Have you ever wondered how craftsmen create perfect patterns? A lathe turning duplicate pattern jig is a secret tool they use. It helps make exact copies quickly and easily.

Imagine making your own toys or tools with precise shapes. With this jig, you can turn simple pieces of wood into beautiful designs. The process is neat and fun!

Did you know that with a lathe turning duplicate pattern jig, you can create items that look just like the originals? This means fewer mistakes and more time to explore new ideas. It’s like having your own magic wand in the workshop.

Let’s dive into the world of lathe turning. Discover how this amazing tool works and the wonders it can create!

Lathe Turning Duplicate Pattern Jig: A Complete Guide

Lathe turning duplicate pattern jigs are amazing tools. They help create identical parts quickly and easily. Imagine needing several wooden toys, like cars or animals. Instead of shaping each one by hand, a jig can help you duplicate the shape perfectly every time. This not only saves time but also increases accuracy. By using a jig, crafters can focus on creativity instead of repetitive tasks. Isn’t it great how a simple tool can make work so much easier?

Understanding the Lathe Turning Process

Explanation of lathe turning and its applications. Importance of precision in pattern making.

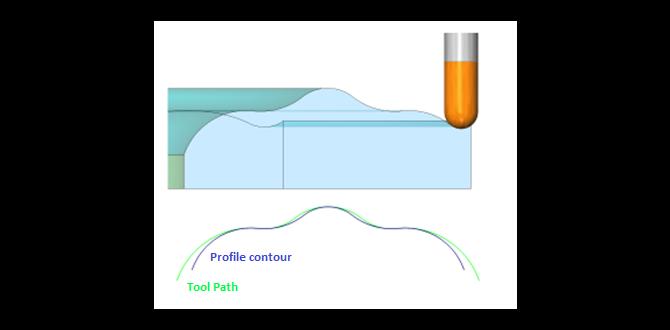

Lathe turning is a process where a spinning piece of material shapes into amazing forms. Think of it as a ride at the fair, but instead of spinning around, it’s making cool designs! People use lathe turning in woodworking, metalworking, and even making toys! Precision matters here, like a chef needing the right amount of salt. If it’s off, the pattern could end up looking like a wobbly pancake!

| Application | Description |

|---|---|

| Woodworking | Creating beautiful furniture pieces. |

| Metalworking | Making parts for machines and tools. |

| Toys | Crafting fun shapes for kids. |

Without precision, your wiggles and wobbles could turn a toy into a new modern art piece! So, always aim to be sharp and accurate!

What is a Duplicate Pattern Jig?

Definition and purpose of a duplicate pattern jig. Key components and materials used in making a jig.

A duplicate pattern jig is a handy tool that helps make copies of patterns quickly and easily. Think of it as a superhero sidekick for your lathe! Its main purpose is to ensure that every piece you create is identical. This jig consists of a base, guiding rods, and a tool holder. You can make it from wood or metal, depending on how tough you want it. It’s like building a Lego set, but instead of toys, you’re crafting perfect duplicates!

| Key Component | Material |

|---|---|

| Base | Wood or Metal |

| Guiding Rods | Steel |

| Tool Holder | Aluminum |

This jig turns your lathe into a duplication machine! With this gadget, you can create more pieces without losing your mind counting them. Why measure twice when you can duplicate once?

Benefits of Using a Duplicate Pattern Jig

Enhanced accuracy and consistency in reproducing patterns. Timesaving advantages in production processes.

Using a duplicate pattern jig makes life easier for everyone involved in crafting. First off, it boosts accuracy like a superhero! Patterns come out just right, each time. Why is this a big deal? Well, no one wants a wobbly design that looks like a rollercoaster ride. Plus, this nifty tool saves **time**. Imagine finishing tasks faster and actually enjoying a donut break instead. So, less hassle, more fun, and double the patterns done!

| Benefits | Details |

|---|---|

| Enhanced Accuracy | Patterns are reproduced perfectly, every time! |

| Time Saving | Finish projects quicker and have time for snacks. |

How to Design a Lathe Turning Duplicate Pattern Jig

Stepbystep guide on sketches and schematics. Considerations for design based on project requirements.

Designing a lathe turning duplicate pattern jig is both fun and practical! Start with simple sketches to map out your ideas. Think about what you need for your project. Is it strong enough? Will it fit your lathe? Once you have a plan, turn those doodles into clear schematics. Don’t forget to consider materials! They matter, just like the secret sauce on a pizza. Here’s a handy table to help with your design:

| Consideration | Details |

|---|---|

| Material | Wood, metal, or plastic? |

| Size | Should match your project dimensions. |

| Adjustment | Can it be fine-tuned easily? |

Remember, a good jig makes all the difference between a masterpiece and a mishap. So, have fun with it!

