ensure it matches the material. Align the lathe to help with cuts. Here’s a quick guide:

- Clean your workspace.

- Set the tool height correctly.

- Align the parting tool with your workpiece.

- Test the setup with a trial run.

Correct alignment is important. It ensures smooth cuts. If the tool is too high or low, it can cause problems. Always double-check!

How do I set the correct tool height for a lathe?

To set the correct tool height, match it with the center of your workpiece. Use a ruler or a tool gauge for accuracy. This helps in getting clean cuts every time!

Techniques for Effective Parting

Recommended cutting speeds and feeds for different materials. Troubleshooting common issues during parting operations.

To part materials effectively, knowing the right cutting speeds and feeds is crucial. Different materials need different settings. For example, aluminum works well at higher speeds, while steel requires slower speeds. Here are quick tips:

- Aluminum: High speed, about 200-300 SFM.

- Brass: Medium speed, around 120-180 SFM.

- Steel: Low speed, typically 70-100 SFM.

- Plastic: Cool speed, close to 100 SFM.

Troubleshooting helps fix common problems. If you hear squeaking or see rough cuts, check the speed. Too fast can cause heat. Too slow may lead to dull tools. Adjusting these settings can make parting smooth and easy.

What are the common issues during parting operations?

Common parting issues include tool chatter, which makes uneven cuts. Overheating can make your tool dull. Lastly, poor finish means you need to adjust your cutting speed and feed rate.

Maintenance and Care for Parting Tools

Best practices for cleaning and storing parting tools. Methods for sharpening and maintaining tool edges.

Keeping your parting tools in good shape is key to smooth projects. First, clean them after each use. Wipe off metal shavings and dirt with a dry cloth. A clean tool performs better, like a shiny superhero! For storage, use a dedicated box or rack to avoid damage. Remember, sharp edges are happy edges! To sharpen, use a file or a sharpening stone. A little maintenance goes a long way, keeping your tools cutting like a champion.

| Best Practices | Details |

|---|---|

| Cleaning | Wipe tools after each use. |

| Storage | Use a box or rack to protect from damage. |

| Sharpening | Use a file or sharpening stone regularly. |

Safety Tips for Using Parting Tools

Essential safety gear for lathe operations. Common hazards and how to prevent accidents during parting.

It’s crucial to gear up before diving into lathe work. Grab your safety glasses, and don’t forget that apron—nobody wants a surprise haircut! Next, let’s talk hazards. Flying metal bits can dance around like they own the place. To keep accidents at bay, always secure your workpiece and stand clear of the spinning area.

Here’s a handy table of essentials:

| Safety Gear | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris |

| Apron | Prevents metal shavings on clothes |

| Ear Protection | Blocks loud noises |

| Steel-Toed Shoes | Protects feet from heavy items |

Stay alert and always follow instructions. If you feel tired, take a break! Remember, no tool is worth a trip to the ER.

Common Parting Tool Projects

Examples of projects that utilize parting tools effectively. Tips for increasing efficiency in project execution.

Many projects benefit from using a parting tool. For example, creating small parts like spacers or washers is a great way to put this tool to work. Need to slice a big metal piece into smaller ones? A parting tool is your best friend! To speed things up, keep your lathe well-oiled and your tools sharp. You can even make a funny face while you work—who doesn’t like a good laugh? Here’s a table with some cool project ideas:

| Project | Description |

|---|---|

| Spacers | Thin discs that fit between other parts. |

| Washers | Flat rings that help distribute load. |

| Standoffs | Keep parts spaced away from a surface. |

These projects are simple and fun! Remember, the right tools save time. Happy turning!

Conclusion

In conclusion, a lathe parting tool is essential for metalworking. It helps you make precise cuts and shape materials easily. Understanding how to use a metal lathe bench will improve your skills. Remember to practice safely and effectively. For more tips and techniques, explore resources or guides online. You can become a better metalworker with time and effort!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools Used With A Metal Lathe:

Sure! A lathe parting tool cuts pieces of metal while they spin on a lathe machine. You use it to separate one part from another. It looks like a flat piece of metal with a sharp edge. When you push it into the spinning metal, it creates a clean cut. This tool helps you make shapes and sizes you need for different projects.