Materials Needed for Building a Duplicate Pattern Jig

Recommended materials for durability and effectiveness. Tools required for construction and assembly.

Building a sturdy duplicate pattern jig is fun and rewarding! You’ll need some key materials for strength and effectiveness. Start with plywood or MDF for the base—because we want it solid, not wobbly like a jelly on a rollercoaster! Combine it with metal brackets for extra support and resist the urge to use spaghetti as a tool. For your tool list, grab a screwdriver, saw, and drill. These are your trusty sidekicks in this little adventure. Below is a handy materials table:

| Material | Purpose |

|---|---|

| Plywood/MDF | Base material for strength |

| Metal Brackets | Support and stability |

| Screwdriver | For assembly |

| Saw | To cut materials to size |

| Drill | For making holes |

Remember, this jig will help you create duplicates like a pro, so take your time and have fun!

Step-by-Step Instructions for Constructing the Jig

Detailed instructions on cutting and assembling the components. Tips for measuring and aligning parts correctly.

Building your own jig is easier than it sounds! First, gather your materials. You’ll need wood, screws, and a saw. Start by cutting the base to the desired size. Remember, measure twice, cut once—unless you enjoy extra trips to the store!

| Component | Dimension |

|---|---|

| Base | 24″x12″ |

| Vertical Support | 4″x4″x12″ |

Next, attach the vertical support to the base with screws. For perfect alignment, use a square. Lastly, double-check all connections. If everything is secure, you’re ready to use your new lathe turning jig!

Techniques for Using the Duplicate Pattern Jig

Best practices for setting up the lathe with the jig. Troubleshooting common issues during operation.

Setting up the lathe with a duplicate pattern jig is like arranging a dance party—everyone needs to know their steps! First, ensure the jig is aligned with the lathe correctly. Check the height and the speed settings; too fast, and you might create a flying project! If something goes wrong, don’t panic. Common problems like vibration or uneven cuts can often be fixed with a simple adjustment. Remember, a steady jig makes for a happy lathe!

| Common Issues | Solutions |

|---|---|

| Vibration | Check alignment and balance. |

| Uneven Cuts | Adjust tool height and sharpen tools. |

| Jam or Stuck Material | Inspect for debris; clean regularly. |

Maintenance and Care for Your Jig

Regular upkeep practices to ensure longevity. How to address wear and tear over time.

To keep your jig in great shape, regular maintenance is key. This ensures it lasts longer and works better. Check for signs of wear and clean it often. Here are some simple tips:

- Keep it clean. Wipe off dust and debris after use.

- Lubricate moving parts to avoid rust.

- Inspect for damages and fix them quickly.

- Store the jig in a dry place to prevent moisture damage.

Addressing wear and tear is vital. Replace worn parts as soon as possible. This simple step keeps your lathe turning duplicate pattern jig working smoothly.

What is the best way to care for my lathe turning jig?

Regular cleaning and lubrication are essential for keeping your jig in good condition. Check it often for any signs of wear, and store it safely to protect it from damage.

Case Studies: Successful Applications of Duplicate Pattern Jigs

Examples from various industries that have improved productivity. Lessons learned and best practices from experienced users.

In many industries, duplicate pattern jigs have proven to be game-changers. For example, a small woodworking shop boosted its productivity by 50% after using these jigs. They made creating duplicates as easy as pie—well, maybe more like a rubber chicken! Lessons learned? Always fine-tune your setup for the best results. Best practices include keeping everything organized and sharing tips with fellow makers. It’s like having a secret club, but with sawdust and fewer snacks!

| Industry | Improvement | Best Practice |

|---|---|---|

| Woodworking | 50% boost in productivity | Share tips! |

| Metalworking | 30% time savings | Keep tools organized |

| Textile | 20% reduction in waste | Test setups regularly |

Frequently Asked Questions (FAQs)

Common queries about lathe turning and jigs. Expert answers to enhance reader understanding.

Many people wonder how lathe turning and jigs work together. One common question is about the purpose of a jig. A jig helps hold materials in place, making turning easier. It keeps things steady, so you can focus on creativity. Another popular query is about choosing the right materials. Beginners often ask, “What should I use?” The answer is simple: start with wood, then experiment! Remember, practice makes perfect, and even the best woodworkers had to start somewhere.

| Question | Answer |

|---|---|

| What does a lathe do? | A lathe shapes materials into round pieces. |

| Why use a jig? | A jig keeps materials steady and saves time. |

| Can I make my own jig? | Yes! Building your own jig can be fun and rewarding. |

Conclusion

In summary, a lathe turning duplicate pattern jig helps you create identical shapes easily. It saves time and improves accuracy in your projects. You can make more pieces with less effort using this tool. We encourage you to explore more about jigs and try building one yourself. It’s a great way to enhance your skills!

FAQs

What Are The Key Components Of A Lathe Turning Duplicate Pattern Jig, And How Do They Function Together?

A lathe turning duplicate pattern jig has a few key parts. First, there’s the base that holds everything steady. Then, there’s the cutting tool that shapes the material. You also have a follower that follows the original pattern. Together, these parts let you copy an object by guiding the tool to make the same shape!

How Can You Accurately Set Up A Lathe Turning Duplicate Pattern Jig To Ensure Precision In The Duplication Process?

To set up a lathe turning jig, first, make sure it’s stable. You should secure the original piece tightly. Next, align the tool so it cuts exactly where you want. Keep checking your measurements as you work. This helps us make sure the new pieces are just like the original.

What Materials Are Commonly Used To Construct A Lathe Turning Duplicate Pattern Jig, And What Are The Advantages Of Each?

You can make a lathe turning duplicate pattern jig from wood, metal, or plastic. Wood is easy to work with and light. It’s great for beginners. Metal is strong and lasts a long time but can be heavier. Plastic is lightweight and won’t rust, but it might not be as strong as metal. Each material has its own benefits depending on what you want to do!

What Techniques Can Be Employed To Adjust And Calibrate A Lathe Turning Duplicate Pattern Jig For Different Sizes And Shapes Of Patterns?

To adjust a lathe turning jig for different patterns, you can change the size of the clamps. These clamps hold the pattern in place. You can also move the cutting tool closer or farther away to match the shape. Lastly, you might need to change the speed of the lathe to get a better finish. Make sure everything is tight and secure before you start!

What Are The Common Applications Of Lathe Turning Duplicate Pattern Jigs In Manufacturing And Woodworking Industries?

Lathe turning duplicate pattern jigs are useful in making copies of shapes. We use them to create identical parts for machines and furniture. They help save time and ensure every piece is the same. In woodworking, you can use them to make parts for toys or decorations, too. These jigs make it easier and quicker to build things in factories and workshops.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Components Of A Lathe Turning Duplicate Pattern Jig, And How Do They Function Together? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe turning duplicate pattern jig has a few key parts. First, there’s the base that holds everything steady. Then, there’s the cutting tool that shapes the material. You also have a follower that follows the original pattern. Together, these parts let you copy an object by guiding the tool to make the same shape!”}},{“@type”: “Question”,”name”: “How Can You Accurately Set Up A Lathe Turning Duplicate Pattern Jig To Ensure Precision In The Duplication Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a lathe turning jig, first, make sure it’s stable. You should secure the original piece tightly. Next, align the tool so it cuts exactly where you want. Keep checking your measurements as you work. This helps us make sure the new pieces are just like the original.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used To Construct A Lathe Turning Duplicate Pattern Jig, And What Are The Advantages Of Each? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can make a lathe turning duplicate pattern jig from wood, metal, or plastic. Wood is easy to work with and light. It’s great for beginners. Metal is strong and lasts a long time but can be heavier. Plastic is lightweight and won’t rust, but it might not be as strong as metal. Each material has its own benefits depending on what you want to do!”}},{“@type”: “Question”,”name”: “What Techniques Can Be Employed To Adjust And Calibrate A Lathe Turning Duplicate Pattern Jig For Different Sizes And Shapes Of Patterns? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust a lathe turning jig for different patterns, you can change the size of the clamps. These clamps hold the pattern in place. You can also move the cutting tool closer or farther away to match the shape. Lastly, you might need to change the speed of the lathe to get a better finish. Make sure everything is tight and secure before you start!”}},{“@type”: “Question”,”name”: “What Are The Common Applications Of Lathe Turning Duplicate Pattern Jigs In Manufacturing And Woodworking Industries? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe turning duplicate pattern jigs are useful in making copies of shapes. We use them to create identical parts for machines and furniture. They help save time and ensure every piece is the same. In woodworking, you can use them to make parts for toys or decorations, too. These jigs make it easier and quicker to build things in factories and workshops.”}}]}