Of course! Please give me the question you want answered, and I’ll help you out.

What Are The Key Features To Look For When Selecting A Parting Tool For A Metal Lathe?

When picking a parting tool for a metal lathe, you should look for a few important things. First, check the size of the tool to make sure it fits your lathe. Next, consider the shape of the cutting edge; it should be sharp and made for cutting metal. You should also look for a sturdy handle that feels comfortable in your hand. Lastly, choose a tool made from strong materials so it lasts a long time.

How Do You Properly Set Up And Use A Parting Tool To Achieve Clean And Precise Cuts?

To use a parting tool, first, make sure it’s sharp and clean. Then, hold it firmly and adjust it so it sits straight. When you start cutting, move slowly and apply even pressure. Always keep your hands safe and stay focused on the cut. This will help you make clean and precise cuts every time!

What Types Of Materials And Coatings Are Commonly Used For Producing Lathe Parting Tools, And How Do They Affect Performance?

Lathe parting tools are made from strong materials like high-speed steel and carbide. High-speed steel is tough and can handle heat well. Carbide is harder and lasts longer but can be more expensive. Sometimes, tools have special coatings like titanium or ceramic. These coatings help the tool cut better and last even longer.

What Are The Common Issues Faced When Using A Parting Tool On A Metal Lathe, And How Can They Be Resolved?

When using a parting tool on a metal lathe, you might face problems like bending or breaking the tool. This can happen if you cut too fast or push too hard. To fix this, cut slowly and gently. You should also make sure the tool is sharp and set at the right angle. If you keep everything steady and take your time, it will work better!

How Does The Design And Geometry Of A Parting Tool Impact Its Cutting Efficiency And Tool Life?

The design and shape of a parting tool affect how well it cuts. A sharper edge helps it slice through materials easily. If the tool fits the job well, it lasts longer. A good design reduces heat and wear, so you can use it more times without breaking it. This means better cuts and less time changing tools.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools Used With A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe parting tool cuts pieces of metal while they spin on a lathe machine. You use it to separate one part from another. It looks like a flat piece of metal with a sharp edge. When you push it into the spinning metal, it creates a clean cut. This tool helps you make shapes and sizes you need for different projects.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please give me the question you want answered, and I’ll help you out.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For When Selecting A Parting Tool For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a parting tool for a metal lathe, you should look for a few important things. First, check the size of the tool to make sure it fits your lathe. Next, consider the shape of the cutting edge; it should be sharp and made for cutting metal. You should also look for a sturdy handle that feels comfortable in your hand. Lastly, choose a tool made from strong materials so it lasts a long time.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Use A Parting Tool To Achieve Clean And Precise Cuts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use a parting tool, first, make sure it’s sharp and clean. Then, hold it firmly and adjust it so it sits straight. When you start cutting, move slowly and apply even pressure. Always keep your hands safe and stay focused on the cut. This will help you make clean and precise cuts every time!”}},{“@type”: “Question”,”name”: “What Types Of Materials And Coatings Are Commonly Used For Producing Lathe Parting Tools, And How Do They Affect Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe parting tools are made from strong materials like high-speed steel and carbide. High-speed steel is tough and can handle heat well. Carbide is harder and lasts longer but can be more expensive. Sometimes, tools have special coatings like titanium or ceramic. These coatings help the tool cut better and last even longer.”}},{“@type”: “Question”,”name”: “What Are The Common Issues Faced When Using A Parting Tool On A Metal Lathe, And How Can They Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a parting tool on a metal lathe, you might face problems like bending or breaking the tool. This can happen if you cut too fast or push too hard. To fix this, cut slowly and gently. You should also make sure the tool is sharp and set at the right angle. If you keep everything steady and take your time, it will work better!”}},{“@type”: “Question”,”name”: “How Does The Design And Geometry Of A Parting Tool Impact Its Cutting Efficiency And Tool Life?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design and shape of a parting tool affect how well it cuts. A sharper edge helps it slice through materials easily. If the tool fits the job well, it lasts longer. A good design reduces heat and wear, so you can use it more times without breaking it. This means better cuts and less time changing tools.”}}]}